Indel GIN-SAC4x4 Series Instructions for use

GIN-SAC4xX

Hardware

User Manual

Version:

1.42en

Date: 01.04.2020

Language: English

Issue: Translation of the original instructions

SAC4xX User Manual

01.04.2020 Rev 1.42en 3

Table of contents

1. General............................................................................................................ 8

1.1. About this manual..............................................................................................................................8

1.2. Sales and Service................................................................................................................................8

1.2.1. Manufacturer .....................................................................................................................................................8

1.2.2. Support..............................................................................................................................................................8

1.3. Disclaimer...........................................................................................................................................8

1.4. Copyright............................................................................................................................................8

1.5. Documentation versions....................................................................................................................9

1.6. Used terms........................................................................................................................................11

1.7. Symbols used ...................................................................................................................................12

2. Safety.............................................................................................................13

2.1. Safety Instructions ...........................................................................................................................13

2.1.1. Qualified personnel .........................................................................................................................................13

2.1.2. Documentation................................................................................................................................................13

2.1.3. ESD- Schutz......................................................................................................................................................13

2.1.4. Protection against contact with electrical components................................................................................13

2.1.5. Turn off ............................................................................................................................................................14

2.1.6. High voltage test, insulation resistance test ..................................................................................................14

2.1.7. Residual Current Circuit Breaker (RCCB) ........................................................................................................14

2.1.8. Safe Torque off (STO) ......................................................................................................................................14

2.1.9. Maximum movement in the event of an error ................................................................................................15

2.2. Safety requirements.........................................................................................................................16

2.2.1. Risk analysis.....................................................................................................................................................16

2.2.2. Checking the safety function ..........................................................................................................................16

2.2.3. Run-on .............................................................................................................................................................16

2.2.4. Braking or Ballast resistance...........................................................................................................................16

2.2.5. Residual energy in the DC intermediate circuit ..............................................................................................17

2.2.5.1 Hot Surface ......................................................................................................................................................17

2.2.6. Safety covers....................................................................................................................................................17

2.2.7. Protection against dangerous movements ....................................................................................................18

2.2.8. Suspended loads .............................................................................................................................................18

2.2.8.1 Loss of the logic power supply........................................................................................................................18

2.2.9. Power failure of the mains supply ..................................................................................................................18

2.2.10. EMC ..................................................................................................................................................................18

2.2.11. Commissioning................................................................................................................................................19

2.2.12. Service life........................................................................................................................................................19

SAC4xX User Manual

01.04.2020 Rev 1.42en 4

2.2.13. Simple protection against bypassing .............................................................................................................19

2.2.14. Responsibility ..................................................................................................................................................19

2.2.15. Defective drives ...............................................................................................................................................19

2.3. Intended use.....................................................................................................................................20

3. Handling.........................................................................................................21

3.1. Storage .............................................................................................................................................21

3.2. Maintenance.....................................................................................................................................21

3.3. Repair Service...................................................................................................................................21

3.4. Disposal ............................................................................................................................................21

4. Product identification......................................................................................22

4.1. Scope of delivery..............................................................................................................................24

4.1.1. GIN-SAC4x4......................................................................................................................................................24

4.1.2. GIN-SAC4x3......................................................................................................................................................24

4.1.3. GIN-SAC4x2......................................................................................................................................................25

4.1.4. GIN-SAC4x1......................................................................................................................................................25

4.2. Rating plates.....................................................................................................................................26

4.2.1. SAC4x4 230V.....................................................................................................................................................26

4.2.2. SAC4x4 400V.....................................................................................................................................................26

4.2.3. SAC4x3 230V.....................................................................................................................................................27

4.2.4. SAC4x3 400V.....................................................................................................................................................27

4.2.5. SAC4x2 230V.....................................................................................................................................................28

4.2.6. SAC4x2 400V.....................................................................................................................................................28

4.2.7. SAC4x1 230V.....................................................................................................................................................29

4.2.8. SAC4x1 400V.....................................................................................................................................................29

5. Stop/Emergency Power Off functions in accordance with EN 60204 .....................30

5.1. Emergency stop................................................................................................................................30

5.1.1. Implementing emergency stop category 0.....................................................................................................30

5.1.2. Implementing emergency stop category 1.....................................................................................................31

5.2. Emergency halt.................................................................................................................................31

5.3. Emergency Power Off.......................................................................................................................32

6. Safety functions with the SAC4.........................................................................33

6.1. Safe Torque Off (STO) ......................................................................................................................33

