Melon Slice User manual

INDEX

Pages:

Operations and Safety

Frame Size 2

Saddle Adjustment 3-4

Safety Checklist 5-7

Helmets 8

Riding Safely 8-11

Operating Gears and Brakes 12-13

Bicycle Assembly and Tuning

Assembly Instructions 14-21

Folding Instructions 22-24

Bicycle Care

Basic Maintenance 25-29

Wheels and Tires 30-39

Headset 40-42

Brakes 43-45

Drivetrain 46-48

Crank Set 49-52

Chain 52-54

Reflectors 54-55

Troubleshooting 56-58

Warranty 59

1

FRAME SIZE

Choosing the appropriate frame and wheel size is impera-

tive when purchasing a new bicycle. For safe riding the size

of your bicycle should properly match your build.

The melon slice folding bike is provided as a one size fits all

bicycle. It can accommodate a height range of 4’8” to 6’3”

in riders. The rider weight limit is 240 lbs.

WARNING:

For safe riding your bicycle should match your

size correctly, otherwise you may lose control

and fall. Ideally there should be a minimum clear-

ance of 25mm between the crotch of the in-

tended rider and the top frame tube of the bike,

while the rider straddles the bicycle with both

feet flat on the ground.

Clearance over the top of the frame ensures that the rider

can safely stand astride the bike when forced out of the

saddle, such as stopping at traffic lights. Frame clearance

is not usually an issue with folding bikes as the frame’s top

tube is only 23.5”.

The melon slice is not designed to fit children. It is not

recommended that children ride this bike.

2

Warranty

Melon Bicycles warrants that any bicycle purchased from

an authorized Melon Bicycle dealer, or from Melon Bi-

cycles directly shall be free from defects in materials and

workmanship for a period of five (5) years from the date

of purchase. This warranty shall extend only to the origi-

nal owner of the bicycle. All components are covered by

the components manufacturers’ warranties. Paint and

finish are covered for one (1) year from the date of pur-

chase by the original owner.

This warranty is void in any instance of abuse, misuse,

neglect, improper assembly, improper maintenance or

from the addition of any components not intended for

the specified model. This warranty shall only be valid if

the bicycle is used for its intended purpose, and shall be

voided by the use of the bicycle for any improper pur-

pose, including, but not limited to, jumping, stunt riding,

riding with heavy loads, or any other non-standard usage.

In the event of any issue, Melon Bicycles may seek to

resolve the problem by replacing the damaged part with

the same or comparable part. Any dealer labor charges

or shipping expenses are the sole responsibility of the

bicycle owner. Correction and/or replacement, in the

manner described herein shall constitute full compliance

with any and all warranties. In no instance shall any war-

ranty extend beyond the purchase price of the bicycle.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND

INLIEU OF ALL OTHER WARRANTIES WHETHER WRIT-

TEN OR IMPLIED.

The terms of this warranty may change without notice.

59

Problem Possible Reason Possible Solution

Chain jumping off

chainwheel sprocket

or chainring

Chainring out of true Re-true if possible or

replace

Chainring loose Secure mounting

bolts

Chainring teeth bent

or broken

Repair or replace

chainring/set

Rear to front derail-

leur side-to-side

travel out of adjust-

ment

Alter derailleur travel

Incorrect gear shifting Derailleur cables

sticking/stretched/

damaged

Lubricate/tighten/re-

place cables

Front or rear derail-

leur not adjusted

properly

Alter derailleurs

Indexed shifting not

adjusted properly

Alter indexing

Steering not accurate Wheels not aligned in

frame

Align wheels correctly

Headset loose or

binding

Adjust/secure head-

set

Front forks or frame

bent

Consult bicycle

mechanic for frame

realignment

TROUBLESHOOTING (Cont’d)

58

SADDLE ADJUSTMENT

Saddle Height:

When your saddle height is adjusted properly, you should

have a small bend in your knee when your foot is at the bot-

tom of the pedal stroke and you are sitting comfortably. If

you have the saddle height too low, you will lose pedaling

efficiency and will have to work much harder-we definitely

don’t want that. If you have the saddle height too high, you

will be stretching just to pedal and your pelvis will have to

rock side to side with each pedal stroke. Adjust the saddle

height by opening and then closing the quick release lever.

3

Saddle Tilt:

For the most comfortable riding position, adjust the saddle

to be as level as possible. Newer riders sometimes desire

the saddle to be pointed downward to ease discomfort in

the groin area. This adjustment will make it difficult to stay

in the saddle, slightly unsafe, and will cause more problems

for the body in the long run. The melon slice folding bike is

provided with a comfortable well padded seat. We suggest

that you allow yourself time to get acclimated to the seat in

the level position if you are new to riding. Adjust the angle

of the saddle by loosening the nut under the saddle on the

right side of the seat post.

Saddle Front to Back:

This adjustment determines how well balanced you are on

the bicycle. If you move the saddle forward, you will end up

with more of your weight being supported by the saddle it-

self. If you move the saddle backwards, you will end up with

more of your weight being supported by your arms and

hands. You can experiment to find the sweet spot that is the

most comfortable riding position for you. Adjust the saddle

position by loosening the nut under the saddle on the right

side of the seat post.

