Des Champs Technologies HVAC Air-Trap P Series User manual

Des Champs Technologies | 2 Nikki Lane | Natural Bridge Station, VA 24579

www.deschampstechnologies.com | info@deschampstechnologies.com | Ph: 540-228-1967

Page | 1

Rev: 12/20

Installation, Operation, and

Maintenance Manual for

Des Champs Technologies

Waterless Trap

HVAC Air-Trap™

P-SERIES

Positive Plenum Pressure

These instructions are a guide to the user of a P-Series

Air-Trap during installation, commission into service,

operation, or periodic maintenance.

Product Description

The P-SERIES Air-Trap allows water to drain from

HVAC equipment and simultaneously prevents air from

escaping from the equipment.

The P-SERIES Air-Trap does not require standing

water to prevent gas (typically air) from leaving the

HVAC unit. With the occurrence of condensate, or

other water sources within the unit, the water flows out

of the HVAC unit but no gas escapes. When there is

no production of condensate or water, there is no water

in the trap and there is no gas leaving through the trap.

Install the P-SERIES Air-Trap in a vertical position.

Delivery Check

Upon receipt of the air-trap(s), inspect for damage that

may have occurred during shipment and check to

insure delivered items match purchased items.

Resolving Shipping Damage

If damage or items are missing:

1. Report all claims of shipping damage to the

delivering carrier (transporter) immediately, and

schedule an inspection.

2. Make specific notations on the freight bill

concerning the damage.

3. Keep damaged material in the same location as

received. The receiver is responsible for

providing reasonable evidence that damage

was not incurred after delivery.

4. Photograph damage if possible.

5. Do not move or discard damaged freight

packaging materials.

6. Notify the sales representative, or Des Champs

Technologies, of the damage. Do not attempt

to repair the unit without consulting the sales

representative or Des Champs Technologies.

DES CHAMPS TECHNOLOGIES IS NOT

RESPONSIBLE FOR SHIPPING DAMAGE.

Storage Considerations

.

Store the Air-Trap in a protected area prior to

installation. The warranty will not cover damage to

the trap resulting from negligence.

MADE IN THE USA

Patented

Des Champs Technologies | 2 Nikki Lane | Natural Bridge Station, VA 24579

www.deschampstechnologies.com | info@deschampstechnologies.com | Ph: 540-228-1967

Page | 2

Rev: 12/20

Installation

.

For positive pressure cooling section(s), always

connect the drain pan directly to a trap to ensure

proper drainage of water while simultaneously

preventing escape of air from the unit.

Important: Install a strainer screen, as shown in

Figure 1, over the drain inlet prior to operation of the

HVAC unit and before installing the trap. An integral

Union-Strainer™( see Figure 8) may also be

inserted in the drain line upstream of the Air-Trap.

