Megmeet Artsen Series User manual

Full Digital Heavy Duty IGBT CO2/MAG/MIG Intelligent

Multifunctional Inverter Welder

User Manual

Version: V1.2

Item: R33010283

Shenzhen Megmeet Electric Co., Ltd. provides comprehensive technical support for customers,

covering but not limited to, CAN communication, welder network monitors, robot collaboration,

welding process database software upgrade, and after-sale service. Users can contact the nearest

Megmeet's offices or customer service centers, or directly contact Megmeet headquarters.

Shenzhen Megmeet Electric Co., Ltd.

All rights reserved. The content may subject to change without notice.

Shenzhen Megmeet Electric Co., Ltd.

Address: 5th Floor Block B, Ziguang Information Harbor, Langshan Road, Shenzhen, 518057, China

Zip code: 518057

Website: www.megmeet.com

Customer service hotline: 4006662163

Email: Welder.4S@megmeet.com

Preface

Thank you for choosing Megmeet's Full Digital Heavy Duty IGBT CO2/MAG/MIG Intelligent

Multifunctional Inverter Welder (hereinafter referred to as the welder).

This document covers the precautions on installation and cable connection, parameter setup, troubleshooting,

and daily maintenance. To ensure that the welder is installed and operated properly and can achieve its

optimal performance, read this user manual before installation. This document must be kept properly and

delivered to users of the welder.

Megmeet continuously pursues development and innovation. If the actual product is not in conformity with

the content, parameters, or diagrams in this document, the actual product shall prevail. This document may

subject to change without notice and Megmeet reserve the right of final interpretation of this document.

Safety Precautions

Safe Definition

Danger

Follow instructions to perform operations. Failing to do so may result in death or serious injuries.

Note

!

Follow instructions to perform operations. Failing to do so may result in medium injuries or

property damages.

•Read this document before using the welder to ensure proper use.

•Although this welder is designed and manufactured with safety considerations, pay attention to the

precautions specified in this document when using the welder, so as to ensure the safety of you and

related personnel and prevent serious accidents.

•Misuse of this welder may cause injuries.

Safety Precautions

Danger

•Before moving the welder, cut off the input power of the distribution box.

•When using a crane to move the welder, make sure that the hoist ring has been tightened and the housing and

cover plate of the welder have been installed.

•Do not lift the welder and other objects at the same time.

•Install the welder on non-inflammable objects to prevent fire risks.

•Do not place inflammable objects near the welder, failing to do so may result in fires.

•Do not install the welder in an environment with explosive gas; failing to do so may result in explosion risks.

•Cable connection must be performed by certified personnel; failing to do so may result in electric shock.

•Before cable connection, measure that the power input has been disconnected completely; failing to do so may

result in electric shock.

•Before connecting the power supply, connect the grounding terminal of the welder properly; failing to do so may

result in electric shock.

•Before connecting the power supply, install the cover plate; failing to do so may result in electric shock.

•Do not touch terminals when the power supply is connected; failing to do so may result in electric shock.

•Do not operate the welder with wet hands; failing to do so may result in electric shock.

•Perform maintenance 5 minutes only after the power supply is disconnected, the power indicator is completely off,

and the voltage of the positive and negative bus bars is lower than 36 V; failing to do so may result in electric shock.

•Parts can be replaced only by professionals. Do not leave cable stubs or metal objects in the welder; failing to do

so may result in fires.

•After replacing the control board, set the parameters correctly before using the welder; failing to do so may result

in property damages.

•Use insulation tapes to wrap the copper nose that connects to cables; failing to do so may result in electric shock.

•The water tank power supply has a high voltage, which is AC 380 V. Disconnect the power supply before

connecting cables; failing to do so may result in electric shock.

Note

!

•Do not impose force on the control panel and cover plate when moving the welder; failing to do so may result in

disconnection of the control panel and cover plate and damages of properties.

•When moving the welder using a forklift truck, fix the wheels of the welder.

•Install the welder only at the place where the welder can be held stably. Otherwise, the falling of the welder may

result in injuries or property damages.

•Do not install the welder at the place where water spray may occur; failing to do so may result in property

damages.

•Prevent bolts, washers, or metal rods from dropping into the welder. They may result in fires and property

damages.

•If the welder is damaged or incomplete, do not install or use it; failing to do so may result in firs and injuries.

•Firmly connect the main loop terminal to the copper nose; failing to do so may result in property damages.

Usage Precautions

Danger

•To ensure safety, welding must be performed by personnel who understand safe operations and possess welding

skills.

•Do not use the welder for purposes other than welding.

•Installation, commissioning, and maintenance of the welder can only be performed by professional personnel.

•People using heart pacemakers are not allowed to get close to the welder and welding sites without doctors'

permission.

•Do not touch the live parts; failing to do so may lead to electric shock.

•Do not use cables with insufficient cross-sectional areas, cables with exposed conductors, and cables with damages.

•Do not remove the housing or cover plate when the welder is in use.

•Wear insulation gloves with good insulation performance and without damages.

•Take safety measures when doing tasks at high places.

•Disconnect the power supply of the welder and distribution box when the welder is not used.

•When performing welding in narrow or confined space, adopt supervision and ensure good ventilation or use

respiratory protection tools; failing to do so may result in asphyxia due to hypoxia.

•Hazardous smoke, dust, and gas may be generated during welding. Ensure good ventilation or use respiratory

protection tools; failing to do so may result in injuries.

•Do not weld pressure vessels that contain gas, such as gas tubes and seal pots.

•Do not move hot workpieces close to combustible materials.

•Do not perform welding near combustible materials.