4

Problem Possible Reason Possible Solution

Brake arms loose Secure mounting

bolts

Wobbling wheel Axle broken Replace axle

Wheel out of true True wheel

Hub cones loose Tighten hub bearings

Headset binding Alter headset

Hub bearings col-

lapsed

Replace bearings

Knocking or shud-

dering when brakes

applied

Bulge in the rim or

rim out of true

True wheel or consult

a bike mechanic

Brake mounting bolts

loose

Secure bolts

Brakes out of adjust-

ment

Center brakes and/

or adjust brake block

toe-in

Forks loose in head

tube

Secure headset

Constant clicking

noises when pedaling

Stiff chain link Oil chain

Loose pedal axel/

bearings

Alter bearings/axle

nut

Loose bottom brack-

et/bearings

Alter bottom bracket

Bent bottom bracket

or pedal axle

Replace bottom

bracket or pedals

Loose crankset Tighten crank bolts

Grinding noise when

pedaling

Pedal bearings too

tight

Adjust bearings

Bottom bracket bear-

ings too tight

Adjust bearings

Chain fouling derail-

leurs

Adjust chain line

Derailleur jockey

wheels dirty/binding

Clean and oil jockey

wheels

57

Problem Possible Reason Possible Solution

Slipping Chain Excessively worn or

chipped chainring

Replaice chainring

Chain worn/stretched Replace Chain

Stiff link in chain Oil or replace link

Non compatible

chain/chainring

Consult a professional

bicycle mechanic

Brake not working

correctly

Brake blocks worn

down

Replace brake blocks

Brake blocks/rim

greasy,wet or dirty

Clean blocks and rim

Brake cables are

binding/stretched/

damaged

Clean/adjust/replace

cables

Brake levers are bind-

ing

Alter brake levers

Brakes out of adjust-

ment

Center brakes

Frequent punctures Inner tube old or

faulty

Replace inner tube

Tire tread/casing

worn

Replace tire

Tire incompatible to

rim

Replace with correct

tire

Tire not checked after

previous puncture

Remove any sharp

objedts from tire

Tire pressure too low Inflate tire to correct

pressure

Spoke protruding into

rim

File down spoke

When the brakes are

applied they squeal/

squeak

Brake blocks worn Replace brake blocks

Brake blocks/rim

greasy,wet or dirty

Clean blocks and rim

Brake block toe-in

incorrect

Correct block toe-in

TROUBLESHOOTING

56

SAFETY CHECKLIST

Safety checks are an important part of any ride. In conjunc-

tion with the recommended maintenance in this manual

it is also suggested that a thorough inspection should be

undertaken fortnightly, tightening all nuts and bolts, replac-

ing worn and damaged parts and ensuring all components

are in their correct positions.

WARNING:

Body parts and other objects should be kept

clear from the moving components of the bicycle

when in use, such as the spinning wheels and the

moving chain. When riding always wear appropri-

ate footwear – i.e. shoes that will grip the pedals

and no sandals. Refrain from jumping with your

bike. Jumping puts enormous stress on many

components of your bicycle, especially your front

fork.

Prior to every ride please complete the following safety

checks:

1. Brakes

• Check front and rear brakes are working correctly

• Check brake control cables for wear and ensure they are

oiled and properly adjusted

• Check brake control levers are lubricated and securely

fastened to the handlebar.

• Check brake shoe pads for wear and their positioning in

relation to the rims

5

2. Wheels and Tires

• Check tire pressure is as recommended according to the

specification displayed on the tire sidewall

• Check tires for tread and ensure they do not have any

bulges or excessive wear.

• Check all wheel spokes are firm and are intact

• Check rims run true and are without any obvious buckles

or kinks

• Check that axle nuts are tight. For bicycles equipped

with quick release axles, ensure locking levers are ten-

sioned appropriately and in the closed position.

3. Saddle

• Check the clamp underneath the saddle is firmly secured

to the saddle post

• Check frame clamping mechanism is tightly fastened

• Ensure that the minimum insertion mark cannot be seen

on the saddle pillar

4. Steering

• Check that the handlebar and stem enable correct

steering and are properly adjusted and tightened

• Check that the setting of the handlebars is correct in

relation to the forks and the direction of travel

• Check the head set locking mechanism is appropriately

fixed and fastened

• If handlebar extensions are fitted check they are posi-

tioned and secured correctly

• Ensure the minimum insertion mark cannot be seen on

the handlebar stem

• Ensure the ends of the handlebars and bar ends are

covered or capped.

5. Chain

• Check the chain is lubricated, clean and runs freely

• In wet or dusty conditions service the chain more fre-

quently

6

WARNING:

The reflectors and the reflector mounting brackets

must not be removed from your bicycle. Doing so

may reduce your visibility to other road users, po-

tentially jeopardizing your safety. Serious injury or

death may result if you are hit by another vehicle

unable to see you.

WARNING:

Reflectors should always be used in conjunction

with powered lighting when riding at night, at

dawn, dusk, or at any other time in poor visibility.

Failure to do so is dangerous and may result in

serious injury or death.

When riding at night, in addition to the reflectors, the

bicycle should also be equipped with powered lights. Re-

flective tape on the rider’s clothing is also recommended to

increase visibility.

55

REFLECTORS

The reflectors fitted to your bicycle are not only an impor-

tant safety feature, but a legal necessity as well. Your bi-

cycle should come equipped with one white (front), one red

(rear), and two orange (wheel) reflectors. Each pedal should

also have two orange reflectors fitted.

As a part of your bicycle maintenance ensure that all reflec-

tors are clean, intact and securely fastened. The front and

rear reflectors should be vertically aligned, and the wheel

reflectors should be secured opposite the valve within

75mm of the rim.

To install a chain on a derailleur geared bicycle:

• Thread the chain around the chainwheel, rear sprocket

and derailleur cage with the rivet facing away from the

bicycle.

• Bring the two ends together within the special tool and

punch the rivet into place. Take care not to push rivet

too far through the side plate. Derailleur geared bicycles

can now be fitted with some new types of chains that do

not require special tools to remove or replace. Instead,

a new, special, disposable connecting link is used every

time you disassemble the chain. For further details on

these particular chains, including installation guidelines,

refer to the manufacturer’s specific instructions.

