Memjet AstroJet M1C User manual

AstroJet™ M1C

HIGH SPEED COLOR

LABEL AND TAG

PRINTER

OPERATOR MANUAL

ASTRO MACHINE CORP.

630 Lively Blvd.

Elk Grove Village, IL 60007

Phone: (847) 364-6363

Fax: (847) 364-9898

www.astromachine.com

SAFETY PRECAUTIONS

THIS EQUIPMENT PRESENTS NO PROBLEM WHEN USED PROPERLY.

OBSERVE SAFETY RULES WHEN OPERATING M1C LABEL PRINTER.

BEFORE USING PRINTER, READ THIS MANUAL CAREFULLY AND FOLLOW

RECOMMENDED PROCEDURES, SAFETY WARNINGS, AND INSTRUCTIONS:

Keep hands, hair, and clothing clear of rollers and other moving parts.

Avoid touching moving parts or materials while machine is in use. Before clearing a jam, be

sure machine mechanisms come to a stop.

Always turn machine off before making adjustments, cleaning machine, or performing any

maintenance covered in this manual.

Power cord and power supply supplied with machine. Plug it into a properly grounded, easily

accessible wall outlet located near machine. Failure to properly ground machine can result in

severe personal injury and/or fire.

Power cord and wall plug are primary means of disconnecting machine from power supply.

DO NOT use an adapter plug on line cord or wall outlet.

DO NOT remove ground pin from line cord.

DO NOT route power cord over sharp edges or trap it between furniture.

Avoid using wall outlets that are controlled by wall switches or shared with other equipment.

Make sure there is no strain on power cord caused by jamming it between equipment,

walls or furniture.

DO NOT remove covers. Covers enclose hazardous parts that should only be accessed by a

qualified service representative. Report any cover damage to your service representative.

This machine requires periodic maintenance. Contact your authorized service representative for

required service schedules.

To prevent overheating, do not cover vent openings.

Use this equipment only for its intended purpose.

In addition, follow any specific occupational safety and health standards for your workplace or area.

This manual is intended solely for the use and information of Astro Machine Corp., its designated

agents, customers, and their employees. The information in this guide was obtained from several

different sources that are deemed reliable by all industry standards. To the best of our

knowledge, that information is accurate in all respects. However, neither Astro Machine Corp. nor

any of its agents or employees shall be responsible for any inaccuracies contained herein.

AstroJetTM is a registered trademark of Astro Machine Corp.

Memjet®is a registered trademark.

All other trademarks are the property of their respective holders.

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher.

TABLE OF CONTENTS

i

Table of Contents

SECTION 1 –Getting Acquainted 1

Front View 1

Rear View 2

Print Engine View 3

Ink Tank View 4

UW-1C Unwinder/Roll Feeder (Optional) 5

RW-1C Winder (Optional) 6

Control Panel Button/LED Indicators: 7

Printer Default Printing Modes 9

SECTION 2 –Installing Printer 10

Contents of Packaging 10

Choose a Location 10

Unpacking and Setup 10

Remove Service Station Transport Tab 11

Install Printer/Winder Spacer Plate (Optional Winder): 12

Connecting Printer 12

Install Printer Driver 13

Install Ink Tanks 20

Install Printhead Cartridge 22

Removing Media Guide 25

Aligning Printer with UW-1C Unwinder and RW-1C Winder 26

Connecting Printer to Optional Unwinder and Winder 28

Loading Labels 29

SECTION 3 –Operating Printer 33

Printer Driver Properties 33

Using Printer Toolbox 38

Updating Firmware 45

SECTION 4 –Maintenance 46

Replacing Ink Tanks 46

Cleaning Ink Tank Contacts 47

Cleaning/Replacing Printhead Cartridge 49

Replacing Ink Waste Tray 59

Removing Jams in Printer 59

Cleaning 60

Shipping or Transporting M1C Printer 62

SECTION 5 –Troubleshooting Guide 65

Memjet Printhead 65

Printer 66

Appendices 67

Appendix A –M1C Specifications 67

Appendix B –Supplies and Optional Hardware 67

Appendix C –Borderless Printing: Overspray vs. Oversize 68

Index 72

Printer Maintenance Schedule 75

ii

NOTES

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

SECTION 1

GETTING ACQUAINTED

1

SECTION 1 –Getting Acquainted

Front View

1.