6.2. Connection example ........................................................................................................................33

6.3. SAC4 drives with STO.......................................................................................................................34

6.4. Diagnostic function in the servo drive.............................................................................................34

6.5. Monitoring of the diagnostic path (K1-K2) by the user...................................................................35

SAC4xX User Manual

01.04.2020 Rev 1.42en 5

7. Technical description ......................................................................................36

7.1. SAC4xX option PRO ..........................................................................................................................36

7.2. Rotary option switch........................................................................................................................36

7.3. Technical specifications...................................................................................................................37

7.3.1. General.............................................................................................................................................................37

7.3.1.1 Leakage Current ..............................................................................................................................................37

7.3.2. Mains connection and intermediate circuit....................................................................................................38

7.3.3. Nominal currents of output stages .................................................................................................................39

7.3.4. Logic power supply .........................................................................................................................................41

7.3.5. Motor................................................................................................................................................................41

7.3.6. Feedback..........................................................................................................................................................42

7.3.6.1 SinCos ..............................................................................................................................................................42

7.3.6.2 Resolver ...........................................................................................................................................................42

7.3.6.3 Incremental encoder .......................................................................................................................................43

7.3.6.4 Absolute value feedback .................................................................................................................................43

7.3.7. Digital IOs.........................................................................................................................................................44

7.3.8. Safe Torque Off (STO)......................................................................................................................................45

7.4. Ambient conditions..........................................................................................................................46

8. Electrical installation.......................................................................................47

8.1. Notes.................................................................................................................................................47

8.2. Pin assignment of SAC4xX................................................................................................................48

8.2.1. GIN-SAC4x4 overview ......................................................................................................................................48

8.2.2. GIN-SAC4x3 overview ......................................................................................................................................49

8.2.3. GIN-SAC4x2 overview ......................................................................................................................................50

8.2.4. GIN-SAC4x1 overview ......................................................................................................................................51

8.2.5. Logic power supply / Digital IOs......................................................................................................................52

8.2.6. Mains connection ............................................................................................................................................52

8.2.7. Motor connections ..........................................................................................................................................52

8.2.8. Intermediate circuit voltage............................................................................................................................53

8.2.9. Ballast Resistance............................................................................................................................................53

8.2.10. Feedback interfaces ........................................................................................................................................53

8.2.11. Safety Connector STO .....................................................................................................................................54

8.3. Motor connection.............................................................................................................................55

8.3.1. 3-phase motor on one output stage ...............................................................................................................55

8.3.2. 3-phase motor on two parallel output stages ................................................................................................55

8.3.3. DC motor at an output stage...........................................................................................................................56

8.4. Mains connection.............................................................................................................................57

8.5. Intermediate circuit .........................................................................................................................58

SAC4xX User Manual

01.04.2020 Rev 1.42en 6

8.6. Logic power supply ..........................................................................................................................58

8.7. Digital IOs..........................................................................................................................................59

8.7.1. Inputs...............................................................................................................................................................59

8.7.2. Outputs ............................................................................................................................................................59

8.8. External Ballast Resistor (brake resistor) ........................................................................................60

8.9. Feedbacks.........................................................................................................................................60

8.9.1. SinCos Feedback .............................................................................................................................................60

8.9.2. Resolver Feedback ..........................................................................................................................................61

8.9.3. Incremental encoder feedback.......................................................................................................................62

8.9.3.1 Connection to absolute value interface .........................................................................................................62

8.9.3.2 Connection to SinCos interface ......................................................................................................................63

8.9.3.3 Connection of single-ended incremental encoder.........................................................................................64

8.9.4. Absolute value feedbacks ...............................................................................................................................65

8.9.4.1 Hiperface..........................................................................................................................................................65

8.9.4.2 EnDat 2.1..........................................................................................................................................................66

8.9.4.3 SSI / Biss C / EnDat 2.2.....................................................................................................................................67

8.9.5. Temperature sensors ......................................................................................................................................67

8.10. Voltage supply..................................................................................................................................68

8.10.1. Logic power supply .........................................................................................................................................68

8.10.2. Mains connection ............................................................................................................................................68

8.11. Wiring................................................................................................................................................69

8.11.1. Conductor cross-sections SAC4x4 ..................................................................................................................69

8.11.2. Routing of motor cables..................................................................................................................................69

8.11.3. Cable routing of the safety function related Circuits .....................................................................................69