•Deploy fire extinguishers near welding sites.

•Fix gas cylinders using only dedicated stands; failing to do so may result in injuries when the gas cylinders fall

down.

Danger

•Do not connect electrodes with gas cylinders.

•Follow instructions to correctly use pressure reducing valves.

•Only professional personnel are allowed to disassemble and repair pressure reducing valves.

•Do not touch the rotating parts such as the fan and wire feeder when the welder is in use; failing to do so lay result

in injuries.

•When performing or supervising welding, use protective equipment with sufficient shading degree to prevent arc

from harming eyes or skin.

•Use protection gears, such as welding-dedicated protection leather gloves, clothes with long sleeves, foot

protection, aprons, and goggles, to protect against arc, spatter, and welding spatter.

•Set up protective barriers around welding sites to prevent arc from injuring others.

•Use soundproof devices to prevent noise hazards.

Note

!

•Do not use this welder for tasks other than welding.

•Do not place heavy objects on the welder.

•Do not seal or block the air vents of the welder.

•Place the welder at places where metal objects such as spatters are unable to enter the welder.

•Keep the welder at least 30 cm away from walls and other welders.

•Use screens to prevent wind from directly blowing against arc.

•Fix the wheels to prevent the welder from sliding.

•To prevent electromagnetic hazards, implement electromagnetic shielding for cables and welding sites.

•The slope of the surface must be less than 15 degrees to prevent the welder from falling down.

•The protection class of the welder is IP23S and is applicable in the following conditions:

Operating temperature range: -10°C to +40°C

Transportation and storage temperature range: -40°C to +70°C

Operating humidity range: ≤ 75% RH at 40°C ; ≤ 95% RH at 20°C

Altitude: ≤ 2000 m

The operating environment must not have significant mechanical vibration or mechanical impact. The welder must

not be tilted more than 15°.

The content of dust, metal dust, and corrosive gas must not exceed the normal level.

Avoid the welder from rain and prevent the fan from taking in rain.

•When the ambient temperature is below 10°C, use antifreeze dedicated to the water tank to prevent water tank

damages.

Scrapping Precautions

Pay attention to the following when scrap the welder:

•The electrolytic capacitors on the main loop and the PCB may explode when getting burnt.

•Toxic gases may be emitted when plastic parts such as the front panel are burnt.

•Dispose the welder as industrial waste.

Contents

Chapter 1 Product Overview................................................................................................................................................................1

1.1 Welder Series Introduction.......................................................................................................................................................1

1.2 Applicable Domains.................................................................................................................................................................1

1.3 Technology Introduction ..........................................................................................................................................................1

1.3.1 DC Short Arc Welding.................................................................................................................................................1

1.3.2 Single-pulse Welding...................................................................................................................................................1

1.3.3 Double-pulse Welding..................................................................................................................................................2

1.4 System Components.................................................................................................................................................................2

1.5 External Dimensions and Gross Weight...................................................................................................................................3

1.6 Model Code Format..................................................................................................................................................................3

Chapter 2 Installation and Cable Connection.....................................................................................................................................4

2.1 Open-Package Inspection.........................................................................................................................................................4

2.2 Installation Requirements.........................................................................................................................................................4

2.3 Transportation Precautions.......................................................................................................................................................4

2.4 Welder Specifications...............................................................................................................................................................4

2.5 Electric Connections.................................................................................................................................................................5

2.5.1 Connecting the Welder.................................................................................................................................................5

2.5.2 Connecting the Water Tank..........................................................................................................................................6

2.5.3 Connecting the Wire Feeder.........................................................................................................................................6

2.5.4 Connecting the Gas Supply System .............................................................................................................................7

2.5.5 Connecting the Welding Torch ....................................................................................................................................7

2.5.6 Connecting the Welding Power Cable (Ground Cable) of the Workpiece ...................................................................8

2.5.7 Connecting the Power Cable on the Power Input Side (AC 380 V).............................................................................8

Chapter 3 Function Description and Usage.......................................................................................................................................10

3.1 Welding Preparation...............................................................................................................................................................10

3.2 Function Description and Usage.............................................................................................................................................10

3.2.1 Welding Parameters ...................................................................................................................................................12

3.2.2 Detect Gas..................................................................................................................................................................13

3.2.3 Wire Inching ..............................................................................................................................................................13

3.2.4 Air-Cooling/Water-Cooling .......................................................................................................................................13

3.2.5 Arc Dynamic..............................................................................................................................................................13

3.2.6 Fusion Depth Control.................................................................................................................................................14

3.2.7 SYNERGIC................................................................................................................................................................15

3.2.8 Starting Arc Parameters .............................................................................................................................................16

3.2.9 Ending Arc Parameters...............................................................................................................................................17

3.2.10 Welding Control(2T/4T /Special 4T/Welding with Repeated Ending Arc)..............................................................18

3.2.11 SAVE and LOAD ....................................................................................................................................................24

3.2.12 Lock .........................................................................................................................................................................25

3.2.13 Internal Menu...........................................................................................................................................................29

3.3 Robot Communication Interfaces...........................................................................................................................................43

3.3.1 Digital Robot Communication Interface ....................................................................................................................43

3.3.2 Analog Robot Communication Interface....................................................................................................................44

3.3.3 Intelligent Function Description.................................................................................................................................45

3.4 Post-welding Tasks.................................................................................................................................................................46

Chapter 4 Troubleshooting.................................................................................................................................................................47

4.1 Failure of Indicators of the Welder.........................................................................................................................................47

4.2 Error Codes of the Welder and Solutions...............................................................................................................................47

Chapter 5 Maintenance.......................................................................................................................................................................49

