meibes LogoFresh Compact Manual

E]aZ]kKqkl]e%L][`fac

Jaf_kljY¿])0%<%(,0*/?]ja[`k`Yaf%L]d&#,1 (!+,*1*/)+%(%>Yp/)+%-(

ooo&e]aZ]k&\]%]%eYad2af^g8e]aZ]k&\]

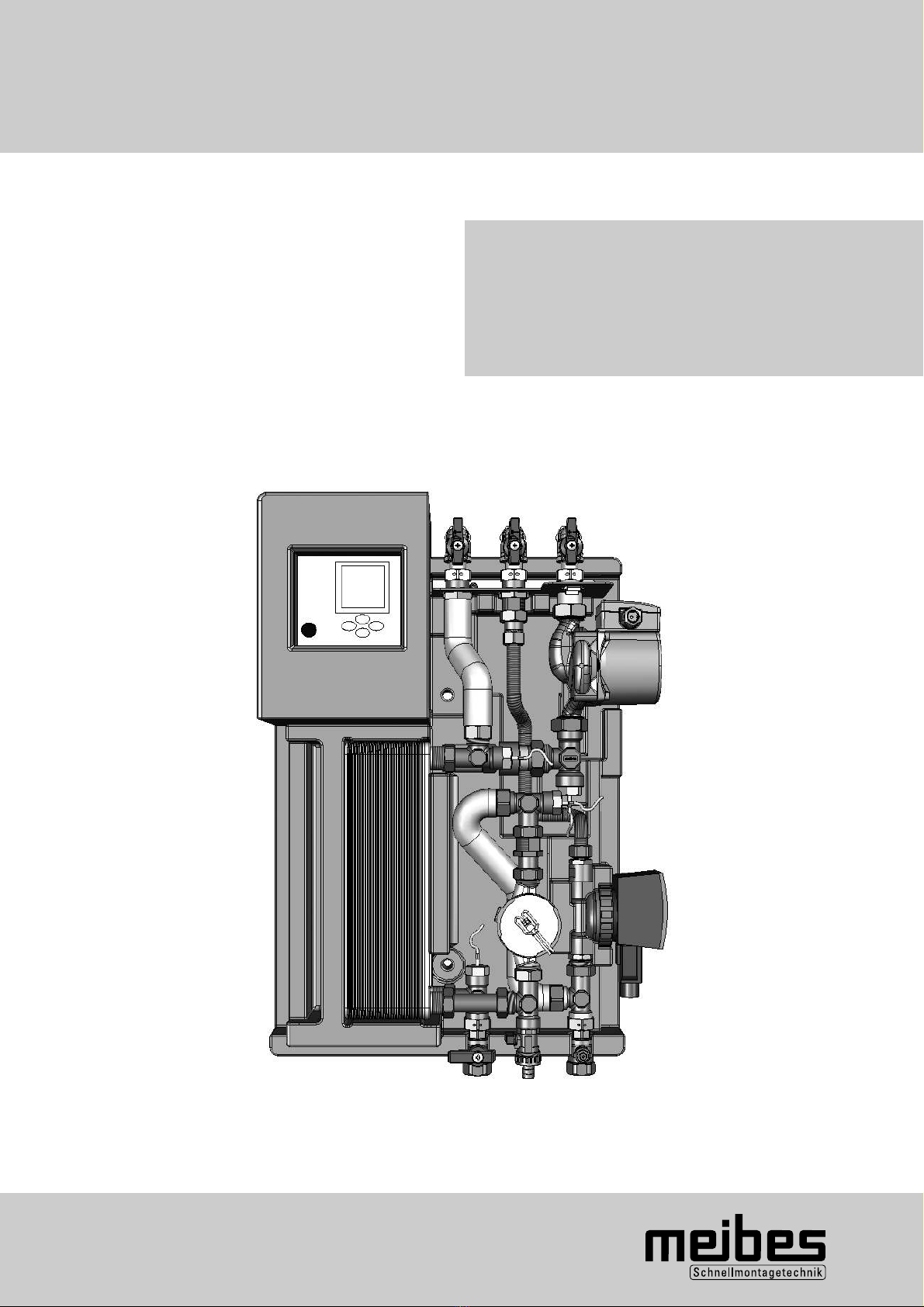

Technical information for installation and operation

Freshwater Station

LogoFresh Compact

electronically controlled

PR 24002.123 31-03-2011 Subject to technical modifications

1

Contents

Chapter Title Page

1. Safety instructions 2

2. Technical specifications 2

2.1 Performance characteristics 3

3. Equipment and functional description 4

4. Installation 5

4.1 Hydraulic connections 5

4.2 Electrical connections 5

5. Control system 6

5.1 Display description 6

5.2 Operating keys – description 6

5.3 Control menu structure 7

5.3.1 Explanation of menu items 8

5.3.2 Information menu 8

5.3.3 Programming menu 8

5.3.4 Manual operation menu 9

5.3.5 Basic setting menu 9

6. Initial operation and system calibration 11

6.1 Flushing and filling the system 11

6.2 Controller calibration 11

6.3 Calibration procedure 11

6.3.1 Selecting pump capacity 11

6.3.2 Characteristic curve calibration 11

6.3.3 Circulation adjustment 12

6.3.4 Detailed description of characteristic curve calibration 13

7. System examples of controller settings 14

7.1 Freshwater station with circulation in a time slot and 14

with tapping detection

7.2 Freshwater station with circulation only via 14

tapping detection

7.3 Freshwater station without circulation 14

7.4 Freshwater station with reheating and/or activation 15

7.5 Increasing the domestic hot water set temperature 15

7.6 Freshwater stations as cascade connection 16

7.6.1 Initial operation and system calibration of freshwater 16

cascade

7.7 Disinfecting the hot water and circulation pipes 17

8. Releasing operating level for specialist tradesmen 17

9. Trouble-shooting 18

10. Factory setting and personal setting 19

11. Diagrams 20

2

1. Safety instructions

QThe installation and initial operation of the freshwater

station is only to be carried out by a specialist

tradesman.

QThe necessary DIN and VDE provisions are to be

observed (e.g. DIN 4751, DIN 4753, DIN 1988

and VDE 0100)

QThe provisions of local energy supply companies are

to be observed

QImproper installation as well as misuse of the

freshwater station will exclude any liability as regards

guarantee claims

Please note:

QBefore operating on the control system and the

circulating pump, they are to be switched at zero

potential as prescribed

QIn the event of a power supply interruption, the

preset values are retained

QIn the event of a power failure, the system clock

settings in the control system are retained for

approx. 24 hours

QA menu for basic settings is available which may only

be modified by a specialist tradesman. This ensures

the technical functioning and security of the system!

QAll the relevant old as well as recently enforced

provisions and norms as well as provisions and

norms not mentioned, but relevant for application in

a particular case, are to be followed

QThe legal provisions relating to the prevention of

accidents are to be followed

2.Technical specifications

Heating connections 3/4“ female 3/4“ IG

Plumbing connections 3/4” female 3/4” IG

Heating operating pressure 3 bar

Plumbing operating pressure 6 bar

Maximum allowed temperature 110°C

Controller protection class IP 54

Supply voltage 230VAC / 50Hz

Dimensions (height/length/breadth) in mm 660 x 455 x 215

3

* at a sufficient domestic water system pressure

Please note: For larger drawing amounts, several freshwater stations can be constructed as a cascade. (page 16)

