Meggitt F145 Series User manual

Maintenance Manual

PRESSURE FUELLING NOZZLE

F145 Series

MMF145

Revision 6.4

05 January 2015

Meggitt (North Hollywood), Inc. Proprietary Information

The information contained in this document is disclosed in confidence. It is the property of Meggitt (North Hollywood), Inc. and shall not be used,

disclosed to others, or reproduced in whole or in part without the express written consent of Meggitt (North Hollywood), Inc. If consent is given, this

notice shall appear in any such reproduction. These commodities, technology, or software were exported from the United States in accordance with

the export administration regulations. Diversion contrary to U.S. law is prohibited.

SENSITIVE BUT UNCLASSIFIED-EXPORT CONTROLLED-EAR RESTRICTED.

These commodities, technology or software are exported from the United States of America in accordance with the Export Administration

Regulations. ECCN EAR99. Diversion contrary to U.S. law is prohibited.

Copyright © 2015 Meggitt (North Hollywood), Inc.

BASIC MODEL SHOWN

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 RR

REVISION RECORD

Keep this record in the front of the manual. When you get the revisions, put the revised pages in the

manual. Write the revision number, date issued and your initials on this page.

REV NO.

PAGES

AFFECTED

DESCRIPTION OF CHANGE

DATE

APPROVED

BY

Original 1.0

ALL

Initial Release

02/16/2011

A.B

1.1

ALL

See DCN

05/02/2011

A.B

2.0

ALL

See DCN

05/30/2011

A.B

3.0

ALL

See DCN

06/15/2011

A.B

4.0

ALL

See DCN

09/30/2011

A.B

5.0

ALL

See DCN

01/15/2013

A.B

6.0

ALL

See DCN

01/16/2014

A.B

6.1

ALL

See DCN

03/31/2014

J. M

6.2

RR, B, 35, 39 and 47

See DCN

10/02/2014

J. M

6.3

RR, 4, 6, 38 and 46

See DCN

11/25/2014

J. M

6.4

Title, RR, 28, 31 and 41

See DCN

02/11/2015

J.M

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 i

TABLE OF CONTENTS

SUBJECT PAGE

IMPORTANT SAFETY INSTRUCTIONS...................................................................................................... A

INTRODUCTION...........................................................................................................................................1

DESCRIPTION AND OPERATION ...............................................................................................................2

SPECIAL TOOLS AND TEST EQUIPMENT .................................................................................................9

TEST........................................................................................................................................................... 10

FAULT ISOLATION..................................................................................................................................... 13

MAINTENANCE ..........................................................................................................................................15

DISASSEMBLY...........................................................................................................................................16

CLEANING..................................................................................................................................................19

CHECK/INSPECTION.................................................................................................................................21

REPAIR....................................................................................................................................................... 24

ASSEMBLY................................................................................................................................................. 30

ILLUSTRATED PARTS LIST....................................................................................................................... 34

LIST OF ILLUSTRATIONS

FIGURE PAGE

Figure 1. Pressure Fuelling Nozzle.............................................................................................................3

Figure 2. Shoulder Bolt Detail................................................................................................................... 23

Figure 3. Latch Ring (3-Slot and 6-Slot) Detail..........................................................................................23

IPL Figure 1. Pressure Fuelling Nozzle (Sheet 1 of 3) ............................................................................. 36

LIST OF TABLES

TABLE PAGE

Table 1. Leading Particulars...................................................................................................................... 5

Table 2. Nozzle Variations (Mod Code Group after F145) .........................................................................6

Table 3. Coupling Variations (Type Number between the Mod and Type Letter Groups)...........................7

Table 4. Swivel Body Inlet Variations (End Type Letter) ............................................................................8

Table 5. Special Tools and Test Equipment ..............................................................................................9

Table 6. Fault Isolation ............................................................................................................................13

Table 7. Parts Information .......................................................................................................................15

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 ii

LIST OF TABLES - CONTINUED

TABLE PAGE

Table 8. Recommended Cleaning Materials ............................................................................................19

Table 9. Component Checks ...................................................................................................................21

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.3 A

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

This manual contains important instructions that should be followed during installation and maintenance of

the Pressure Fuelling Nozzle (nozzle). The following are general safety precautions that are not related to

specific procedures and therefore do not appear elsewhere in this publication. These are recommended

precautions that personnel must understand and apply during maintenance.