5.1 Daily Inspection .....................................................................................................................................................................49

5.2 Regular Inspection..................................................................................................................................................................50

5.3 After-Sale Service ..................................................................................................................................................................51

Appendix I Technical Specifications..................................................................................................................................................52

Appendix II Electric Connections ......................................................................................................................................................53

Appendix III System Configurations .................................................................................................................................................54

Appendix IV Processing Technique Details.......................................................................................................................................55

Appendix V Structure Details.............................................................................................................................................................56

Chapter 1 Product Overview 1

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Chapter 1 Product Overview

1.1 Welder Series Introduction

Products in theArtsen PM/CM series are full digital heavy duty IGBT CO2/MAG/MIG intelligent

multifunctional inverter welders designed for professional users. Connected to digitally controlled wire

feeders, they can:

Provide multiple intelligent welding control methods, including the DC, single-pulse, and

double-pulse options based on real-time energy control.

Weld various materials including carbon steel, stainless steel, and aluminum alloy.

Weld solid wires and flux-cored wires.

Be used by special welding control means.

Work with automated equipment, including robots and intelligent equipment.

Work with Megmeet's welding tractor to achieve higher mobility.

Work with Megmeet's water cooling equipment to better cool the welding torch.

1.2 Applicable Domains

Products in theArtsen PM/CM series are applicable to various domains including automobile and parts,

instrument manufacturing, machine and rail transportation, shipbuilding and offshore platform, and

chemical engineering.

1.3 Technology Introduction

1.3.1 DC Short Arc Welding

Products in the Artsen CM series are equipped with the "short-circuiting transfer for special energy

control" technology, which controls the welding current and voltage in real time to adjust the metal

transfer feature and droplet shapes for better welding seam appearances, higher welding speeds, and less

spatters. It is especially suitable for welding carbon steel plates with medium, low, or extra-low thickness

and for backing welding.

Figure 1-1 shows the control waveform.

Figure 1-1 DC short arc welding

1.3.2 Single-pulse Welding

Products in the Artsen PM series are equipped with the "pulse energy adjustment" metal transfer control

technology, which controls the pulse current to adjust the droplet size and shape for globular transfer, so

as to increase the arc energy, optimize welding seam appearances, and reduce spatters. It is especially

suitable for welding stainless steel, aluminum alloy, and some nonferrous metals.

2 Chapter 1 Product Overview

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Figure 1-2 shows the control waveform.

Figure 1-2 Single-pulse welding

1.3.3 Double-pulse Welding

Products in the Artsen PM are equipped with the collaborative pulse energy control technology based on

variable wire inching speed, which periodically controls the wire inching speed, pulse current parameters,

and arc length parameters to adjust the welding heat input for better welding seam appearances and higher

welding seam quality. It is especially suitable for welding aluminum, aluminum alloy, and other metals.

Figure 1-3 shows the control waveform.

Figure 1-3 Double-pulse welding

1.4 System Components

Figure 1-4 shows the welding system.

Wire

feeder

Welder

Water tank

Welding power

cable (ground

cable) on the

workpiece side

Gas supply

system

Cable

bundle

Welding

torch

Welding

tractor

Figure 1-4 System components

Chapter 1 Product Overview 3

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

1.5 External Dimensions and Gross Weight

Table 1-1 shows the external dimensions and gross weight of the welder with accessories.

Table 1-1 External dimensions and gross weight of the welder with accessories

Component

External Dimensions (L x W x H mm)

Gross Weight (kg)

Welder

620 x 300 x 480

55

Water tank

643 x 300 x 268

15

Manual wire feeder

630 x 250 x 400

14.5

Robotic wire feeder

300 x 170 x 200

6.5

1.6 Model Code Format

Figure 1-5 describes the welder model code format.

Artsen XX XXX (X)

PM:CO2/MAG/MIG

CM:CO2/MAG

350: nominal current

400: nominal current

500: nominal current

F: carbon steel

N: carbon steel/stainless steel

A: carbon steel/stainless

steel/aluminium alloy

T: customized

(X)

(X)

R: analog robot/digital robot

(X)

D: double-pulse and aluminium alloy

S: single-pulse and aluminium alloy

Welder series

Figure 1-5 Model code format

Note: The fields in parentheses indicate welder models and are optional.

Example 1:

Artsen PM500ADR indicates a C02/MAG/MIG Double-pulse and aluminum-alloy robotic welder in the

Artsen series whose nominal current is 500 A.

Example 2:

Artsen CM350 indicates a C02/MAG carbon-steel manual welder in the Artsen series whose nominal

current is 350 A.

4 Chapter 2 Installation and Cable Connection

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Chapter 2 Installation and Cable Connection

This chapter describes the welder installation requirements, installation procedure, and precautions.

2.1 Open-Package Inspection

1. Before opening the package, check whether the external package is intact.

2. After opening the package, check whether all the components of the welder are delivered and

whether their models are correct.

Upon detection of missing or incorrect components, contact the supplier in a timely manner.

2.2 Installation Requirements

Environment Requirements

Pay attention to the following when selecting the installation environment:

The installation site must have good ventilation and vibration must be less than 5.9 m/s2 (0.6g).

Do not install it in a site with lots of dust or metal dust.

Do not install it in a site with corrosive or explosive gas.

The ambient temperature must range from -10°C to +40°C . When the temperature exceeds 40°C , forcible

external cooling or temperature derating is required.

The humidity must be lower than 95% without condensation.

When necessary, use windbreak at the welding site to prevent wind from affecting the welding quality.

If you have special installation requirements, perform prior consultation and confirmation.