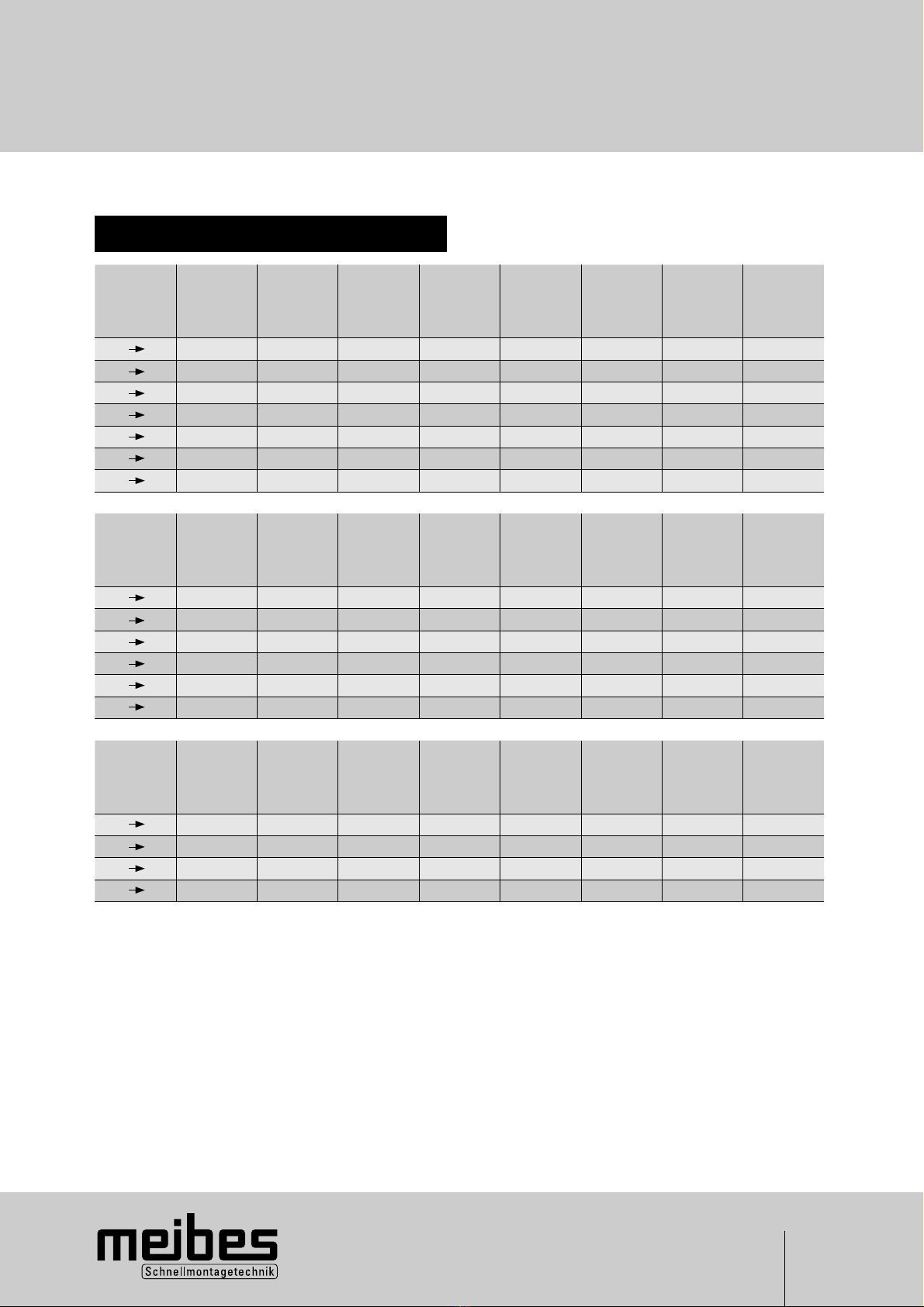

2.1 Performance characteristics

2.Technical specifications

Heating

cold water

K

Flow

temperature

primary

°C

Return

temperature

primary

°C

Domestic hot

water drawn

amount*

l/min

Domestc

hot water

capacity

kW

Volumetric

flow

primary

l/h

Pressure loss

primary

bar

Remaining

discharge

head

primary

bar

Pressure loss

secundary

bar

40 (10 50°C) 55 33 12 33 1350 0,24 0,15 0,14

40 (10 50°C) 60 31 17 46 1350 0,24 0,15 0,28

40 (10 50°C) 65 29 20 57 1350 0,24 0,15 0,38

40 (10 50°C) 70 27 24 66 1350 0,24 0,15 0,55

40 (10 50°C) 75 26 27 76 1350 0,24 0,15 0,69

40 (10 50°C) 80 25 30 84 1350 0,24 0,15 0,86

Heating

cold water

K

Flow

temperature

primary

°C

Return

temperature

primary

°C

Domestic hot

water drawn

amount*

l/min

Domestc

hot water

capacity

kW

Volumetric

flow

primary

l/h

Pressure loss

primary

bar

Remaining

discharge

head

primary

bar

Pressure loss

secundary

bar

50 (10 60°C) 65 40 11 39 1350 0,24 0,15 0,12

50 (10 60°C) 70 36 15 53 1350 0,24 0,15 0,22

50 (10 60°C) 75 33 19 64 1350 0,24 0,15 0,34

50 (10 60°C) 80 32 22 75 1350 0,24 0,15 0,46

Heating

cold water

K

Flow

temperature

primary

°C

Return

temperature

primary

°C

Domestic hot

water drawn

amount*

l/min

Domestc

hot water

capacity

kW

Volumetric

flow

primary

l/h

Pressure loss

primary

bar

Remaining

discharge

head

primary

bar

Pressure loss

secundary

bar

35 (10 45°C) 50 31 11 30 1350 0,24 0,15 0,12

35 (10 45°C) 55 28 17 42 1350 0,24 0,15 0,28

35 (10 45°C) 60 26 22 53 1350 0,24 0,15 0,46

35 (10 45°C) 65 25 26 62 1350 0,24 0,15 0,64

35 (10 45°C) 70 24 29 71 1350 0,24 0,15 0,80

35 (10 45°C) 75 23 33 80 1350 0,24 0,15 0,04

35 (10 45°C) 80 22 36 88 1350 0,24 0,15 1,25

4

QThe freshwater station allows for a hygienic and

energy-saving preparation of warm water via a

stainless steel plate heat exchanger. It provides fresh

hot water for one to two apartment units. The source

of supply is a storage tank with a variable tempera-

ture of 60 to 95°C. At very high storage tempera-

tures (up to 95°C) a temperature reduction of the

heat transfer media is recommended by admixture.

The primary pump P1 is controlled via block

modulation in such a way that the desired hot water

temperature is kept constant as much as possible.

For the control system to calculate the necessary

pump capacity, it uses the heat transfer media

temperature on the primary side, the inlet tempera-

ture of the cold water and the circulation on the

secondary side as well as the current flow.

QIn addition to the preparation of freshwater, the

circulation can also be activated. In the “basic

setting” menu the circulation is switched ON or

OFF.

QFor circulation, up to 3 time slots can be specified in

the “programming” menu.

QFor the stainless steel plate heat exchanger there

are three modes of operation besides the drawing of

hot water:

water temperature-cold, water temperature -hot

and water temperature-timed heating

(See 5.3.3).

3. Equipment and functional description

QAfter-run

Should water temperature-cold be selected, it is

possible to set the circulation pump at an after-run,

to allow the stainless steel plate heat exchanger

to cool down and to prevent calcification.

The after-run function is however, only possible and

meaningful outside the circulation time!

QActivating the hot water controller and reheating

With the additional T5 sensor (not included in

delivery), it is possible to put the control system in

operation only after a specified buffer temperature

has been attained. With the T5 sensor it is further-

more possible to activate a boiler for reheating via a

potential-free contact. Both functions are deactiva-

ted in the factory setting.

QDisinfection

With this function it is possible to disinfect the

circulation pipes against the danger of legionella.

This function is only activated when a circulation

pipe is available and the circulation has been

switched on.

QData logging

With a „data stick” all measured values and the

status of pump outputs can be recorded for a

specific time period. A special computer programme

is used to analyse the measured values at the

freshwater station manufacturer.

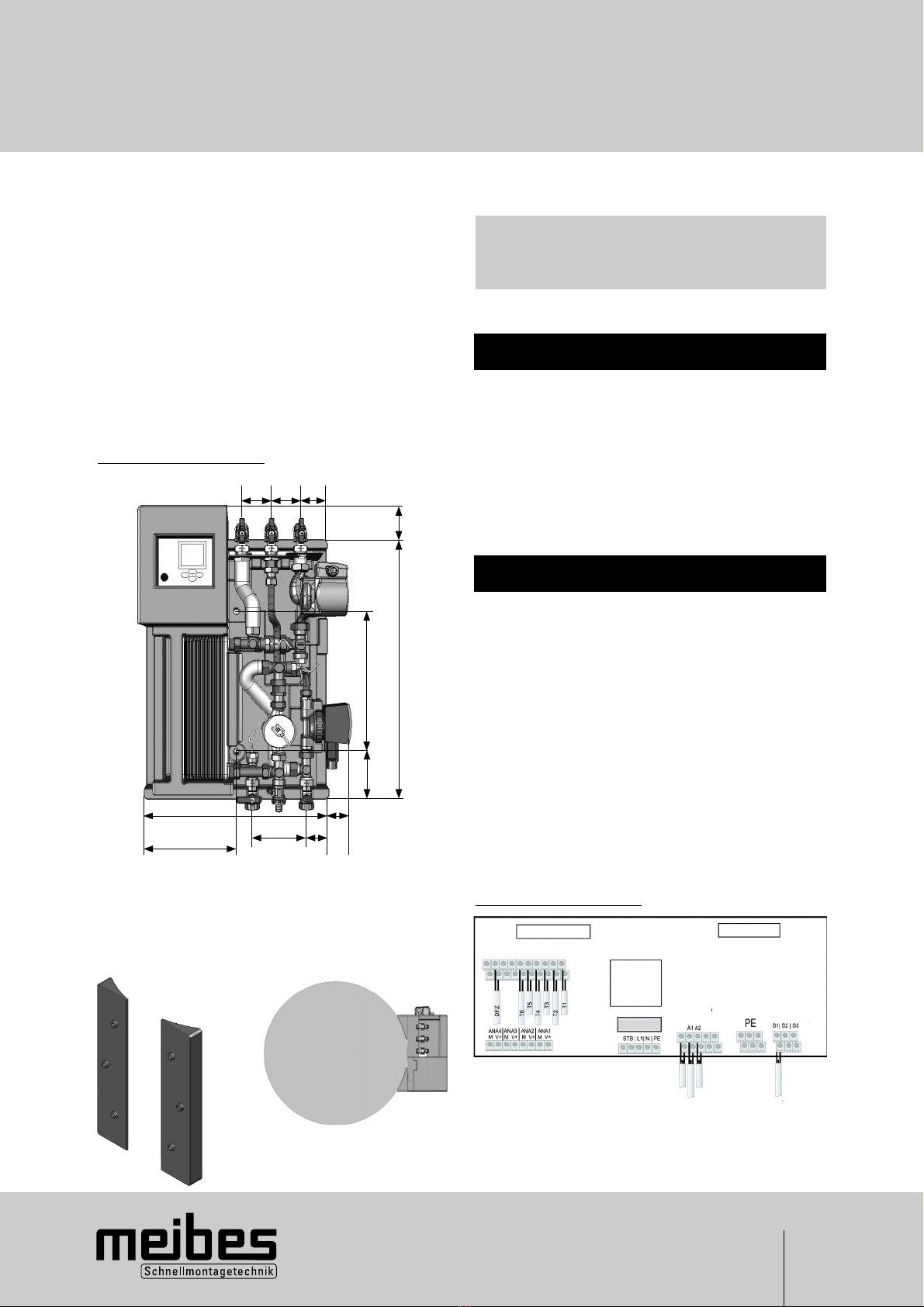

T1 = Domestic hot water

T2 = Heat transfer media flow

T3 = Cold water and

circulation temperature

T4 = Heat transfer media return

T5 = Storage tank sensor for

„reheating“ and release of the

hot water controller and

circulation

P1 = Primary heat transfer pump

P2 = Circulation pump

DFZ = Flow rate metre

1 = Heat transfer unit

2 = Return flow preventer

3 = Control

4 = Shut-off valve

5 = Flow rate restrictor 3l

6 = Filling and draining tap

A = Flow heating

B = Return heating

C = Domestic hot water outlet

D = Hot water circulation

E = Cold water (domestic water)

5

4. Installation

Heat transfer media side

Connection A: Flow heating 3/4“ female

Connection B: Return heating 3/4“ female

Plumbing

Connection C: Domestic hot water outlet 3/4“ female

Connection D: Hot water circulation 3/4“ female

Connection E: Cold water (domestic water) 3/4“

female

4.1 Hydraulic connections

Kindly observe the EVU (energy supply companies)

provisions! To prevent the dry running of pumps, the

freshwater station may only be switched on once

the system has been filled and vented.

