Contents

Application · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · •· · • · 2

Notes

on

safety · · · · · · · · · · · · · · · · · · · · · · · · • · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2

Commissioning · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2

Oiling · · · · · · · · · · · · · · · · ·

~

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2

Needle and thread · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

Inserting the needle · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

Winding

fue

bobbin · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

1breading the bobbin case · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

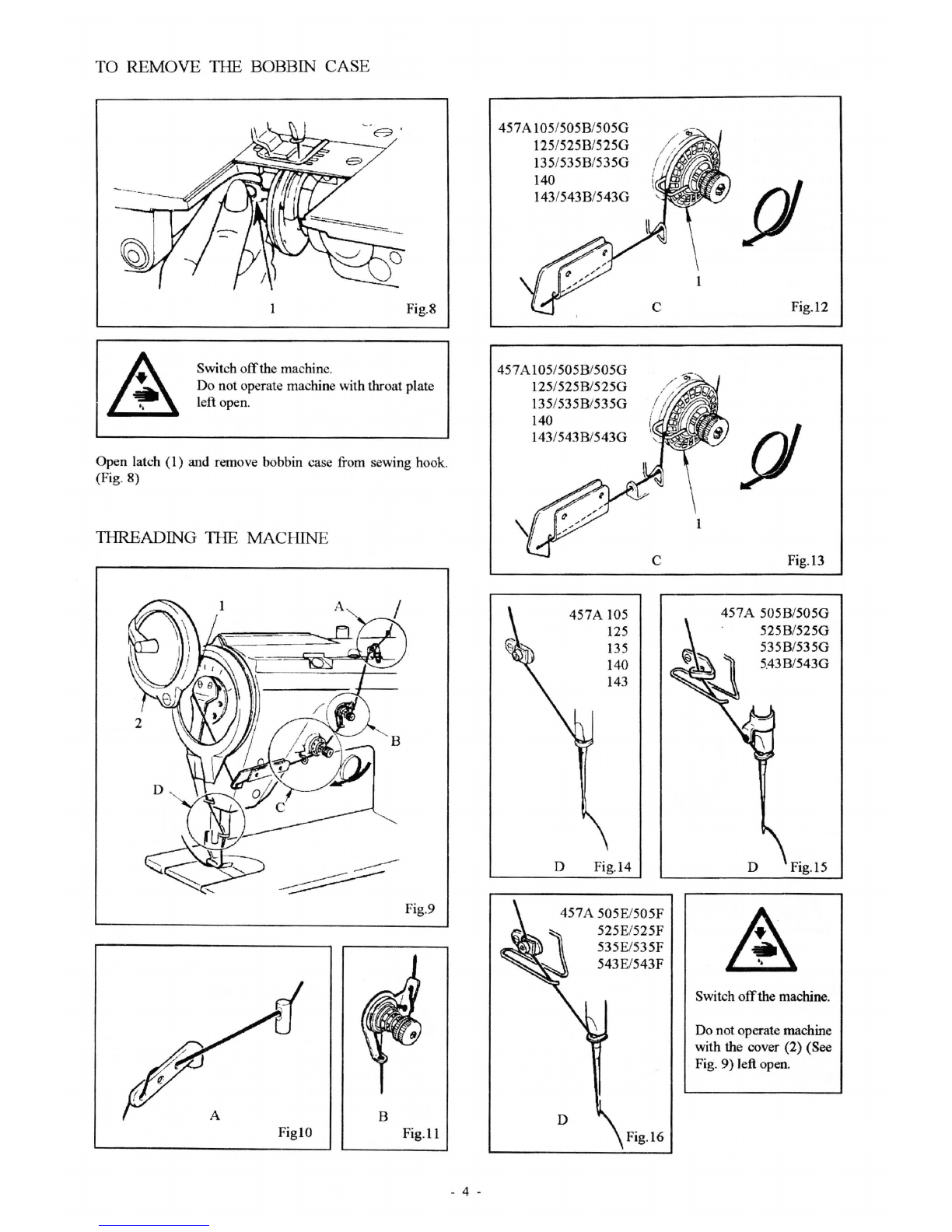

To remove the bobbin case · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4