The nozzle is a mechanical device and can be dangerous if incorrectly operated or maintained.

Safety Alert Symbols

Safety alert symbols are used in this manual to identify potential or immediate personal injury hazards. The

safety alert symbol words are explained below:

- indicates an imminently hazardous situation which, if not

avoided, will result in injury or serious injury.

- indicates a potentially hazardous situation which, if not avoided,

could result in injury or serious injury.

- indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

- used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in

property damage.

WEAR PROTECTIVE CLOTHING

Wear protective clothing (gloves, apron, etc.) approved for the materials and tools being used.

USE APPROVED SAFETY EQUIPMENT

Use only approved equipment and make sure firefighting equipment is readily available.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.3 B

GIVE CLEANERS SPECIAL CARE

When cleaners are being used read and follow the material safety data sheet (MSDS) instructions for

correct handling.

Equipment Safety Information

The following safety information briefly discusses hazards peculiar to the equipment, which are likely to be

encountered during maintenance activity.

GENERAL OPERATING LOCATION PRECAUTIONS

Use only authorized replacement parts or hardware.

Obey Lock-Out/Tag-Out procedures when working on the nozzle and make sure that personnel

protection equipment such as electrical grounds are installed.

Avoid hazardous voltage situations that can result from unsafe conditions such as, but not limited, to

the following:

o Incorrect grounding

o Handling electrical leads or devices with wet hands or on wet ground.

o Damaged electrical wire insulation.

o Incorrect connection of the power terminals.

o Short circuits to ground.

OPERATION AND MAINTENANCE OF FUEL SYSTEMS

BEFORE TURNING THE OPERATING LEVER; MAKE SURE ALL 3 LUGS

OF AIRCRAFT FUELING ADAPTER ARE PROPERLY ENGAGED IN THE

F145J NOZZLE. REFER TO SAFETY BULLETIN 7872 FOR MORE DETAILS.

Protect all fuel lines from damage or puncture. Do not operate the nozzle if a fuel leak is detected.

Do not use flammable solvents for cleaning parts.

Check for tools, rags, or loose parts left in the area before resuming operation.

Do not attempt to remove the nozzle from the system without first isolating it from the line pressure and

venting all of the trapped internal pressure.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 1

INTRODUCTION

1. General

The information and procedures contained in this manual have been prepared to assist qualified repair

personnel in off-aircraft maintenance of the Pressure Fuelling Nozzle. The instructions provide

information necessary to perform maintenance functions. The nozzle is manufactured by Meggitt (North

Hollywood), Inc., 12838 Saticoy Street, North Hollywood, California 91605.

2. Scope

The instructions contained in this manual do not claim to cover all details or variations in equipment.

They do not provide for every problem that could occur during installation, operation, or maintenance. If

further information is required, contact Meggitt (North Hollywood), Inc., Product Support Department.

3. Standard Shop Practices

Use approved procedures and safety precautions to prevent damage to the equipment and injury to

personnel.

4. Weights and Measurements

Weights and measurements in this manual are expressed in both English (U.S. customary) and

Metric (SI) units.

5. Revision Service

This manual will be revised, as necessary, to reflect current information.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 2

DESCRIPTION AND OPERATION

1. Description

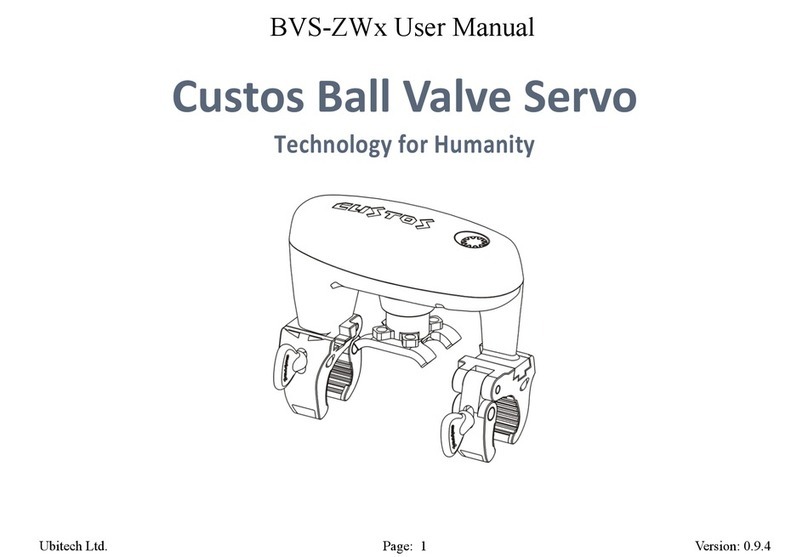

The Pressure Fuelling Nozzle (nozzle) (see Figure 1) provides the means of controlling the flow of fuel

in pressure fuelling operations. The nozzle inlet port couples to a fuelling hose. The outlet port attaches

to the inlet adapter of the system being fueled. The nozzle provides a leak proof connection between

the system being fueled and the fuel supply.