54

6. Bearings

• Check headset, wheel bearings, pedal bearings and bot-

tom bracket bearings

• Check all bearings are oiled, run smoothly and show no

signs of excess movement, grinding or rattling

7. Cranks and Pedals

• Check cranks are securely fastened to the axle and are

straight

• Check pedals are properly and firmly attached to the

crank

8. Derailleurs

• Check the rear mechanism is operating appropriately

• Check control levers are securely anchored

• Check derailleurs, control cables and shift levers are suf-

ficiently lubricated

• If the gear components come with a separate, specific

manual, refer to this for further information

9. Frame and fork

• Check that the frame and fork are straight and intact.

• Replace if either is bent or broken.

10. Safety & Accessories

• Check that all reflectors are attached correctly and vis-

ible

• For riding at night, fit fully functioning dynamo or bat-

tery powered lights

• Check that the bell is fully operational

• Check all additional components on the bike are appro-

priately secured and functioning

7

When riding your bicycle it is recommended that you always

wear an appropriately fitting Country Standards Approved

bicycle helmet.

A bicycle helmet must:

• Carry the Country Standards Approved

• Fit properly

The helmet should be:

• Well ventilated

• Comfortable

• Lightweight

HELMETS

WARNING:

The wearing of helmets is mandatory in many

areas.

Noncompliance may result in an enforceable pen-

alty

RIDING SAFELY

General Rules

• The same road rules used for vehicles apply to cyclists.

Obey the road rules at all times, such as giving way to

pedestrians, and stopping at red traffic signals

• Notify the Road Traffic Authority in your state if further

information is required.

8

To remove a chain on a derailleur geared bicycle:

• Fit the rivet tool so that the punch pin is centered over

any one of the chain rivets.

• Push the rivet almost all the way out, then back out the

punch and remove he tool.

• Holding the chain on both sides of the punched rivet,

bend it slightly to release the link from the rivet.

Adjustment and Replacement

The chains on derailleur geared bicycles are automatically

tensioned by the rear derailleur making manual adjustment

of the chain unnecessary. The chains on derailleur geared

bicycles are narrower, meaning a special tool is needed to

complete any of the procedures.

Check that all links of the chain move freely. Replace the

chain if it appears stretched, broken or causes problems

when changing gears.

53

CHAIN

Inspection and Lubrication

Regular inspection and maintenance of your chain is vital to

guard against premature wear. At least monthly, or after rid-

ing in wet, muddy or dusty conditions, the chain should be

cleaned and lightly oiled. Any excess oil should be removed

and care taken to ensure the lubricant does not come into

contact with the tires or rim braking surfaces.

Lubrication and Replacement - Cartridge Bottom Bracket

Freeplay cannot be removed from a cartridge bottom

bracket. It is a sealed unit and is designed to be replaced

as an entire unit when it is worn out. Once the cranks have

been removed a specific extraction tool is required to re-

move the cartridge bottom bracket. Consult your specialist

bicycle dealer for further advice regarding this process.

52

• Ride on the right side of the road and never against the

traffic.

• Take extra care when attempting to overtake other ve-

hicles and at intersections.

• Indicate intended actions, such as turning or stopping,

by using appropriate hand signals.

• Ride predictably and in a straight line.

• Always ride defensively. You may be difficult to see to

other road users.

• Closely observe the riding terrain. Avoid obstacles

such as pot holes, gravel, wet road markings, oil, curbs,

speed humps and drain grates.

• Be alert. Watch for such things as motorists opening

doors or backing out of concealed driveways.

• Sound your bell for a warning when required.

• Train and tram tracks should be crossed at a 90 degree

and preferably walk your bicycle over.

• Know how your bicycle operates. Practice braking, gear

shifts and if fitted, using toe clips and straps.

• Always apply the rear brake first, then the front when

braking. The front brake is more potent and if it is not

used properly you may lose control and fall.

• Allow reasonable space between yourself and other

vehicles and objects when riding and stopping. Take

note of weather conditions and its possible impact on

safe braking distances. e.g.. Wet riding surfaces increase

braking distances.

• Use leg clips or elastic bands if you are wearing loose

trousers to stop them catching in the chain.

• Ensure your vision or control of the bicycle is not ob-

structed by any items you may be transporting.

• Do not use items that may impede your hearing. e.g.

headphones

9

Wet Weather

• Ride more cautiously in wet weather. Avoid sudden

braking, slow overall riding pace and approach corners

more carefully.

• Brake sooner, stopping distance increases in wet condi-

tions.

• Remember pot holes and slippery surfaces such as line

markings and tram tracks all become more hazardous in

the wet. Try to avoid where possible.

• Cornering traction will also be reduced in wet weather.

Night Riding

• Wear reflective and light colored clothing.

• Reflectors should be fitted correctly to the bicycle and

clearly visible. Riding in the dark should never be un-

dertaken without fully operational front and rear bicycle

lights. The use of bicycle lights is mandatory for night

riding in most Australian States.

• Attach a fully operational lighting set. Lights should have

a white front lamp and a red rear lamp.

• Use a flashing rear light to improve visibility.

• Charge batteries if battery powered lights are to be

used. Check wiring connections for dynamo powered

lights.

• Avoid riding at night if possible. If not, slow down and

opt for familiar roads with street lighting when able

On Road Off Road

• The melon slice is designed for on road riding. Extra

care should be taken when riding on dirt or gravel sur-

faces.

10

Three Piece Crank Replacement

1. Place the crank arm onto the axle.

2. Use a soft mallet to gently tap the crank arm.

3. Reattach the washer and secure the flange nut or bolt

securely to a torque of 27Nm.