1breading

fue

machine · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4

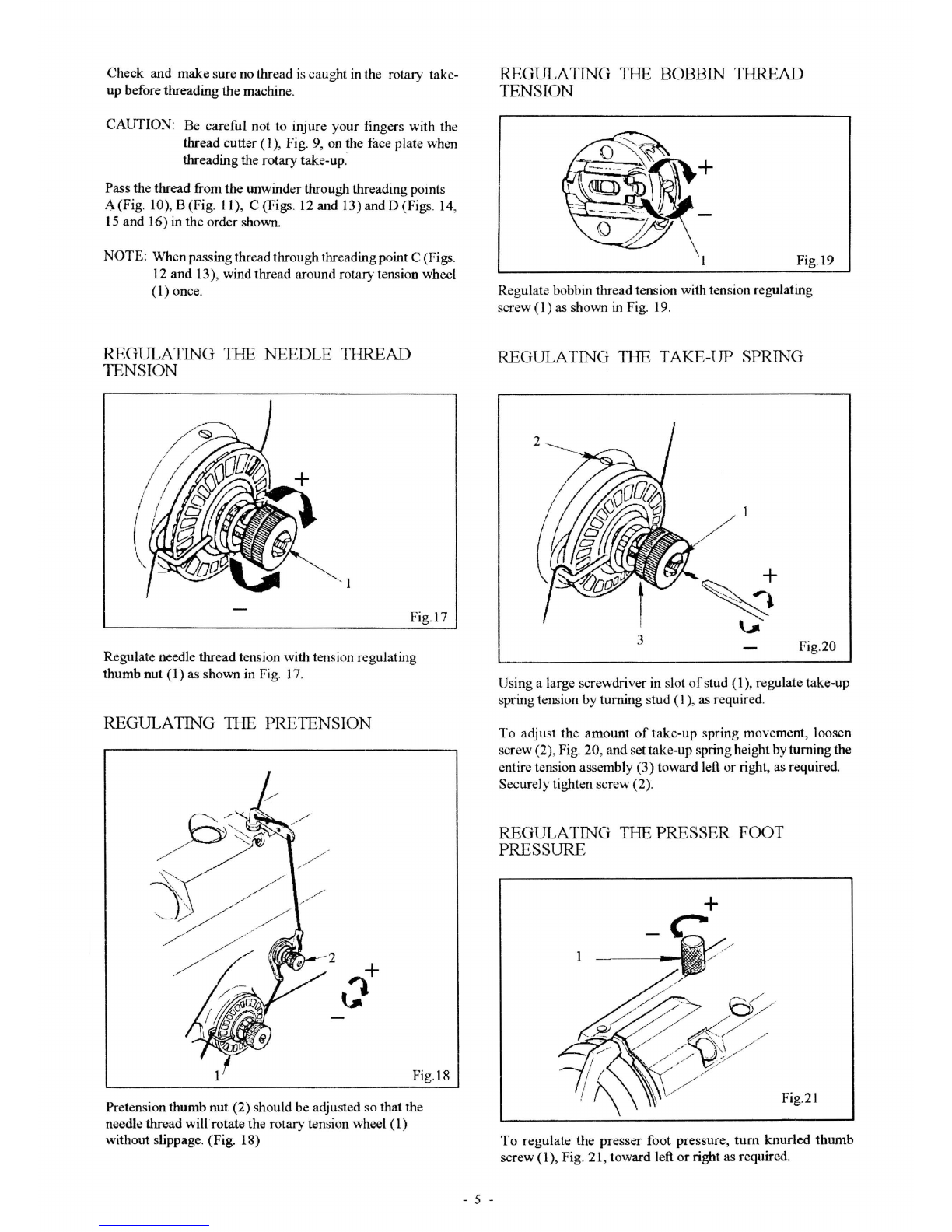

Regulating the needle thread tension · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5

Regulating the pretension · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5

Regulating the bobbin thread tension · •· · · · · · • · • · • · · · · · · · · · · · · · · · • · · • · · • · • 5

Regulating the take-up spring • · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5

Regulating the presser foot pressure · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5