The freshwater station is cabled in working order

when delivered. The connection at the electrical supply

network 230 V/ 50 Hz AC takes place via the installed

power supply cable. This circuit is to be secured with a

10 A line protector switch.

Loading capacity of the control outputs:

Triac outputs A1 and A2 for the pumps max. 1A 230 V

AC Potential-free contact S1 (changeover contact) max.

4A 230 V AC1

4.2 Electrical connections

Wiring diagram

Assembly drawing

Please note:

QSafeguarding the cold water should be done

according to DIN 1988, i.e. with a safety group

and if necessary, an expansion tank.

Wall distance to the centre lines of the connections:

82mm

ADC

E

B

65 65 63

50

320

580

100

205

410

120 50

45

QThe freshwater station has been pre-assembled and

pre-wired.

QInstallation should take place on a load-bearing dry

wall.

QWith a pre-formed insulating wall it is possible to

mount the freshwater station directly onto a storage

tank (Ø 600mm) using connectable insulation

wedges (not included in delivery)

QThe freshwater station should preferably be moun-

ted low so as to be at the same height as the cold

area of the stratified storage tank!

QThe piping should be connected according to their

relevant function (see drawing).

Connectable insulation wedges

for mounting the storage tank

Example storage tank mounting

Temperature sensor

Fuse

Outputs

230V/AC

Potential-free

switch outputs

Power supply

Pump 1

Pump 2

Boiler standards

6

5. Control system

5.1 Display description

5.2 Operating keys - description

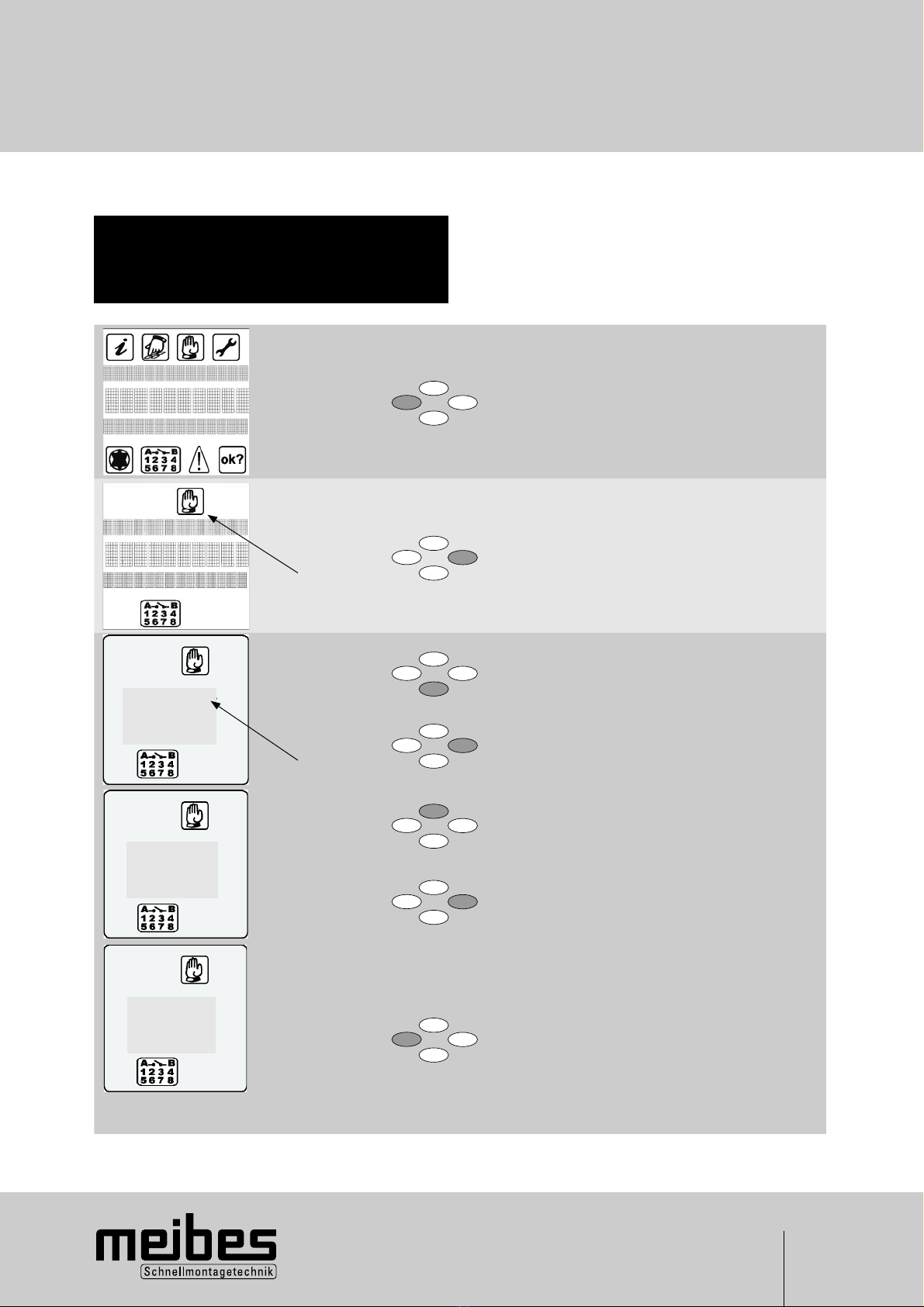

1 2 3 4

13 12 11 10

5

6

7

8

9

1 ,,Info” menu Display of all measured

values and system states

2 ,,Programming” menu Contains programming

values which can be ad-

justed by the end customer.

3 „Manual Mode“ menu Set/ reset the outputs,

determination of the

operating points

4 „Basic Setting“ menu Contains all set values,which

can only be adjusted after

„Release“.

5 Main menus

6 Measuring point assignment

7 Value/ units

8 Additional information, e.g. temperature sensor

9 Status indicator

10 „OK“ symbol Confirmation of inputs/ value

change/ value reset

11 „Important“ symbol Group error message for all

faults

12 „Outputs“ symbol Indicates which switching

outputs are active.

13 „Pump“ symbol Indicates that the controller

is active.

