Megmeet M5-N Series User manual

1

M5-N Series Servo System

User Manual

Document Version: V1.0

Archive Date: 2023/12/14

BOM Code:

Shenzhen Megmeet Electric Co., Ltd. provides full technical support for our

customers,customers can contact local Megmeet offices or customer service centers, or

directly contact Megmeet headquarters.

Shenzhen Megmeet Electric Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Shenzhen Megmeet Electric Co., Ltd.

Address: 5th Floor, Block B, Unisplendor Information Harbor, Langshan Rd., Science &

Technology Park, Nanshan District, Shenzhen, 518057, China

Website: www.megmeet.com

Tel: +86-755-86600500

Fax: +86-755-86600562

Service Email: driveservice@megmeet.com

Customer Service Tel: +86-400-666-2163

2

Foreword

Thank you for choosing the M5-N series servo system of Shenzhen Megmeet Electric Co., Ltd.

M5-N servo system use a new hardware design platform and a new generation of control algorithms, this series

of drive with excellent performance, perfect function, compact structure, convenient installation, simple

debugging, easy maintenance, is the cost-effective products for drive generic and OEM markets. This series of

servo supports EtherCAT communication protocol and can realize network operation of multiple sets of servo

systems with the host computer. With the functions of rigid table setting, inertia identification and oscillation

suppression, making the servo easy to use, it is applicable for machine tool, robot, semiconductor, glass

manufacturing, lithium battery equipment, woodworking machinery, textile machinery, packaging machinery,

spraying machinery and other industries, realizing rapid and accurate position,speed and torque control.

M5-N servo system can realize high mechanical time constant and stable operation together with medium inertia

servo motor. This series of servo supports absolute encoder.

The relevant precautions during the installation, wiring, parameter setting, troubleshooting and daily maintenance

will be detailed in this manual. To ensure the correct installation and operation of the M5-N series servo system

as well as its high performance, please read carefully this user manual before installing the equipment. This

manual shall be kept properly and delivered to the actual users of the drive.

Precautions for unpacking inspection

Please check carefully when unpacking the product:

·Whether the product has the damage signs;

·Whether the rotating shaft of the servo motor rotates smoothly(except for motor with brake);

·Whether the rated value in the nameplate is consistent with your order requirement;

·Whether the wiring is damaged and whether the wiring can be used.

We have implemented strict inspection on the manufacturing, package and delivery of the product. If there is any

error, please contact us or your distributor immediately.

We are engaged in the continuous improvement of drive. The relevant manuals provided by us are subject to

change without prior notice.

3

Safety Precautions

Operation without following instructions can cause death or severe personal injury.

Operation without following instructions can cause medium or slight personal injury or

damage to the product and other equipment.

◆Please install the product on the incombustible materials (e.g., metal), otherwise, fire may be caused.

◆Do not place any combustible material near the product, otherwise, fire may be caused.

◆Do not install the product in the environment with explosive gas, otherwise, explosion may be caused.

◆Only qualified personnel can wire the drive, otherwise, electric shock may be caused.

◆Never wire the drive unless the input AC supply is completely disconnected, otherwise, electric shock

may be caused.

◆The grounding terminal of the drive must be reliably grounded, otherwise, electric shock may be caused.

◆The cover must be properly closed before power up, otherwise, electric shock and explosion may be

caused.

◆When powering up the drive that has been stored for over 2 years, the input voltage must be gradually

increased with the voltage regulator, otherwise, electric shock and explosion may be caused.

◆Do not touch the terminals when the product is powered up, otherwise, electric shock may be caused.

◆Do not operate the drive with wet hands, otherwise, electric shock may be caused.

◆Maintenance operation can not be conducted until 10 minutes has passed after disconnecting the power

supply. Meanwhile, be sure to confirm that the charge LED is completely off and the DC bus voltage is

below 36V, otherwise, electric shock may be caused.

◆Only qualified personnel can replace the components. Do not leave any wire or metal parts inside the

drive, otherwise, fire may be caused.

◆The bare parts of the terminal lugs in the main circuit must be wrapped with insulation tape, otherwise,

electric shock may be caused.

◆Please install the drive on the place that can withstand the weight of the drive, otherwise, the drive may

drop and cause human injury or property damage.

