DeLUX DP Series User manual

INSTALLATION &

OPERATION MANUAL

DP & DPSL SERIES

DPX & DPXSL SERIES

DPX4T SERIES

DPX8T SERIES

DPX12T SERIES

DPX16GT SERIES

© 2014

DELUX MANUFACTURING COMPANY

4650 AIRPORT ROAD

KEARNEY, NEBRASKA 68848

TOLL FREE (800) 658-3240

WWW.DELUXMFG.COM

01/01/2014

TABLE OF CONTENTS

SECTION 1. GENERAL

A. INTRODUCTION

B. USE OF MANUAL

C. !!!SAFETY CODE!!!

D. SERVICE INFORMATION

E. WARRANTY PROCEDURES

F. DELUX STANDARD LIMITED WARRANTY

SECTION 2. INSTALLATION

A. BEFORE DELIVERY

B. SETUP

C. ELECTRICAL

D. LP FUEL SYSTEM

E. NG FUEL SYSTEM

SECTION 3. ELECTRICAL – FUEL HOOK-UP AND CHECKOUT

SECTION 4. STARTUP PROCEDURE

- Watlow EZ-ZONE Automatic Temperature Controller

- Watlow EZ-ZONE Automatic Moisture Controller

SECTION 5. SYSTEM OPERATION

SECTION 6. GRAIN DRYER PERFORMANCE CHART

SECTION 7. GRAIN SHRINKAGE TABLE

SECTION 8. DRYER OPERATING LOG

SECTION 9. SYSTEM SEQUENCE ANALYSIS AND TROUBLESHOOTING

SECTION 10. SHUTDOWN AND EMERGENCY SHUT-DOWN PROCEDURE

SECTION 11. DRAWINGS

SECTION 12. GENERAL OPERATOR MAINTENANCE

SECTION 13. REPLACEMENT PARTS

SECTION 14. COMPONENT LITERATURE

SECTION 15. SUNFLOWER DRYING RECOMMENDATIONS

SECTION 1

1-1

01/01/2013

GENERAL

A. INTRODUCTION

DELUX MFG COMPANY OF KEARNEY, NEBRASKA HAS MANY YEARS OF EXPERIENCE IN

PRODUCING ENERGY SAVING, HIGH CAPACITY CONTINUOUS FLOW GRAIN DRYERS FOR

BOTH FARM AND COMMERCIAL APPLICATIONS.

DELUX GRAIN DRYERS ARE DESIGNED AND MANUFACTURED TO PRODUCE QUALITY

GRAIN AT A PROFIT. AN IDEAL BALANCE OF HOLDING CAPACITY, AIR FLOW, HEAT AND

EXPOSURE TIME ARE PROVIDED. ALL DRYERS ARE DESIGNED FOR CONTINUOUS FLOW

OPERATION. GRAIN ENTERS THE ROOF SECTION OF THE DRYER WHERE IT IS PREHEATED

AS IT FLOWS DOWN INTO THE COLUMNS WHERE THE DRYING PROCESS IS STARTED.

TWELVE(12) INCH GRAIN COLUMNS ON EACH SIDE OF THE DRYER PROVIDE FOR MAXIMUM

FUEL EFFICIENCY AND MINIMUM GRAIN MOISTURE DIFFERENTIAL ACROSS THE COLUMNS.

AS THE GRAIN ENTERS THE COOLING CHAMBER, OUTSIDE AMBIENT AIR IS DRAWN

THROUGH THE WARM GRAIN REDUCING THE DRYER FUEL CONSUMPTION OVER COMPETITIVE

CONVENTIONAL DRYERS, THUS COMPLETING THE DRYING PROCESS AND CONDITIONING

THE GRAIN FOR A LONG SAFE STORAGE LIFE.

B. USE OF MANUAL

THIS MANUAL PROVIDES OPERATION AND SERVICE RECOMMENDATIONS ALONG WITH

A REPLACEMENT PARTS LIST FOR YOUR DELUX GRAIN DRYER.

EACH SECTION OF THIS MANUAL IS FULLY ILLUSTRATED FOR FAST, ACCURATE

REFERENCE. IT IS HIGHLY RECOMMENDED THAT THIS MANUAL BE READ THOROUGHLY BY

THOSE WHO ARE RESPONSIBLE FOR THE OPERATION AND MAINTENANCE OF THIS

MACHINE. REFER TO THE TABLE OF CONTENTS FOR THE LOCATION OF SPECIFIC

INFORMATION.

C. SAFETY CODE---------USE CAUTION IN OPERATING THIS EQUIPMENT.

!!THE DESIGN AND MANUFACTURE OF THIS DRYER IS DIRECTED TOWARD OPERATOR SAFETY!!

USE EXTREME CAUTION IN WORKING AROUND HIGH SPEED FANS, GAS FIRED

BURNERS, DISCHARGE AUGERS, AND AUXILIARY AUGERS, WHICH MAY START WITHOUT

WARNING WHEN THE DRYER IS OPERATING ON AUTOMATIC CONTROLS.

CONTINUED SAFE, DEPENDABLE OPERATION OF AUTOMATIC EQUIPMENT DEPENDS TO

A GREAT DEGREE UPON THE OWNER. FOR A SAFE DEPENDABLE DRYING SYSTEM, FOLLOW

THE RECOMMENDATIONS WITHIN THE MANUAL AND MAKE IT A PRACTICE TO REGULARLY

INSPECT THE OPERATION OF THE UNIT FOR ANY DEVELOPING PROBLEMS OR UNSAFE

CONDITIONS. KEEP A CLEAN DRYER. DO NOT ALLOW FINE MATERIAL TO ACCUMULATE

ON THE PLENUM FLOOR OR A TRASH FIRE CAN RESULT. CHECKING THE DRYER AT

LEAST EVERY 24 HOURS AND CLEANING WILL HELP PREVENT PROBLEMS.

DRYER SHOULD NOT BE LEFT UNATTENDED FOR EXTENDED PERIODS OF TIME!!

D. SERVICE INFORMATION

OUR SERVICE DEPARTMENT WILL PROVIDE CONSULTATION ON THE INSTALLATION,

OPERATION, AND MAINTENANCE TO YOU. ALSO, INFORMATION FROM YOU REGARDING

ENCOUNTERED OPERATION OR SERVICE PROBLEMS THAT ARE NOT COVERED IN THIS

MANUAL WILL BE GREATLY APPRECIATED.

SECTION 1

1-2

01/01/2013

DELUX MFG COMPANY HAS TRAINED SERVICE TECHNICIANS AVAILABLE TO ASSIST

YOU IN THE EVENT YOU OR YOUR DEALER CANNOT CORRECT A PROBLEM. A PHONE CALL

TO DELUX MFG COMPANY WILL PROVIDE AN ANSWER TO YOUR SERVICE PROBLEMS.

DELUX MFG COMPANY KEEPS A COMPLETE RECORD OF EACH CUSTOMER ORDER.

