iROB®501 PRO

EN - 3

7.6.3 Example of parameters for MAG short arc welding........................................ EN-50

7.6.4 Example of parameters for MAG pulse welding...............................................EN-51

7.6.5 Example of parameters for MIG pulse aluminum welding.............................. EN-55

7.6.6 Example of parameters for MIG aluminum short arc welding........................ EN-55

7.7 Additional functions........................................................................................................... EN-56

7.7.1 Setting the arc characteristic .............................................................................. EN-56

7.7.2 Adjusting the penetration control....................................................................... EN-56

7.7.3 Adjusting the move frequency............................................................................ EN-56

7.7.4 Setting kinetic move............................................................................................. EN-56

7.8 Setting internal functions................................................................................................... EN-57

7.8.1 Making settings.................................................................................................... EN-57

7.8.2 Description of the internal functions................................................................... EN-58

7.9 Managing the job memory .............................................................................................. EN-73

7.9.1 Saving jobs .......................................................................................................... EN-73

7.9.2 Changing the job................................................................................................. EN-73

7.9.3 Recalling a saved job ..........................................................................................EN-74

7.9.4 Deleting a job.......................................................................................................EN-74

7.10 Carrying out the welding process.....................................................................................EN-75

7.10.1 Starting the welding process...............................................................................EN-75

7.10.2 Adjusting parameters during the welding process............................................EN-75

7.11 Restoring factory settings...................................................................................................EN-76

7.12 Creating a data backup ....................................................................................................EN-76

7.12.1 Welding parameter/internal function settings .................................................. EN-77

7.12.2 Simplified data log function................................................................................ EN-79

7.12.3 Fault log function ................................................................................................. EN-79

7.12.4 Backup operations .............................................................................................. EN-80

7.12.5 Importing backup data ........................................................................................EN-81

7.13 Checking the software version......................................................................................... EN-82

8 Decommissioning..................................................................................................................... EN-83

9 Maintenance and cleaning .................................................................................................. EN-83

9.1 Maintenance and cleaning intervals............................................................................... EN-84

9.2 Cleaning the device.......................................................................................................... EN-85

9.3 Maintenance work on the wire feed control unit ........................................................... EN-86

9.3.1 Switching off the main switch............................................................................. EN-86

9.4 Maintenance work on the Push Feeder KINETIC........................................................... EN-86

9.4.1 Replacing the conveyor roller ............................................................................ EN-86

9.5 Maintenance work on the Pull Feeder KINETIC .............................................................EN-87

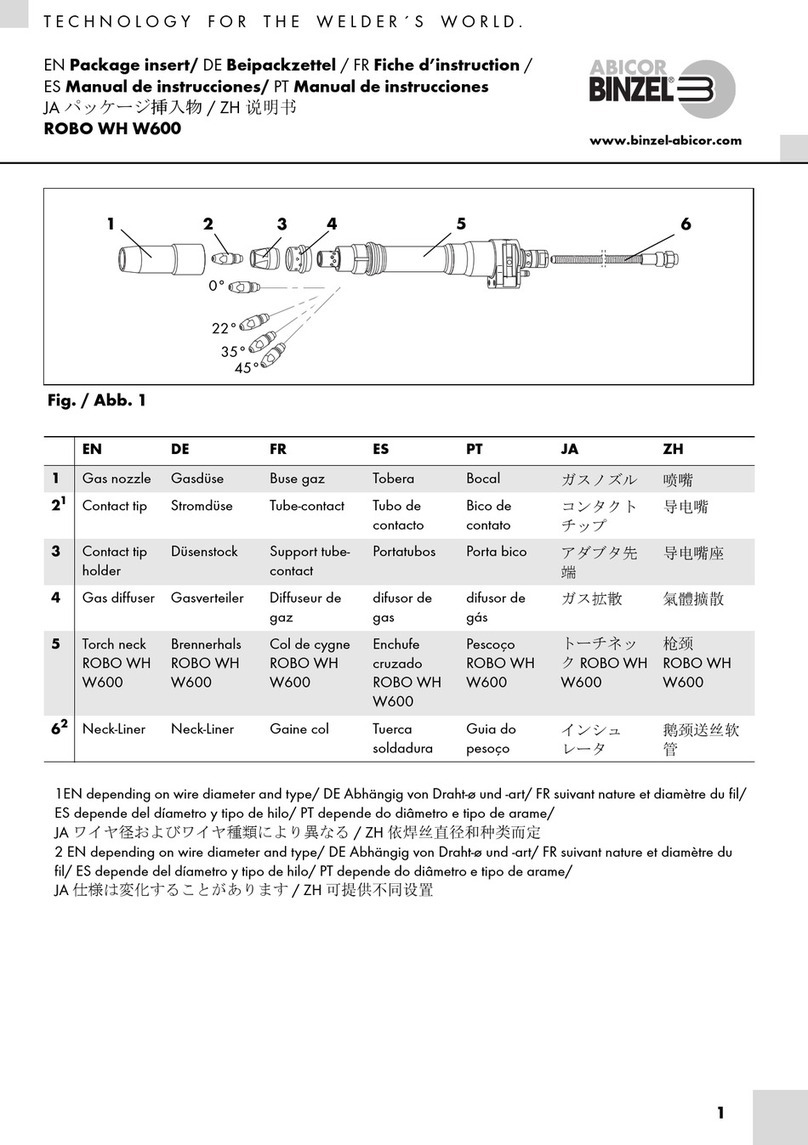

9.5.1 Replacing the neckliner........................................................................................EN-87

9.5.2 Replacing the conveyor roller ............................................................................ EN-88

9.5.3 Replacing the wire guide nozzle ....................................................................... EN-89

9.5.4 Replacing the pressure roll ................................................................................. EN-90

9.6 Maintenance work on the Wire Buffer KINETIC.............................................................EN-91

9.6.1 Replacing the wire guide.....................................................................................EN-91

9.6.2 Replacing the wire guide and guide rollers in the Wire Buffer KINETIC........EN-91

10 Faults and troubleshooting ................................................................................................. EN-93

10.1 General faults .................................................................................................................... EN-93

10.2 Faults on the control panel ................................................................................................EN-94

10.3 Fault with Wire Buffer KINETIC‘s automatic position adjustment ..................................EN-97

10.4 Faults on the wire feed control unit.................................................................................. EN-98

10.4.1 Read out assistance code................................................................................... EN-98

11 Disassembly............................................................................................................................. EN-106

12 Disposal ..................................................................................................................................... EN-106

12.1 Disposal of materials.......................................................................................................EN-106

12.2 Disposal of consumables................................................................................................ EN-106

12.3 Packaging ........................................................................................................................ EN-106

13 IFR-800 fieldbus connection tool ..................................................................................... EN-107

13.1 Configuration................................................................................................................... EN-107

13.2 Specification .................................................................................................................... EN-107

13.3 Processing time for communication data........................................................................EN-110

13.4 Application specifications................................................................................................EN-111

13.4.1 List of I/O data ................................................................................................... EN-111

13.4.2 Simplified table for output data ........................................................................EN-113