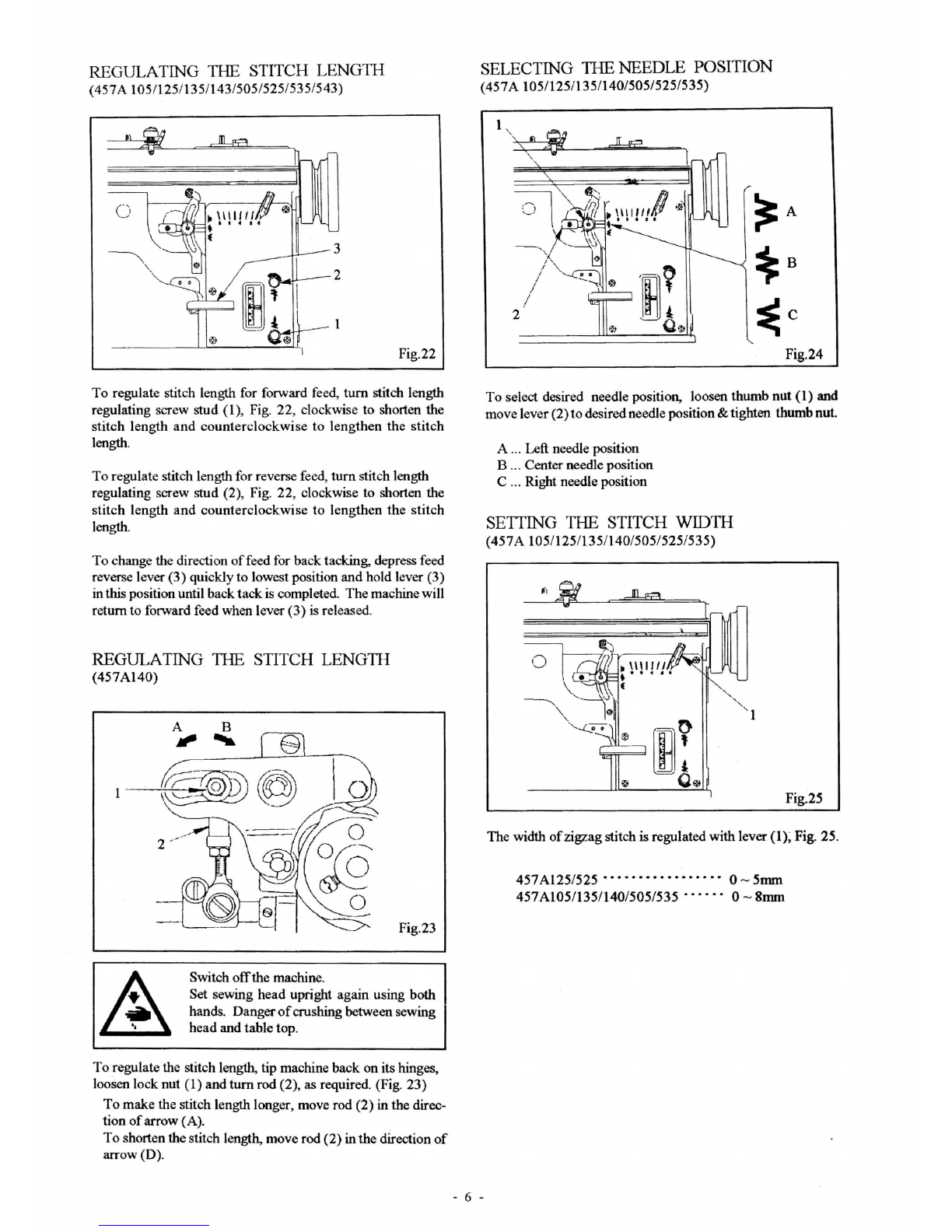

Regulating the stitch length · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 6

(457A105/125/135/143/505/525/535/543)

Regulating the stitchlength (457A140) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • • · 6

Selecting the needle position · · · · · · · · · · · · · · · · · · · · · · · · · ·

··

· · · · · · · · · · · · · · · · 6

(457A105/125/135/140/505/525/535)

Setting the stitch width · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • • • · 6

(457A105/125/135/140/505/525/535)