HOWEVER, VALUABLE TIME CAN BE SAVED IF THE INFORMATION BELOW IS PROVIDED

WITH YOUR INQUIRY. IT IS SUGGESTED THAT YOU OBTAIN THE MODEL NUMBER AND

SERIAL NUMBER LOCATED IN THE ELECTRICAL CONTROL BOX ENCLOSURE AND ENTER IT

BELOW FOR YOUR OWN RECORDS:

DEALER:_______________________________________________

DATE OF PURCHASE:_____________________________________

MODEL:________________________________________________

SERIAL NUMBER:________________________________________

CALL OR WRITE: DELUX MFG COMPANY

4650 AIRPORT ROAD

P.O. BOX 1027

KEARNEY, NE 68848-1027

PHONE: 308-237-2274 TOLL FREE: 800-658-3240

FAX: 308-234-3765 WEB: http://www.deluxmfg.com

E. WARRANTY PROCEDURES:

ALL WARRANTY ISSUES, PARTS AND SERVICE REQUESTS SHOULD BE HANDLED

THROUGH YOUR LOCAL DEALER. IN THE CASE NO DEALER OR REPRESENTATIVE EXISTS

IN YOUR AREA, OR A CONFLICT OF INTEREST EXISTS WITH YOUR DEALER AND/OR

REPRESENTATIVE, PLEASE CONTACT THE DEPARTMENT OF ENGINEERING AND SERVICE AT

DELUX MFG. COMPANY FOR PROCEDURES TO FOLLOW.

WARRANTY ON ALL DEFECTIVE PARTS MANUFACTURED BY DELUX MFG COMPANY WILL

BE LIMITED TO THE SPECIFICATIONS SET FORTH BY THE INFORMATION PROVIDED BY

DELUX MFG COMPANY IN IT’S STANDARD LIMITED WARRANTY POLICY. WARRANTY ON ALL

DEFECTIVE PARTS NOT MANUFACTURED BY DELUX MFG COMPANY ARE LIMITED TO THE

WARRANTIES PROVIDED BY THAT PART’S MANUFACTURER. THIS INCLUDES, BUT IS NOT

LIMITED TO, ELECTRIC MOTORS, GEARHEADS, VALVES, REGULATORS AND OTHER PARTS.

DELUX MFG COMPANY IS NOT RESPONSIBLE FOR DEFECTIVE PARTS NOT OF ITS MANUFACTURE

AUTHORIZATION FOR CREDIT OR REPLACEMENT UNDER WARRANTY FOR DEFECTIVE

PARTS OR MATERIAL MANUFACTURED BY DELUX MFG COMPANY WILL NOT BE ISSUED

UNLESS STRICT COMPLIANCE IS GIVEN TO THE WARRANTY PARTS RETURN PROCEDURES

LISTED BELOW. WHEN CONTACTING DELUX MFG COMPANY IN REGARD TO THE POLICIES

AND PROCEDURES SET FORTH IN THIS MANUAL, DIRECT ALL CORRESPONDENCE AND

CALLS TO THE DEPARTMENT OF ENGINEERING AND SERVICE AT DELUX MFG COMPANY.

EXCEPT AS SPECIFIED PREVIOUSLY, REFER ALL WARRANTY CLAIMS TO YOUR DEALER.

WARRANTY PARTS RETURN AND CREDIT PROCEDURE:

SECTION 1

1-3

01/01/2013

1. DELUX MFG COMPANY MUST BE NOTIFIED BY WRITING OR PHONE WITHIN

FIFTEEN(15) DAYS AFTER AN ALLEGED FAILURE OF A PART MANUFACTURED BY

DELUX MFG COMPANY IS DISCOVERED. FAILURE TO GIVE SUCH NOTICE WITHIN

THE TIME SPECIFIED SHALL BE DEEMED AN ADMISSION BY THE PURCHASER THAT

THE PRODUCT IS AS REPRESENTED AND WARRANTED BY DELUX MFG COMPANY AND

FREE FROM ALL DEFECTS AND DELUX MFG COMPANY SHALL BE RELEASED FROM

ANY AND ALL CLAIMS ARISING OUT OF OR IN CONNECTION WITH THE SALE OF

THE PART OR PRODUCT.

2. UPON NOTIFICATION FROM PURCHASER THAT A PART MANUFACTURED BY DELUX

MFG COMPANY HAS ALLEGEDLY FAILED, THE FAILURE IS COVERED BY THE

STANDARD LIMITED WARRANTY AND THE ORIGINAL WARRANTY REGISTRATION CARD

IS ON FILE WITH DELUX MFG COMPANY AT ITS KEARNEY, NEBRASKA

HEADQUARTERS, ARRANGEMENTS WILL BE MADE BY DELUX MFG COMPANY TO SHIP

THE REPLACEMENT PART TO PURCHASER WITH FREIGHT CHARGED AT THE

STANDARD GROUND SHIPPING RATE.

3. ONCE THE REPLACEMENT PART HAS BEEN SHIPPED, PURCHASER WILL RECEIVE AN

INVOICE FOR THE VALUE OF THE EQUIPMENT SHIPPED PLUS THE SHIPPING

CHARGES. PURCHASER MUST THEN FULLY COMPLETE A RETURN PARTS TAG

IDENTIFYING THE ALLEGED PART FAILURE AND RETURN SAID TAG ALONG WITH

THE ALLEGEDLY FAILED PART TO DELUX MFG COMPANY WITH FREIGHT PREPAID

BY PURCHASER. NO WARRANTY CREDIT SHALL BE GIVEN TO PURCHASER ON

ALLEGEDLY FAILED PARTS THAT ARE NOT RETURNED TO DELUX MFG COMPANY

WITHIN THIRTY(30) DAYS FROM DATE OF THE DISCOVERY OF THE ALLEGED

FAILURE OR WITHIN FIFTEEN(15) DAYS FROM THE SHIPPING DATE INDICATED

UPON THE INVOICE SENT WITH THE REPLACEMENT PART, WHICHEVER DATE IS

LATER. PURCHASER MUST USE PROPER PACKING MATERIAL TO ENSURE AGAINST

DAMAGE DURING SHIPPING. ANY SHIPPING DAMAGE CAUSED BY IMPROPER

PACKING IS NOT COVERED UNDER THE STANDARD LIMITED WARRANTY.

4. THE INVOICE FOR THE REPLACEMENT PART PLUS THE FREIGHT CHARGE REMAINS

PAYABLE BY PURCHASER UNTIL SUCH TIME AS THE ALLEGEDLY FAILED PART HAS

BEEN RETURNED WITH A COMPLETED RETURN PARTS TAG ATTACHED AND THE PART

HAS BEEN INSPECTED BY DELUX MFG COMPANY TO DETERMINE IF THE WARRANTY

CLAIM IS VALID. PURCHASER WILL THEN RECEIVE NOTIFICATION FROM DELUX

MFG COMPANY AS TO THE RECEIPT OF THE DEFECTIVE PART AND DELUX MFG

COMPANY’S FINDINGS ON THE WARRANTY CLAIM WITHIN A REASONABLE TIME

THEREAFTER.