key Function Description

„up“

„UP“

„+“

QPage to the next menu

QValue change: incremental increase in the displayed

value, if pressed continuously the values increase continuously

„down“

„Open“

„Down“

„-“

QIn the basic menu: Open a main menu

QPage to the next menu

QValue change: incremental reduction in the displayed value,

if pressed continuously the values decrease continuously

„Page left“

„Quit“

„Cancel“

„ESC“

QPage to the left in the main menu

QQuit a menu

„Page right“

„Select“

„Confirm“

„Enter“

QQuit a menu item

QCancel a value change without saving

QPage to the right in the main menu

QSelect a menu item

QConfirm a value change with save

7

5. Control system

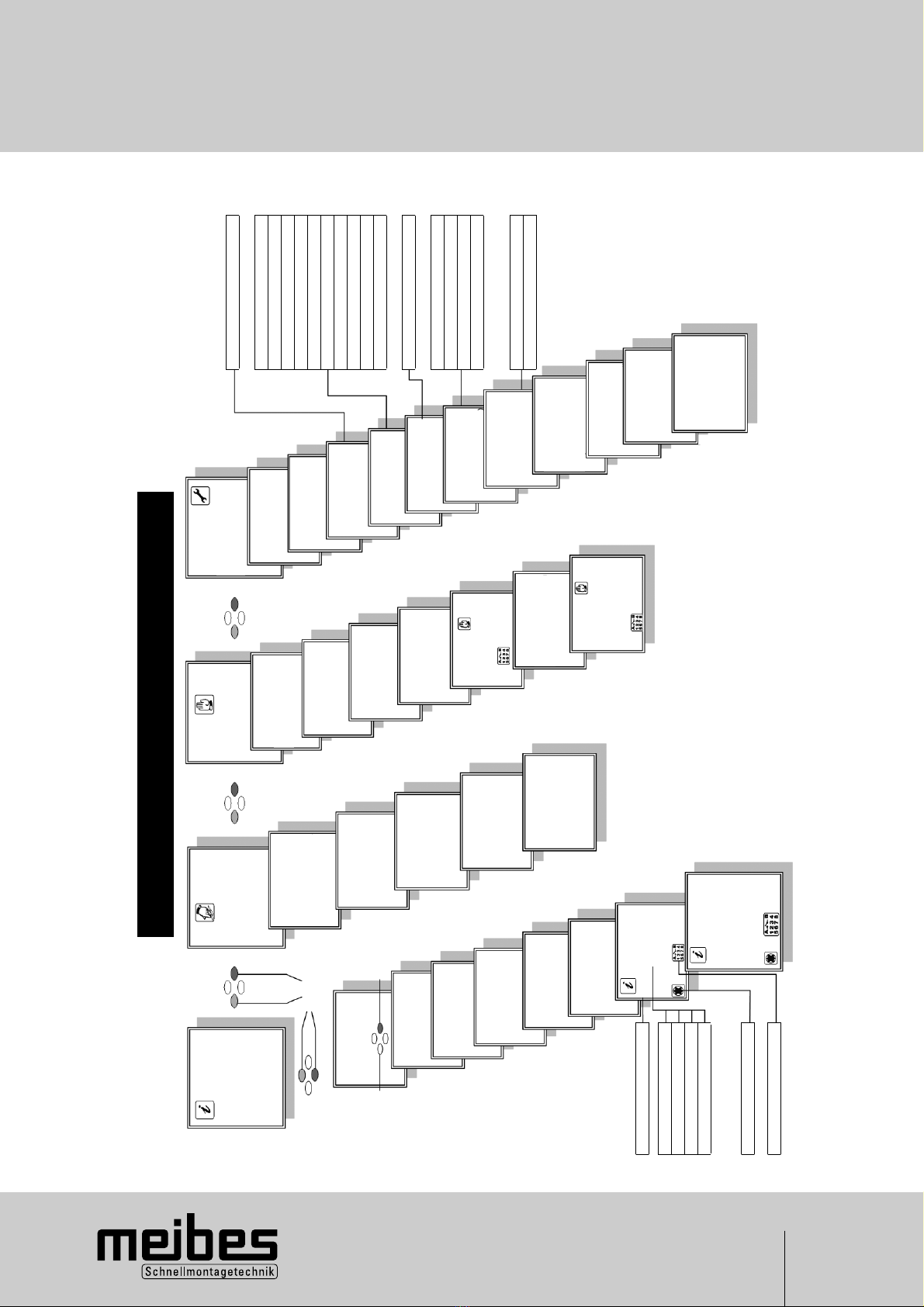

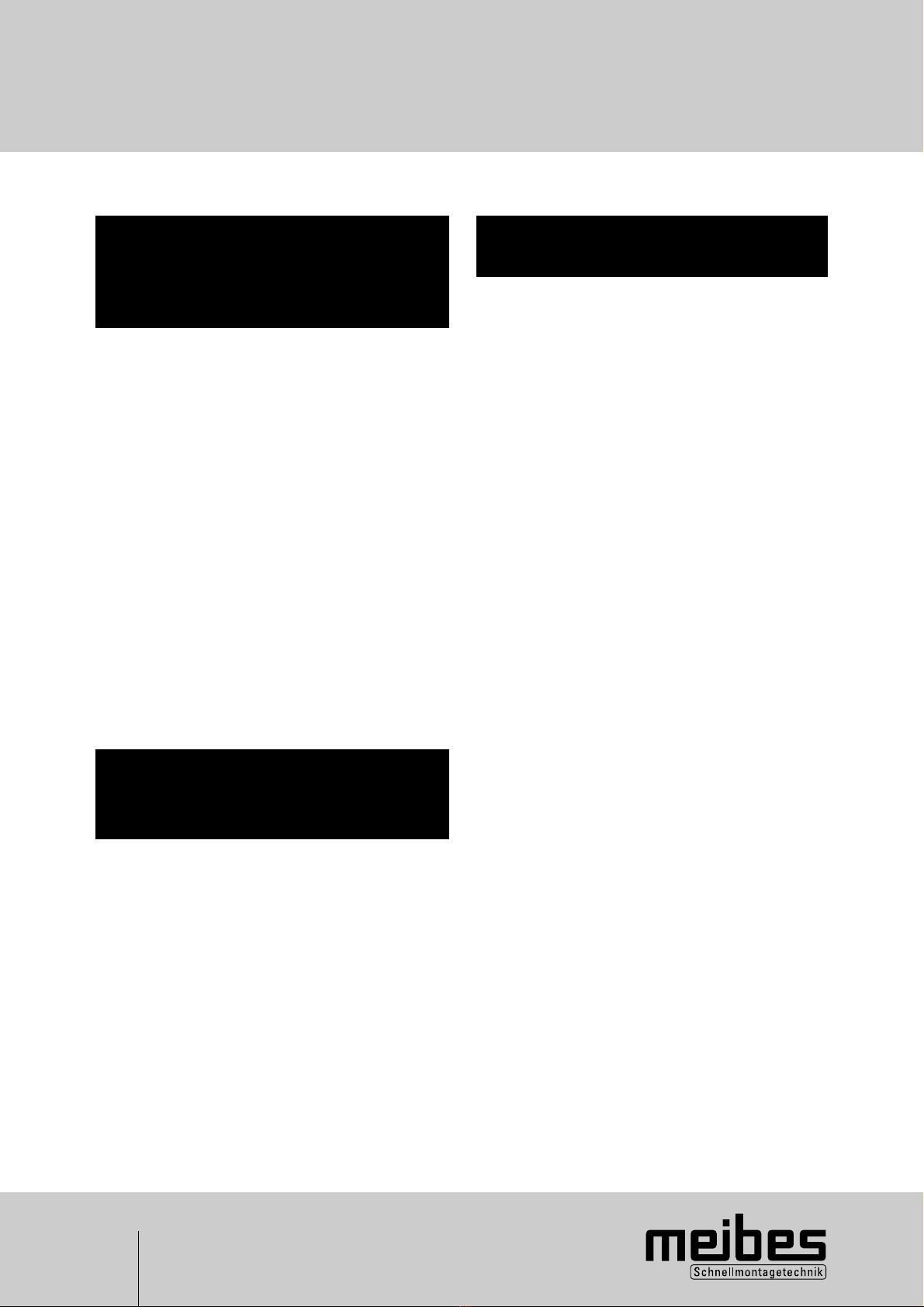

Information menu

Scrolling

Quit

Select

Confirm

Drinking water T1

Hot water VL T2

Cold water T3

Hot water RLT4

Accumulator T5

Flow l/min

6,0 l/min kW WW

P1: P2:

Status

Controlled variables

P1 % WW

Flow status VL

Tapped quantity

Off

Active 50= hot water control

Z – active = circulation

After run

Controller active

Active outputs

Programming

the menu

Heat exchanger

Hot water setpoint 50°C

WT operating mode

Cold, hot or timed

heating

WT setpoint 40°C

WT hysteresis 3K

Circulation

Time slot 1

Time slot 2

Time slot 3

Reheat 3)

65°C SP setpoint

or

15 K spread

Data logging 6)

1s to 30s

Single or cyclical

recording Control

Reset

Time

Time

Date

Manual Mode

menu

Output 1

Output 2

Output 3

Outputs

Whole test

Characteristic curve

calibration

Circulation

calibration

C: 14.0 H: 40.5

P: %

D: 5.0 T: 75.0

Basic Setting

menu

Information

Softw. version

1.XX

Pulse generator

Controller On/Off 2)

Control parameters

Characteristic

curve 1)

Heat exchanger

Circulation 1)

On/Off

Activation T5

Off/On

Reheating 1)

On/Off

Absolute or relative

Accumulator setpoint

Premixer 1)

On/Off

Factory 1)

configuration

Off/On

Release 1)

For maintenance

and settings

6)

4)

7)

7)

1) Within one minute after mains connection or executable using key combination. Access

is automatically blocked after 60 minutes!

2) Can be run with button combination: Basic Setting menu -> Release -> Select with right

click 2x -> Up, Down and Right button - press simultaneously > 2 s -> „Release On“

appears -> quit with left click.

3) Only visible if Reheat is active.

4) On visible if T5 activation in operation.

5) Only visible if a data stick is plugged in.

6) Only visible through button combination: Characteristic curve adjustment alternatively

by hand

7) Only visible through button combination

5.3 Menu structure of the V1.54 controller

Shutdown 60°C

Flow min 4 l/min

Output min 7 %

Flow middle 8 l/min

Output middle 20 %

Flow max 25 l/min

Output max 76 %

Correction per 5K 10 %

Calibration Heating medium 75°C

Calibration T cold water 15°C

Calibration Setpoint 50°C

After run 0-300 s 60s

Circ. Run time 0-600 90s

Circ. Rest time 1-120 min 0 min

Circulation setpoint 10-50°C 40°C

Sensor T3 or T6

Activation temp 35-55°C 35°C

Activation hysteresis 3-10K 3K

8

5. Control system

5.3.1 Explanation of menu items

5.3.2 Information menu

In this menu all the measured values of the temperature

sensor, volumetric flow metre as well as the control

system (system conditions) are displayed.

Status display:

Active 50 = Control system on domestic hot water

set temperature value of 50°C

Z - active 4 = Control system on circulation set

temperature value of 40°C

After-run = After-run of the circulation pump for

cooling down the stainless steel plate

heat exchanger (See 5.3.5)

Disinfection = Control system on disinfection

temperature

Off = No control system function active

5.3.3 Programming menu

The programming menu contains values which are to be

set by the end customer.

QHeat transfer unit

Hot water – set value 50°C, adjustment range

45°C to 60°C for domestic hot water. Should this

value be increased, the 60°C temperature value of

the safety shutdown should also be increased, by

going in the basic setting menu, submenu

„Controller“. A blending valve should in any event be

installed on the freshwater station outlet!

Water temperature – operating mode:

cold, hot or timed heating.