2. Operation

A. Uncoupled

When the nozzle is not coupled to a mating fuel system inlet adapter, its poppet valve is closed, so

that there is no flow or leakage of fuel from the outlet port. The flow control handle that operates

the poppet valve remains locked in the CLOSED position until the nozzle is coupled to the mating

fuel system inlet adapter.

B. Coupling and Opening

When the nozzle is coupled to the mating fuel system inlet adapter, the nose seal of the nozzle is

compressed against the sealing surface of the inlet adapter to form a fluid-tight connection. When

the nozzle is fully engaged and locked to the bayonet flange of the inlet adapter, the flow control

handle is unlocked. Rotation of the flow control handle to the OPEN position opens the poppet

valve, providing a flow passage into the system being fueled. As the system is being fueled, fuel

pressure acts on the floating nose seal of the nozzle to increase the sealing force.

C. Closing and Uncoupling

Rotation of the flow control handle to the CLOSED position closes the poppet valve and the flow

passage into the system being fueled. When the nozzle is unlocked and disengaged from the

bayonet flange of the inlet adapter, the flow control handle is locked in the CLOSED position.

D. Adapters

Suitable attachment adapters such as swivels and/or hose end control valves (HECV) may be

used to adapt the nozzle to any fuel system.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 3

Figure 1. Pressure Fuelling Nozzle

(Sheet 1 of 2)

BASIC MODEL

SHOWN

FLOW CONTROL CAM HANDLE

(

SHOWN CLOSED

)

TO OPEN ROTATE HANDLE TO

OPPOSITE SIDE

NOZZLE BODY

DUST COVER

HANDLE ASSEMBLY

(

2

places

)

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 4

GROUNDING CABLE

(MODEL A)

VACUUM

BREAKER

(MODEL B)

PRESSURE

GAUGE

(MODEL M)

DRAG RING

(MODEL F)

STIRRUP HANDLES

(MODEL C)

BASIC MODEL

F145

SWIVEL ADAPTER

(MODEL G1, H1, L1, N1, P,

Q, R, 3, 3†, 4, 4†, 6†, 7, 7†)

INTERLOCK STORAGE

BRACKET

(MODEL S)

(Alternate locations Model B, M)

SWIVEL ADAPTER

(MODEL 8†, 9, 9†)

COUPLING ASSY

(MODEL 9, 9†)

LONG HANDLES (10")

(MODEL K)

STRAINER

(MODEL T, U, V,

3, 3†, 4, 4†, 6†, 7,

7†, 8†, 9, 9†)

HECV

(MODEL G1, H1,

L1, N1)

COUPLING ASSY

(MODEL 3, 3†, 4,

4†, 6†, 7, 7†)

DRYBREAK ASSY

(MODEL 8†)

SPECIAL

COUPLING

WITH O-RING

(MODEL Q)

FLIGHT

ADAPTER

ASSY

(MODEL R)

Figure 1. Pressure Fuelling Nozzle

(Sheet 2)

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 5

3. Leading Particulars

For the leading particulars refer to Table 1.

Table 1. Leading Particulars

Service Fluid ........................................................................................... Automotive and Aviation Fuels

Performance:

Operating Pressure ........................................................................................ 120 psig (827 kPaG)

Temperature:

Ambient.................................................................................................. -40 to 165°F (-40 to 74°C)

Fluid ....................................................................................................... -40 to 165°F (-40 to 74°C)

Mating Inlet Swivels ....................................................................... F595 HECV, F575/F584, F577/F582,

F581 Swivels, F1516/F596 Dry Disconnect

4. Model Variations

The F145 series nozzle is a straight-in fuelling nozzle with a swivel inlet. It is equipped with bicycle-type

grip handles and a dust cover. A flanged swivel adapter is not supplied with the basic nozzle, but can

be ordered as a variation. Refer to Tables 2, 3, and 4 for the available F145 series nozzle variations. An

explanation of the F145 series part numbering system is as follows:

BASIC PART NUMBER

MODIFICATION LETTER GROUP

COUPLING TYPE

SWIVEL BODY TYPE

F145 XXX X X

P/N

P/N Example: F145APV7A - This nozzle is equipped with a ground cable and has a flanged swivel

adapter and a 100 mesh strainer. The coupling is the 2.5 inch aluminum type with wire raceways to

mate with the F577/F582 swivel body. The swivel body has a 2.5 inch NPT inlet.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 6

Table 2. Nozzle Variations (Mod Code Group after F145)

Examples: F145APV7A, F145BG7A

NOZZLE MOD

LETTER

DESCRIPTION

A

Adds Ground Cable

B

Adds Vacuum Breaker

C

Changes to Stirrup Handles

D

Change nose seal to F117 (1 Piece)

E

Ring Handles

F

Adds Drag Ring

G1

Adds 45 PSI HECV (Flanged)

G2

(Inactive)

G3

Adds additional 45 PSI HECV (Flanged Connection)

H1

Adds 35 PSI HECV (Flanged)

H2

(Inactive)

H3

Adds additional 35 PSI HECV (Flanged Connection)

J

Six (6) Slot Configuration

K

Changes to 10” Long Handles

L1

Adds 50 PSI HECV (Flanged)

L2

(Inactive)

L3

Adds additional 50 PSI HECV (Flanged Connection)

M

Adds 0-100 PSI Pressure Gauge

N1

Adds 55 PSI HECV (Flanged)

N2

(Inactive)

N3

Adds additional 55 PSI HECV (Flanged Connection)

P

Adds Flanged Swivel Adapter

Q

Adds Adapter for J.C.C. Inlet Flange

R

Adds Flight Adapter

Note: Use of a 100 mesh filter (Customer Furnished Equipment CFE))

is recommended.

S

Interlock Storage Bracket

T

Adds 40 Mesh Strainer

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 7

Table 2. Nozzle Variations (Mod Code Group after F145) (continued)

NOZZLE MOD

LETTER

DESCRIPTION

U

Adds 60 Mesh Strainer

V

Adds 100 Mesh Strainer

W

TBD

X

TBD

Y

TBD

Z

TBD

Table 3. Coupling Variations (Type Number between the Mod and Type Letter Groups)

Examples: F145APV7A (Basic model w/ grounding cable, swivel adapter flange, 100 mesh 3”

strainer, F582E coupling assembly with 2-1/2 NPT inlet,

COUPLING TYPE

NUMBER

DESCRIPTION

3

Standard 3-inch aluminum coupling with corrosion resistant steel wire

races to mate with F575/F584 swivel body (uses 3-inch strainer)

*When ordering less HECV must include “P” modification

4

Standard 3-inch aluminum coupling with corrosion resistant steel wire

races to mate with F596 dry disconnect swivel assembly (uses 3-inch

strainer)

*When ordering less HECV must include “P” modification

6

Standard 2½-inch aluminum coupling with corrosion resistant steel wire

races to mate with F1516 dry disconnect swivel body (uses 2½-inch

strainer)

*When ordering less HECV must include “P” modification

7

Standard 2½-inch aluminum coupling with corrosion resistant steel wire

races to mate with F577/F582 swivel body (uses 2½-inch strainer)

*When ordering less HECV must include “P” modification

8

Adds F1516 dry disconnect with integral coupling

*Option can only be ordered less HECV mod

9

Adds 2½” integral coupling, straight

*Option can only be ordered less HECV mod

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 8

Table 4. Swivel Body Inlet Variations (End Type Letter)

Examples: F145APV7A

SWIVEL BODY TYPE

LETTER

DESCRIPTION

A

2½-inch ANPT inlet. Available for coupling types 3, 4, 6 or 7 only.

B

2½-inch BSPPL inlet. Available for coupling types 3, 4, 6 or 7 only.

C

3-inch ANPT inlet. Available for coupling types 3, 4, 6 or 7 only.

D

2-inch ANPT inlet. Available for coupling types 3, 4, 6 or 7 only.

E

3-inch BSPPL inlet. Available for coupling types 3, 4, 6 or 7 only.