5. IF THE PART IS FOUND TO BE DEFECTIVE BY DELUX MFG COMPANY, DELUX

MFG COMPANY SHALL CREDIT THE AMOUNT OWED UNDER THE INVOICE SENT

WITH THE REPLACEMENT PART EXCEPT FOR THE FREIGHT INCURRED IN SHIPPING

THE REPLACEMENT PART TO PURCHASER.

6. IF THE PART RETURNED BY PURCHASER IS FOUND BY DELUX MFG COMPANY TO

BE FUNCTIONAL AND OPERATIONAL AND IN COMPLIANCE WITH THE MANUFACTURED

SPECIFICATIONS, IT WILL BE RETURNED UPON REQUEST TO PURCHASER AT

PURCHASER’S COST. IF NO REQUEST IS RECEIVED BY PURCHASER, THE PART

SHALL BE DESTROYED AFTER A PERIOD OF TEN(10) DAYS. DELUX MFG

COMPANY’S CHARGES FOR INSPECTION OF A NON-DEFECTIVE DELUX MFG CO

PART WILL BE SUBJECT TO THE STANDARD HOURLY RATE AND ZONE CHARGES.

7. NO NON-DELUX MFG COMPANY LABOR OR NON-DELUX MFG COMPANY REPLACEMENT

PART WILL BE AUTHORIZED WITHOUT FIRST AN ESTIMATE OF THE COST OF

PART AND LABOR PROVIDED TO DELUX MFG COMPANY. DEVIATIONS FROM THIS

ESTIMATE WILL BE SOLELY AT THE PURCHASER OR DEALER’S COST.

SECTION 1

1-4

01/01/2013

F. DELUX MFG COMPANY STANDARD LIMITED WARRANTY:

DELUX MFG COMPANY’S WARRANTY OBLIGATIONS ARE LIMITED TO THE TERMS SET FORTH BELOW:

DELUX MFG COMPANY WARRANTS TO THE ORIGINAL PURCHASER THAT IF ANY PART MANUFACTURED BY

DELUX MFG COMPANY IS PROVEN TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP WITHIN ONE(1)

YEAR FROM DATE OF ORIGINAL INVOICE FROM DELUX MFG COMPANY AND PURCHASER FOLLOWS THE

ABOVE WARRANTY PARTS AND CREDIT PROCEDURE, DELUX MFG COMPANY WILL, AT ITS OPTION,

EITHER REPLACE OR REPAIR SAID PART AT ITS COST. THIS STANDARD LIMITED WARRANTY DOES NOT

APPLY TO ANY DAMAGE RESULTING FROM NEGLIGENT USE, MISUSE, ACCIDENTAL DAMAGE, ABNORMAL

OR UNUSUALLY HEAVY USE, NORMAL WEAR AND TEAR, NEGLECT, ABUSE, ALTERATION, IMPROPER

INSTALLATION, UNAUTHORIZED REPAIR OR MODIFICATION, POOR OR IMPROPER MAINTENANCE OR USE

BEYOND RATED CAPACITY.

THIS WARRANTY AND THE REMEDY SET FORTH ABOVE IS EXCLUSIVE AND IN LIEU OF ALL OTHERS,

WHETHER ORAL OR WRITTEN, EXPRESSED, IMPLIED OR STATUTORY. DELUX MFG COMPANY

SPECIFICALLY DISCLAIMS TO THE MAXIMUM EXTENT PERMITTED BY LAW ANY AND ALL IMPLIED

WARRANTIES OR CONDITIONS AS TO THE PRODUCTS OR ANY OTHER MATTER WHATSOEVER. IN

PARTICULAR, BUT WITHOUT LIMITATION, DELUX MFG COMPANY SPECIFICALLY DISCLAIMS ANY AND ALL

IMPLIED WARRANTIES OR CONDITIONS OF SATISFACTORY QUALITY, MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, DESCRIPTION, NON-INFRINGEMENT OF THIRD PARTY RIGHTS, ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR

EMPLOYEE OF DELUX MFG COMPANY REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION,

LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS, OR

ANY OTHER WARRANTY ARISING FROM A COURSE OF DEALING OR USAGE OF TRADE. DELUX MFG

COMPANY RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

THIS STANDARD LIMITED WARRANTY DOES NOT APPLY TO, AND DELUX MFG COMPANY MAKES NO

WARRANTY TO THE PURCHASER WITH REGARD TO, PARTS AND PRODUCTS NOT MANUFACTURED BY

DELUX MFG COMPANY. IN THE EVENT AND TO THE EXTENT THAT APPLICABLE LAW DOES NOT ALLOW

THE EXCLUSION OF IMPLIED WARRANTIES, THE ABOVE EXCLUSION WITH REGARD TO IMPLIED

WARRANTIES MAY NOT APPLY.

DELUX MFG COMPANY SHALL NOT BE RESPONSIBLE OR LIABLE FOR ANY LOST PROFITS, DIRECT,

INDIRECT, UNFORSEEABLE, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES HOWEVER CAUSED

AND WHETHER OR NOT DELUX MFG COMPANY WAS ADVISED OF THE POSSIBILITY OF SUCH DAMAGES,

WHETHER BASED ON CONTRACT, IN TORT OR ANY OTHER LEGAL THEORY. THE REMEDY STATED HEREIN

SHALL BE THE SOLE AND EXCLUSIVE REMEDY AVAILABLE UNDER THIS WARRANTY.

DELUX MFG COMPANY ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION

DEFECTS WHICH CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS, MODIFICATIONS TO THE

PRODUCT NOT SPECIFICALLY COVERED BY THE CONTENTS OF THE DELUX MFG COMPANY SERVICE

MANUAL WILL NULLIFY ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN AVAILABLE OTHERWISE.

NO DELUX MFG COMPANY DISTRIBUTOR, RESELLER, DEALER, AGENT OR EMPLOYEE IS AUTHORIZED

TO MAKE ANY MODIFICATIONS, EXTENSION OR ADDITION TO THIS WARRANTY. DELUX MFG COMPANY

SHALL NOT BE RESPONSIBLE FOR ANY CHARGES INCURRED IN THE REPAIRING OR SERVICING OF

ANY DELUX MFG COMPANY PRODUCT OR PART EXCEPT AS SUCH REPAIRS ARE MADE BY

AUTHORIZED DELUX MFG COMPANY FIELD SERVICE PERSONNEL OR AS APPROVED IN WRITING

FROM DELUX MFG COMPANY.

PRIOR TO INSTALLATION, PURCHASER IS RESPONSIBLE FOR RESEARCHING AND COMPLYING WITH

ALL FEDERAL, STATE AND LOCAL STATUTES, REGULATIONS AND/OR CODES WHICH MIGHT APPLY

TO THE LOCATION AND INSTALLATION OF THE DELUX MFG COMPANY PRODUCT.

SECTION 1

1-5

01/01/2013

ADDITIONAL DISCLAIMER OF WARRANTY:

ALL MANUFACTURER LABEL PRODUCTS NOT MANUFACTURED BY DELUX MFG COMPANY ARE

EXCLUDED FROM COVERAGE UNDER THE DELUX MFG COMPANY STANDARD LIMITED

WARRANTY.