8.11.4. Routing of SinCos, incremental, and resolver lines........................................................................................70

8.11.5. Potential equalisation.....................................................................................................................................70

8.11.6. Protective earth connection ...........................................................................................................................70

8.12. Motor overload protection...............................................................................................................70

8.12.1. I2t cut-out.........................................................................................................................................................70

8.12.2. Ballast resistor.................................................................................................................................................70

9. Mechanical installation....................................................................................71

9.1. Notes.................................................................................................................................................71

9.2. Assembly instructions......................................................................................................................71

9.3. GIN-SAC4x4.......................................................................................................................................72

9.3.1. Assembly..........................................................................................................................................................72

9.3.2. Dimensions ......................................................................................................................................................73

9.4. GIN-SAC4x3.......................................................................................................................................74

9.4.1. Assembly..........................................................................................................................................................74

SAC4xX User Manual

01.04.2020 Rev 1.42en 7

9.4.2. Dimensions ......................................................................................................................................................75

9.5. GIN-SAC4x2.......................................................................................................................................76

9.5.1. Assembly..........................................................................................................................................................76

9.5.2. Dimensions ......................................................................................................................................................77

9.6. GIN-SAC4x1.......................................................................................................................................78

9.6.1. Assembly..........................................................................................................................................................78

9.6.2. Dimensions ......................................................................................................................................................79

10. Troubleshooting..............................................................................................80

10.1. Status LED.........................................................................................................................................80

10.2. Table of faults...................................................................................................................................81

11. Further documents..........................................................................................83

11.1. EC Declaration of Conformity ..........................................................................................................83

11.2. SUVA Type-examination certificate for SAC4x4 ..............................................................................84

11.3. SUVA Type-examination certificate for SAC4x3 ..............................................................................86

11.4. SUVA Type-examination certificate for SAC4x2 ..............................................................................88

11.5. SUVA Type-examination certificate for SAC4x1 ..............................................................................90

11.6. CB Test Certificate............................................................................................................................92

12. Standards.......................................................................................................94

SAC4xX User Manual

01.04.2020 Rev 1.42en 8

1. General

1.1. About this manual

This user manual describes the Indel servo drives of the SAC4 series. This document is a translation of the

German version of the original user manual.

This user manual is only valid for Devices with the Safety-Function STO.

This user manual is not valid for Devices that support the enhanced Safety Function Option FS.

1.2. Sales and Service

1.2.1. Manufacturer

Indel AG

Tüfiwis 26

CH-8332 Russikon

Switzerland

www.indel.ch

Phone: +41 44 956 20 00

Fax: +41 44 956 20 09

1.2.2. Support

Indel AG provides you with extensive technical support:

Engineering for hardware and software

Worldwide support via Team Viewer

Worldwide on-site technical support

Commissioning of controls and drives on site

1.3. Disclaimer

The documentation was created to the best of our knowledge and belief. However, the products de-

scribed are constantly being developed and improved. The documentation should therefore never be

considered complete. All information in the documentation is without guarantee. We reserve the right to

make changes at any time without notice. No claims can be made regarding changes to products which

have already been delivered.

1.4. Copyright

© Indel AG

Unless specifically authorised by Indel, the redistribution and reproduction of this document is prohib-

ited.