Water temperature – cold1) No heat exchange

media is added to the stainless steel plate heat

exchanger after hot water has been drawn off. It

remains at the lowest temperature level after

drawing off. This results in a favourable control

behaviour arising for the drawing off of hot water.

Water temperature – hot 1) 2) The stainless steel

plate heat exchanger is continuously kept at a

constant operating temperature. When there is a

deviation lower than the water temperature set value

minus hysteresis, the P1 is activated with a capacity

of 25 % until the water temperature set value has

been achieved. This happens provided that a tempe-

rature is measured at T2 or at the “reheating” option

at T5 which is greater than that of the hold-warm

temperature. Should this condition not be fulfilled at

T2, the temperature is again requested after a resting

period of one hour.

Water temperature – timed heating 1) 2) For the

duration of the time slot the stainless steel plate

heat exchanger is kept warm.

Water temperature – set value 2) 40°C, adjustment

range 20°C to 50°C for the hold-warm temperature

of the stainless steel plate heat exchanger for water

temperature – hot and water temperature – timed

heating.

Water temperature – Hysteresis 3 K, adjustment

range 1 K to 20 K for the water temperature set

value. Only visible if water temperature = hot or

water temperature = timed heating has been

selected!

Note:The water temperature – hot function should

be used if the buffer storage is located far from

the freshwater station and the system is

operated without circulation.

Hot water max. 5K (2 K – 10 K)

Hot water min. 5K (2 K – 10 K)

Testing period 5 min (1 min – 30 min)

An error message is displayed when the tempera-

ture exceeds or is lower than the hot water set

value. When the threshold values are exceeded or

the temperature drops below these values, a fault is

generated after the preset monitoring period, and

output S2 is switched as a potential-free contact.

The output is reset once the temperature is again

within the temperature range or it can be reset in

the information menu/error message upon actuation

of the right key. This monitoring is only valid when

drawing off takes place – not during circulation!

QTime slot

There are tree time slots available to set the

circulation. Should the switch-on and the switch-off

time be set the same, this time slot is no longer

active. For further circulation functions, see 5.3.3.

The time slots are also used for the water tempera-

ture - timed heating. (See 5.3.3)

QReheating

This menu item is only visible once the reheating

function has been activated in the basic setting

menu. If „absolute value” has been selected, „65°C

storage tank set value” will be displayed. This value

is adjustable between 20°C and 90°C. If „relative

value” is selected „15 K splay” is displayed here.

This value is adjustable between 2 K and 50 K.

For further information regarding functions, see

points 5.3.5 and 7.4. Storage tank set value = buffer

set value

QData logging

This menu is only visible if a data stick has been

connected to the front side of the control system.

Measured values can be recorded on this data stick.

In a measurement interval of 1 second (factory

setting) measured values for approx. 4.5 hours can

be logged. The data can be analysed at the plant

with special software.

QClock time

Submenu for setting the clock time, date and the day

of the week.

9

5. Control system

1) Based on the physical fact that the existing heat

energy in the heat transfer unit has to be controlled

by the control system, short-term temperature

fluctuations at the start of a hot water tapping

cannot be ruled out completely. Favourable control

behaviour is achieved with the water temperature –

cold function, which results in very short or no

reheating time!

2) The plate heat exchanger is kept hot by the heat

exchange media from the buffer. The heat exchange

media can take on temperatures of more than 60°C.

Please note that such temperatures can result in

calcium oxide precipitation!

5.3.4 Manual operation menu

QThe output 1, output 2, output 3 and outputs

„overall test” can be switched on and off manually,

in order to check the functioning of the pumps.

QCharacteristic curve calibration

Here the regulation of the characteristic curve is

determined during the initial operation. (See 6.3.2)

QCirculation adjustment

In this menu item the circulation adjustment is

carried out.(See 6.3.3)

5.3.5 Basic setting menu

This menu contains important technical information and

parameters for controlling, which may be modified by

a specialist tradesman. In order to modify values, the

submenu “release” in the basic setting menu has to be

activated. (See 8)

QInformationen

Here information regarding the software and system

version is given.

QController ON/OFF 3)

Amongst other things, this menu item contains the

safety shutdown for a domestic hot water tempera-

ture of 60°C. Should this temperature be exceeded

at T1, pump P1 switches off until the temperature

drops to below 60°C. This value should be increased

when the hot water – set value is increased.

However, a blending valve should additionally be

mounted on the domestic hot water outlet of the

freshwater station. The other control parameters

should not be adjusted!

QPulse generator 2)

These values are used to adapt the flow rate

generator at the control system.

QCharacteristic curve 2)

In this menu item the pre-determined operating

points of the control system can be read.

In this menu item the pre-determined operating

points of the control system can be read. Likewise

the default value for flow max. of the characteristic

curve calibration can be modified. Should, for

example, the 25l/mm for the characteristic curve at

flow max. not be reached, the default value for flow

max. can be lowered to 15l/mm. (See 6.3.2)

QHeat transfer unit

After run 2)

Outside the circulation time and after a drawing off of

hot water, it is possible to keep the circulation pump

running afterwards. The stainless steel plate heat

exchanger is cooled down and its decalcification is

counteracted. The function of the after-run, from an

energy point of view, is only meaningful and possible

outside the circulation time!

QCirculation ON/OFF

If this function has been activated, up to three time

slots can be set in the „programming” menu.

In the time slot, controlling is always based on the

circulation temperature. If the time slot has ended, or

drawing off takes place or the circulation temperature

has been reached, the circulation switches off. It is

attached to the circulation rest time. No circulation

can be activated in the circulation rest time. To avoid

the heat transfer media in the buffer from being

mixed, the heat transfer media temperature is

checked at the heat transfer media- flow- sensor

T2 or with the option at T5 at the start of the circula-

tion process, to ensure that the heat transfer media

temperature is greater than the circulation set

temperature +2K. This happens at T2 with the

following procedure: The heat transfer pump P1 runs

for 5 minutes at minimal capacity. Should the

circulation set temperature plus 2K not be attained

after expiry of the 5 minute run time, the heat

transfer pump P1 is switched off – and restarts the

process again after a waiting period of one hour.

Following this, the flashing message „error

message flow temperature” will be seen on the

display in the information menu.

Flow increase 5 K

In some cases (high temperature drops in circula-

tion capacity), the circulation return temperature is

not reached. The set value of the circulation tempera-

ture (flow increase 5K) can be increased up to 20 K.

The input is limited to the hot water set temperature

value. Should the hot water set temperature be

reduced, the flow increase value for circulation is

also reduced!

Example:

Circulation set = 35°C, hot water set = 50°C, flow

Increase = 15 K possible

Circulation set = 40°C, hot water set = 50°C, flow

Increase = 10 K possible

Circulation set = 40°C, hot water set = 45°C, flow

Increase = 5 K possible

10

5. Control system

If a buffer sensor T5 is available as an option for the

activation of the reheating function and its temperature

is less than the circulation temperature + 2K, the

circulation is then discontinued.

As a result of the reheating function it is to be assumed

that after reheating and for a conceivable period of

time thereafter sufficient temperature is available in the

buffer.

Outside the active time slot, the circulation is always

in the “pulse generated” mode, i.e. always when a

drawing off of approx. 1 s has been carried out, the

circulation pump is switched on for the programmed

time in “circulation-running time” and the circulation is

then also blocked from being reactivated for the preset

“circulation-rest time” period.

Circulation running time = 300 s

From 0 – 600 s adjustable running time of the circulation

pump.

Circulation rest time = 5 min

From 0 – 120 min adjustable blocking time for

reactivating the circulation.

Circulation hot water set value = 40°C

From 10°C to 50°C adjustable temperature for circulation

in the time slot.

Sensor TF3 = select sensor T3 or T6 (optional)

In the factory setting T3 is used for measuring the

circulation temperature. However, an independent

sensor T6 (optional) can also be used directly in the

circulation pipes for this purpose.

Option T5: With an additional sensor T5 (optional),

which is installed in the buffer, two further functions

can be activated.

QActivation T5

If the activation T5 = on is selected, it is possible to

only put the control system into operation after a

specified buffer temperature has been attained.

Factory setting = off

Switch-on temperature = 35°C temperature

(adjustment range 35°C to 55°C)

Hysteresis = 3 K

(adjustment range 3 K to 10 K)

QReheating ON/OFF

Optionally the additional „reheating” function can be

activated. When there is a deviation lower than an

adjustable set value for the buffer, this function is an

external heat source which is activated to reheat

the buffer until it reaches the set level.

The requirement for this is that the heat source is

actually able to supply the desired temperature level.

For this purpose the contact S1 on the controller

circuit board is used. This contact can be charged

with 4 A 230 V AC. The set value for the storage

temperature can be defined as an absolute value

(fixed value e.g.: 65°C) or as a relative value.

Should the relative value be used, the set value for

the buffer temperature is calculated from the

programmed hot water – set temperature + the

entered value for the „splay”. e.g.: hot water set

temperature 50°C + splay 20 K = 70°C buffer

temperature. Should the programmed or calculated

set value deviate lower by 3 K, the external heat

source is kept activated until the set value is reached

again. The temperature values needed for this can be

set in the programming menu, under the submenu

“reheating”. (See 5.3.3)

QPre-mixer ON/OFF

As a rule, this selection is not active in this control

system!

QDisinfection

The “disinfection” function can be activated in the

basic setting menu, but only if there is a circulation

pipe available. The circulation return temperature is

controlled, which is measured at the cold water

sensor. This temperature must be attained for the

preset disinfection time period. Short-term lower

temperature deviations are corrected. In total, the

actual time that the set temperature was attained,

is counted. Should the flow temperature for the

control system not be achieved, a corresponding

error message is sent to the information menu after

30 minutes. During the disinfection of the hot water

and circulation pipes, very high temperatures are

achieved. There is therefore a danger of scalding!