NO ELECTRIC MOTOR WARRANTY:

DELUX MFG COMPANY’S STANDARD LIMITED WARRANTY DOES NOT COVER ANY AND ALL

ELECTRIC MOTORS USED BY DELUX MFG COMPANY IN ITS PRODUCTS. PURCHASER’S SOLE

CLAIM FOR WARRANTY ON THESE ELECTRIC MOTORS LIES WITH THE MOTOR’S

MANUFACTURES. IN SUCH EVENT, PURCHASER’S DRYER SERVICE MANUAL CONTAINS A

LIST OF THE MOTOR MANUFACTURE’S SERVICE CENTERS WHERE ALL FURTHER INQUIRIES

REGARDING THE MOTOR AND ITS WARRANTY SHOULD BE PLACED. UNDER NO

CIRCUMSTANCES WHATSOEVER WILL DELUX MFG COMPANY BE LIABLE FOR AN

UNAUTHORIZED ELECTRIC MOTOR REPAIR BY A LOCAL MOTOR SHOP OR ELECTRICIAN.

RETURN MERCHANDISE PROCEDURES:

1. CALL OR WRITE: PHONE: 308-237-2274 TOLL FREE: 800-658-3240

FAX: 308-234-3765 WEB: http://www.deluxmfg.com

DELUX MFG COMPANY

4650 AIRPORT ROAD

P.O. BOX 1027

KEARNEY, NE 68848-1027

ASK FOR A RETURN PARTS TAG. IN THAT REQUEST IDENTIFY THE MERCHANDISE

YOU WISH TO RETURN, ITS CONDITION AND THE INVOICE ON WHICH IT WAS

ORGINALLY BILLED.

2. AFTER RECEIPT OF THE RETURN PARTS TAG, SHIP THE ITEM(S) WITH PREPAID

FREIGHT ALONG WITH THE RETURN PARTS TAG TO DELUX MFG. COMPANY. A 15%

RESTOCKING FEE WILL BE CHARGED ON ALL MERCHANDISE RETURNED THIRTY

(30) DAYS AFTER THE ORIGINAL DATE OF PURCHASE.

3. ONCE THE MERCHANDISE HAS BEEN RECEIVED AND INSPECTED BY DELUX MFG.

COMPANY, IF APPROPRIATE A CREDIT WILL BE ISSUED TO YOUR ACCOUNT.

4. ANY MERCHANDISE RETURNED THAT HAS BEEN USED OR ABUSED WILL NOT

RECEIVE A CREDIT TO YOUR ACCOUNT. SHIPMENTS OF INCORRECT MERCHANDISE

DUE TO MIS-ORDERING BY THE PURCHASER ARE ALSO SUBJECT TO A 15%

RESTOCKING FEE.

SECTION 1

1-6

01/01/2013

OUT OF WARRANTY SERVICE:

DRYERS REQUIRING DELUX MFG COMPANY REPAIR WORK WILL BE REPAIRED AT THE

STANDARD SERVICE CHARGES (HOURLY LABOR CHARGE, TRIP CHARGE (INCLUDES COST

OF LODGING, MEALS, AND MILEAGE COSTS), PLUS PARTS). THE REPAIRED PARTS WILL

CARRY A THIRTY(30) DAY LIMITED WARRANTY. THE SAME EXCLUSIONS AND

LIMITATIONS OF THE DELUX MFG COMPANY STANDARD LIMITED WARRANTY POLICY

REFERENCED ABOVE ALSO APPLY TO THIS THIRTY(30) DAY LIMITED WARRANTY. REFER

TO THE TABLE OF CONTENTS FOR LOCATION OF THE PRESEASON AND REGULAR SEASON

RATE CHARGES.

TERMS:

DELUX DRYERS REQUIRING SERVICE FOR CUSTOMERS WHO HAVE AN ESTABLISHED LINE

OF CREDIT WILL BE INVOICED FOR SERVICES RENDERED. CUSTOMERS NOT HAVING AN

ESTABLISHED LINE OF CREDIT WILL BE ON A CASH IN ADVANCE OR CASH ON

COMPLETION OF SERVICE. ALL SERVICE OR REPAIR WORK RENDERED BY AUTHORIZED

DELUX SERVICE PERSONNEL MUST BE INVOICED THROUGH AN EXISTING AUTHORIZED

DELUX MFG COMPANY DEALER.

SECTION 2

2-1

01/01/2014

INSTALLATION

THE DRYER IS DESIGNED FOR MINIMAL FIELD ERECTION TIME, DEPENDING ON

DRYER MODEL AND ASSOCIATED SECTIONS. THIS MAY INCLUDE ASSEMBLY AND

INSTALLATION OF THE GARNER BIN.

A. BEFORE DELIVERY

1. SITE SELECTION: THE DRYER IS NOT TO BE OPERATED INSIDE A

BUILDING OR ENCLOSURE. SUFFICIENT AREA AROUND THE DRYER MUST BE MAINTAINED

TO ALLOW ADEQUATE AIR FLOW TO SUPPLY THE DRYER AND TO ALLOW EXHAUSTED AIR

TO ESCAPE FREELY TO ATMOSPHERE. DO NOT OPERATE DRYER IN AN AREA WHERE

COMBUSTIBLE MATERIALS CAN BE DRAWN INTO THE FANS. ALSO CONSIDER THE GRAIN

HANDLING SYSTEMS AND THE LOCATIONS OF STORAGE BINS AND EXISTING CONVEYORS

IN SELECTING THE DRYER SITE. REFER TO BACK PAGE OF BROCHURE FOR GENERAL

DIMENSIONS AND SPECIFICATIONS.

2. SUPPLY AND TAKE AWAY SYSTEMS SUCH AS FILL AUGER AND UNLOAD AUGERS

SHOULD BE OF SUFFICIENT CAPACITY TO HANDLE MAXIMUM LOAD AND UNLOAD

REQUIREMENTS OF EACH DRYER. (APPROXIMATELY TWO (2) TIMES EACH DRYER'S

RATED CAPACITY, BASED ON FIVE(5) POINT MOISTURE REMOVAL IS RECOMMENDED.)

3. DRYER IS TO BE SET PERMANENTLY. DELUX MAINTAINS RECOMMENDED

FOUNDATION DRAWINGS FOR EACH DRYER MODEL THAT SHOULD BE FOLLOWED FOR NEW

INSTALLATIONS. IF ANY DOUBT, CONSULT LOCAL CERTIFIED ENGINEER FOR YOUR

SEPECIFIC APPLICATION.

IMPORTANT: DRYER MUST BE LEVEL BOTH LENGTHWISE AND CROSSWISE AT ALL TIMES

DURING THE DRYING PROCESS OR DAMAGE TO THE DRYER WILL RESULT.

4. CONSULT YOUR LOCAL ELECTRICAL POWER COMPANY FOR PROPER

TRANSFORMER SIZING. CONSULT WITH YOUR LOCAL ELECTRICIAN FOR INSTALLATION

OF ELECTRICAL SERVICE.

5. CONSULT YOUR PROPANE OR NATURAL GAS SERVICE SUPPLIER FOR LOCATING

AND SIZING TANK, METERS AND REGULATORS.