4. Replace the dust cover.

After fitting new three piece cranks some additional

maintenance is required as components can become

loose with use. The following adjustments should

be made after several hours of riding, and repeated

two or three times after further use. There after the

cranks should remain secure.

1. Remove the dust cap.

2. Gently tap the crank arm with a mallet.

3. Re-tighten the flange nuts, and refit the dust caps.

51

Lubrication and Adjustment – Three Piece Cranks (Cot-

terless Cranks)

To adjust:

• Turn the lockring on the left side anti-clockwise.

• Turn the adjusting cup until appropriately set.

• Carefully re-fasten the lockring without disturbing the

cup adjustment.

To disassemble:

1. Remove the cranks from the axle.

2. Turn the left side lockring anti-clockwise and remove.

3. Turn the adjusting cup anti-clockwise and remove.

4. Remove the left ball retainer and slide the axle out of

the frame to the left.

5. Turn the right side fixed cup anti-clockwise and remove,

as well as the right ball retainer.

Once the crank is dismantled clean all bearing surfaces and

the ball retainers and check for wear. Replace any damaged

parts and pack grease into the ball bearing retainers. Re-

assemble the crank in the reverse order of the procedure

listed above.

Three Piece Crank Removal

To remove Cotterless cranks you will need to use a spe-

cific removing tool. Follow the outline below to guide you

through the process.

1. Use a coin or a screwdriver to remove the dust cap.

2. Remove the flange nut or bolt and washer after loosen-

ing.

3. Attach the removing tool into the crank and tighten.

4. Turn the screw bolt until the crank comes away from the

axle.

50

Pedaling Technique

• Place the ball of your foot on the centre of the pedal.

• Ensure your knees are parallel to the bicycle frame when

pedaling.

• Keep your elbows slightly bent. This will help to absorb

shock.

• Learn how to use the gears correctly

Hill Technique

• Prior to a climb, gear down and continue gearing down

as necessary in order to sustain pedaling speed.

• By standing up on your pedals you will be able to gener-

ate greater power from each turn of the pedal. This is

useful if you are straining and are using the lowest gear.

• Use the high gears on a descent to prevent rapid pedal-

ing.

• Take extra care when descending. Do not exceed a com-

fortable speed and maintain control.

Cornering Technique

• Before entering a corner brake slightly and begin to lean

your body into the corner.

• The inside pedal should be held at the 12 o’clock posi-

tion and the inside knee angled slightly in the direction

you are turning. The other leg should be kept straight.

• Avoid pedaling through fast or tight corners.

As suggested by the Consumer Affairs Department

riding bicycles with small wheel diameter at excessive

speeds can lead to instability and is therefore not recom-

mended.

CAUTION:

When riding downhill never take your hands off

the handlebars, or feet off the pedals

11

OPERATING GEARS AND BRAKES

Derailleur Gears

Derailleur gears are the most common type of gear sys-

tems used on bicycles. They are the changing mechanism

used to move the drive chain up and down a series of cogs

or sprockets (the cluster or cassette stack) at the rear of

the bicycle and across the chainwheel at the front of the

bike (if fitted). Multispeed bicycles today can range form

5-6 gears to as many as 30. Rear derailleurs are fitted to all

multispeed bicycles while front derailleurs are only present

on those bicycles with the higher number of gears. Gears

enable the cyclist to select the most appropriate pedaling

resistance best suited for the riding conditions. The more

gears fitted to the bicycle the greater choice available to

the rider.

Operating Principles

Although the number of gears present on multispeed bi-

cycles varies greatly, how the gears function remains the

same. The right shifter works the rear derailleur and the left

shifter works the front derailleur. If the pedals are station-

ary or rotating backwards, gears cannot be changed. They

can only be altered when pedaling forward. To achieve a

successful gear change, either moving up or down in gears,

the pedaling pressure must be relaxed. Failure to ease the

pressure when changing gears may result in bicycle damage

or could even cause the rider to lose control. If a rubbing

sound is detected after attempting to alter gears, adjust the

shifter until the sound ceases. Generally the lower gears are

for ascending hills and the higher gears are for descending.

12

WARNING:

Never attempt to force a pedal into a different

sized bicycle crank.

CRANK SET

Inspection and Maintenance

Every month the crank set should be checked to ensure that

it is properly adjusted.

For Three Piece Cranks:

• Check that the crank axle nuts are tight.

• Adjust the bottom bracket bearings as necessary.

• Remove the chain and test for crank movement on the

axle by attempting to move the cranks from side to side

with your hands. Only very slight movement in the bot-

tom bracket should be noted.

• Rotate the cranks. Adjust and oil if they do not spin

freely or a grinding noise is detected.

• Check the chainrings for any broken teeth, and clean off

any excess dirt and grease.

CAUTION:

Always ensure that your Three Piece cranks are

firmly secured before riding. Riding with loose

cranks is potentially hazardous to both the rider

and condition of the crank arms.

49

Attachment

Each pair of pedals has a specific right and left pedal. It is

important that a pedal is never forced into the incorrect

crank arm as the thread is different for the two pedal sides.

The right pedal, as indicated by the “R” stamped on the

end of the axle, screws into the crank on the chainwheel

side of the bicycle in a clockwise direction. The left pedal

is marked with an “L” on the axle, and it is attached to the

other side in an anti-clockwise direction.

To attach, place the pedals into the correct crank arm and

wind on by hand as tightly as possible in the appropriate

direction. Use a 15mm wrench to fasten more securely.

Removing a pedal is the reverse process of attaching. The

right pedals needs to be turned anti-clockwise and the left,

clockwise.