Qualified personnel should take the necessary

precautions for the protection of persons and

property!

QFactory setting ON/OFF

Should the controller be set back to the original

factory positions as on delivery, this menu item is to

be activated.

QRelease

In order to „unlock“ the controller for different

settings, the following should be done:

Release by pressing the right key twice and

“OFF” will flash. Press UP and DOWN and right

key simultaneously for approx. 2s and release

changes to „ON“. To subsequently leave the setting,

press the left key.

The same operating sequence is used to block

access to the controller. Alternatively, this takes

place automatically after 60 minutes.

2) This is executable within one minute after mains

connection or by using the key combination. Access

is automatically blocked after 60 minutes.

3) Only possible to activate „release” by using the

key combination in the menu. Access is automati-

cally blocked after 60 minutes.

11

6. Initial operation and system calibration

6.1 Flushing and filling the

system

QThe entire system should be flushed before filling.

QThe flat-sealing connections of the freshwater station

should be checked for leakage and the connections

should be tightened, if necessary. When tightening

the connections, always use the appropriate tools to

counter-resist!

QAir which has accumulated in the heating system

should be removed by opening the vent screw.

Caution:

In doing so, pay attention to the system pressure and

refill, if necessary.

6.2 Controller calibration

Why is it necessary to calibrate the controller?

In doing the controller calibration and the subsequent

circulation adjustment, the values of the freshwater

station is optimised and adapted to the local conditions.

In the calibration menu you will be requested to draw

hot water three times. In doing so, the operational

points are determined for the control system and are

independently taken over into the control system.

The control system then operates on the characteristic

curve so recorded. Under optimal conditions this

process takes10 to 15 minutes. The subsequent

circulation adjustment connected to this process,

serves to log the volumetric flow of the circulation.

Note: Please draw off hot water for a longer period

before calibration so that stable temperature conditions

for cold water and hot water can be set at the fresh-

water station.

6.3 Calibration procedure

1. Pump capacity

2. Characteristic curve calibration

3. Circulation adjustment

6.3.1 Selecting pump capacity

UPS15-60 pump stage I for drawn off amounts up to

15 litres

UPS15-60 pump stage II for drawn off amounts up

40 litres

Operating at pump stage II is generally recommended

for low buffer temperatures.

6.3.2 Characteristic curve

calibration

A buffer temperature which lies above the domestic hot

water temperature is necessary for the characteristic

curve calibration. The relevant amounts are found at 2.1

Performance characteristics!

Determining the control system operating

points

1. Select the “manual” menu

2. Select the “characteristic curve calibration” submenu

3. Select using the right key; „OFF“ flashes; Use

upper key to go on “ON”; confirm with right key

twice and start a 25 litre hot water tapping accor-

ding to the menu navigation. After approx. three minutes

you will be requested to reduce the hot water discharge

volume to 8 litres. After a further approx. three minutes

you will again be requested to reduce the hot water

discharge volume (4 litres).

4. If thereafter the “characteristic curve calibration on”

is displayed again, leave this submenu using the left

key. The characteristic curve calibration is now

complete and the values are independently logged

into the control system.

5. Should it not be possible to draw off a volume of

25l/min, the value for “flow max.” can be reduced to

another value e.g. 15l/min. Additionally, a change into

the “flow max” is required in the basic setting menu,

submenu characteristic curve by using the “UP” or

“DOWN” keys, and to select using the right key. The

display 25l/min flashes and can be reduced by using

the “DOWN” key. Thereafter, confirm this setting by

pressing the right key twice.

12

6. Initial operation and system calibration

6.3.3 Circulation adjustment

A circulation adjustment is to be undertaken if the

freshwater station is fitted with a circulation pump and

a circulation pipe is connected to it! For the controller to

detect a withdrawal of water, the actual circulation cycle

must be known as the flow rate is always measured by

the sum of the hot water withdrawal and the overlaying

circulation.

Information for a software update:

As of software version V 1.54 the 3 l/min flow rate

restrictor can be left out.

A prerequisite for the calibration is that all hot water

tapping points are closed.

Procedure to be followed:

Qselect: manual menu

Qmenu item „circulation adjustment“

Qselect by using the right key,

„OFF“ flashes

Qusing the „UP“ key change to „ON“

Qconfirm twice using the right key

Qthe message “flowing” is displayed

Qwhen the message „Circulation calibration

complete“ is displayed, measuring has been

finished.The measured value is displayed

and independently logged into the control

system.