B. SET-UP

1. POSITION DRYER IN SELECTED LOCATION, LEVEL AND SECURE.

2. MAKE SURE ALL BOLTS AND SCREWS ARE IN PLACE AND TIGHT. MAKE SURE

METERING ROLLS AND AUGERS ARE FREE OF ANY FOREIGN MATERIAL.

3. ASSEMBLE GARNER BIN PARTS, REFER TO DRAWING FOR PROPER PART

ASSEMBLY. GARNER BIN CAN BE ASSEMBLED ON THE GROUND AND HOISTED TO THE TOP

OF THE DRYER, OR IT CAN BE ASSEMBLED PIECE BY PIECE ON TOP OF THE DRYER. A

HOLE IS PROVIDED IN THE ROOF SECTION OF THE GARNER BIN FOR FILL SPOUTING

ATTACHMENT. THE HINGED DOOR IN THE TOP OF THE GARNER BIN ALLOWS ACCESS TO

AUGER BEARINGS AND HANGERS FOR ASSEMBLY AND REPAIR.

4. INSTALL CATWALK RAILINGS AS SHOWN ON DRAWING.

5. INSTALL MOTOR AND CONDUIT ASS'Y PLUS HOOK-UP OF HIGH GRAIN

SHUTDOWN ASS'Y LOCATED ON THE TOP ROOF SECTION. ATTACH ELECTRICAL WIRING

PER DRAWING. (NOTE: FILL SWITCH ADJUSTMENT FOR PROPER OPERATION MUST BE

DONE AT THE TIME OF INITIAL FILLING).

SECTION 2

2-2

01/01/2014

C. ELECTRICAL

1. POWER SUPPLY - AN ADEQUATE POWER SUPPLY AND PROPER WIRING ARE

IMPORTANT FACTORS FOR MAXIMUM PERFORMANCE AND LONG DRYER LIFE. ELECTRICAL

SERVICE MUST BE OF ADEQUATE SIZE TO PREVENT LOW VOLTAGE DAMAGE TO MOTORS

AND CONTROL CIRCUITS. SEE TABLE 2.1 FOR FULL LOAD AMPS PER DRYER MODEL.

NOTE: ALL MOTORS ARE EQUIPPED FOR 230V SINGLE (1)PHASE, 208V, 240V,

380V, 415V, 480V OR 575V THREE (3)PHASE OPERATION. WHEN ONLY 230V SINGLE

(1)PHASE POWER IS AVAILABLE, A PHASE CONVERTER MAY BE INSTALLED AHEAD OF

DRYER TO OBTAIN THREE (3)PHASE POWER TO OPERATE 240V OR 480V THREE (3)PHASE

DRYERS.

2. POWER SUPPLY DISCONNECT - ALL DRYERS SHOULD BE EQUIPPED WITH A

POWER DISCONNECT SWITCH AHEAD OF DRYER CONTROL BOX TO PERMIT TOTAL POWER

SHUT DOWN BEFORE OPENING CONTROL BOX, AS REQUIRED FOR INSPECTION AND

SERVICE. THE POWER DISCONNECT SWITCH SHOULD ALSO BE LOCATED CLOSE TO THE

DRYER FOR QUICK SHUT DOWN.

3. ELECTRICAL PHASING - FOR YOUR CONVENIENCE YOUR DRYER HAS HAD ALL

MOTORS PHASED. IF ONE MOTOR RUNS BACKWARDS, THEY ALL WILL. SIMPLY CHANGE

THE TWO MAIN WIRE LEADS AROUND AT MAIN TERMINAL CONNECTION BLOCK FOR PROPER

ROTATION. (NOTE: CONTROL DESIGN REQUIRES WILD LEG TO BE CONNECTED TO

TERMINAL "L2" ON 240V THREE (3)PHASE DRYERS).

4. CONNECTING AUXILIARY CONVEYORS - AUXILIARY STARTING EQUIPMENT IS

SUPPLIED AS STANDARD EQUIPMENT. REFER TO DRAWING FOR PROPERLY CONNECTING

AND INTERLOCKING WET LOADING AND DRY UNLOADING AUXILIARY STARTING EQUIPMENT

LOCATED IN THE ELECTRICAL CONTROL PANEL. MAKE CERTAIN THAT THE MOTOR

OVERLOAD PROTECTION MATCHES THE MOTOR BEING USED.

5. IMPORTANT:

1. MAKE SURE DRYER IS PROPERLY GROUNDED. GROUND LUG IS

PROVIDED.

2. HAVE THE POWER COMPANY OR YOUR LOCAL ELECTRICIAN CHECK

LINE VOLTAGE AND AMPERAGE. MAKE SURE VOLTAGE DROP IS

MINIMUM.

SECTION 2

2-3

01/01/2014

D. LP FUEL SYSTEMS

1. CONSULT YOUR LOCAL PROPANE SUPPLIER FOR PROPER LINE SIZING

REQUIREMENTS AND LOCAL GAS CODES. PROPER LINE AND PRESSURE

REQUIREMENTS SHOULD BE BASED OFF OF MAXIMUM BTU/HR CONSUMPTION PER

DRYER MODEL. SEE TABLE 2.2.

2. THE DRYER IS DESIGNED TO OPERATE ON LIQUID PROPANE DRAWN FROM THE

SUPPLY TANK, HOWEVER INITIAL START-UP REQUIRES VAPOR TO BE DRAWN

FROM THE TANK TO ALLOW THE DRYER WARM UP. ONCE THE TEMPERATURE

INSIDE THE DRYER HAS RISEN, YOU MAY SWITCH OVER TO LIQUID.

TYPICALLY, A “Y” IS INSTALLED AT THE SUPPLY TANK TO FEED EITHER

LIQUID OR VAPOR TO THE LP INLET MANIFOLD OF THE DRYER. IN OTHER

INSTANCES RUNNING SEPARATE LINES FOR BOTH LIQUID AND VAPOR MAY BE

APPROPRIATE.

3. NORMAL OPERATING VAPOR PRESSURE (ON REGULATOR) IS 10-20 PSI.

4. BEFORE STARTING THE DRYER FOR THE FIRST TIME, MAKE CERTAIN THAT

PIPE UNIONS & FITTINGS ARE PROPERLY TIGHTENED BOTH INSIDE AND

OUTSIDE OF THE DRYER.

5. IN SOME CASES BURNER ORIFICES MAY NEED TO BE RESIZED TO

ACCOMMODATE VARYING DRYING CONDITIONS.

E. NG FUEL SYSTEMS

1. CONSULT YOUR LOCAL GAS SUPPLIER FOR PROPER LINE SIZING

REQUIREMENTS AND LOCAL GAS CODES. PROPER LINE SIZE AND PRESSURE

REQUIREMENTS SHOULD BE BASED OFF OF MAXIMUM BTU/HR CONSUMPTION PER

DRYER MODEL. SEE TABLE 2.2.

2. ALL NATURAL GAS DRYERS REQUIRE A PRESSURE REGULATOR NEAR THE BASE

OF THE DRYER TO MINIMIZE PRESSURE FLUCTUATIONS.