Installation Space Requirements

The welder must be at least 20 cm away from walls. If there are multiple welders, they must be at least 30

cm away from each other. You are recommended to reserve space for the welder as specified in Table 2-1.

Table 2-1 Space required for the welder

Front

Top

Left

Right

Back

Space required

≥20cm

≥10cm

≥20cm

≥20cm

≥20cm

2.3 Transportation Precautions

1. Before moving the welder, cut off the input power of the distribution box.

2. When moving the welder using a forklift truck, fix the wheels of the welder.

3. Mounting the welder off the ground is dangerous. Therefore, it is not recommended.

2.4 Welder Specifications

Table 2-2 describes the welder specifications of the Artsen PM/CM series.

Chapter 2 Installation and Cable Connection 5

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Table 2-2 Welder specifications

Item

Model Power

CM350

CM400/PM400

CM500/PM500

Rated power

Three phase 380 V AC

50Hz/60Hz

Three phase 380 V AC

0.50Hz/60Hz

Three phase 380 V AC

0.50Hz/60Hz

Power device capacity

Grid

30 kVA or greater

30 kVA or greater

30 kVA or greater

Generator

50 kVA or greater

50 kVA or greater

50 kVA or greater

Input protection device

(distribution box)

Air circuit breaker

Grade C and 63 A or

greater

Grade C and 63 A or

greater

Grade C and 63 A or

greater

Power cable

Input of the welder

10 mm2or greater

16 mm2or greater

16 mm2or greater

Output of the welder

35 mm2or greater

50 mm2or greater

50 mm2or greater

Housing grounding

cable

≥power supply cable

≥power supply cable

≥power supply cable

Note: The welder specifications of the robot welder series are the same as those in the preceding table.

Safety Warning

When the operating site is wet and the welder is used on an iron plate or frame, install a ground fault circuit

interrupter (GFCI).

2.5 Electric Connections

Safety Warning

1. Electric connections must be set up by certified professional electric device operators.

2. Electric connections can be set up only after the distribution box is switched off and necessary safety measures

are taken.

3. Use specified cables.

4. Do not touch electric connections with wet hands.

5. Do not place heavy objects on the power cables.

6. Running water pipes and reinforcing bars of houses may not be adequately grounded. Do not connect

grounding cables to them.

7. Connect this welder only to the matching or specified wire feeder, welding torch, gas meter, and water tank.

Otherwise, the welding performance and quality will be affected.

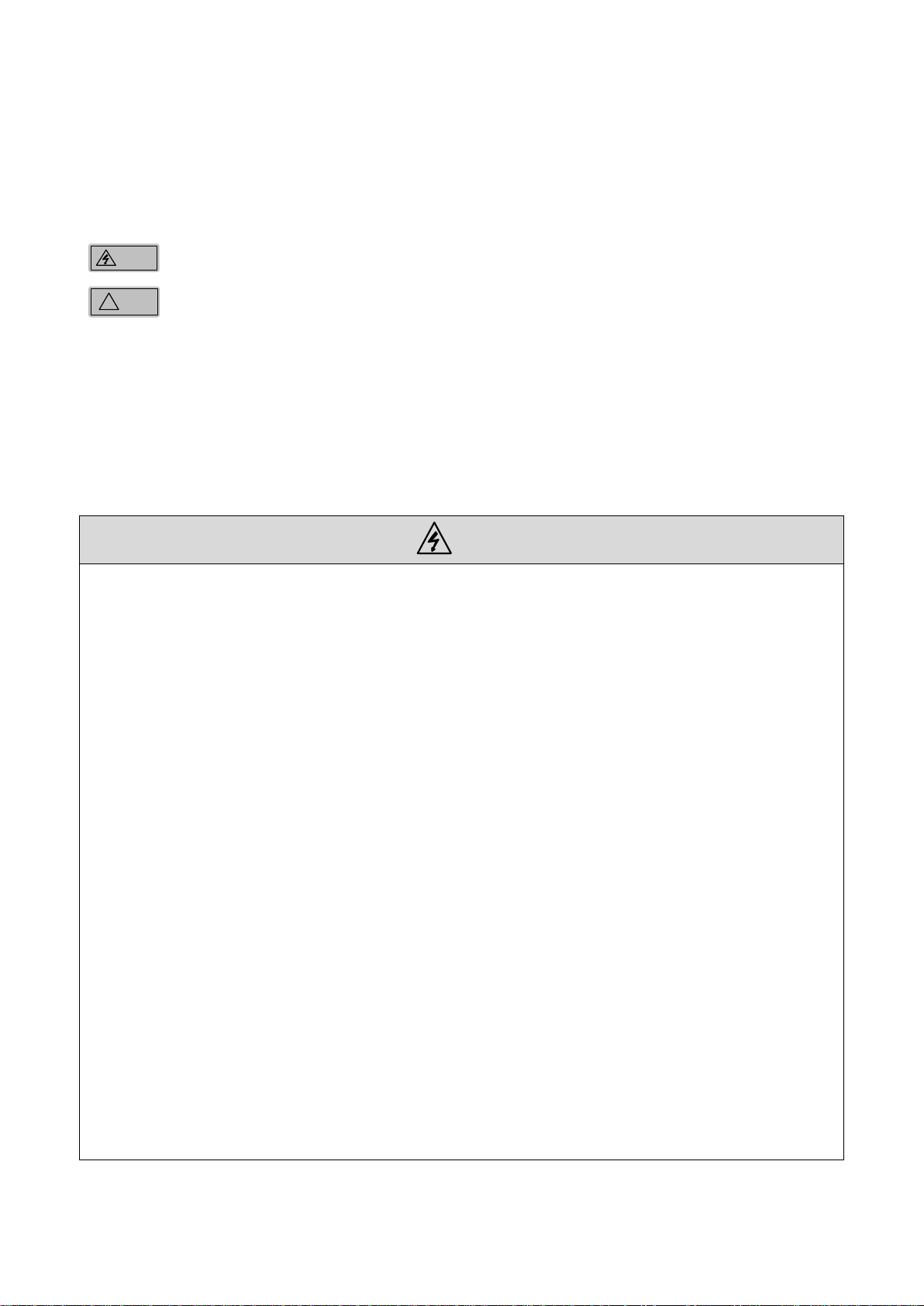

2.5.1 Connecting the Welder

Firmly connect the connector of the welding power cable to the positive pole of the welder. Firmly