SAC4xX User Manual

01.04.2020 Rev 1.42en 9

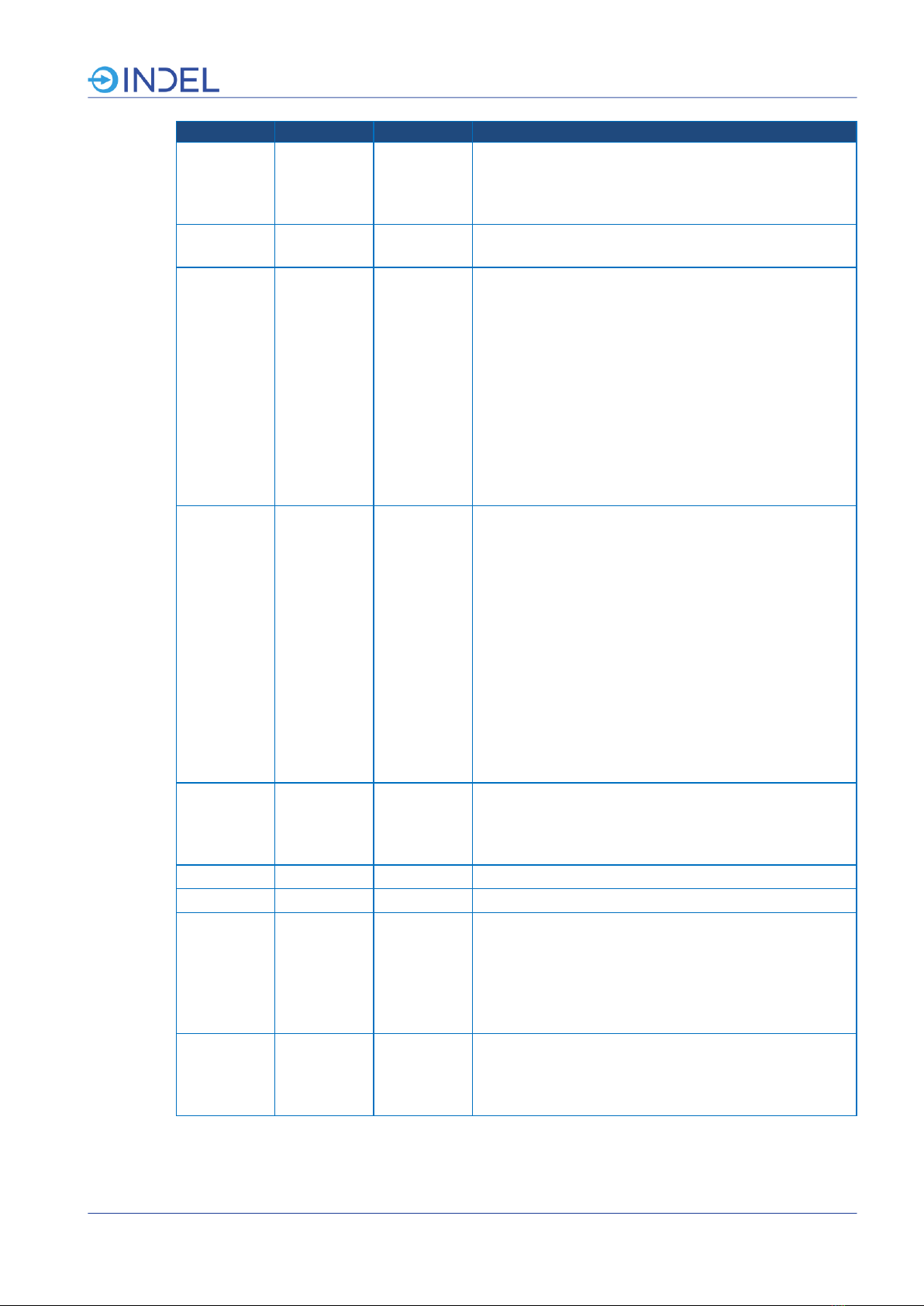

1.5. Documentation versions

Version

Datum

Author

Comments

Rev pr

M. Suter

All draft versions issued before the first release.