3. SUPPLIED PRESSURE TO DRYER FUEL SYSTEM SHOULD NOT EXCEED 20 PSI.

4. BEFORE STARTING THE DRYER FOR THE FIRST TIME, MAKE CERTAIN THAT

ALL PIPE UNIONS BOTH INSIDE AND OUTSIDE THE DRYER ARE PROPERLY

TIGHTENED.

5. IN SOME CASES BURNER ORIFICES MAY NEED TO BE RESIZED TO ACCOMADATE

VARYING DRYING CONDITIONS.

SECTION 2

2-4

01/01/2014

TABLE 2.1

MODEL FT

FULL LOAD AMPS (DRYER ONLY)

230V

1P

208V

3P

240V

3P

380V

3P

480V

3P

575V

3P

MSF-31010

10

55.9

N/A

N/A

N/A

N/A

N/A

MSF-41515

10

77.9

50.3

48.3

29.6

24.3

19.8

MSF-62520

15

N/A

66.2

62.9

37.2

31.6

25.4

MSF-72525

15

N/A

78.5

74.9

44.2

37.6

30.1

DP 2510

10

50.0

N/A

N/A

N/A

N/A

N/A

DP 3015

10

72.0

N/A

N/A

N/A

N/A

N/A

DP 4020

15

99.5

N/A

N/A

N/A

N/A

N/A

DP 5020

20

99.5

N/A

N/A

N/A

N/A

N/A

DP 7530

30

145.6

N/A

N/A

N/A

N/A

N/A

DP 10040

40

191.2

N/A

N/A

N/A

N/A

N/A

DP 3015

10

N/A

47.2

45.3

27.8

22.8

18.6

DP 4025

15

N/A

78.5

74.9

44.2

37.6

30.1

DP 6030

20

N/A

91.2

87.3

53.2

43.8

35.8

DP 7550

25

N/A

147.7

140.3

81.8

70.3

56.1

DP 9045

30

N/A

135.1

128.9

77.8

64.6

52.7

DP 12060

40

N/A

181.0

172.2

105.0

86.5

70.4

DPSL 3520

10

N/A

60.2

57.1

33.8

28.7

23.0

DPSL 4530

15

N/A

93.2

90.9

51.2

45.6

35.2

DPSL 7040

20

N/A

117.2

110.9

65.2

55.6

44.6

DPSL 8560

25

N/A

177.1

172.3

95.8

86.3

66.3

DPSL 10560

30

N/A

174.1

164.3

95.8

82.3

65.9

DPSL 14080

40

N/A

233.0

219.4

129.0

110.1

88.0

DPX 4525

10

N/A

75.6

72.1

42.6

36.2

28.9

DPX 7040

15

N/A

117.2

110.9

65.2

55.6

44.6

DPX 9050

20

N/A

141.8

134.9

79.2

67.6

54.0

DPX 13575

30

N/A

214.0

202.9

117.8

101.6

80.9

DPX 180100

40

N/A

293.7

278.5

163.1

139.4

111.1

DPXSL 5030

10

N/A

90.3

88.1

49.6

44.2

34.0

DPXSL 8050

15

N/A

141.8

134.9

79.2

67.6

54.0

DPXSL 10060

20

N/A

171.2

169.7

93.2

83.6

64.2

DPXSL 12560

25

N/A

180.1

174.9

96.8

87.6

67.2

DPXSL 15090

30

N/A

258.1

250.9

138.8

125.6

96.2

DPXSL 200120

40

N/A

352.5

342.5

191.1

171.4

131.5

** FULL LOAD AMPS BASED ON MOTOR TAG DATA AVAILABLE AT DATE PUBLISHED.

** FULL LOAD AMPS DOES NOT INCLUDE ANY AUX. HANDLING EQUIPMENT.

SECTION 2

2-5

01/01/2014

TABLE 2.1 – CONT’D

MODEL FT

FULL LOAD AMPS (DRYER ONLY)

230V

1P

208V

3P

240V

3P

380V

3P

480V

3P

575V

3P

DPX4T 5630

10

N/A

93.2

90.9

51.2

45.6

35.2

DPX4T 8460

15

N/A

167.1

152.7

91.3

76.8

61.8

DPX4T 11260

20

N/A

177.1

172.3

95.8

86.3

66.3

DPX4T 140100

25

N/A

280.1

254.9

146.8

127.6

101.2

DPX4T 16890

30

N/A

263.0

255.4

143.0

128.1

98.2

DPX4T 224120

40

N/A

352.5

342.5

191.1

171.4

131.5

DPX8T 6440

10

N/A

117.2

110.9

65.2

55.6

45.2

DPX8T 12880

20

N/A

225.1

212.3

123.8

106.3

86.3

DPX8T 160120

25

N/A

327.0

297.4

178.0

149.7

120.0

DPX8T 192120

30

N/A

335.0

315.4

185.0

158.1

128.2

DPX8T 256160

40

N/A

448.5

422.5

247.1

211.4

171.5

DPX12T 7250

10

N/A

143.2

130.9

76.2

65.6

52.2

DPX12T 10860

15

N/A

174.1

169.7

94.8

85.0

65.4

DPX12T 144100

20

N/A

277.1

252.3

145.8

126.3

100.3

DPX12T 175120

25

N/A

327.0

297.4

178.0

149.7

120.0

DPX12T 216150

30

N/A

413.0

375.4

218.0

188.1

149.2

DPX12T 288200

40

N/A

557.4

507.0

295.3

253.9

201.5

DPX16GT 8250

10

N/A

143.2

130.9

76.2

65.6

52.2

DPX16GT 12360

15

N/A

174.1

169.7

94.8

85.0

65.4

DPX16GT 164100

20

N/A

277.1

252.3

145.8

126.3

100.3

DPX16GT 210120

25

N/A

327.0

297.4

178.0

149.7

120.0

DPX16GT 246150

30

N/A

413.0

375.4

218.0

188.1

149.2

DPX16GT 328200

40

N/A

557.4

507.0

295.3

253.9

201.5

** FULL LOAD AMPS BASED ON MOTOR TAG DATA AVAILABLE AT DATE PUBLISHED.

** FULL LOAD AMPS DOES NOT INCLUDE ANY AUX. HANDLING EQUIPMENT.

SECTION 2

2-6

01/01/2014

TABLE 2.2

MINIMUM

MAXIMUM

MAX. w/ OPT. RECLAIM

TEMP.

BTU/HR

TEMP.

BTU/HR

TEMP.