Before fitting any new pedals ensure that the axle thread

size is compatible with the cranks on your bicycle. The two

types of cranks available each have different axle threads.

Cranks that are a one piece design have no separate axle

and are compatible with pedals that have a 1/2” thread.

Three piece crank sets with a separate left and right crank

use a slightly larger 9/16” thread.

48

Hand Grip Shifters

Hand grip shifters are built into the hand grip and attach to

the handlebars. Unlike other types of shifting mechanisms

the hand grip shifters mean you do not need to change

your hand position to select different gears. The rider just

simply twists forwards or backwards dependent upon their

gear selection. By twisting the right shifter toward you, a

lower gear is chosen as a larger rear cog is selected. Twist-

ing this shifter away from you has the opposite effect; a

higher gear is selected as a smaller rear cog is engaged.

Turning the left shifter forward or away from you activates

a smaller, front chainwheel, and a larger, front chainwheel

is engaged by twisting it backwards. The number of gear

changes to occur at any one time corresponds with how

many turns are made of the shifter.

Brakes

V-brakes are activated by pulling of the brake hand levers

located on the bike’s handlebars. The right brake lever

activates the rear brake and the left hand lever activates

the front brake. Always apply the rear brake first and then

slowly add pressure to the front brake.

WARNING:

Applying the front brake first or with a dispropor-

tionate amount of pressure can cause the bike

rider to flip over the front wheel.

13

BICYCLE ASSEMBLY AND TUNING

You will need the following tools for the assembly and main-

tenance of your melon:

Before you unpack your new melon, make sure to keep the

box in the upright position. Open the box from the top.

Assembly Instructions:

14 mm wrench

15mm wrench

Philips screwdriver

Hex allen wrenches:

2mm,2.5mm,5mm, and 6mm

Needle nose pliers

Tire pump

14

Inspection

Every month the pedals should be inspected. Check that:

• Pedals are securely fastened into the cranks. Loose

pedals are a potential hazard for both the rider and the

integrity of the cranks.

• Pedal bearings are adjusted correctly. Alter, grease or

replace if any roughness or looseness is detected in

the pedal bearings when the pedals are moved up and

down, laterally or rotated by hand.

• The front and rear pedal reflectors are clean and firmly

attached.

• If toe clips are fitted, ensure that they are fastened

tightly to the pedals.

Lubrication and Adjustment

The maintenance your pedals need will depend upon

whether or not they can be disassembled to enable access

to the internal bearings and axle. If they cannot be disas-

sembled, every six months a small amount of oil should be

injected onto the inside bearings of pedals. Pedals that can

be fully disassembled should have the bearings removed,

cleaned and greased every six to twelve months. However,

due to the complexity of this task it is recommended that it

be completed by a professional

bicycle mechanic.

47

DRIVETRAIN

The drivetrain consists of the

pedals, chain, chainwheel,

crank set, and freewheel.

These are all the compo-

nents of the bicycle that

transmit power to the rear

wheel.

Pedals

There is a vast range of pedals available, designed for many

different uses. Pedals fitted with toe clips and straps aim to

make the pedaling process easier for the rider. The toe clips

and straps ensure the cyclist’s feet stay correctly positioned

and cause a pulling force, as well as a downward pressure,

to be generated on the pedals. To get the full benefit of

these pedals it is recommended that the rider wear cycling

shoes especially designed for use with toe clips. Consult

your bicycle dealer for instruction on how toe clips and

straps operate.

WARNING:

Pedals fitted with toe clips and straps require a

certain level of skill to operate safely. Riders should

repeatedly practice using such pedals in areas free

from traffic, hazards or obstacles, until operation

becomes a reflex action. Failure to do so could

result in the cyclist losing control of the bicycle and

falling. It is also recommended that the straps be

kept loose initially and gradually tightened as the

rider’s skill in using the pedals increases. However,

toe straps should never be tight when riding in

traffic.