connect the plug of the wire feeder control cable to the power jack of the welder. See Figure 2-1.

6 Chapter 2 Installation and Cable Connection

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Plug of the wire feeder

control cable

Connecter of the welding

power cable

Water inlet tube

Water outlet tube

Figure 2-1 Schematic diagram of connecting the welder

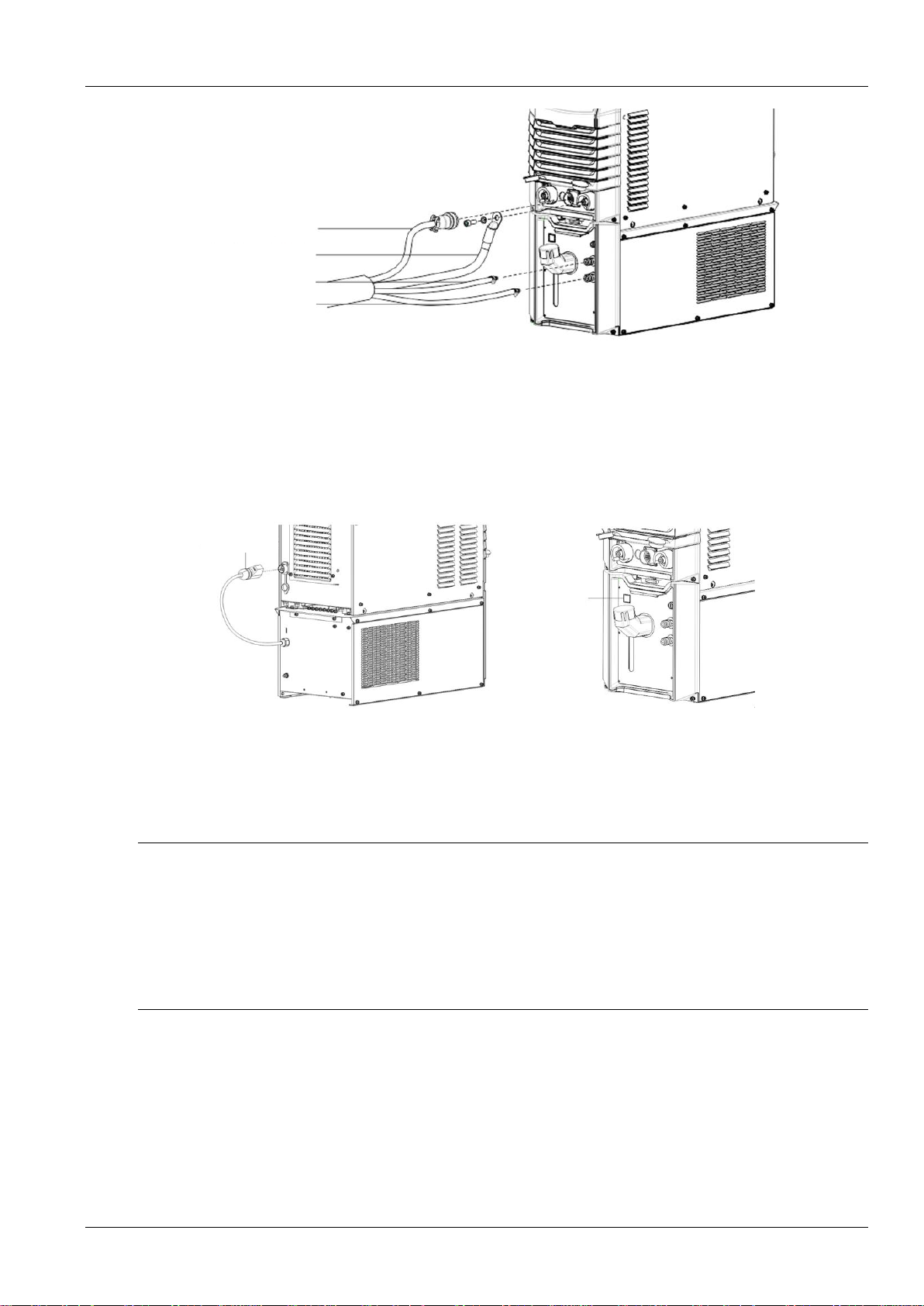

2.5.2 Connecting the Water Tank

Connecting the Water Tank Power Cable

Connect one end of the water tank power cable to the welder and the other end to the water tank power

jack. See Figure 2-2.

Water tank

power switch

Water tank

power plug

Figure 2-2 Schematic diagram of connecting the water tank power cable

Water Tube Connection

Connect the water inlet tube and water outlet tube in the cable bundle to the water inlet tube and water

outlet tube of the water tank respectively. See Figure 2-1.

Safety Warning

1. When using the water tank, turn on the power switch of the water tank and enable the

air-cooling/water-cooling function on the water tank panel. Otherwise, the welding torch may get burnt.