BTU/HR

MODEL

(FT)

TOTAL

CFM

RISE

(F)

(MILLION)

RISE

(F)

(MILLION)

RISE

(F)

(MILLION)

MSF-31010 (10) 13,435 50 0.7 200 2.9 na

MSF-41515

(10)

19,150

50

1.0

200

4.1

na

MSF-62520

(15)

21,863

50

1.2

200

4.7

na

MSF-72525

(15)

24,804

50

1.3

200

5.4

na

DP 2510

(10)

10,077

50

0.5

170

1.9

140

1.5

DP 3015 (10) 14,985 50 0.8 170 2.8 140 2.3

DP 4020 (15) 20,154 50 1.1 170 3.7 140 3.0

DP 5020

(20)

20,154

50

1.1

170

3.7

140

3.0

DP 7530

(30)

30,231

50

1.6

170

5.6

140

4.6

DP 10040

(40)

40,308

50

2.2

170

7.4

140

6.1

DP 3015

(10)

14,985

50

0.8

170

2.8

140

2.3

DP 4025 (15) 20,511 50 1.1 170 3.8 140 3.1

DP 6030 (20) 29,970 50 1.6 170 5.5 140 4.5

DP 7550

(25)

41,022

50

2.2

170

7.5

140

6.2

DP 9045

(30)

44,955

50

2.4

170

8.3

140

6.8

DP 12060

(40)

59,940

50

3.2

170

11.0

140

9.1

DPSL 3520

(10)

17,808

50

1.0

170

3.3

140

2.7

DPSL 4530

(15)

22,896

50

1.2

170

4.2

140

3.5

DPSL 7040 (20) 35,616 50 1.9 170 6.5 140 5.4

DPSL 8560 (25) 45,792 50 2.5 170 8.4 140 6.9

DPSL 10560

(30)

53,424

50

2.9

170

9.8

140

8.1

DPSL 14080

(40)

71,232

50

3.8

170

13.1

140

10.8

DPX 4525

(10)

20,511

50

1.1

170

3.8

140

3.1

DPX 7040

(15)

35,616

50

1.9

170

6.5

140

5.4

DPX 9050

(20)

41,022

50

2.2

170

7.5

140

6.2

DPX 13575 (30) 61,533 50 3.3 170 11.3 140 9.3

DPX 180100 (40) 82,044 50 4.4 170 15.1 140 12.4

DPXSL 5030

(10)

22,896

50

1.2

170

4.2

140

3.5

DPXSL 8050

(15)

41,022

50

2.2

170

7.5

140

6.2

DPXSL 10060

(20)

45,792

50

2.5

170

8.4

140

6.9

DPXSL 12560

(25)

57,876

50

3.1

170

10.6

140

8.7

DPXSL 15090 (30) 68,688 50 3.7 170 12.6 140 10.4

DPXSL 200120 (40) 91,584 50 4.9 170 16.8 140 13.8

** OPERATING FUEL CONSUMPTION WILL FALL BETWEEN THE MINIMUM AND MAXIMUM

VALUES, AND IS DEPENDENT UPON AMBIENT CONDITIONS AND HEAT RECAPTURE FROM

COOLING GRAIN.

SECTION 2

2-7

01/01/2014

TABLE 2.2 – CONT’D

MINIMUM

MAXIMUM

MAX. w/ OPT. RECLAIM

TEMP.

BTU/HR

TEMP.

BTU/HR

TEMP.

BTU/HR

MODEL

(FT)

TOTAL

CFM

RISE

(F)

(MILLION)

RISE

(F)

(MILLION)

RISE

(F)

(MILLION)

DPX4T 5630

(10)

28,938

50

1.6

170

5.3

140

4.4

DPX4T 8460

(15)

44,043

50

2.4

170

8.1

140

6.7

DPX4T 11260

(20)

57,876

50

3.1

170

10.6

140

8.7

DPX4T 140100 (25) 79,500 50 4.3 170 14.6 140 12.0

DPX4T 16890 (30) 86,814 50 4.7 170 15.9 140 13.1

DPX4T 224120

(40)

115,752

50

6.3

170

21.3

140

17.5

DPX8T 6440

(10)

34,201

50

1.8

170

6.3

140

5.2

DPX8T 12880

(20)

68,402

50

3.7

170

12.6

140

10.3

DPX8T 160120

(25)

88,086

50

4.8

170

16.2

140

13.3

DPX8T 192120 (30) 102,603 50 5.5 170 18.8 140 15.5

DPX8T 256160 (40) 136,804 50 7.4 170 25.1 140 20.7

DPX12T 7250

(10)

39,750

50

2.1

170

7.3

140

6.0

DPX12T 10860

(15)

57,876

50

3.1

170

10.6

140

8.7

DPX12T 144100

(20)

79,500

50

4.3

170

14.6

140

12.0

DPX12T 175120

(25)

88,086

50

4.8

170

16.2

140

13.3

DPX12T 216150

(30)

119,250

50

6.4

170

21.9

140

18.0

DPX12T 288200 (40) 159,000 50 8.6 170 29.2 140 24.0

DPX16GT 8250

(10)

39,750

50

2.1

170

7.3

140

6.0

DPX16GT 12360

(15)

57,876

50

3.1

170

10.6

140

8.7

DPX16GT 164100

(20)

79,500

50

4.3

170

14.6

140

12.0

DPX16GT 210120

(25)

88,086

50

4.8

170

16.2

140

13.3

DPX16GT 246150

(30)

119,250

50

6.4

170

21.9

140

18.0

DPX16GT 328200 (40) 159,000 50 8.6 170 29.2 140 24.0

** OPERATING FUEL CONSUMPTION WILL FALL BETWEEN THE MINIMUM AND MAXIMUM

VALUES, AND IS DEPENDENT UPON AMBIENT CONDITIONS AND HEAT RECAPTURE FROM

COOLING GRAIN.

SECTION 3

3-1

01/01/2013

ELECTRICAL - FUEL HOOK-UP AND CHECKOUT

1. POWER SUPPLY

AN ADEQUATE POWER SUPPLY AND PROPER WIRING ARE IMPORTANT FOR MAXIMUM

PERFORMANCE AND LONG DRYER LIFE. ELECTRICAL SERVICE MUST BE ADEQUATE IN

SIZE TO PREVENT LOW VOLTAGE DAMAGE TO MOTORS AND CONTROL CIRCUITS. PROPER

LINE PHASING MUST ALSO BE OBSERVED.

2. POWER SUPPLY CIRCUIT BREAKER

ALL DELUX GRAIN DRYERS SHOULD BE EQUIPPED WITH A MASTER CIRCUIT

DISCONNECT TO PERMIT TOTAL SHUT-DOWN OF THE DRYING SYSTEM. IT IS SUGGESTED

THAT ALL WET AND DRY HANDLING EQUIPMENT BE INTERLOCKED THROUGH MASTER

CIRCUIT DISCONNECT. CALCULATE TOTAL AMP. LOAD OF SYSTEM TO MAKE SURE LOAD

DOES NOT EXCEED DISCONNECT RATING.

3. TRANSFORMERS - WIRE - VOLTAGE DROP

CONTACT THE SERVICE REPRESENTATIVE OF YOUR LOCAL POWER COMPANY TO

ADVISE OF ADDITIONAL LOAD TO BE PLACED ON THE LINE. CHECK ON KVA RATING OF

TRANSFORMERS, CONSIDERING TOTAL H.P. LOAD. THE POWER SUPPLY WIRING AND

TRANSFORMERS MUST BE CAPABLE OF PROVIDING ADEQUATE MOTOR STARTING AND

OPERATING VOLTAGE.