◆Do not install the drive in the environment with water splash (e.g., near the water pipe), otherwise, you

may suffer the property loss.

◆Take care not to drop any foreign objects, such as the screws, gaskets and metal bars, into the drive,

otherwise, fire and property damage may be caused.

◆Do not install and operate the drive if it is damaged or its components are not complete, otherwise, fire

and human injury may be caused.

4

◆Do not install the product in the place exposed to direct sunlight, otherwise, property damage may be

caused.

◆Cable lugs must be firmly connected to the terminals of main circuit, otherwise, property damage may

be caused.

◆When removing the servo motor, we can not just pull the cable or hold the rotating shaft to pull the

motor, otherwise, the motor may drop and cause human injury or property damage.

◆Do not directly strike the axis core, for example: tap or beat, this may cause the axis core and the

encoder attached to the opposite side of the axis damaged, otherwise, property damage may be

caused.

◆Do not store the servo motor in the place that exceeds predetermined vibration, otherwise, property

damage may be caused.

5

Contents

M5-N Series Servo System .......................................................................................................1

Chapter 1 M5-N Servo System Selection ................................................................................. 8

1.1 Servo motor and drive model ..........................................................................................................................8

1.2 Servo system configuration specifications ...................................................................................................12

1.3 Applicative cables and models ..................................................................................................................... 12

Chapter 2 Servo System Specifications ..................................................................................15

2.1 Servo drive standard specifications ............................................................................................................. 15

2.2 Servo motor standard specifications ............................................................................................................17

2.3 Servo drive dimensions .................................................................................................................................18

2.4 Servo motor dimensions and interface definition ........................................................................................ 19

Chapter 3 Installation Description ........................................................................................... 22

3.1 Servo drive installation ..................................................................................................................................22

3.1.1 Installation site .........................................................................................................................................................22

3.1.2 Installation environment requirements .................................................................................................................... 22

3.1.3 Servo drive installation precautions .........................................................................................................................22

3.2 Servo motor installation ................................................................................................................................ 24

3.2.1 Installation site .........................................................................................................................................................24

3.2.2 Installation environment requirements .................................................................................................................... 24

3.3 System wiring diagram ..................................................................................................................................25

3.4 Recommended specifications for circuit breakers and fuses ..................................................................... 27

3.5 Related specifications of braking resistor .................................................................................................... 27

Chapter 4 Wiring of Servo System ..........................................................................................28

4.1 Servo drive main circuit connection ............................................................................................................. 29

4.1.1 Main circuit specifications ........................................................................................................................................29

4.1.2 Main circuit cable dimensions ................................................................................................................................. 29

4.2 Servo motor encoder signal connection (CN2) ............................................................................................30

4.3 Control signal interface definition ................................................................................................................. 31

4.3.1 Digital input and output signals ............................................................................................................................... 31

4.4 Communication port wiring ........................................................................................................................... 35

Chapter 5 Operation Panel ..................................................................................................... 36

5.1 Interface introduction .....................................................................................................................................36

5.2 Working status display .................................................................................................................................. 37

5.3 Working status display and parameter setting flowchart .............................................................................37

5.4 Parameter value display ............................................................................................................................... 38

Chapter 6 Commissioning Instructions ................................................................................... 39

6

6.1 Check before running ....................................................................................................................................39

6.2 Commissioning ..............................................................................................................................................39

6.3 Electronic gear ...............................................................................................................................................40

6.4 Brake settings ................................................................................................................................................44

6.4.1 Servo motor brake wiring diagram .......................................................................................................................... 44

6.4.2 Brake timing ............................................................................................................................................................ 44

6.4.3The brake timing when the servo motor is stationary ...............................................................................................44

6.4.4 The brake timing when the servo motor is rotating ................................................................................................. 46

6.4.5 Servo drive fault status brake timing ....................................................................................................................... 48

Chapter 7 EtherCAT Communication ......................................................................................49

7.1 Overview of EtherCAT bus ........................................................................................................................... 49

7.2 M5-N drive bus function introduction ............................................................................................................49

7.2.1 M5-N communication specifications ........................................................................................................................49

7.2.2 EtherCAT Network reference model ........................................................................................................................50