F

2-inch BSPPL inlet. Available for coupling type 6 only.

G

3-inch BSPPL inlet. Available for coupling type 7 only.

K

4-inch ANPT inlet. Available for coupling type 7 only.

T

2-inch female Camlock inlet. Available for coupling type 7 only.

U

4-inch female Camlock inlet. Available for coupling type 7 only.

V

3½-inch ANPT inlet. Available for coupling type 7 only.

X

2-inch BSPPL inlet. Available for coupling type 7 only.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 9

SPECIAL TOOLS AND TEST EQUIPMENT

1. General

For special tools and test equipment recommended for maintenance of the nozzle refer to Table 5.

Table 5. Special Tools and Test Equipment

PART

NUMBER

CAGE

DESCRIPTION

APPLICATION

F65-0-1130

79318

Nose Seal Test Fixture

Leakage testing of the nose seal

F65-0-2083

79318

Test Fixture

To accommodate fluid pressure source

GTP-8963

32218

Gammon Gauge

Check for wear on mating 3 lug adapter

T-90465

79318

Ball Tool

For removal and installation of swivel ball bearing

T-90466

79318

Nose Seal Removal Tool

For removing nozzle seat in 3 and 6 slot nozzles

2878018

79318

Test Plug, 3-inch ANPT

Leakage testing of 3-inch NPT connections

2878019

79318

Test Plug, 3-inch BSPPL

Leakage testing of 3-inch BSPPL connections

2878020

79318

Test Plug, 2½-inch ANPT

Leakage testing of 2½-inch NPT connections

2878021

79318

Test Plug, 2½-inch BSPPL

Leakage testing of 2½-inch BSPPL connections

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 10

TEST

1. General

Perform all tests using Stoddard solvent (or equivalent) as the test fluid, supplied by a 0 to 180 psig

(0 to 827 kPaG) test stand. Use only petroleum jelly as a lubricant to aid in the assembly of seals and

O-rings.

2. Functional Test

To functional test the nozzle (see IPL Figure 1), do as follows:

A. Place the nozzle in the test fixture (P/N F65-0-1130) and use handles (52, 52A or 52B) to rotate

nozzle clockwise and lock nozzle to test fixture.

B. Use knob (36) on cam handle (38) to set the position to OPEN and then to CLOSED.

Note: The cam handle (38) shall operate freely with no mechanical interference or binding. If

binding occurs refer to REPAIR section.

C. Use the handles (52, 52A or 52B) to rotate the nozzle counter clockwise to unlock it from the test

fixture.

Note: The nozzle shall lock and unlock freely from the test fixture without binding. If binding

occurs refer to REPAIR section. The nozzle body shall rotate approximately 30° when

connecting to the adapter. If nozzle over rotates, refer to the REPAIR section.

D. Do steps A thru D three times.

3. Leakage Test (Basic, G1, G2, H1, H2, L1, L2, N1, N2, and P)

Note: Adapter Swivel Assembly (71) must be installed on “BASIC” nozzle for leakage test. For Mods;

G, H1, L1, L2, N1 and N2; the lockout device p/n 941020-101 shall be installed in the vent port

of the nose end control valve.

A. Make sure the nozzle is in the CLOSED position (see Figure 1).

B. Place the nozzle in the test fixture (P/N F65-0-1130) and rotate nozzle clockwise to lock nozzle to

test fixture.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 11

C. Use knob (IPL Figure 1, 36) and cam handle (38) to set the nozzle in the open position.

D. Place the test fixture (P/N F65-0-2083) on Adapter Swivel Assembly (71) and secure with

washer (74) lock washer (73) and screws (72).

E. Test fixture (P/N F65-0-2083) has a 1/4 inch NPT port for pressure source. Attach applicable

adapter to connect pressure source to test fixture (P/N F65-0-2083).

F. Test fixture (P/N F65-0-1130) has a 1/4 inch NPT tap for a test plug. Fill nozzle with test fluid and

let air bleed thru the hole in test fixture (P/N F65-0-1130). Plug up test fixture (P/N F65-0-1130)

after all air has escaped from the nozzle.