4. CONSIDERING TOTAL H.P. LOAD AND DISTANCE FROM TRANSFORMER, SIZE AND

INSTALL WIRE AND CONDUIT BETWEEN TRANSFORMER AND DRYER ELECTRICAL SERVICE

CENTER.

*NOTE: MAKE SURE DRYER IS ADEQUATELY GROUNDED.

5. CONDUIT INSTALLATION

GARNER BIN HIGH GRAIN SHUTDOWN, LOW GRAIN SHUTDOWN CONTROLS AND THE

LEVELING AUGER MOTOR ARE SUPPLIED WITH CONDUIT AND WIRING, REFER TO DRAWING

OF GARNER.

6. INTERNAL FUEL LINE HOOK-UP

THE DRYER IS EQUIPPED WITH A PLUMBING TRAIN CONTAINING SAFETY

CONTROLS. REFER TO DRAWINGS OF FUEL LINE HOOK-UP FOR ALL MODELS.

7. FUEL SUPPLY

(REFER TO SECTION 5 OF SERVICE MANUAL FOR "FUEL SUPPLY RECOMMENDED").

CONTACT YOUR LOCAL FUEL SUPPLIER FOR PROPER SIZING OF REGULATORS AND

PLUMBING.

8. FLAME ROD(S) AND SPARK IGNITER ADJUSTMENT

CHECK BURNER FLAME ROD(S) AND SPARK IGNITER ADJUSTMENT.

A. THE FLAME ROD(S) SHOULD BE CHECKED TO SEE THAT THE CERAMIC BASE

HAS NOT BEEN CRACKED. CHECK SPARK IGNITER: (SHOULD HAVE 1/8" TO

3/16" GAP).

SECTION 3

3-2

01/01/2013

9. INSPECT INSIDE OF DRYER

CHECK INSIDE OF DRYER SECTION FOR FOREIGN MATERIAL AND REMOVE. CHECK

METERING ROLLS FOR FOREIGN OBJECTS SUCH AS BOLTS, ETC.

10. MOTOR ROTATION

A. FAN ROTATION: LOOKING INTO FAN OUTLET, ROTATION SHOULD BE

CLOCKWISE. WHEN ELECTRICAL SERVICE IS INSTALLED, ATTENTION

MUST BE PAYED TO PROPER PHASING. ALL MOTORS HAVE BEEN PHASED

AT FACTORY. IN THE EVENT PHASES ARE REVERSED, SHUT OFF POWER

ON MAIN BREAKER, REVERSE T1 AND T2 AT MAIN BREAKER. CHECK

BACKSIDE OF FAN HUBS FOR FOREIGN OBJECTS THAT WILL THROW FAN

OUT OF BALANCE. FAN CURRENT SHOULD BE CHECKED TO BE SURE

AMPERAGE IS WITHIN LIMITS ON NAMEPLATE.

B. DISCHARGE CONVEYOR:

1. SCREW CONVEYOR - CHECK ROTATION BY OBSERVING AUGER FLIGHT

WHILE IN OPERATION. IF ROTATION IS INCORRECT, REVERSE T1

AND T2 MOTOR LEADS AT CONVEYOR STARTER.

2. METERING ROLL DIRECTION - THIS SHOULD BE CORRECT FROM THE

FACTORY. ROTATION SHOULD ALLOW GRAIN TO FLOW OVER FEED

ROLL. IF DIRECTION IS INCORRECT, REVERSE LEADS A1 AND A2

ON SCR CONTROL UNIT.

This manual suits for next models

62

Table of contents

Other DeLUX Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

FIELD OF VIEW

FIELD OF VIEW GeoSnap Basic manual

Waterous

Waterous Eclipse Installation, operation and maintenance

Software Bisque

Software Bisque Paramount ME II manual

Siemens

Siemens 3VA9978-0BL Series operating instructions

GE

GE GEI-44233 F instructions

JohnDow Industries

JohnDow Industries JDI-AFT106 user manual

Sumitomo

Sumitomo Bevel BUDDYBOX 4 Series Maintenance manual

TriangleTube

TriangleTube MAXI-FLO MF 350 PT Series Installation and maintenance manual

ABB

ABB HT570679 Operation manual

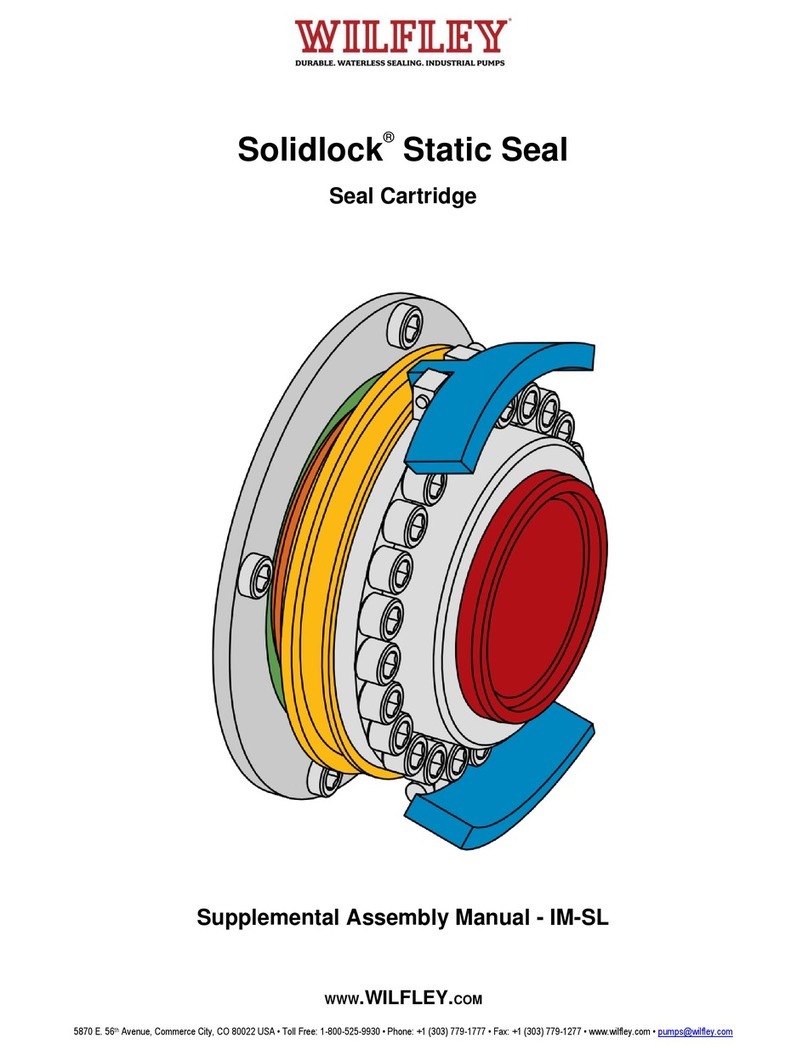

Wilfley

Wilfley SolidLock Supplemental Assembly Manual

Siemens

Siemens 3VL9400-3AU11 operating instructions

ABB

ABB C571-AC instructions