Rev 1.00

26.02.2014

M. Suter

Release

Rev 1.10

19.05.2014

M. Suter

Incorporation of the GIN-SAC4x3

Rev 1.11

20.05.2014

M. Suter

Addition of assembly instructions, rotary option

switch and rotary switch description

Rev 1.12

13.06.2014

M. Suter

Correction GIN-SAC4x3 only 3x output stage

Rev 1.20

09.07.2014

M. Suter

Chapter 6.1 deleted

Issue: Original added to cover page

Chapter 2.3 not to be used in explosion hazard ar-

eas

Chapter 2.3 Only for use in industrial contexts

Chapter 2.1.1 extended

Chapter 2.2.2 added

Chapter 7.3.8, fuse protection of the relay 1A

Chapters 5.1.1 and 5.1.2 for illustrative purposes

only

Rev 1.21

28.07.2014

M. Suter

Change to interactive PDF format

Rev 1.22

06.08.2014

M. Suter

Various corrections

Standards updated

Rev 1.23

11.08.2014

M. Suter

Adaptations to EMC standard

Rev 1.24

12.08.2014

M. Suter

Declaration of Conformity added

Rev 1.25

11.11.2014

M. Suter

Chapter 7.3.4, Power consumption of logic power

supply < 2A

Rev 1.26

25.11.2014

M. Suter

Type certificate for SAC4x4 and SAC4x3 added

Rev 1.27

02.04.2015

M. Suter

Status LED chapter 10.1 on page 78 added

Rev 1.28

02.04.2015

M. Suter

Reaction time tOFF of the STO in chapter 7.3.8 on

page 42 corrected from 3ms to 15ms

Rev 1.29

15.04.2015

M. Suter

Modification to conductor cross-sections chapter

8.11.1

Modification to motor overload protection chapter

8.12

Modification to assembly instructions chapter 9.2

Rev 1.30

31.07.2015

M. Suter

Suva approval on rating plates

Incorporation GIN-SAC4x1

Various corrections

Rev 1.31

28.10.2015

M. Suter

PT100 and PT1000 can now also usable as tempera-

ture sensors, chapter 8.9.5

Rev. 1.32

19.04.2016

M. Bleuler

Declaration of Conformity adjusted according to

current guidelines, chapter 11.1

Intermediate circuit capacity added for SAC4x3,

SAC4x2 and SAC4x1, chapter 7.3.2

Rev. 1.33

17.10.2016

M. Bleuler

D-Sub mating connector corrected in chapters

4.1.1, 4.1.2, 4.1.3 and 4.1.4

GIN-SAC4x2 in chapter 4, chapter 4.1.3, chapter

6.2.1, chapter 7.3.1, chapter 7.3.3, chapter 8.2.3 and

chapter 9.5 added

Type-examination certificate GIN-SAC4x2 and

GINSAC4x1 added in chapters 11.4 and 11.5

SAC4xX User Manual

01.04.2020 Rev 1.42en 10

Version

Datum

Author

Comments

Rev. 1.34

13.12.2016

M. Bleuler

New sketch added under assembly instructions in

chapter 9.2

EC Declaration of Conformity adapted only for STO

option in chapter 11.1

Rev. 1.35

15.06.2017

M. Bleuler

Old Indel logo replaced with new Indel logo

Relinking the URLs

Rev. 1.36

06.02.2018

M. Bleuler

Former Chapter 8.3.3 "three parallel ouput stages"

deleted, as not implemented to date.

Additional note added under chapter 6.2.2 in con-

nection with internal evaluation.

Chapter 6.2.3 added for better understanding in

conjunction with Chapter 6.1.

Overvoltage category standard in chapter 7.3.2 ad-

justed.

Overvoltage category standard in chapter7.4 ad-

justed.

Pin assignment of positions in image in chapters

8.2.2 and 8.2.3 corrected.

Rev. 1.37

02.04.2019

S. Bärtschi

Converted Document to «MS-Word»

Removed the Fuse in the N-Line of drawing (chapter

)

Corrected some typos

Illustrations of the devices with the new Indel Logo

Illustrations of the devices with rating plates with

the new Indel Logo

Remark to FS-Option Devices in chapter 1.1

Added feature Biss C and Endat 2.2

Added feature Dout und DIN as GPIO (chapter 8.7)

Constraints for DC-Motor and STO (chapter 2.1.9,

7.3.5, 8.3.3)

Detail wording of the STO description (chapter 6.1)

Illustration EC Declaration of Conformity: new Logo

Rev. 1.38

16.07.2019

S. Bärtschi

Clarified diagnostic path of STO function (chapter

6.5)

Changed safety checking interval period according

the latest EN61800-5-2:2016 (chapter 2.2.2)

Rev. 1.39

11.09.2019

S. Bärtschi

Renewed Type-examination certificate SUVA

Rev. 1.40

27.09.2019

S. Bärtschi

Rating Plates with new Indel Logo

Rev. 1.41

19.11.2019

S. Bärtschi

Added chapter “hot surface” (chapter 2.2.5.1)

added Power S1 and remark to external fuse and

mains filter (chapter 7.3.2)

added leakage current information (chapter 7.3.1.1)

added information “residual current circuit-

breaker” (chapter 2.1.7)

Rev. 1.42

01.04.2020

S. Bärtschi

Updated the English Version

minor enhancements in Drawings for German/Eng-

lish support

Added CB Test Certificate (chapter 11.6)

SAC4xX User Manual

01.04.2020 Rev 1.42en 11

1.6. Used terms

Abbreviation

Meaning

GinLink

Indel communication Fieldbus, 1GBit/s Ethernet based

PE-Leiter

Protective Earth conductor

GIN-SAC4xX

Designation for entire GIN-SAC4 series

GIN-SAC4

Designation for entire GIN-SAC4 series

GIN-SAC4x4

Designation for GIN-SAC4 with 4 output stages

GIN-SAC4x3

Designation for GIN-SAC4 with 3 output stages

GIN-SAC4x2

Designation for GIN-SAC4 with 2 output stages

GIN-SAC4x1

Designation for GIN-SAC4 with 1 output stage

+DC / -DC-

Intermediate DC circuit tapped onto the servo drives

Fieldbus Master

Master of the GinLink fieldbus

STO

Safe Torque Off

SAC4xX User Manual

01.04.2020 Rev 1.42en 12

1.7. Symbols used

Important notice for the user

The symbol indicates important information for the user.