1. Install the P-SERIES Air-Trap vertically with the

end marked “top” facing upward and the

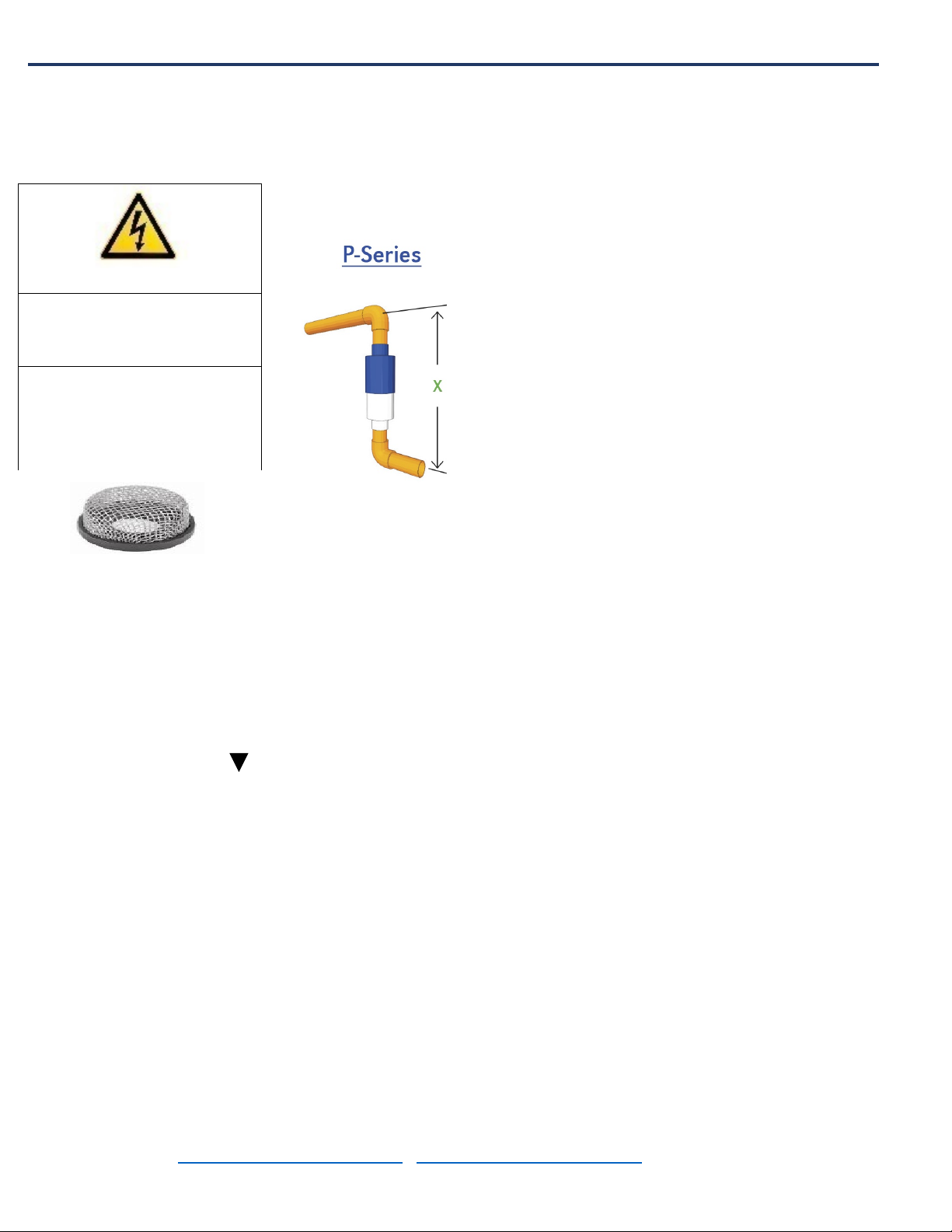

embossed arrowhead, , pointing downward. This

is a requirement for proper movement of the

internal float valve component.

2. Install the trap in accordance with manufacturer’s

instructions and with all applicable local or national

plumbing, drainage, and mechanical codes.

3. NEVER CONNECT CONDENSATE DRAIN

DIRECTLY TO A SANITARY DRAIN LINE.

Connect only to a storm drain or a condensate

drain line.

Operation

The P-SERIES Air-Trap operates dry when no water

removal is required and wet when it is required. When

dry, essentially no air exits the HVAC unit. When

removing water, the water exits the unit, but essentially

no air exits the unit through the drain connection.

Install the P-SERIES Air-Trap in a vertical orientation.

With no production of condensate within the AHU the

positive pressure that exists within the plenum that

contains the drain line forces the capsule (or

spherocylinder), downward onto the valve seat. With

the production of water within the plenum, the capsule

rises from the seat when the net buoyancy force

upward equals or exceeds the net downward force

created by air pressure. See cutaway view in Figure

3. The standard model P-SERIES operates as a

positive trap up to 12 inches WG of positive pressure.

If a pressure of more than 12 inches WG could occur,

then please contact Des Champs Technologies for

information on the Engineered P-Series Air-Trap.

The P-SERIES Air-Trap accomplishes the following:

•Reduces sludge buildup that normally

accumulates in standard “P” traps

•Prevents freezing of trap during cold periods

since during periods of no water removal there

is no water in the trap. If, for some reason,

water is flowing from the unit during freezing

temperatures, and the trap is located within this

freezing temperature region, then the trap will

require thermal protection.

•P-Series Air-Trap requires no water head to

cause the trap to operate. Simply come out of

the plenum with the condensate line and go

down into the P-Series Air-Trap. Come out of

the trap and go horizontally with your drain line.

The height, x, requirement then becomes the

height of the trap plus two street elbows.See

Figure 2.

•Eliminates air escaping from an HVAC unit that

would result from a standard P-trap

experiencing a “dry-out” condition.

•Note: If there is a possibility of a syphoning

effect (suction pressure) at the exit point of the

Air-Trap then it is necessary to install a vent as

close as possible to the bottom of the trap (see

Figure 9).

•If height, x, is an issue, the P-Series Air-Trap

may be installed at a 45° angle, as shown in

Figure 5. When installed at a 45° angle, the

maximum positive pressure it can withstand is

5” of WG instead of 12”. The reduced pressure

capability is a result of a reduction in buoyancy.