7.2.3 EtherCAT network state machine ............................................................................................................................51

7.2.4 Process Data PDO .................................................................................................................................................. 52

7.2.5 Mailbox data SDO ................................................................................................................................................... 53

7.2.6 Distributed Clock (DC) .............................................................................................................................................54

7.3 CiA402 Device Control (Device Protocol) ....................................................................................................54

7.3.1 CoE state machine .................................................................................................................................................. 54

7.3.2 Object dictionary ......................................................................................................................................................56

7.3.3 Device control word and status word ...................................................................................................................... 56

7.3.4 Common conversion factor ..................................................................................................................................... 59

7.4 Bus operation mode ...................................................................................................................................... 60

7.4.1 Profile Position Mode .............................................................................................................................................. 61

7.4.2 Profile Velocity Mode ............................................................................................................................................... 64

7.4.3 Profile Torque Mode ................................................................................................................................................ 67

7.4.4 Homing Mode .......................................................................................................................................................... 70

7.4.5 Cyclic Synchronous Position Mode ....................................................................................................................... 102

7.4.6 Cyclic Synchronous Velocity Mode ....................................................................................................................... 104

7.4.7 Cyclic Synchronous Torque Mode.........................................................................................................................106

Chapter 8 Drive Parameter Object ........................................................................................ 110

8.1 M5-N Drive parameters ...............................................................................................................................110

Index 2000h(P00): Drive parameters ............................................................................................................................. 110

Index 2001h(P01): Servo motor parameters .................................................................................................................. 111

Index 2002h(P02): Basic control parameters ................................................................................................................. 113

Index 2003h(P03): Digital input and output terminal parameters ................................................................................... 116

Index 2005h(P05): Position control parameters ............................................................................................................. 120

Index 2006h(P06): Speed control parameters ............................................................................................................... 125

Index 2007h(P07): Torque control parameters ...............................................................................................................127

7

Index 2008h(P08): Gain parameters .............................................................................................................................. 129

Index 2009h(P09): Adjustment parameters ....................................................................................................................131

Index 200Ah(P10): Fault and protection parameters ..................................................................................................... 135

Index 200Bh(P11): Display parameters ......................................................................................................................... 143

Index 200Ch(P12): Servo positioning parameters ......................................................................................................... 147

Index 2011h(P17): EtherCAT communication parameters ............................................................................................ 150

Index 2012h(P18): Advanced parameters ......................................................................................................................153

Index 2014h(P20): Bus configuration group parameters ............................................................................................... 153

8.2 Slave station address assignment function ............................................................................................... 154

8.3 User unit selection .......................................................................................................................................154

8.3.1 Position user unit ................................................................................................................................................... 154

8.3.2 Speed user unit ..................................................................................................................................................... 154

8.3.3 Torque user unit .................................................................................................................................................... 154

Chapter 9 Troubleshooting ....................................................................................................155

Appendix 1 Warranty and Service .........................................................................................167

Chapter 1 M5-N Servo System Selection

8

Chapter 1 M5-N Servo System Selection

1.1 Servo motor and drive model

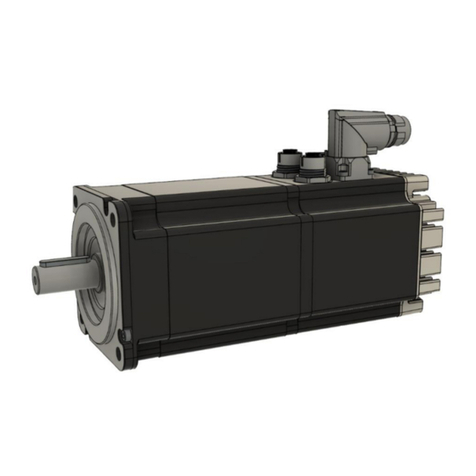

1.Servo motor model

Fig.1-1 M5-N servo motor model

2.Servo motor nameplate

Fig.1-2 M5-N servo motor nameplate

SPM-SC80401MAK-L

SPM-SC80401MAK-L

Chapter 1 M5-N Servo System Selection

9

3.Servo drive model

Fig.1-3 M5-N servo drive model

4.Servo drive nameplate

Fig.1-4 M5-N servo drive nameplate

Chapter 1 M5-N Servo System Selection

10

5.The name and introduction of each part of the servo drive

Fig.1-5 Schematic diagram of each part of M5-N servo drive (SIZEA)

Table 1-1 Description of each part of M5-N servo drive (SIZEA)

No.