All instructions must be observed

Attention

The symbol indicates information which, if not observed,

could lead to damage to property and/or personal injury.

Danger

This symbol indicates information which, if not observed,

could result in personal injury caused by electricity.

Hyperlink

Indicates a hyperlink to a file or information on the Internet

Reference

Reference to a chapter within the documentation

WWW.

SAC4xX User Manual

01.04.2020 Rev 1.42en 13

2. Safety

2.1. Safety Instructions

The following safety instructions male no claim to completeness. If you have any questions, uncertainties

or problems, please contact us.

2.1.1. Qualified personnel

All work such as transport, installation, commissioning and service may only be carried out by qualified

specialist personnel. Qualified specialist personnel are persons who are familiar with the transport, in-

stallation, assembly, commissioning and operation of the product and who have the qualifications re-

quired for their job. National accident prevention regulations must be observed. The safety instructions,

the information on the connection conditions (rating plate and documentation) and the limit values spec-

ified in the technical data must be read carefully before installation and commissioning and must be

strictly adhered to.

2.1.2. Documentation

Before installation and commissioning, please read this documentation as well as the documentation

which is referenced in their entirety. Incorrect handling can lead to personal injury or damage to prop-

erty. Be sure to comply with the technical specifications, connection conditions and environmental con-

ditions.

2.1.3. ESD- Schutz

The servo amplifiers contain electrostatically sensitive components that can be damaged by improper

handling. Discharge your body before touching the servo amplifiers. Avoid contact with highly insulating

materials (synthetic fibers, plastic films etc.). Place the servo amplifiers on a conductive surface in a volt-

age-free state. Do not touch the contacts of the connector on the drive and the connected cables or the

contact pins on the conductors.

2.1.4. Protection against contact with electrical components

For the operation of the servo amplifier it is necessary that certain parts carry voltages of more than

50VAC, exceeding extra-low voltage limit. If such parts are touched, life-threatening electric shocks may

occur. There is a risk of death or serious damage to health.

Before switching on a drive, make sure that the device is properly connected to the PE conductor. The

earth connection must always be connected, even if the drive is only put into operation for a short time.

Before switching on, live parts with more than 50VAC must be protected against direct contact by means

of suitable measures.

Connections can also carry dangerous voltages when the motor is not turning. Touching the terminals

when they are switched on is therefore prohibited. Before working on the drive, disconnect it from the

mains and secure it against being switched on again.

Contact with live parts (e.g. terminals) may result in death or serious health or material damage. Never

disconnect the electrical connections of the modules whilst live. In unfavorable cases, arcing can occur,

harming people and hardware such as contacts.

SAC4xX User Manual

01.04.2020 Rev 1.42en 14

2.1.5. Turn off

After switching off the mains supply, residual voltages can be present for several minutes. Measure the

intermediate circuit voltage and wait until the voltage has fallen below 50V.

2.1.6. High voltage test, insulation resistance test

Do not perform a high voltage test or an insulation resistance test on the mains connection and motor

connection of the drives, otherwise the drive will be damaged.

2.1.7. Residual Current Circuit Breaker (RCCB)

When this product is supplied by a 3phase mains supply, a defect can cause a DC Current at the protective

earth conductor. If an RCCB is installed in the grid connection system, only “RCCB Type B” are allowed.

Only type B universal current-sensitive Residual Current Circuit Breakers may be used.

2.1.8. Safe Torque off (STO)

The safety function STO as described in chapter 6 is designed as a safety pulse inhibitor. The drive may

restart after resetting the pulse inhibitor, depending on the application.

Activating the safety function is not suitable for de-energising the drive.

Activating the safety function does not provide protection against electric shock.

In case of multiple faults (hardware defects of power semiconductors inside the output power stage)

the motor can move a certain limited angle/distance even in the safe STO state. See chapter 2.1.9 for

more information.