•Another option when height is an issue is to

install the N-Series Air-Trap vertically, as

opposed to horizontally when used as a

negative trap, shown in Figure 6. The

maximum positive plenum pressure it

CAUTION

Failure to provide adequate

drainage piping may result in

water damage to equipment or

building.

Place stainless steel filter

screen, Figure 1 over drain

inlet or install a

Union-Strainer™, see Fig 8,

upstream of the trap.

Figure 1 Strainer Screen

Figure 2: P-Series Air-

Trap Installed

Des Champs Technologies | 2 Nikki Lane | Natural Bridge Station, VA 24579

www.deschampstechnologies.com | info@deschampstechnologies.com | Ph: 540-228-1967

Page | 3

Rev: 12/20

can withstand is 3” of WG. The cleanout port is on the

bottom when used for positive pressure.

Maintenance and Techniques for Cleaning the

P-Series Air-Trap

In some operations, particulate matter can move from

the HVAC unit through the drain line and into the

P-SERIES Air-Trap. The accumulation of particulate

matter in the trap may cause the trap to operate less

efficiently or fail. Therefore, a means to remove the

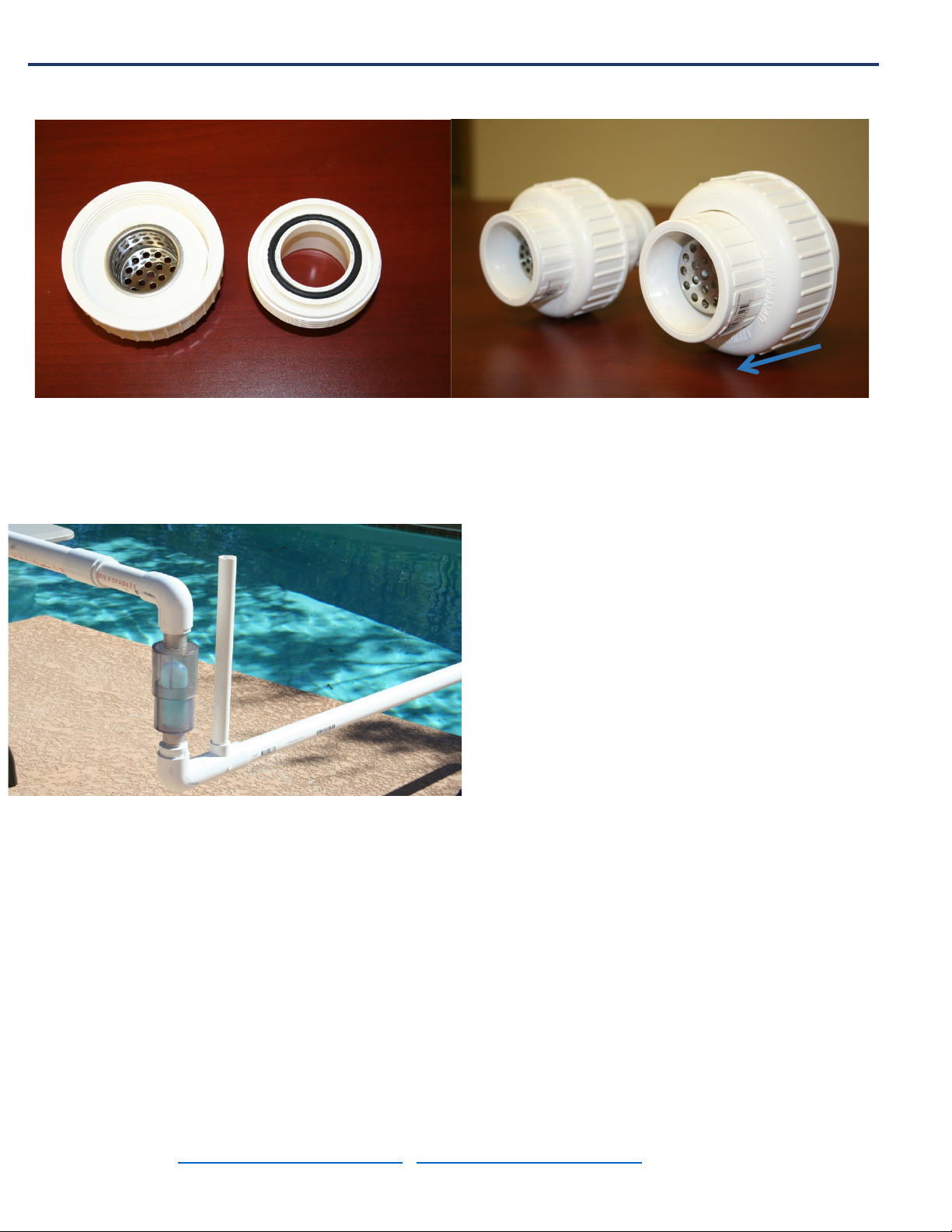

accumulated debris is required. A stainless steel filter

screen (Figure 1) over the drain inlet or a

Union-Strainer™ (Figures 7 & 8) within the drain line

extends the time between maintenance. Install the

Union-Strainer™ upstream of the Air-Trap.