Name

Description

①

CN3, CN4

Communication interface

Two RJ45 ports for EtherCAT communication

②

CN5

Type-C USB

communication port

Connect the USB of the computer through this port, you can adjust the

parameters of the drive and debug the performance.

③

LED digital tube

5-digit 8-segment digital tube for status monitoring, parameter display and

setting.

④

Operation keys

5 keys for parameter adjustment and display status switching, etc.

⑤

CN1

Control IO interface

DB15 female connector, control IO interface, used to connect with external IO

and host controller.

⑥

CN2

Encoder interface

1394 female connector for connecting motor encoder

⑦

CHARGE

Bus power indicator

It is used to indicate the state of the bus power. The indicator light indicates

that the capacitor of the bus is charged. Do not touch the power terminal even

if the main power supply is cut off to avoid electric shock.

⑧

Main

circuit

terminal

L1, L2

Main power

supply input

Main power supply input, single-phase 220V.

○—, P

DC bus

terminal

DC bus terminal for common bus connection

P, PB

Braking resistor wiring terminals, connect between P and PB for external

①

②

④

③

⑤

⑥

⑦

⑧

⑨

Chapter 1 M5-N Servo System Selection

11

Brake resistor

wiring terminal

braking resistors.

U, V, W

Servo motor

power

terminals

Servo motor UVW power terminal

PE

Motor ground terminal.

⑨

Ground terminal

Power ground terminal.

Fig.1-6 Schematic diagram of each part of M5-N servo drive (SIZEB)

Table 1-2 Description of each part of M5-N servo drive (SIZEB)

No.

Name

Description

①

CN3, CN4

Communication interface

Two RJ45 ports for EtherCAT communication

②

CN5

Type-C USB

communication port

Connect the USB of the computer through this port, you can adjust the

parameters of the drive and debug the performance.

③

LED digital tube

5-digit 8-segment digital tube for status monitoring, parameter display and

setting.

④

Operation keys

5 keys for parameter adjustment and display status switching, etc.

⑤

CN1

Control IO interface

DB15 female connector, control IO interface, used to connect with external IO

and host controller.

⑥

CN2

Encoder interface

1394 female connector for connecting motor encoder

⑦

CHARGE

It is used to indicate the state of the bus power. The indicator light indicates

①

②

④

③

⑤

⑥

⑦

⑧

⑨

Chapter 1 M5-N Servo System Selection

12

Bus power indicator

that the capacitor of the bus is charged. Do not touch the power terminal even

if the main power supply is cut off to avoid electric shock.

⑧

Main

circuit

terminal

L1, L2, L3

Main power

supply input

Main power supply input, three-phase 220V.

○—, P

DC bus

terminal

DC bus terminal for common bus connection

P, PB, IR

Brake resistor

wiring terminal

Braking resistor wiring terminals, please short-circuit PB and IR for internal

braking resistors; connect between P and PB for external braking resistors.

U, V, W

Servo motor

power

terminals

Servo motor UVW power terminal

PE

Motor ground terminal.

⑨

Ground terminal

Power ground terminal.

1.2 Servo system configuration specifications

Table 1-3 Servo motor configuration specification table

Voltage

Rated

speed

(rpm)

Maximum

speed

(rpm)

Power

(W)

Motor model

Rated

torque

(N.m)

Motor

frame

number

Matching

drive model

Drive

SIZE

220V

3000

6000

100

SPM-SC*0401M**-L

0.32

40

M5-NS1R6A

A

6500

200

SPM-SC*0602M**-L

0.64

60

M5-NS1R6A

A

5000

400

SPM-SC*0604M**-L

1.27

60

M5-NS2R8A

A

5000

750

SPM-SC*0807M**-L

2.39

80

M5-NS5R5A

B

5000

1000

SPM-SC*0810M**-L

3.19

80

M5-NS7R6A

B

1.3 Applicative cables and models

The model descriptions of the servo system power cable and encoder cable are shown in Fig. 1-7 and Fig. 1-8.