2. The water tank power supply has a high voltage, which is AC 380 V. Disconnect the power supply before

connecting cables; failing to do so may lead to electric shock.

3. When the ambient temperature is below 10°C, use antifreeze dedicated to the water tank to prevent water tank

damages.

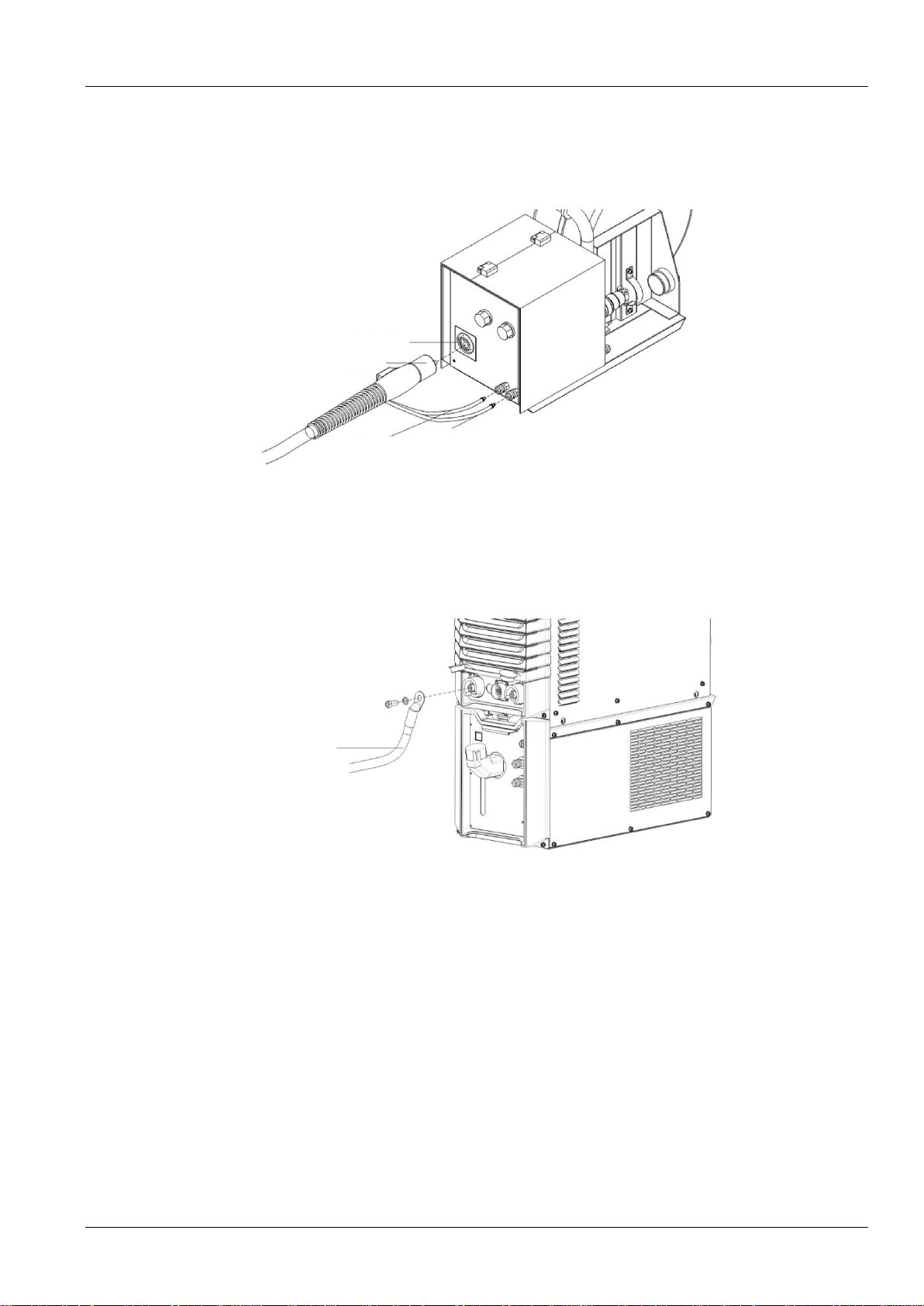

2.5.3 Connecting the Wire Feeder

1. Loose the fastener at the rear end of the wire feeder.

2. Use a but to firmly connect the welding power cable to the threaded rod on the wire feeder mother

board.

Chapter 2 Installation and Cable Connection 7

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

3. Rotate the plug of the wire feeder control cable to connect the cable firmly to its jack. See Figure

2-3.

Gas tube

Plug of the wire feeder control cable

Welding power cable

Water outlet tube

Water inlet tube

Fastener

Figure 2-3 Schematic diagram of connecting the wire feeder

2.5.4 Connecting the Gas Supply System

Note

1. If the protective atmosphere containing CO2is adopted, use a carbon dioxide heating regulator.

2. The gas tube must be connected firmly to the wire feeder and gas meter to prevent gas leakage.

Connect one end of the gas tube to the gas tube connector on the wire feeder and tighten the gas tube hose

clamp. Connect the other end to the gas tube connecter of the gas meter and tighten the hose clamp. See

Figure 2-4.

Gas tube connector of

the gas meter

Gas tube connector of

the wire feeder

Figure 2-4 Schematic diagram of connecting the gas tube

2.5.5 Connecting the Welding Torch

Note

When installing the welding torch, check whether the welding torch contains a wire inching hose and whether the

components are correct.

8 Chapter 2 Installation and Cable Connection

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Install the welding torch to the welding torch jack on the wire feeder. Connect the water outlet tube and

water inlet tube of the welding torch to the water outlet tube and water inlet tube of the wire feeder

respectively. See Figure 2-5.