46

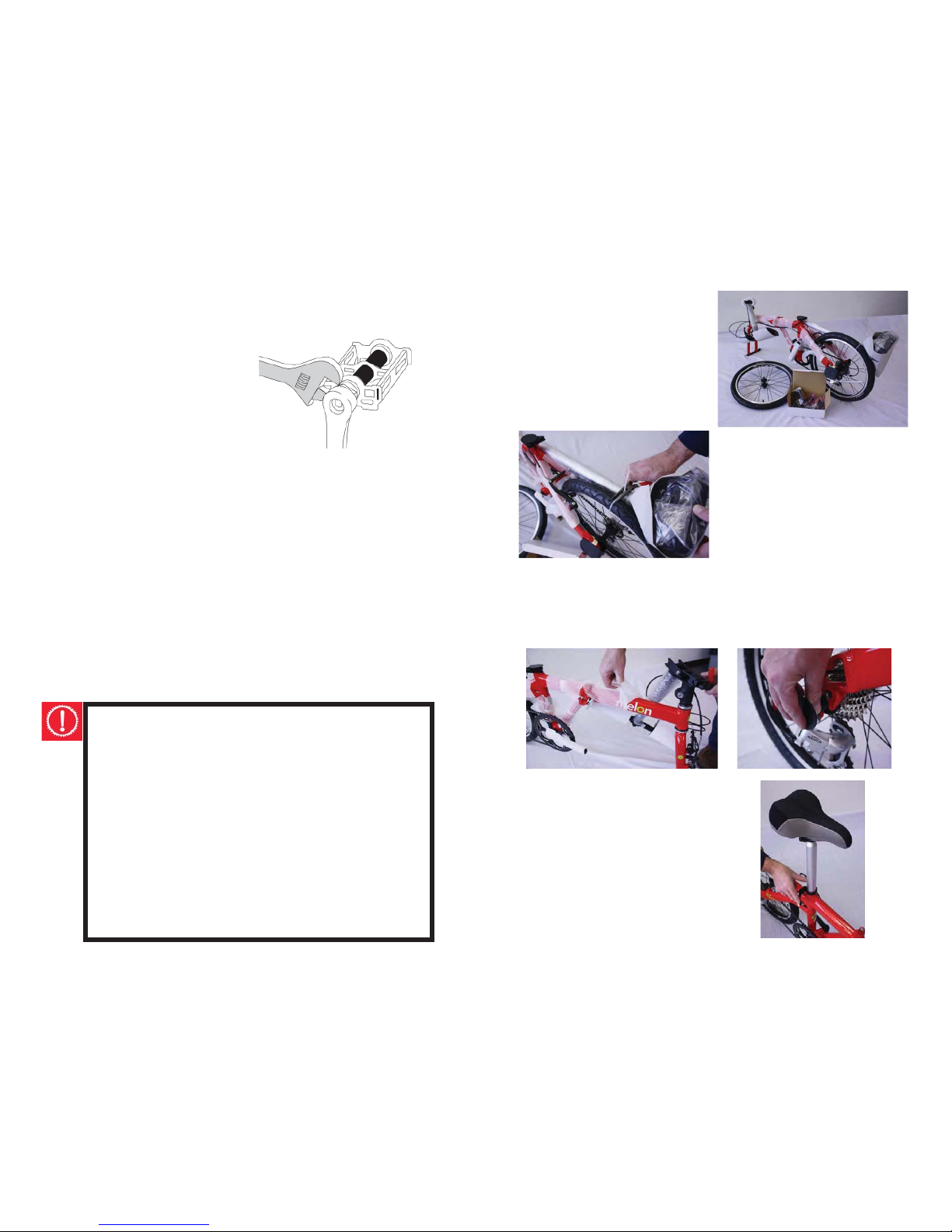

You will find three pieces in-

side: the bike, the front tire,

and a box with pedals and

reflectors.

Cut the plastic ties holding

the seat post to the frame

and the piece of foam to the

stem joint.

Remove the foam wrap and cardboard from the bikes

frame. Take off the plastic guards around the top of the

seat tube, both sides of the rear axle, and the bottom of

the front fork.

Spread some grease around the

bottom outside of the seat tube.

Insert the seat post into the seat

tube and tighten the quick release

lever.

15

Raise the stem and tighten it in place by turning the stem

joint.

Release the front brake and

slide the front tire into posi-

tion. Loosen the bolts on

either side of the front wheel

axle and push the axle into the

top of the fork slots firmly. At

the same time, you will need

to make sure that the wheel is

properly centered in the fork.

When you think you have got it

right, tighten the axle nuts with

a 15mm wrench (turn clockwise

on both sides). Spin the wheel

to make sure that it is properly

centered in the fork and does

not wobble. If the wheel is not

centered, loosen the nuts and

try again. Re-attach the front

brake when finished.

16

Brake Shoe Replacement

Check your brakes shoes monthly for any indication of wear.

If the pads are worn past the “wear line” indication (See

diagram), the brake shoes need to be replaced. Always re-

place the brake shoes in pairs – never one side only.

For replacement, disconnect the holding mechanism spe-

cific to your brake type -i.e. a hexagonal nut or an Allen

screw arrangement, or a combination of both. Remove the

worn brake shoes paying careful attention to the order and

position in which the various curved washers and spacers

are attached. Fit the new brake shoes, and tune the angle

and the clearance to the rim as required. Typically, before

the rim clearance can be adjusted the control cable anchor

bolt needs to be loosened and then the cable adjusters

fasten and the cable tensioned. (Refer to the Installation/

Adjustment section relevant to your brake type for detailed

instructions.) Once the adjustments are complete, securely

fasten the brake shoes in place and test that the brakes

are functioning correctly. Do not ride the bicycle until the

brakes are working effectively.

45

Brake Inspection

The brake levers and the brake pads are the two main

components that need to be checked to ensure your brakes

are functioning effectively. Positioning of the brake levers

should be checked to ensure they can be easily reached by

the rider’s hands and alterations made as necessary. Some

brake levers have a screw adjuster to change the distance

between the lever and the handlebar grip. This should be

checked for tightness every three months. Similarly, at least

every three months the brake levers should be tested to

ensure they do not move on the handlebars and each brake

lever moves freely when compressed.

Prior to every ride inspection of the brake pads is recom-

mended. The brake pads must be centered, with approxi-

mately 1.5mm – 2mm clearance between each pad and

the rim when the brakes are not in use. Test that when the

brakes are applied that the brake pads squeeze the rims

sufficiently to stop the bike. Replace the brake pads if the

grooves or pattern has worn away from the surface. Ensure

that the brake pads are firmly secured before every ride

and at least every three months check the tightness of the

numerous bolts and nuts supporting the brake pads.