Fig.1-7 Power cable model description

Chapter 1 M5-N Servo System Selection

13

Fig.1-8 Encoder cable model description

Servo system cable options and their descriptions are shown in Table 1-4 and Table 1-5.

Table 1-4 Servo system cable options

Name

Model

Appearance

40

servo system

motor power

cable

SPL-MZ01--M5-xx-x

60/80

servo system

motor power

cable

SPL-MA04-M5--xx-x

40/60/80

servo system

multi-turn

absolute

encoder cable

SPL-E01-M5-xx-x

40/60/80

servo system

single-turn

absolute

encoder cable

SPL-E05-M5-xx-x

Chapter 1 M5-N Servo System Selection

14

Table 1-5 Cable description

No.

Model

Name

Description

Cable

diameter

(mm2)

1

SPL-MZ01-M5-xx-x

Main motor

cable (40 base)

Main motor cable, motor side Amp female connector

0.25

2

SPL-MA04-M5-xx-x

Main motor

cable (60/80

base)

Main motor cable, motor side Amp female connector

0.75

8

SPL-E01-M5-xx-x

Multi-turn

absolute

encoder cable

Drive side 6-pin male connector, motor side 9-pin Amp

female connector (with battery case)

—

9

SPL-E05-M5-xx-x

Single-turn

absolute

encoder cable

Drive side 6-pin male connector, motor side 9-pin Amp

female connector (without battery case)

—

Chapter 2 Servo System Specifications

15

Chapter 2 Servo System Specifications

2.1 Servo drive standard specifications

2.1.1 Servo drive electrical specifications

Table 2-1 Drive list and electrical specifications

Voltage level

220V

Model

M5-NS1R6A

M5-NS2R8A

M5-NS5R5A

M5-NS7R6A

Power level

200W

400W

750W

1kW

Outline

SIZE A

SIZE B

Phase

Single phase

Single/three phase

Rated input

current (A)

2.3

4

7.6/3.7

9.6/5.1

Rated output

current (A)

1.6

2.8

5.5

7.6

Maximum output

current (A)

5.8

9.3

16.9

20

Main circuit power

supply

200~240V, -10%~+10%, 50/60HZ

Braking resistor

No built-in

braking resistor

Built-in

braking resistor

2.1.2 Servo drive basic specifications

Table 2-2 Servo drive basic specifications

Basic specifications

Basic

specifications

Control mode

IGBT, PWM control, sine wave current drive mode

Encoder

Rotating

motor

Absolute encoder

Control IO

DI

Different

functions

configured

according

to parameters

5 general inputs, optocoupler isolation, NPN and PNP inputs can be

selected

Input voltage range 20~30V, input impedance 3.9K

DO

Different

functions

configured

according

to parameters

3 general outputs, optocoupler isolation, NPN and PNP output can be

selected

Maximum operating voltage 30V, maximum current 100mA

Chapter 2 Servo System Specifications

16

Communication

function

RS485

Support MODBUS communication protocol, only M5-P, M5-C series support

CAN

Support CANopen communication protocol, follow CiA402 profile, only M5-C series

support

EtherCAT

Support CoE and SoE communication protocol, follow CiA402 profile, only M5-N series

support

USB

Connect the computer and the servo drive to debug and adjust the servo

Other

ports

Button

5 buttons

LED display

5 8-segment LED display

Power indicator

CHARGE lamp

STO safety function

General safety STO function, optional, only M5-N series support

General function

Auto-adjust

The host computer issues an action command, drives the motor to run, estimates and

determines the load rotational inertia ratio in real time, and automatically sets the rigidity

level

Multi-control mode

switching

Position mode, speed mode, torque mode, position/speed mode switching, speed/torque

mode switching, position/torque mode switching, EtherCAT mode.