QLeave the menu using the left key

13

6. Initial operation and system calibration

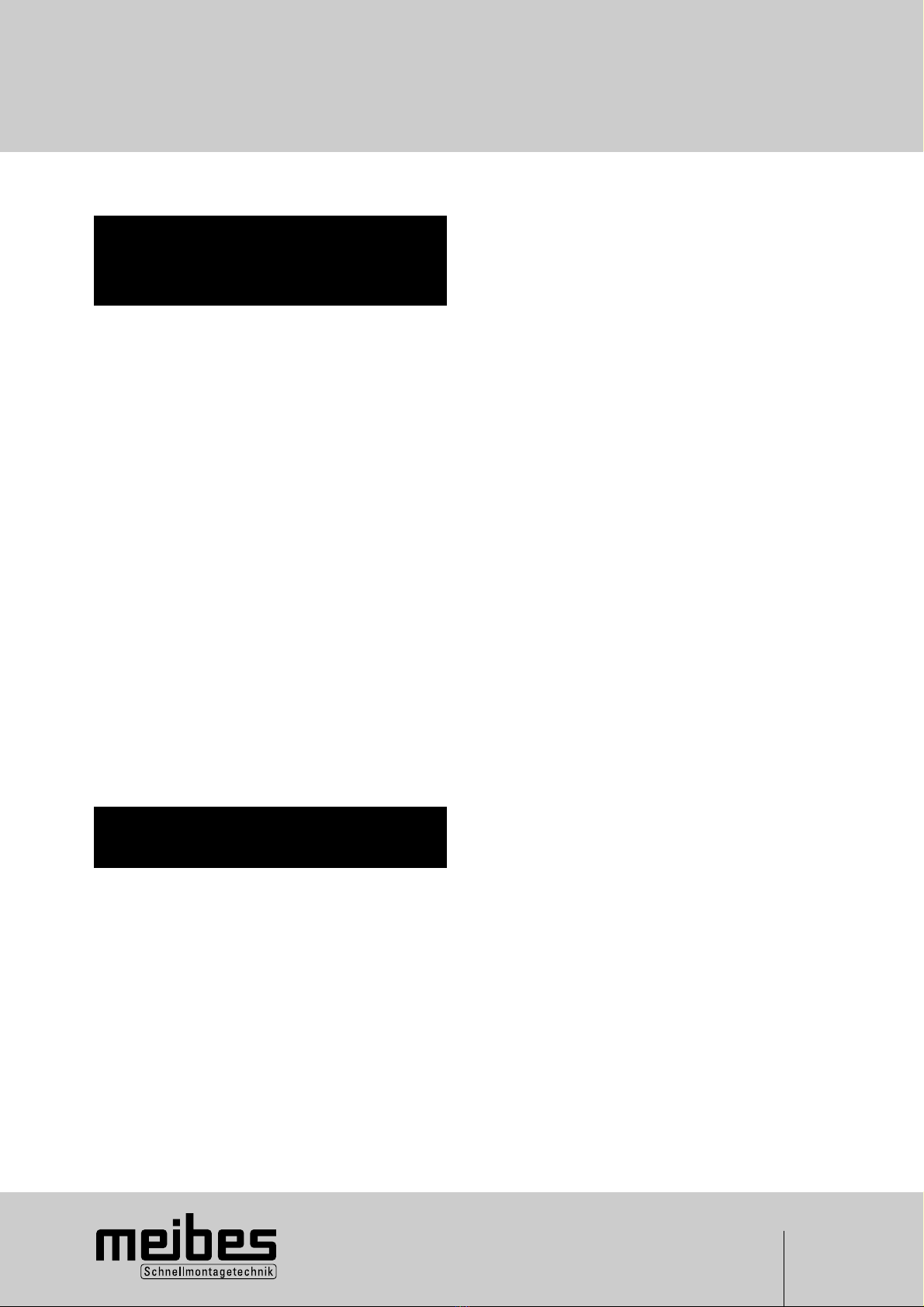

6.3.4 Detailed description of

characteristic curve

calibration

Determining the operating points of the

control system

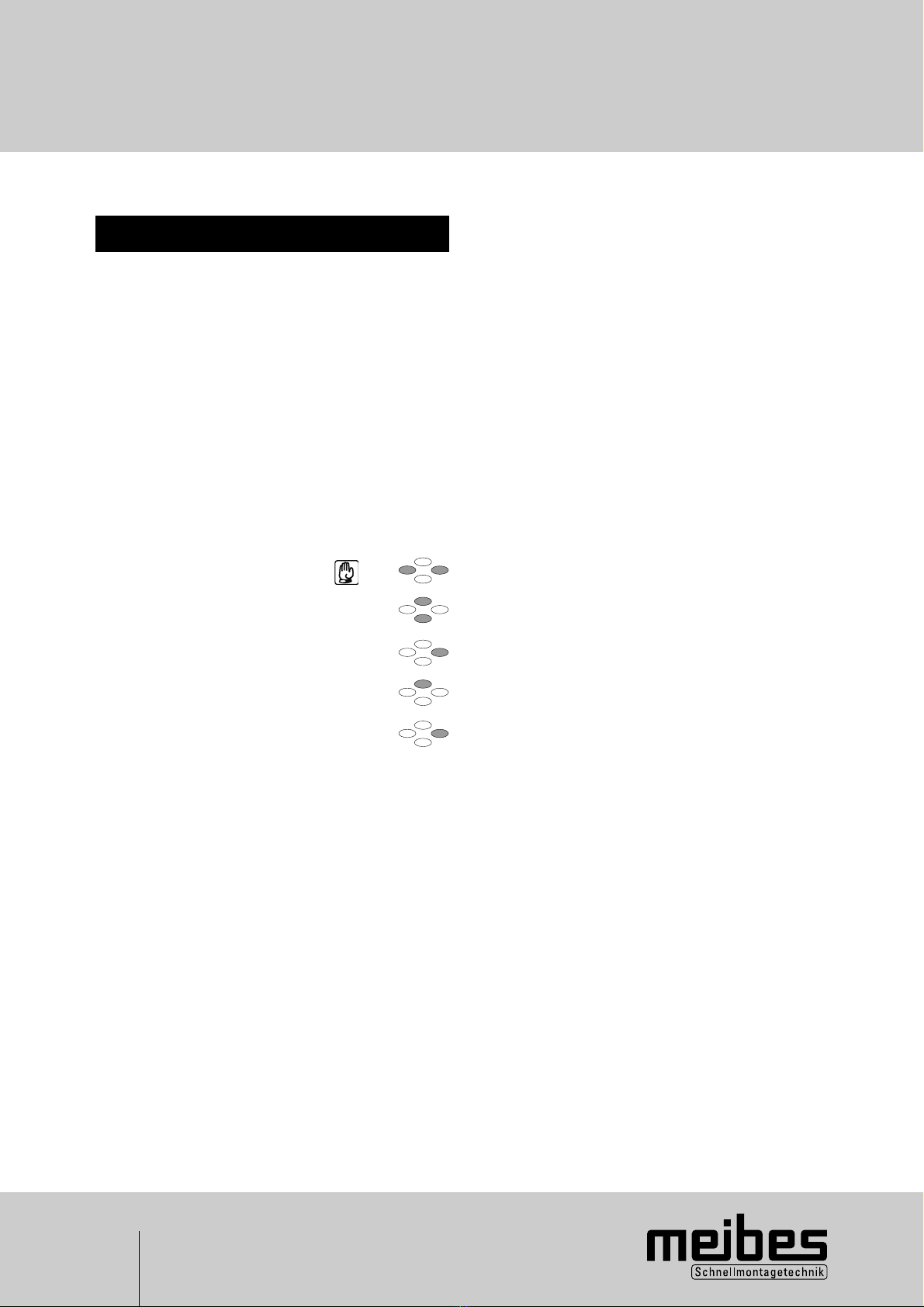

QManual operation menu

QCharacteristic curve calibration submenu

1x Leave the info menu using the “escape” key

2x

flashes

Select the menu: manual operation

5x

and then

1x

flashes

Select the menu: manual operation

Qselect using right key, OFF flashes.

1x

2x

QUsing the upper key, switch to On and

Qconfirm twice with the right key.

Calibration procedure starts.

1x

Kindly follow the menu guidance on the

display.

Consecutive drawn amounts of 25 litres,

8 litres and 4 litres are required. After the

relevant operating points of the pump have

been determined and independently logged

into the control system, characteristic curve

calibration “on” again appears on the display.

Leave this submenu using the left key.

The characteristic curve calibration is now

complete.

Characteristic

curve off

calibrate

Characteristic

curve on

calibrate

Withdrawal

starts

14

7. System examples

7.1 Freshwater station with

circulation in a time-slot

and with tapping detection

outside the time slot

QInitial operation and system calibration from point 6

QSetting the time and date, point 5.3.3

QDomestic hot Qset value e.g.: 50°C, point

water 5.3.3 and 5.3.5

QCirculation QBasic setting menu,

Circulation submenu = select

“on”, point 5.3.5

Q In programming menu,

circulation submenu up

to 3 select time slot,

point 5.3.3

Q Circulation temperature 40°C,

for control in time slot,

point 5.3.5

Q Circulation time e.g.: 60 s,

Circulation rest time.: e.g.

10 min, for controlling the

circulation through tapping

detection outside the

time slot, point 5.3.5

QHeat transfer unit QWT = cold, point 5.3.3

QTime lag Qe.g.: 20 s, point 5.3.5

7.2 Freshwater station with

circulation only via tapping

detection

QInitial operation and system calibration from point 6

QSetting the time and date, point 5.3.3

QDomestic hot Qset value e.g.: 50°C,

water point 5.3.3 and 5.3.5

QCirculation QBasic setting menu,

Circulation submenu = select

“on”, point 5.3.5

Q In programming menu,

Circulation submenu is the

start and stop times within

each 3 time slots which are

to be set at the same time

e.g.: start 6h00 - stop 6h00

point 5.3.3

Q Circulation time e.g.: 60 s,

Circulation rest time e.g.:

10 min, point 5.3.5

QHeat transfer unit QWT = cold, point 5.3.3

QTime lag Qe.g.: 20 s, point 5.3.5

7.3 Freshwater station without

circulation

QInitial operation and system calibration from point 6

QSetting the time and date, point 5.3.3

QDomestic hot Qset value e.g.: 50°C, point

water 5.3.3 and 5.3.5

QCirculation QBasic setting menu,

Circulation submenu = select

“off”, point 5.3.5

QHeat transfer unit QWT = cold can be selected,

if the distance between

the buffer and the freshwater

station is not too great.

After-run e.g.: 20 s,

point 5.3.5

Q WT = hot can be selected,

if there is a great distance

between the buffer and the

freshwater station, and the

comfort of the “rapid” hot

water drawing has been

attained. Set the after-run

point 5.3.5 on nought, as no

circulation pipe is available.

15

7. System examples

7.4 Freshwater station with

reheating option and/or

activation

The freshwater station with or without circulation can be

extended by two functions via an additional temperature

sensor T5 (not included in delivery) in the buffer. These

functions must be activated in the basic setting menu.

Point 5.3.5

The temperature sensor T5 becomes visible in the

information menu after activation.

1. A boiler must be requested to reheat the buffer.

For this a potential-free contact S1 on the control

circuit board is used.

This contact can be charged with 4 A 230 V AC.

A description as well as the settings for the reheating

option is found under point 5.3.5, reheating menu

item.

2. The same temperature sensor T5 can be used to

specify the buffer temperature, from where the hot

water regulation and the circulation are activated.

This function makes sense if the buffer temperature

could at some point take on unfavourably low values

as a result of renewable energy sources, and if the

freshwater station should not yet run at such low

buffer temperatures.

A description as well as the settings for the option

activation can be found under point 5.3.5, Activation

menu item.

7.5 Increasing the domestic

water set value

The following example is used to show what factors

should be taken into account when the domestic hot

water temperature is to be increased from 50°C to 60°C:

1. WW – set value increase

2. Increase the electronic safety shutdown and install a

blending valve.

3. Carry out a characteristic curve calibration!

re 1. In the programming menu, submenu heat transfer,

increase the hot water set value from 50°C to

60°C. To do this, select 50°C with the right key.

Once 50°C flashes, the value can be increased

to 60°C by using the upper key. Thereafter, confirm

by pressing the right key twice.

re 2. Release the operating level for the specialist

tradesmen in the basic setting menu. See point 7.

In the programming menu, submenu controller,

increase the menu item 60°C deactivation from

60°C to 70°C. To do this, the submenu controller

must be selected by pressing the right key once

until the bracket goes out. Then press the lower

key once. 60°C activate will be displayed. Now

select by pressing the right key once until the

60°C flashes. Using the upper key, increase to

70°C and confirm by pressing the right key twice.

You have now increased the safety shutdown

(scalding protection) of the control system to a

higher value and must now re-install a blending

valve on the hot water outlet!