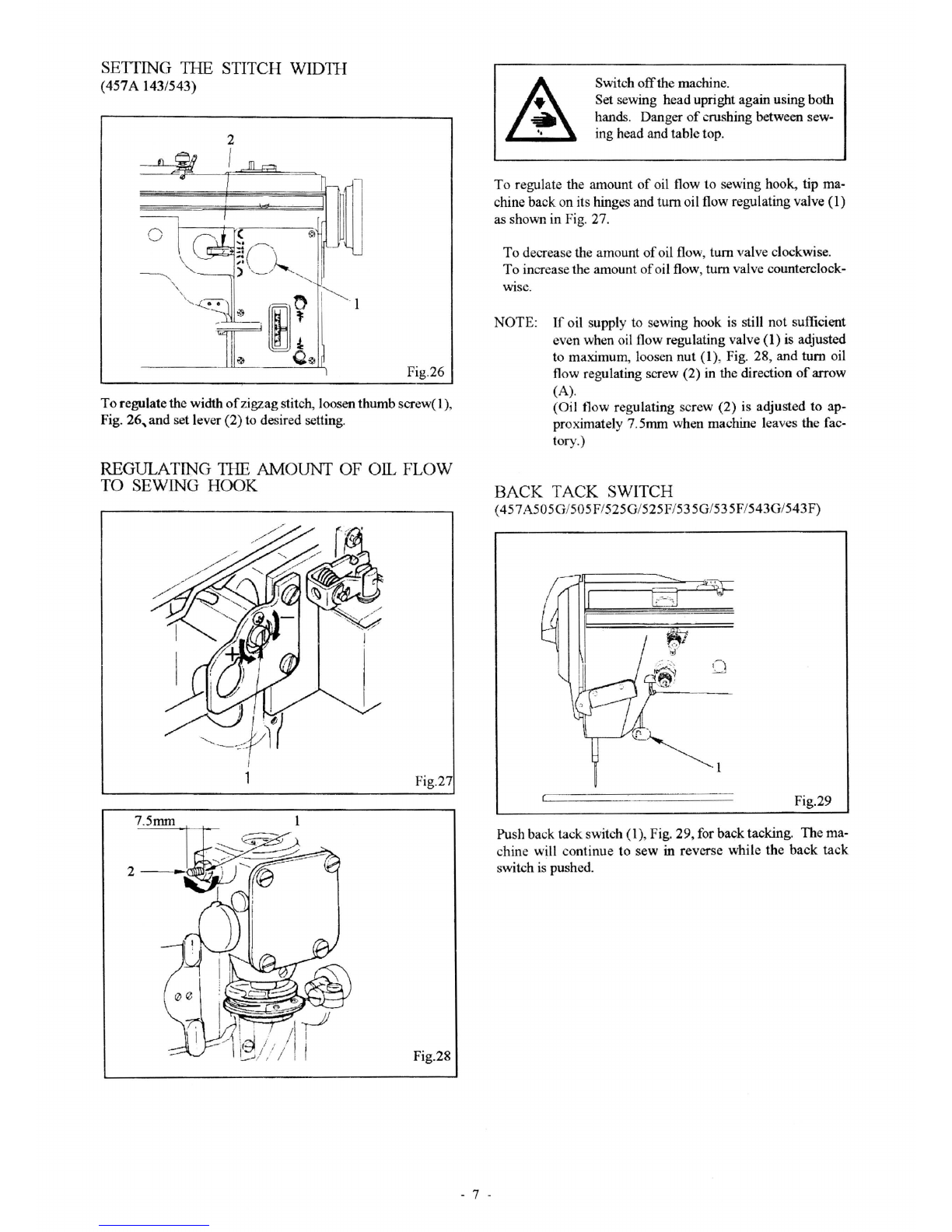

Setting the stitch width (457A 143/543) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

Regulating the amount

of

oil flow to sewing hook · · · · · · · · · · · · · · · · · · · · · · · · · · 7

Back tack switch · · · · · · · · ··· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

(457A505G/505F/525G/525F/535G/535F/543G543F)

Adjusting

fue

slack needle thread regulator · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 8

(457A505E/505F/525E/525F/535E/535F/543E/543F)

Adjusting the bobbin thread holder · · · · · · · · · · · · •· · · · · · · · · · · · · · · · •· •· · · · · · 8

(457A505/525/535/543)

Adjusting

fue

length

of

thread end in needle eye · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 8

(457A505/525/535/543)

Adjusting the needle tread holder puller · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · •• 8

(457A505E/505F/525E/525F/535E/535F/543E/543F)

