Section I / Page 4

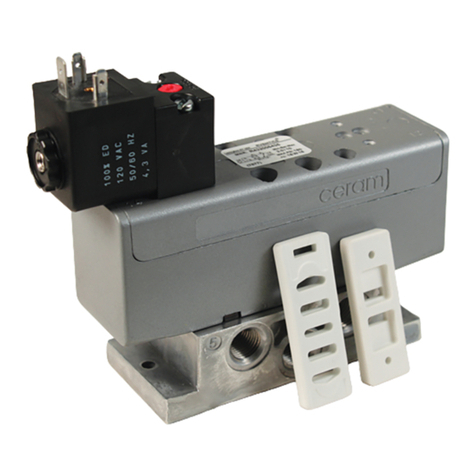

INSTALLATION

Before installing the PowerMaster® Valve, all air lines in

the system should be blown clean to remove any

moisture or loose material. To further ensure long,

trouble-free service, an efficient filter should be installed

in the air line on the supply side of the valve. Although

the valve is lubricated at the factory, an air line lubricator

is also recommended for high-cyclic applications. See

Catalog SC-500 for complete air line conditioner units.

Install the valve in any convenient position but, if installed

with the spool axis vertical, a spring-returned model

provides more positive operation. The preferred

mounting for all models is horizontal.

The valve is offered in four port sizes, both tapped body

and subplate mounted models. Port sizes are 1/4, 3/8,

1/2 & 3/4, inches NPTF. Port numbers or designations

are marked on the top of the valve body.

Solenoid operated models have an external pilot port in

the operator that is tapped 1/4-18 inch NPTF. This port is

plugged on solenoid operators when the valve is

internally piloted.

Prior to connecting power supply, be sure that the coils

match the power supply. Voltage characteristics for

solenoid operators are indicated by the suffix of the piece

number on the nameplate of the valve. Voltage of a

solenoid coil is indicated on the coil nameplate.

OPERATION

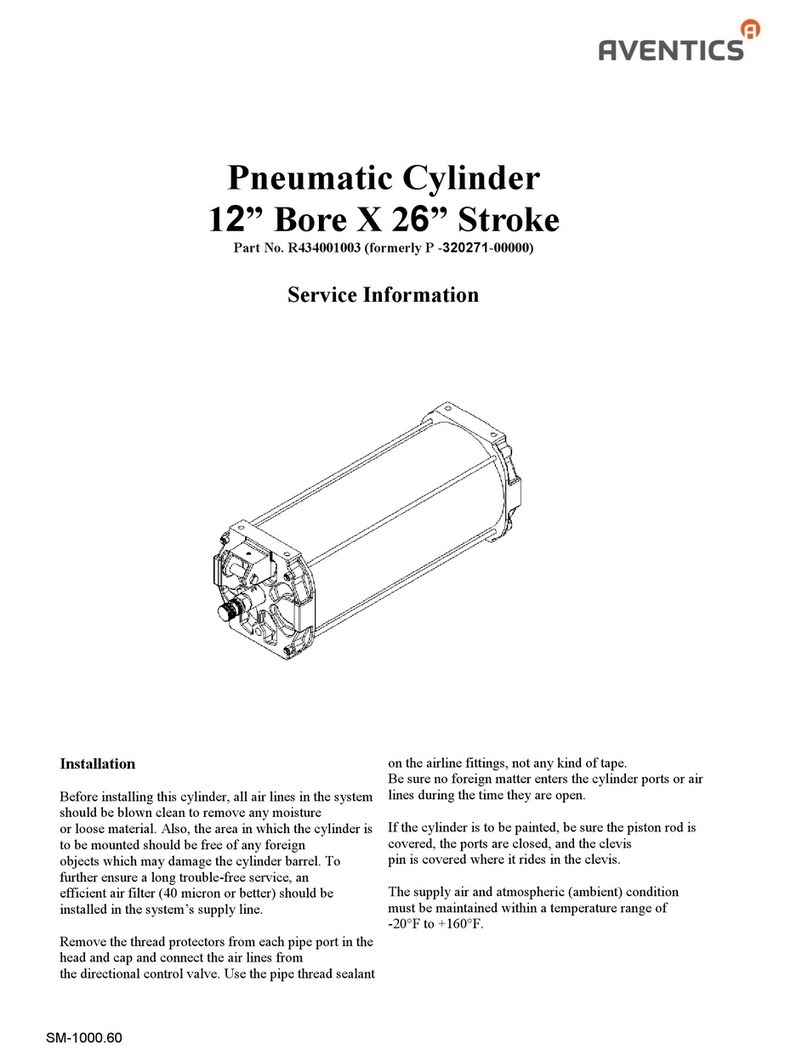

Temperature Range - 20°F to +160°F (+29°C to 71°C)

Pressures

Valve inlet and air pilot maximum air pressure: 150 psi

(10.3 bar) Minimum air pilot pressure: 15 psi (1.0 bar)

without return springs; 50 psi (3.4 bar) for 1/4” and 3/8”

valves with return springs; 40 psi (2.8 bar) for 1/2” and

3/4” valves with return springs.

Any PowerMaster Valve can be provided to obtain either

two or three position operation.

Three-position valves offer a choice of center functions,

determined by the spool used (see Page 3). These

functions are closed center (all ports blocked), inlet open

center (supply port open to both delivery ports), and

exhaust open center (delivery ports open to the exhaust

port).

The air pilot signal is controlled in solenoid operators by

energizing the solenoid coil to open and close a 3-way

valve in the operators. When electrical power is not

present, the valve may be operated by depressing the

manual override button located on the side of the operator.

Although the solenoid coil may be energized for extended

periods of time, it is better practice to design your electrical

circuit so the coil is de-energized for the extended period,

and energized for the shorter period.

ADJUSTMENTS

No adjustments are require on the PowerMaster Valve.

MAINTENANCE

Tapped body valves may be serviced by shutting off and

venting the main air supply, but removal of the valve from

its mounting is recommended. On subplate mounted

models, the complete valve portion can be removed from

the subplate for servicing without disconnecting piping;

however, air pressure must be shut off and vented.

If a solenoid operated valve fails to operate, depressing the

manual override button on the end of the operator should

quickly indicate whether the trouble is electrical or

mechanical. If required, the solenoid coil can be easily

replaced by removing the top lock nut & slipping off the

solenoid.

PowerMaster Valves are lubricated at the factory for long,

trouble-free service. An efficient air line lubricator will

further extend the service life of the valve. When no

additional lubrication is provided, the valve should be

disassembled every one million cycles for lubrication,

cleaning, and inspection. Clean all metal parts with a

nonflammable solvent and wash all rubber parts with soap

and water. Rinse thoroughly and blow dry with a low-

pressure air jet. When applicable, check the internal pilot

ports in the valve body to make sure the passages are

open.

Replace any parts that are damaged or worn, giving

particular attention to the seal rings (8) in the valve portion.

Repair parts for valve portions and solenoid operators

(Page 3), are available in convenient repair kit form as

shown under the appropriate parts list.

When reassembling the valve portion, one new spacer (9)

should be installed in the stack of spacers and sealing

rings (8) to make the necessary compression in the post

sockets and assure a tight seal stack. Place the new

spacer in the center of the valve body, with sealing rings

and spacers added on each side as assembly of the stack

proceeds. Lubricate each seal with Dow Corning 55M. Tilt

the sealing rings as they are inserted into the valve body to

avoid cutting or damage from sliding over port openings.

Lubricate all metal-to-metal surfaces with Number 107

Lubriplate and all rubber parts with Shell Alvania EP-RO

Grease.

SERVICE INFORMATION