re 3. Characteristic curve calibration see point 6.2 to

6.3.2

16

7. System examples

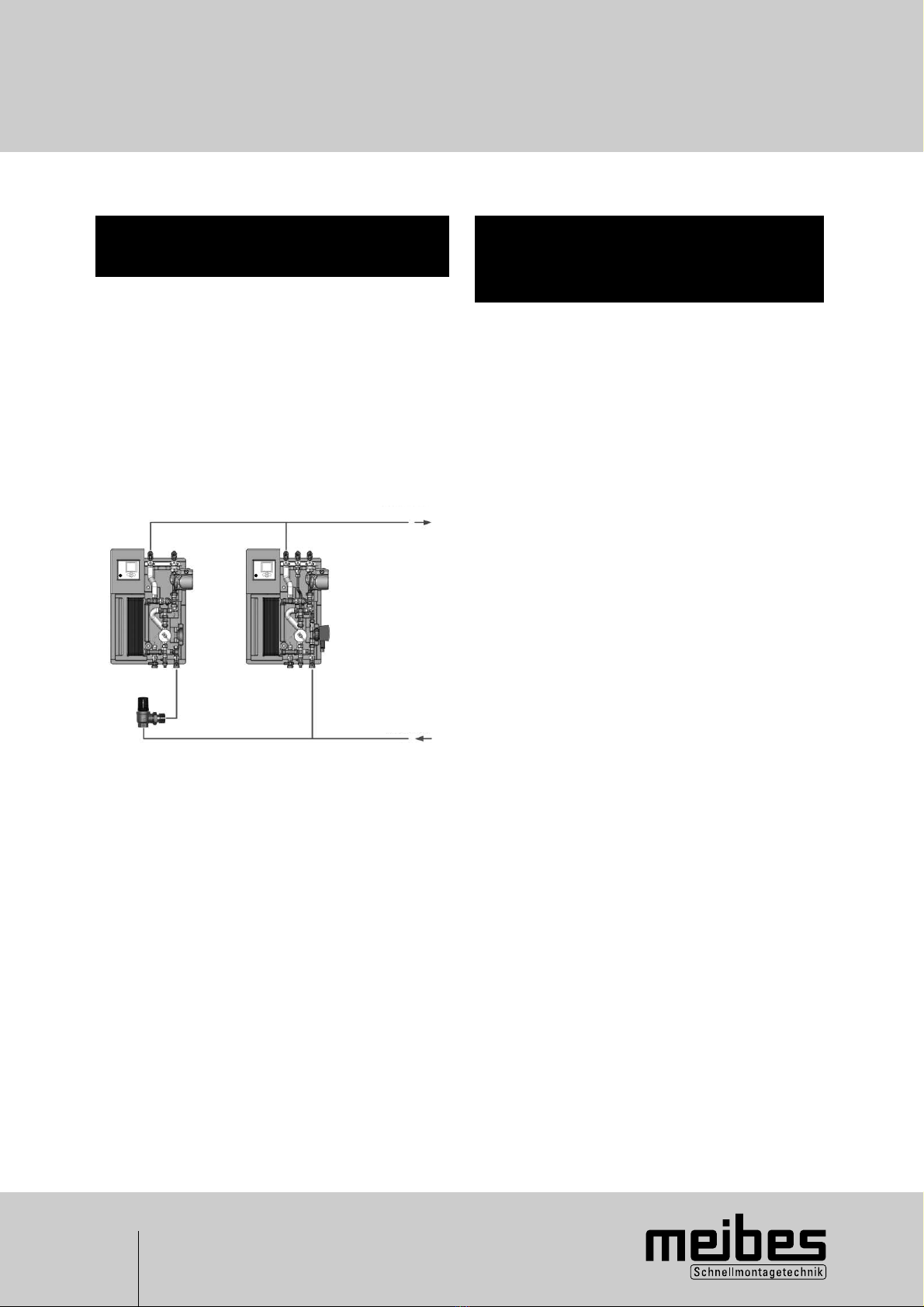

7.6 Freshwater station as

cascade connection

Should larger volumes of hot water be needed, overflow

valves allow for the interconnection of two or more

freshwater stations as a cascade. Here, the service

water circulation module can be left out for the second

and other freshwater stations.

The circulation is controlled only by the first freshwater

station.

Basic circuit diagram:

Second station First station

7.6.1 Initial operation and

system calibration of the

freshwater cascade

First station

QInitial operation and system calibration from point 6

QSetting the time and date, point 5.3.3

QDomestic hot Qset value e.g.: 50°C, point

water 5.3.3 and 5.3.5

QCirculation QBasic setting menu,

Circulation submenu = select

“on”, point 5.3.5

QIn programming menu,

circulation submenu up to

3 select time slot, point 5.3.3

QCirculation temperature

40°C, for control in time slot,

point 5.3.5

QCirculation time e.g.: 60 s,

Circulation rest time.: e.g.

10 min, for controlling the

circulation through tapping

detection outside the time

slot, point 5.3.5

QHeat transfer unit QWT = cold, point 5.3.3

QTime lag Qe.g.: 20 s, point 5.3.5

Second station

QInitial operation and system calibration:

The determined values of the characteristic curve

calibration of the first station are taken over. These

values are read in the first control system in the

basic setting menu, characteristic curve submenu

and in the same menu they are set in the second

control system.

QSetting the time and date, point 5.3.3

QDomestic hot QSet value e.g.: 50°C,

water point 5.3.3 and 5.3.5

QCirculation off

QHeat transfer unit QWT = cold, point 5.3.3

QAfter-run Qe.g.: 20 s, point 5.3.5

Differential pressure-overflow valve

Hot water should be drawn off of e.g.: 35l/min.

This domestic water volumetric flow can be read in

the control system information menu of the first

freshwater station. Set the differential pressure-

overflow valve so that the second freshwater station

starts operating (determination of opening pressure of

the overflow valve). Loosen the locking screw at the

differential pressure-overflow valve. Afterwards the

opening pressure can be adjusted in stages by turning

the hand wheel valve. The selected position should

subsequently be checked at the locking screw to

ensure it against accidental adjustment.

Required accessories:

Overflow valve DN 25 for

Cascade connection

Adjustment range:

100 to 500 mbar

Article no.: 69072.9

Domestic water

Domestic water

hot

cold

17

8. Releasing operating level for specialist

tradesmen!

QIn the basic setting menu press the „down“ key

downwards nine times until submenu release is

attained [values].

QNow press „right” key twice, this causes “off” to

flash.

QPress the „up“ and „down“ and „right“ keys

simultaneously for approx. 2 s, release switches

to “on”.

QThereafter leave the menu by using the “left” key.

7.7 Disinfecting the hot water

and circulation pipes

During the disinfection of the hot water and circulation

pipes, very high temperatures are generated.

There is a danger of scalding!

Qualified personnel should take the necessary

precautions for the protection of persons and property!

7. System examples

Example for setting the control system:

1. Release the operating level for the specialist

tradesmen in the basic setting menu.

2. In the basic setting menu, submenu

disinfection, select “in”.

3. Set the hot water set value.

Adjustment range 65 - 75°C

4. Select disinfection time (duration of

disinfection) Adjustment range 0 - 60 minutes

5. Select the day, week day or daily.

6. Start time (0 - 24 hours)

This function should be deactivated after

disinfection! The function is described in

5.3.5!

The releasing of the operating level can be reset again in the same way.

Access to the adjustable values is blocked automatically after 60 minutes!

18

9.Trouble-shooting

The following is to be checked if the domestic hot water

temperature is not reached:

QSystem voltage (fuses)

QBuffer temperature

QVent the freshwater station

QA temperature sensor interruption or a short circuit

is displayed in the information menu by a flashing

general error message and is shown individually

when requesting each sensor.

QCarry out characteristic curve calibration, from

point 6.3.2.

QCarry out a circulation adjustment, point 6.3.3.

QDuring a hot water withdrawal, the circulation pipe

becomes cold.

Cause: The return flow preventer in the connecting

nipple above the circulation pump can start leaking

due to soiling in the cold water network.

QFlow rate metre: To check this, a hot water tapping

is required and the flow in litres per minute read in

the information menu. An intact flow rate metre

should show a relatively constant value. Should

fluctuations occur, check whether this comes from

the domestic water network, for example in pressure

increase systems

QSet the freshwater station according to the system

examples.

QThe pumps P1 and P2 run alternatively and the status

display in the information menu switches between

active 50, after-run and off.

Q Carry out a circulation adjustment, point 6.3.3.

QAfter several months of smooth running operation

the hot water capacity is no longer reached.

Q If a dirt filter has been installed in front of the

station, this should be cleaned.

Q Check return flow preventer.

Q Vent the buffer and the freshwater station

QA short time after drawing off hot water at the tap

(e.g.: washbasin) the hot water temperature drops

sharply even though the control system displays

e.g.: 50°C hot water temperature.

Q The return flow preventer should be checked in

the connecting nipple above the circulation pump

to see if it leaks as a result of soiling in the cold

water system and if cold water has been

pressed into the circulation piping.

Q The circulation does not work:

Q Carry out circulation adjustment!

Q Check time slot!

Q The temperature of the heat transfer media

in the buffer is too low.

The circulation set temperature + 2 K is not

being reached at T2 or at T5, if present.

(see point 5.3.5 Circulation)

Please ensure that there is a sufficient quantity

of heat in the buffer!

With option T5 „reheat buffer“, a type of boiler

can be activated.

19

10. Factory setting and personal setting

Menu Submenu Factor

setting

Personal

setting

Heat transfer unit

Hot water set value 50°C

Water temperature (WT)

operating mode hot / cold / timed

heating

cold

Hot water set value 40°C

Water temperature hysteresis 3 K

Hot water max 5 K

Hot water min -5 K

Test time 5 min

Circulation

Time slot 1

Time slot 2

Time slot 3

6:00 - 9:00

11:00 - 13:00

16:00 - 20:00

Circulation

adjustment

Volumetric flow rate

Circulation 3 l

Pulse generator 72 lmp. / litre

Characteristic curve

Flow min 4 l/min

Capacity min 8 %

Flow middle 8 l/min

Capacity middle 20 %

Flow max 25 l/min

Capacity max 76 %

Correction 5 K 10 %

Heat transfer media adjustment 75°C

Temperature - cold water adjustment 15°C

Se value adjustment 50°C

Heat transfer unit After - run 20 s

Circulation

On/Off on

Running time 90 s

Rest time 0 min

Set value 40°C

Flow increase circulation 5 K

Temperature sensor 3 or 6 TF3

Activation T5

On or Off Off

Temperature 35°C

Hysteresis 3 K

Reheating On/Off Off

absolute or relative absolute

Pre-mixer On/Off Off

Disinfection On/Off Off

Hot water set value Off

Disinfection time 70°C

Start Monday

Start 1:00

UPS 15-60 Pump stage 2

Table of contents

Popular Industrial Equipment manuals by other brands

SUHNER MACHINING

SUHNER MACHINING MAX40R Technical document

Schmalz

Schmalz FS Series Assembly instructions

Siemens

Siemens SIRIUS 3RU1.1 Reference manual

Huawei

Huawei FusionModule 1000A40 Maintenance Guide

KINSHOFER

KINSHOFER EuroRail Operator's guide

Des Champs Technologies

Des Champs Technologies HVAC Air-Trap P Series Installation, operation and maintenance manual