Jack on the wire

feeder

Plug of the welding

torch

Water outlet

tube of the

welding torch

Water inlet tube

of the welding

torch

Figure 2-5 Schematic diagram of connecting the welding torch

2.5.6 Connecting the Welding Power Cable (Ground Cable) of the Workpiece

Firmly connect one end of the welding power cable (ground cable) of the workpiece side to the negative

pole output terminal and the other end to the workpiece. See Figure 2-6.

Welding power

cable of the

workpiece side

Figure 2-6 Schematic diagram of connecting the welding power cable (ground cable) of the workpiece

2.5.7 Connecting the Power Cable on the Power Input Side (AC 380 V)

1) Turn off the power switch of the distribution box (user equipment) and remove the input terminal

cover.

2) Firmly connect one end of the input power cable to the power input terminal using the power cable

clamp. Connect the ground cable to the M6 grounding threaded rod on the housing of the welder. See

Figure 2-7.

3) Install the input terminal cover.

4) Connect the other end of the input power cable to the output terminal of the power switch of the

distribution box.

Chapter 2 Installation and Cable Connection 9

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Input terminal cover

Power switch of

the distribution box

Input power cable

clamp

Input power cable

Ground cable

Figure 2-7 Schematic diagram of connecting the power cable on the power input side

Note

The welder has no special requirement for the phase sequence of the three phase power supply from the grid. The

cross-sectional area of the power cable for Artsen CM350 must be at least 10 mm2. The cross-sectional area of the

power cable for Artsen PM/CM400 and Artsen PM/CM500 must be at least 16 mm2.

10 Chapter 3 Function Description and Usage

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Chapter 3 Function Description and Usage

3.1 Welding Preparation

a) Verify that the welder cables are connected properly.

For details, see Section 2.5 "Electric Connections."

b) Install the welding wire.

See the User Manual for CO2/MAG/MIG Wire Feeder .

c) Turn on the power switches.

Turn on the power switches of the welder and water tank.

d) Verify that the parameters on the control panel are set correctly.

When using the water-cooled welding torch, enable the air-cooling/water-cooling function on the

control panel. For details, see Section 3.2.4 "Air-Cooling/Water-Cooling."

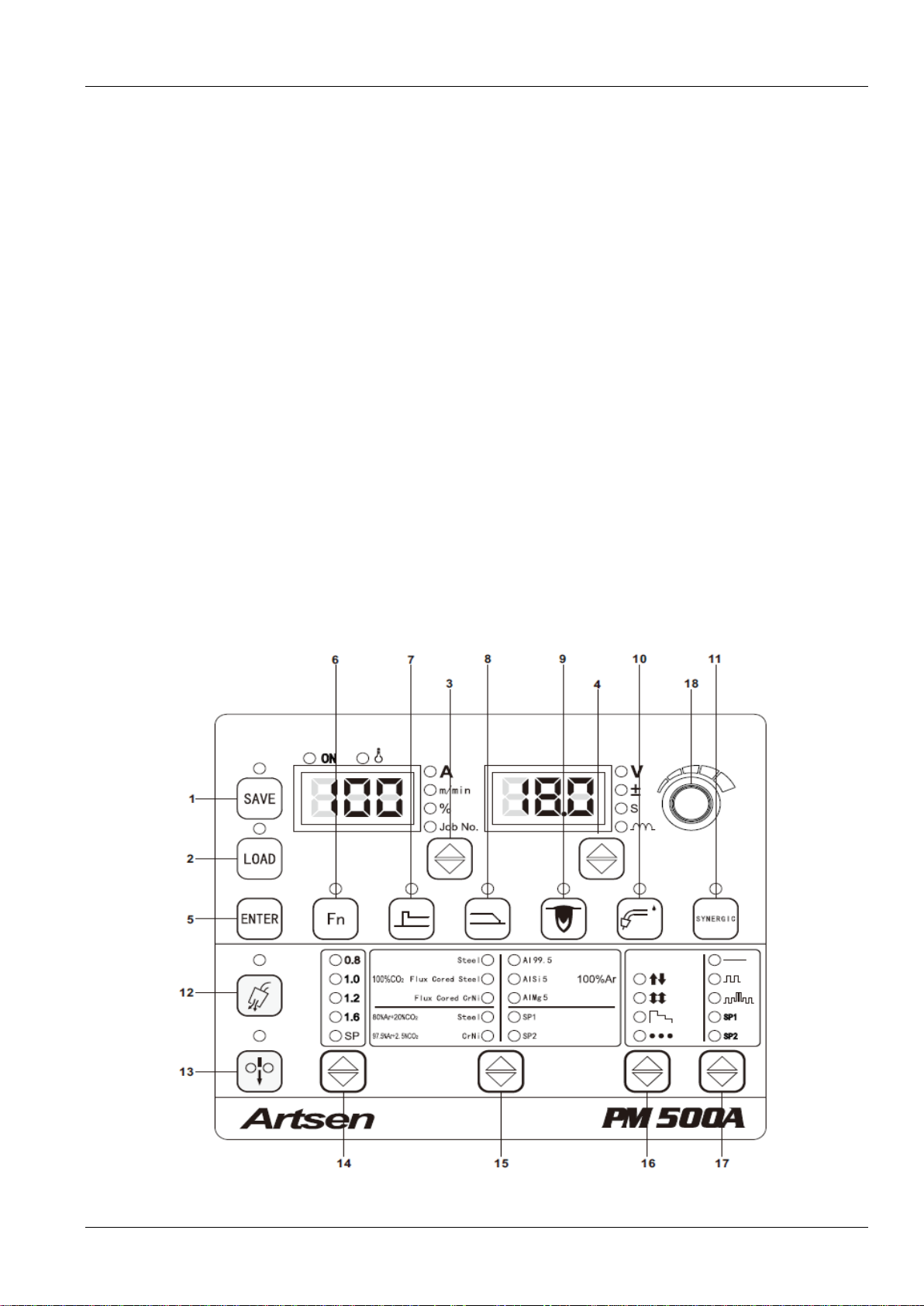

3.2 Function Description and Usage

Figure 3-1 shows the functions of the control panels of the welder and wire feeder.