G. Apply 180 psig of fluid pressure to the nozzle for 5 minute. Then reduce pressure to 0 psig.

H. Use knob (36) on handle (38) to set the nozzle in the closed position.

I. Disconnect nozzle from test fixture (F65-0-1130).

J. Apply 180 psig of fluid pressure to the nozzle for 5 minute. Then reduce pressure to 0 psig.

K. There must not be any leakage from the exterior of the nozzle, thru any seals or from the plugs (3).

L. Remove all test fixtures from the nozzle.

4. Leakage Test (3, 3†, 4, 4†, 6, 6†, 7, 7†, 8 and 9)

A. Make sure the nozzle is in the CLOSED position (see Figure 1)

B. Place the nozzle in the test fixture (P/N F65-0-1130) and rotate nozzle clockwise to lock nozzle to

test fixture).

C. Rotate knob (IPL Figure 1, 36) on cam handle (38) and place the nozzle in the open position.

D. Install matching test plugs (P/N‟s 2878018, 2878019, 2878020 or 2878021) in the inlet port of the

nozzle under test.

E. Test plugs (P/N‟s 2878018, 2878019, 2878020 or 2878021) have a 1/4 inch NPT port for pressure

source. Attach appropriate connector to connect pressure source to the test plugs (P/N‟s 2878018,

2878019, 2878020 or 2878021).

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 12

F. Test fixture (P/N F65-0-1130) has a 1/4 inch NPT tap for a test plug. Fill nozzle with test fluid and

let air bleed thru the hole in test fixture (P/N F65-0-1130). Plug up test fixture (P/N F65-0-1130)

after all air has escaped from the nozzle.

G. Apply 180 psig of fluid pressure to the nozzle for 5 minute. Then reduce pressure to 0 psig.

H. Use knob (IPL Figure 1, 36) on handle (38) to set the nozzle in the closed position.

I. Disconnect nozzle from test fixture (P/N F65-0-1130).

J. Apply 180 psig of fluid pressure to the nozzle for 5 minute. Then reduce pressure to 0 psig.

K. There must not be any leakage from the exterior of the nozzle, or from the plugs (3).

L. Remove all test fixtures and test plugs from the nozzle.

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 13

FAULT ISOLATION

1. General

This section contains fault isolation procedures for the nozzle. Operate the nozzle in accordance with

the Operation section, if the nozzle fails to operate correctly refer to Table 6 and select the appropriate

action. Table 6 identifies the Fault, Probable Cause and Corrective Action.

Table 6. Fault Isolation

FAULT

PROBABLE CAUSE

CORRECTIVE ACTION

Leakage at the poppet seat when

closed

Damaged or worn nose seal seat

(IPL Figure 1, 2 and 68)

Check condition and if necessary

replace nose seal seat.

Damaged or worn poppet (20)

Check condition and if necessary

replace the poppet.

Damaged or worn O-ring (4)

Check condition and if necessary

replace the O-ring.

Damaged or worn shoulder bolt (31)

Check condition and if necessary

replace the shoulder bolt.

Leakage past nose seal when

coupled

Nose seal seat (2, 68) damaged

Check condition and if necessary

replace the nose seal seat.

Mating flange and locking lugs on

airplane fuel system inlet adapter

damaged or worn

Check the three locking lugs of the

bayonet flange for wear,

straightness, and alignment. If they

are damaged, the airplane inlet

adapter must be replaced.

Leakage past flow control handle

shaft

O-ring (25) or backup ring (26)

damaged, twisted, or incorrectly

installed

Check condition and if necessary

replace the O-ring or backup

ring (26)

Meggitt Fuelling Products

Maintenance Manual (MMF145)

Pressure Fuelling Nozzle –F145 Series

USE OR DISCLOSURE OF DATA ON THIS PAGE IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT

05 Jan 2015 Revision 6.4 14

Table 6. Fault Isolation (continued)

FAULT

PROBABLE CAUSE

CORRECTIVE ACTION

Leakage at swivel adapter

Damaged or worn O-ring (6)

Check condition and if necessary

replace the O-ring.

Damaged or worn cap seal (76)

Check condition and if necessary

replace the cap seal.

This manual suits for next models

1

Table of contents

Other Meggitt Control Unit manuals

Popular Control Unit manuals by other brands

Emerson

Emerson Fisher Baumann 87000 instruction manual

Quantum Data

Quantum Data 980 Application guide

Quanser

Quanser Q1-cRIO quick start guide

Sirona

Sirona XIOS XG Operating instructions and installation

Aventics

Aventics CL03 operating instructions

Control Techniques

Control Techniques EMERSON DeviceNet user guide