44

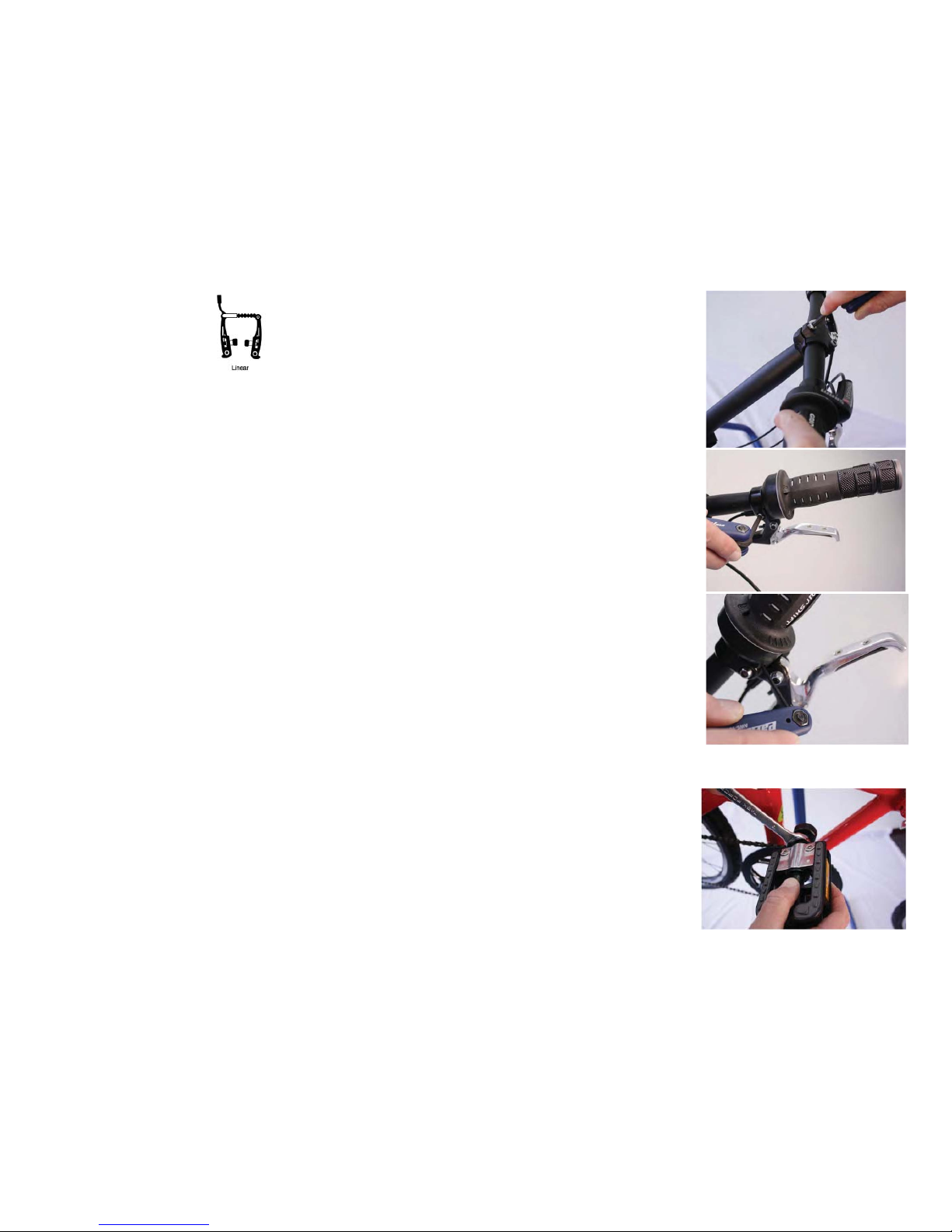

Check the positioning

of the handlebars. The

sweep (handlebar curve

towards the seat) should

be coming straight

back, not upwards or

downwards-unless you

like it that way? To adjust

the angle of the handle

bars, loosen the (2) 5mm

adjustors at the top of

the stem. To adjust the

angle of the (2) brake

levers; loosen the 5 mm

adjustor under each lever.

To adjust the angle of the

SRAM grip shift indicator,

loosen the 2.5mm adjus-

tor.

Install the pedals into

the crank. Each pedal is

labeled for left or right

side (R,L) on the end of

their bolts. Use a 15mm

wrench to firmly tighten

the pedals by moving the

wrench toward the front

of the bike on both sides.

17

Inflate the tires to 50-55 psi (tires have schraeder valves).

Adjust the saddle height and positioning. Attach the white

reflector to the handlebars and the (2) yellow reflectors to

the spokes of each wheel. The red reflector has a mounting

bracket which snaps onto the reflector at one end and bolts

to the cross frame piece just above the rear tire (please see

the mounting hole in this frame piece) on the other end.

Proceed to our tuning section to fine tune the performance

of your melon bicycle.

The brake pads should be 1/16-1/8" away from the rim

(closer for faster stops, furtheraway for slower, more con-

trolled stops).Tighten the screw on the side of the brake-

housing clockwise to increase the distance and loosen the

screw counterclockwise toshorten the distance.

Brakes

18

BRAKES

For safe riding it is crucial that your bicycle’s brakes func-

tion correctly. With use the bicycle’s brake pads wear and

the control cables stretch. Consequently, prior to every ride

the brakes should be inspected and adjusted as necessary

to ensure proper operation.

WARNING:

A bicycle should never be ridden unless the

brakes are working correctly. Take care when us-

ing the front brake. Applying it abruptly or exces-

sively may throw the rider over the handlebars,

potentially causing serious injury or death.