Protection function

Overvoltage, undervoltage, overcurren,t overspeed, stall, overheat, overload, encoder

abnormality, input phase loss, excessive position deviation

High frequency

vibration

suppression

4 sets of traps suppress the vibration frequency of 100~2000Hz

End vibration

suppression

2 sets of filters suppress the end low frequency vibration of 1~100Hz

Homing mode

Multiple homing functions

Reverse clearance

compensation

Function to improve the response delay that occurs when the direction of travel of the

machine is reversed

Mechanical analyzer

function

Analyze the frequency characteristics of the mechanical system through the host

computer software

Inertia identification

Offline and online system inertia identification

Torque observer

Load torque observation and compensation

Electronic cam

512 point electronic cam curve

Friction

compensation

Compensate system friction

Position

control

Control input

Deviation counter clearing, electronic gear switching, etc.

Control output

Positioning completed

Position reference

EtherCAT

Electronic gear

4 sets of electronic gear ratio/on line

Speed control

Performance

Speed variation

rate

Load variation

rate

0~100% load: below 0.5% (at rated speed)

Voltage

variation rate

Rated voltage ±10%: 0.5% (at rated speed)

Temperature

variation rate

25±25 ℃: below 0.5% (at rated speed)

Speed control

range

1~5000

Speed loop

response

characteristics

2kHz

Soft start time

0~6000ms

Control input

Internal speed command selection 1/2/3, zero speed clamp, etc.

Control output

Speed arrival etc.

Chapter 2 Servo System Specifications

17

Torque control

Performance

Torque control

accuracy

±1%

Frequency

characteristics

3kHz

Control input

Zero speed clamp, torque command symbol input, etc.

Control output

Speed arrival etc.

Speed limit function

The speed limit value can be set according to the parameters

2.2 Servo motor standard specifications

2.2.1 Servo motor basic specifications

Table 2-3 General basic specifications of servo motors

Servo motor basic index items

Protection degree

IP65

Ambient temperature

0℃~+40℃

Ambient humidity

Relative humidity <90% (no frost condition)

Installation method

Flange mounted

Insulation resistance

50MΩ (500V)

Insulation voltage

1500V (220V motor)

1800V (380V motor)

Insulation class

F

2.2.2 Servo motor rated specifications

Table 2-4 Servo motor standard specifications

Motor model

Rated

voltage

(V)

Rated

power

(kW)

Rated

speed

(RPM)

Maximum

speed

(RPM)

Rated

torque

(N.m)

Peak

torque

(N.m)

Rated

current

(A)

Peak

current

(A)

Rotor inertia

(10-4kg.m2)

SPM-SC*0401M**-L

220

0.1

3000

6000

0.32

0.95

0.92

2.85

0.062(0.072)

SPM-SC*0602M**-L

220

0.2

3000

6500

0.64

1.91

1.5

4.66

0.28(0.3)

SPM-SC*0604M**-L

220

0.4

3000

5000

1.27

3.81

2.1

6.5

0.56(0.58)

SPM-SC*0807M**-L

220

0.75

3000

5000

2.39

7.17

4.1

13.4

1.5(1.65)

SPM-SC*0810M**-L

220

1

3000

5000

3.19

9.56

5.7

17.7

2(2.15)

Note: Parameters in parenthesis is the parameter of the motor with brake.

Chapter 2 Servo System Specifications

18

2.3 Servo drive dimensions

1.SIZE A (Applicable drive: M5-NS1R6A, M5-NS2R8A)

Fig.2-1 Dimensions for servo drive of SIZE A

2.SIZE B (Applicable drive: M5-NS5R5A, M5-NS7R6A)

Fig.2-2 Dimensions for servo drive of SIZE B

Chapter 2 Servo System Specifications

19

2.4 Servo motor dimensions and interface definition

1. 40 base medium inertia servo motor

(1) Dimensions

Key

S lo t

Fig.2-3 Dimensions for 40 base medium inertia servo motor

Table 2-5 Dimensions for 40 base medium inertia servo motor

Model

L(mm)

SPM-SC*0401M**-L

67.7(95)

Note: Dimensions in parentheses is the dimension of the motor with brake.