There are several other options for cleaning.Option 1,

is to use the ½-inch cleanout port in the trap housing.

This will allow insertion of a water or air hose for

washing or blowing away material that may be

hampering operation of the trap. See Figure 3.

Option 2, shown in Figure 7, is to isolate the

P-SERIES Air-Trap from the main drain line by

installing unions that allow Air-Trap removal for

replacement or cleaning.

The best way to reduce maintenance is to install a

Des Champs Union-Strainer™ upstream of the

Air-Trap,(See Figure 8). The Union-Strainer™ is

also a convenient way to prevent unwanted creatures

and objects from entering the terminus of the drain line,

like snakes, rats, lizards, insects, and other

miscellanious items like, rocks, screws, and nuts. The

water flow is in direction of arrow shown in Figure 8,

with the strainer cup oriented to capture debris within

the cup.

Des Champs Technologies also offers engineered

traps for positive plenum pressure above 12 inches in

WG.Figure 4is a cut away view of an engineered

trap showing a cleanout port and the cylindrical float

that rises off the seat when condensate begins to

accumulate in the trap. Engineered Air-Traps are

designed for applications above the 12 inches of

positive pressure of the standard P-Series Air-Trap.

The Engineered Air-Trap can withstand positive

pressure up to 50” of WG or greater. Caution, do not

puncture the Float Valve.

Figure 3½-inch cleanout

port - Standard Model of P-

SERIES Air-Trap up to 12”

of positive pressure.

Figure 4 ¾-inch thread cleanout

plug- Engineered Model of P-

SERIES Air-Trap, for positive

pressure above 12” up to 50” WG.

Figure 5P-SERIES Air-Trap

installed at 45° angle can

reduce trap height by 30%

and operate at up to 5” of

positive pressure.

Figure 6N-SERIES Air-Trap

when installed vertically can

operate properly up to 3” of

positive pressure.

Threaded

plug for

cleaning

Threaded

plug for

cleaning

Figure 7 Use

unions to isolate

the Air-Trap for

removal or for

maintenance

Des Champs Technologies | 2 Nikki Lane | Natural Bridge Station, VA 24579

www.deschampstechnologies.com | info@deschampstechnologies.com | Ph: 540-228-1967

Page | 4

Rev: 12/20

Figure 8 In-line Union-Strainers. Install in the drain line

upstream of the Air-Trap. This will aid in preventing

debris from entering trap.

Figure 9 Installation of a Vertical Vent Pipe installed

directly downstream of a P-Series Air-Trap to prevent a

suction pressure from developing below the trap. A

suction pressure could develop depending upon the

length of drainpipe, the diameter, and the water flow

rate.

Inspect the P-Series Air-Trap on an annual basis;

remove any sludge or foreign materials that might

obstruct proper operation of the internal mechanism or

general drainage of the drain line. Remove obstacles

utilizing the clean out port located at the bottom of the

Air-Trap. Caution – do not damage the internal

mechanism inside the P-Series Air-Trap. Properly

dispose of any contaminated materials.

,

Limited Warranty

.

Des Champs Technologies warrants to the original consumer

purchaser (“Purchaser”) of its product, P-SERIES Air-Trap,

that it is free from defects in material or workmanship. If

within the 12-month period from the date of the original

consumer purchase this product shall prove to be defective,

it shall be repaired or replaced at Des Champs Technologies

option. Your original receipt of purchase is required to

determine warranty eligibility. The warranty does not cover

damage due to misuse, misapplication, lack of maintenance,

or failure to comply with the manufacturer’s installation

instructions or recommendations or any other loss or damage

exceeding the purchase price of the equipment purchased

from Des Champs Technologies. Des Champs Technologies

assumes no responsibility for damage or injury resulting

from chemical incompatibility between its products and the

process fluids to which they are subjected. This warranty is

limited to repair or replacement of the P-SERIES Air-Trap

only and is the only warranty issued by Des Champs

Technologies on its trap products.

This product design is Patented by Des Champs

Technologies LLC, Natural Bridge Station, Virginia

24579.

Des Champs Technologies also has a full line of

Commercial grade Negative Pressure Traps. Call or

go to the Website below for more information.

Figure 8: Union-

Strainers™,