SAC4xX User Manual

01.04.2020 Rev 1.42en 15

2.1.9. Maximum movement in the event of an error

It should be noted that a multiple fault in the IGBT bridge could cause the motor to advance for a short

period. The maximum rotational angle of the motor shaft or maximum linear distance occurring when

advancing depends on the number of pole pairs in the motor used.

For permanent-magnet synchronous servo motors:

For linear motors:

For DC-Motors:

DC-Motors connected to GIN-SAC4xX devices shall not be used for dangerous or safety relevant appli-

cations.

As a matter of principle the STO Safety-function can get completely ineffective when using DC-Motors in

case of faults in the IGBT bridge or the motor wiring.

SAC4xX User Manual

01.04.2020 Rev 1.42en 16

2.2. Safety requirements

During the installation and operation of Indel Drives in applications with stop category 0 or 1 safety re-

lated Torque off of the drive according to EN 60204-1 and fail-safe protection against restart in accord-

ance with EN ISO 13849-1 cat. 3 / PL d, all conditions inside this Manual apply and all conditions that are

referred to apply, are compulsory and must be observed.

Indel servo drives with the STO function have been developed according to the relevant standards.

2.2.1. Risk analysis

The machine manufacturer must prepare a risk analysis for the machine and take appropriate measures

so that unforeseen movements do not lead to damage to persons or property.

There are also indications in this document regarding possible dangers. All information on dangers, warn-

ings, precautionary measures and information must be observed.

2.2.2. Checking the safety function

See chapter 6.5 “Monitoring of the diagnostic path (K1-K2) by the user”.

Periodic test cycle:

The EN 61800-5-2 2016 Standard defines the following maximum time between 2 test cycles depending

on the required safety Performance Level (PL) and Category:

For SIL 2, PL d Category 3 at least 1 test per year

For SIL 3, PL e Category 3 at least 1 test every 3 months

For SIL 3, PL e Category 4 at least 1 test per day

PL and Category as specified in ISO 13849-1.

2.2.3. Run-on

If application-dependent dangers arise as a result of the run-on, additional protective measures must be

taken (e.g. movable guards with locks), in order to cover the danger area until there is no danger to per-

sons or property. It must be taken into account that, without a mechanical brake or with a defective

brake, drive run-on is possible.

2.2.4. Braking or Ballast resistance

The braking resistor is not safely controlled by the Indel servo drives. A defective or improperly connected

braking resistor will cause the motor to stop outside the expected timespan. In the worst case, this can

lead to personal injury and damage to property.

SAC4xX User Manual

01.04.2020 Rev 1.42en 17

2.2.5. Residual energy in the DC intermediate circuit

Residual charge in the intermediate circuit capacitors can be retained for up to 10 minutes after switching

off the power supply (opening the main contactor or motor contactor). It is possible to move the motor

with this residual charge. This can potentially lead to dangerous situations. If additional external capaci-

tor modules are used, it will take longer for the intermediate circuit capacitors to discharge.

The following warning is attached to the drives.

2.2.5.1 Hot Surface

Under high load the device will run hot and some parts of the case reach temperatures up to 80°C.

Warning: Risk of burn.

The following warning is attached to the drives

2.2.6. Safety covers

Additional safety covers must be designed and integrated in accordance with the safety category re-

quired for the machine according to EN ISO 13849-1. After the stop command has been triggered, de-

pending on the danger posed, access must remain locked until the drive has come to a complete stop.

SAC4xX User Manual

01.04.2020 Rev 1.42en 18

2.2.7. Protection against dangerous movements

Incorrect activation of motors can trigger unintended and dangerous movements.

Incorrect installation

Faulty design

Faulty or incomplete wiring

Defective devices or cables

Incorrect control by the software

As a rule, after switching on the drive, motor movement is to be expected. Protection of persons and ma-

chines can only be guaranteed by means of overarching measures. Suitable measures are to be taken in

order to protect the range of motion of machinery against unintentional access by people. Removing,

bridging, or bypassing safety devices is strictly prohibited. A sufficient number of easily accessible Emer-

gency Power Off switches is to be attached to the machine. Keep all covers and cabinet doors closed dur-

ing operation.

2.2.8. Suspended loads

In the case of suspended loads, addition measures must be taken in order to ensure that the axis stays in

place. The Indel servo drives do not offer any outputs which allow you to safely control securing brakes.

Holding brakes provide no protection when slowing down the motor.

2.2.8.1 Loss of the logic power supply

If the 24V logic power supply fails on the drive, the motor may spin out. If this is not permitted, external

measures must be taken to prevent the axis from spinning out.