(2) Interface definition

Fig.2-4 Interface definition for 40 base medium inertia servo motor

Motor connection

specifications

Pin

Signal

1

U

2

W

3

V

4

PE

Motor with brake

connection

specifications

Pin

Signal

1

+

2

-

Absolute encoder

connection specifications

Pin

Signal

1

PE

2

5V

3

GND

4

SD+

5

SD-

6

E+

7

E-

Chapter 2 Servo System Specifications

20

2. 60 base medium inertia servo motor

(1) Dimensions

Fig.2-5 Dimensions for 60 base medium inertia servo motor

Table 2-6 Dimensions for 60 base medium inertia servo motor

Model

L(mm)

SPM-SC*0602M**-L

71.8(101)

SPM-SC*0604M**-L

88.8(118.1)

Note: Dimensions in parentheses is the dimension of the motor with brake.

(2) Interface definition

Fig.2-6 Interface definition for 60 base medium inertia servo motor

Motor connection

specifications

Pin

Signal

1

U

2

W

3

V

4

PE

Motor with brake

connection

specifications

Pin

Signal

1

+

2

-

Absolute encoder

connection specifications

Pin

Signal

1

PE

2

5V

3

GND

4

SD+

5

SD-

6

E+

7

E-

This manual suits for next models

4

Table of contents

Other Megmeet Servo Drive manuals

Popular Servo Drive manuals by other brands

Motor Power Company

Motor Power Company DUET AD Series Reference manual

Honeywell

Honeywell MF4000 Series instruction sheet

Higen

Higen FDA5000 Series Operation manual

Leadshine

Leadshine EL7-EC Series user manual

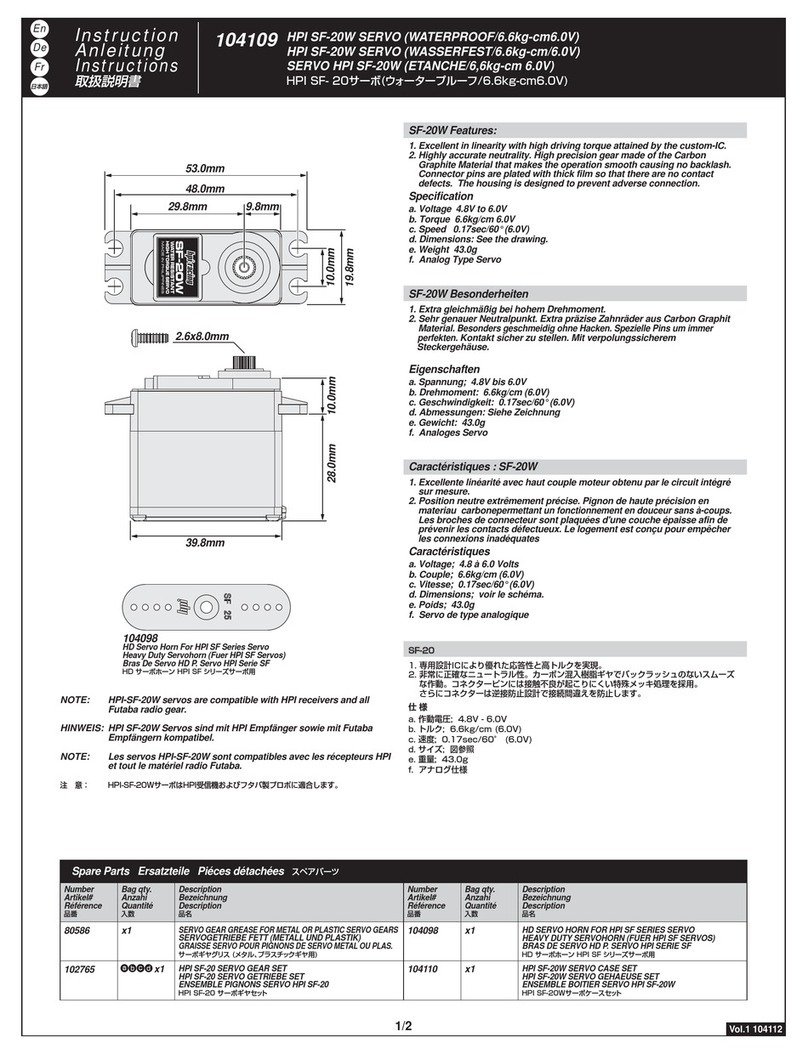

HPI Racing

HPI Racing SF-20W instruction manual

Rockwell Automation

Rockwell Automation Allen-Bradley Ultra3000 manual