The serial numbers on the control panel of the welder correspond individually to a button serial number in

error codes.

Chapter 3 Function Description and Usage 11

Full Digital IGBT CO2/MAG/MIG Multifunctional Inverter Welder User Manual

Current

adjusting knob

Voltage

adjusting knob

Welding

torch jack

Water outlet

Water inlet

Detect gas

Inch wire

Current Voltage

Figure 3-1 Description of functions of the control panes of the welder and wire feeder

Table 3-1 Function description

SN

Button

Function

1

SAVE

Saves selected welding parameters.

2

LOAD

Loads saved welding parameters.

3

Switch among the options

of the left LED

Changes the current, wire inching speed, percentage, and channel number.

4

Switch among the options

of the right LED

Changes the voltage, corrected voltage value, time parameter, and electric arc dynamic.

5

ENTER

Confirms and locks parameters.

6

Fn

Sets internal menu parameters.

7

Starting arc parameters

Views starting arc parameters, including the current, wire inching speed, and voltage for

starting arc, adjustable percentage of starting arc, corrected voltage for starting arc,

starting arc generation time, and arc dynamic.

8

Ending arc parameters

Views ending arc parameters, including the current, wire inching speed, and voltage for

ending arc, adjustable percentage of ending arc, corrected voltage for ending arc, ending

arc generation time, and arc dynamic.

9

Fusion depth control

Ensures consistent fusion depth when wire stick-out is changed.

10

Air-cooling/Water-cooling

Switches between the air-cooling and water-cooling functions.

11

SYNERGIC

In synergic setup mode, the system sets the voltage according to the current.

In the manual setup mode, the current and voltage are set independently.

This manual suits for next models

9

Table of contents

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric IDEALARC IM402-B Operator's manual

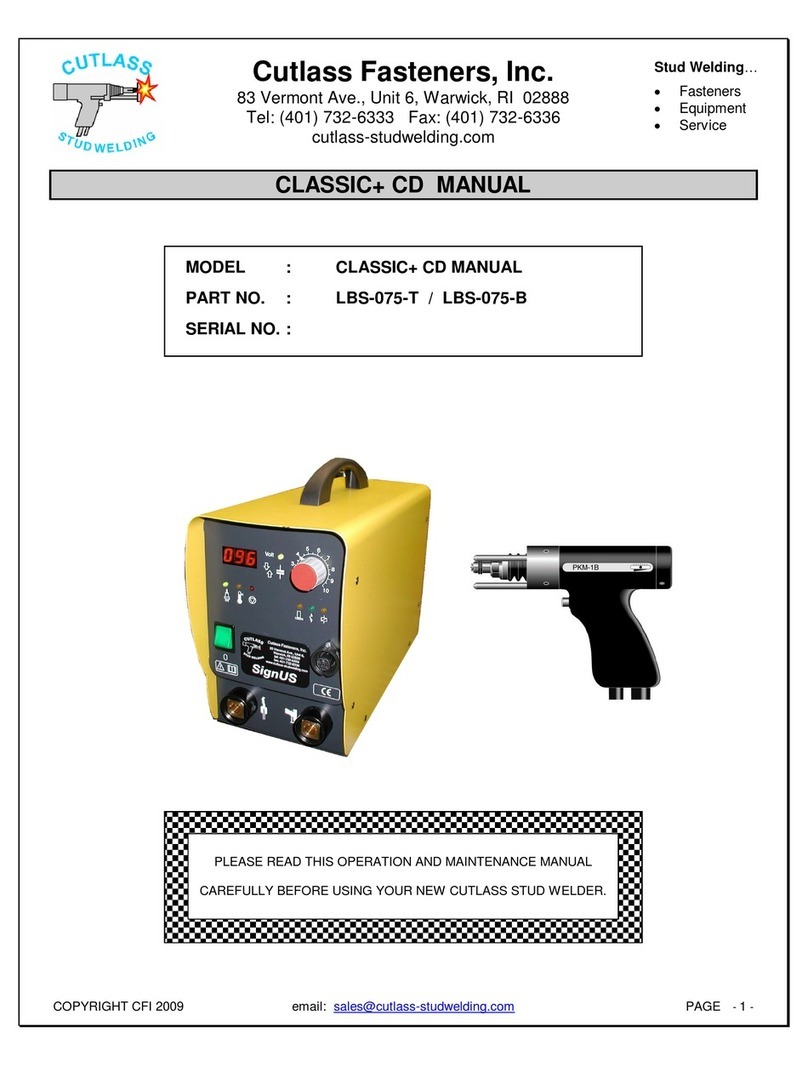

Cutlass Fasteners

Cutlass Fasteners CLASSIC+CD manual

Northern Industrial

Northern Industrial Flux Core 125 Quick setup guide

Lincoln Electric

Lincoln Electric OUTBACK 145 Operator's manual

Chicago Electric

Chicago Electric 6271 Assembly and operating instructions

Stahlwerk

Stahlwerk AC/DC WIG241P user manual