2.2.9. Power failure of themains supply

In the event of a power failure of the mains supply or the supply for the motors, the motor may spin out. If

the intermediate circuit voltage Ucc drops below the configured limit Ucc MIN, the servo drive will signal

an error and the motors will be deactivated.

2.2.10. EMC

For EMC-compliant wiring, see further document INDEL Wiring Guidelines and INDEL installation Guide-

line and all wiring instructions in this document.

INDEL Wiring Guidelines

INDEL Installation Guideline (only available in German)

The machine or system manufacturer must take additional measures for EMC protection if the product

standard contains lower limit values applicable to the machine in question. In the case of machines

which contain many Indel servo drives, additional EMC protection measures may also be required.

The Gin-SAC4 devices are intended for use in industrial environment. A line filter is required on the mains

connection preceding the GIN-SAC4. See also chapter 8.10.2

In a residential environment (first environment), this product may cause high frequency interference,

which may require further suppression measures.

WWW.

WWW.

SAC4xX User Manual

01.04.2020 Rev 1.42en 19

2.2.11. Commissioning

Before switching on a servo drive, make sure that the device is properly connected to earth. The earth

connections must always be provided, even if the drive is only put into operation for experimental pur-

poses.

Control and power connections can carry voltage even when the motor is not moving. Touching the

terminals when the power is on is prohibited. Before working on the drives, they must be disconnected

from the mains and secured against being switched on again.

Documented commissioning and demonstration of the safety functions must take place. For Indel servo

drive applications with stop category 0 or 1 safety-related cut-out of the drive according to EN 60204-1

and fail-safe protection against restart in accordance with EN ISO 13849 cat. 3, commissioning of the cut-

out mechanism and the correct wiring must always be carried out and recorded.

During commissioning, signal detection must be included in the functional test. The status of the auxiliary

contacts of the safety relays can be viewed in the “actual parameters”in the servo drive. However, these

contacts and displayed values are for diagnostic purposes only and not part of the safety function.

2.2.12. Service life

Fifteen years after delivery at the latest, the safety module in the servo drives must be replaced. If used

for more than 15 years, safe operation is no longer guaranteed. This applies not only to the operating

time, but also to standstill and storage time.

2.2.13. Simple protection against bypassing

Measures must be taken to prevent bypassing of the safety functions in accordance with EN ISO 138491

Cat.3 / PL d.

2.2.14. Responsibility

The servo drives are not completely fail-safe. In the event of a failure, the operator is responsible for en-

suring that the machine / system is put into a safe condition.

All of the diagnostic and monitoring functions can only interrupt the control of the motor. As a conse-

quence of this, the motor is de-energised and can no longer be controlled and braked. Depending on the

application, additional measures may be required to slow down or stop the motor.

The operator is responsible for safety.

2.2.15. Defective drives

Defective and damaged drives must under no circumstances be taken into operation. This can lead to

serious personal injury and property damage.

SAC4xX User Manual

01.04.2020 Rev 1.42en 20

2.3. Intended use

Indel Servo Drives may only be used as specified in this document and in the documents to

which reference is made.

The intended use is prohibited until it has been established that the machine complies with the

provisions of Machinery Directive 2006/42/EC and the EMC Directive 2004/108/ EEC, or the rele-

vant current version of said directives. Otherwise, the Indel servo drives cannot be placed on

the market.

Indel Servo Drives must only be used in industrial contexts.

The servo drives are designed for installation in stationary electrical machines/systems that

comply with the Machinery Directive, Low Voltage Directive and the EMC Directive.

Indel Servo Drives must be installed in a control cabinet that can only be opened using a tool.

The drives must be installed so that no live parts can be touched.

It is imperative that the environmental conditions listed on page 43 in chapter 7.4 be observed.

Ventilation or cooling measures may be necessary to keep the cabinet temperature below 40°C.

The GIN-SAC4 servo drives can be used directly in three-phase, earthed industrial grid networks

(TN system, TT system with earthed star point at 400V +10%). The servo drives must not be op-

erated on unearthed networks, nor on asymmetrically earthed networks.

The machine manufacturer is obliged to carry out a risk analysis of the machine and to take ap-

propriate measures to prevent unforeseen movements from causing damage to persons or

property.

The drives must not be used in an explosion hazard area.

This manual suits for next models

5

Table of contents

Other Indel Servo Drive manuals