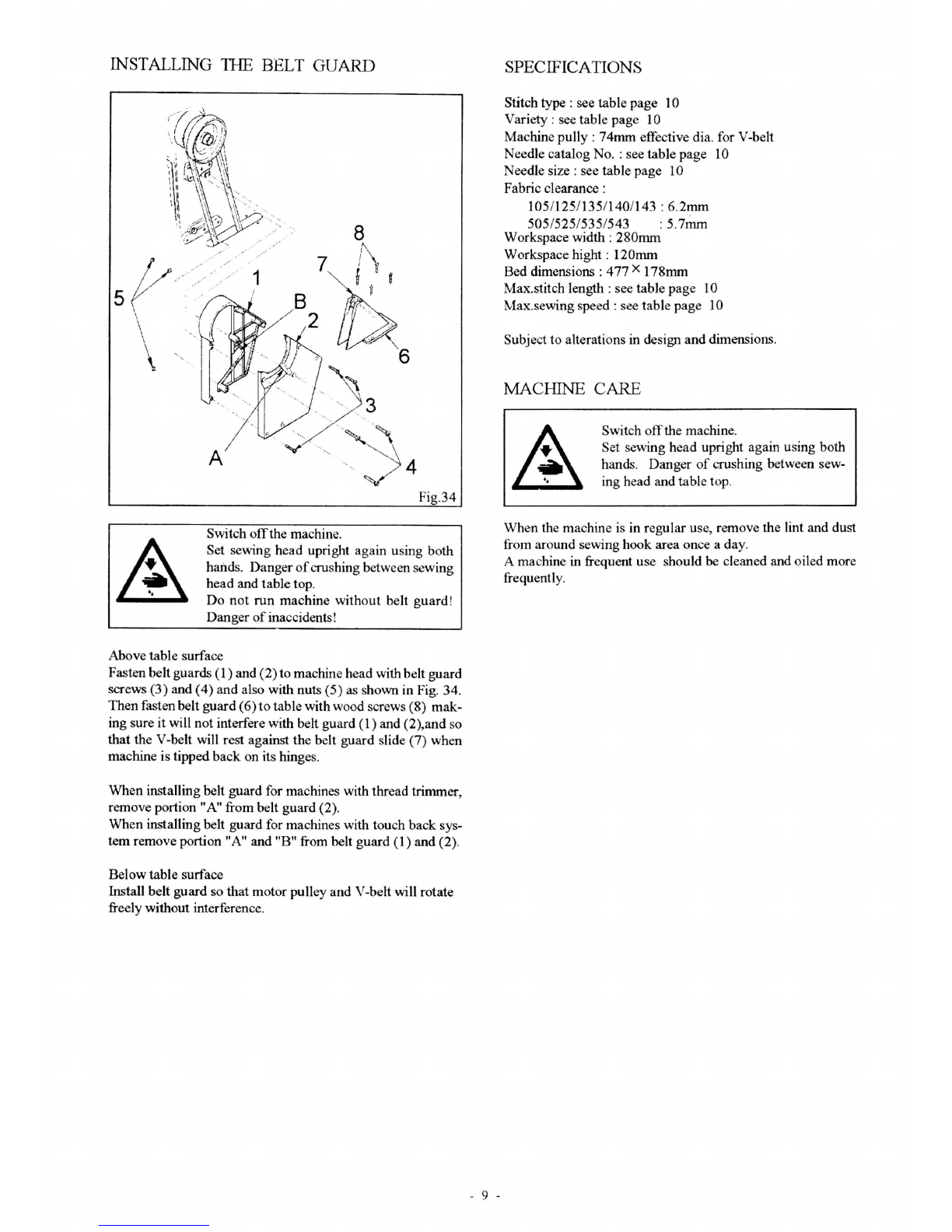

Installing ilie belt guard · · · · ··· · · · · · •· · · · · • • • · · · · • • · •· · • · · · · · · · · · · · · · • • • 9

Specifications · · · · · · · · · · · · · · · · · · · • · · · · · · · • · • • · • · • • • · • · · · · · · · · · · · · · · • 9

Machine care · · · · · · • · · · · · · •• · · · · · · · · · • · · · · · · • · · •· · · · · · · •· · · • • • · · · · · • 9