43

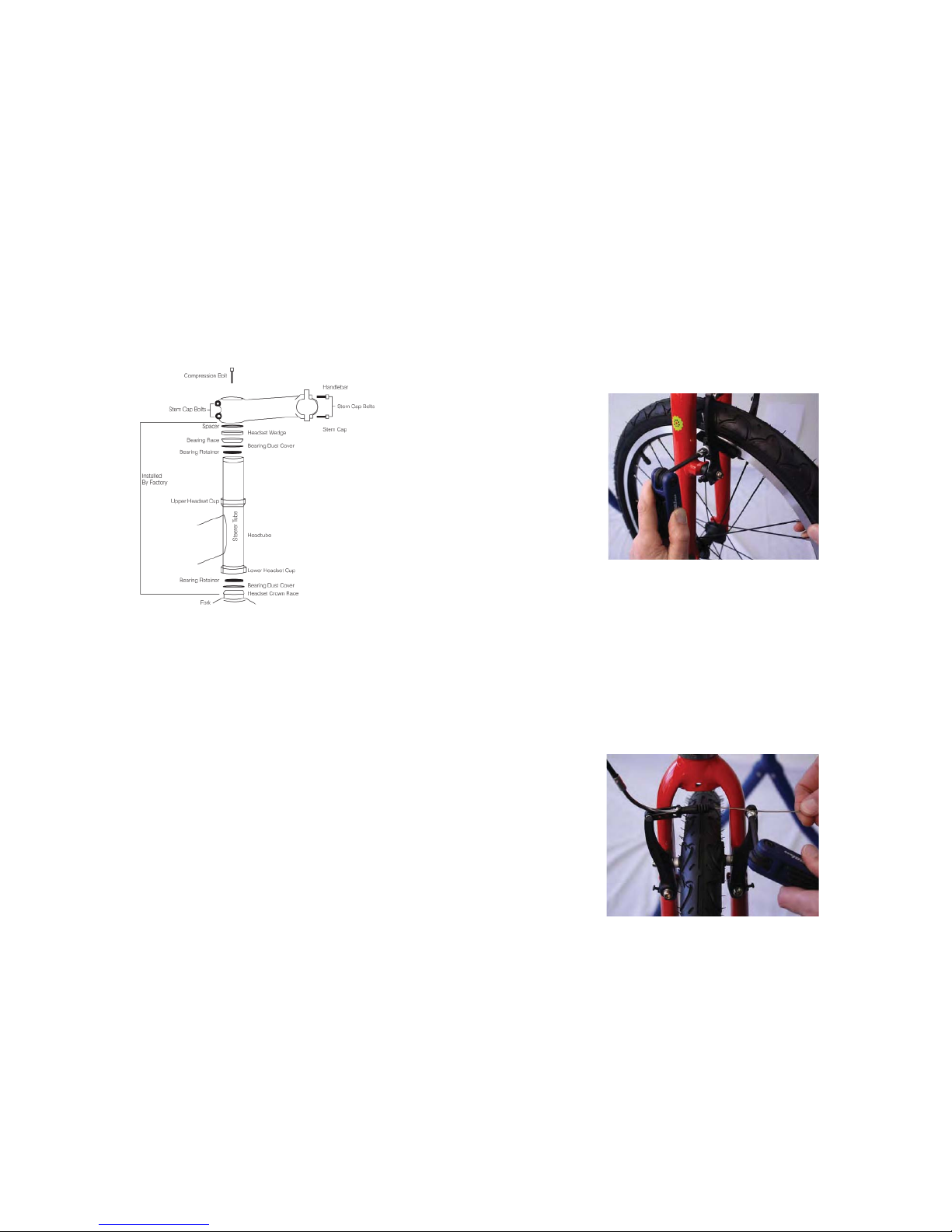

Lubrication and Attachment of An ‘Ahead Set Stem To

The Fork Diagram:

42

The brake pads should be lined up on the rim when the

brake levers are pulled. They should not make contact with

the tire or be positioned too far towards the center of the

wheel. Loosen the 5mm adjustor on the outside of the

brakes to reposition the pads.

Adjust the response of the brakes by loosening the locking

wheel and then loosening or tightening the barrel adjustor

(counterclockwise increases cable tension, clockwise re-

duces cable tension). When the response is what you want,

tighten the locking wheel back in place. If greater adjust-

ment is needed, loosen the adjustor that holds the brake

cable on one side of the brakes. Move the cable in or out

and tighten the screw again.

19

Have someone hold the rear wheel in the air (or hang the

seat from something) so that you can move the pedals

freely with your hand. Move the grip shifter to gear position

1 and apply gentle pressure with the shifter to see if the

chain will move off the largest sprocket towards the spokes.

If the chain moves towards the spokes at all, tighten (clock-

wise) the bottom screw (marked L) on the back of the rear

derailleur until the chain remains firmly on the sprocket. Do

the same thing with the shifter in position 8 and the chain

on the smallest rear sprocket. If the chain moves towards

the bicycle's frame at all, tighten (clockwise) the top screw

(marked H) on the back of the rear derailleur until the chain

remains firmly on the sprocket.

Gears

Move the grip shift through the gears and make sure the

shifting is crisp and responsive.

20

Lubrication and Attachment of An 'Ahead Set' Stem To

The Fork

1. Every year your bicycle should have a complete lubrica-

tion. This can be quite a complex task and may be best

handled by a professional bicycle mechanic. However, if

you feel capable the following procedure will guide you.

2. Suspend the bicycle so that the front wheel is off the

ground.

3. Take the handlebar assembly from the steering tube.

4. Loosen and remove the compression bolt, the top cap

assembly and then the stem clamp bolts.

5. Remove the headset wedge whilst supporting the forks

with one hand, then remove the dust cover upper ball

retainer.

6. Pull the forks out of the frame and remove the lower ball

retainer.

7. Thoroughly clean and check each part of the headset for

damage.

8. Replace if necessary. (See your dealer to replace the

headset).

9. Grease both the head set cups. To work grease into the

lower head cup re-fit a ball retainer into it. Re-attach the

forks.

10.Install a bearing retainer into the bearing race and pack

it with grease. Push the screw cup down onto the fork

steerer and into position then re-fit the bearing dust

cover/bearing race / headset wedge and spacer.

11.Alter the upper cup by hand until no movement can be

detected in the forks.

12.Firmly tighten the stem clamp bolts, then replace and

secure the handlebar assembly.

41

Table of contents