Top Cover –Provides access to Print Engine.

2.

Front Cover –Provides access to Ink Tanks and Service Station.

3.

Winder Interface Connection –Winder Interface Cable plugs in here.

4.

Service Port –Provides advanced diagnostic access for service technicians.

5.

Unwinder Interface Connection –Unwinder Interface Cable plugs in here.

6.

USB Port Connection –Attach USB cable to Printer here.

7.

Network Connection –Attach network cable here.

8.

Main Power Switch, Receptacle and Fuse –Receptacle: Power cord plugs in

here. Power Switch: Turns main power ON/OFF. (Use Control Panel LED Power

switch to turn machine OFF for cleaning and maintenance). Fuse: Protects Printer’s

electronic circuits.

SECTION 1

GETTING ACQUAINTED

2

Rear View

1.

ON/OFF LED Button –Use to turn power ON or OFF during idle time

and maintenance.

2.

Print/Pause LED Button –Press to stop printing, press to restart printing.

Press switch to continue printing.

3.

Cancel/Cut LED Button –Press switch to cancel the job being printed. Also

activates cutter to cut labels or roll at point desired.

4.

Adjustable Media Guide –Adjusts to hold paper/media against Alignment Guides.

5.

Top Center Chamber Assembly (Brush Assembly) –Keeps media flat as it

feeds into Printer. Brushes remove debris and reduce static. Lift Assembly to load

or clear media.

SECTION 1

GETTING ACQUAINTED

3

Print Engine View

1.

Printhead Latch –When closed, connects Ink Revolver Couplings with Printhead

Cartridge. When opened, retracts Ink Couplings from Printhead Cartridge and provides

access to Printhead Cartridge for cleaning and replacement.

WARNING! Never attempt to open Printhead Latch manually, severe damage will

result. Use Printhead Release function in Toolbox on your PC.

2.

Ink Revolver Couplings –Connect ink hoses to Printhead Cartridge.

Printhead Latch extends and retracts couplings from Printhead.

3.

Printhead Cartridge –Memjet®Printhead produces an 8.5" wide full color print area.

4.

Clamshell Latches –Lift both latches at same time to open top half of Print Engine.

DO NOT open while Printer is operating. DO NOT lift assembly more than 60 degrees.

DO NOT let assembly drop, close it gently.

SECTION 1

GETTING ACQUAINTED

4

Ink Tank View

1.

Cutting Blade Assembly –Cuts media after each piece or at end of a job.

2.

Ink Tank Latches –Hold Ink Tanks in place.

3.

Ink Tank Dock –Holds 5 Ink Tanks. (Ink Tanks shown installed).

4.

Ink Waste Tray –Absorbs excess ink and drips that may occur during Printer

operation and maintenance. Release Tabs located on both sides.

5.

Service Station Dock –Service Station is located here. Service Station keeps

Printhead clean and hydrated during operation and maintenance cycles.

SECTION 1

GETTING ACQUAINTED

5

UW-1C Unwinder/Roll Feeder (Optional)

1.

Speed Control –Turn clockwise to speed up, counterclockwise to slow down.

2.

AUTO/Manual Mode Switch –Use to set Unwinder in Automatic or

Manual Mode.

3.

Fuse –Unwinder fuse is located here.

4.

Hub Assembly –Reversible to fit 1-1/2" and 3" cores.

5.

Spindle Lock –Holds Label Roll on Spindle.

6.

Label Roll Spindle –Holds Label Roll.

7.

Label Tension Guide Shaft –Spring-loaded shaft controls starting and stopping

as tension is maintained or released by media.

8.

24V, 2.5A External Power Connector*–For connecting printers or equipment

other than M1C.

NOTE: External power supply must be a UL Listed power supply.

*Requires disconnecting wire from Unwinder circuit board and connecting wire

from External Power Connector.

9.

Unwinder Interconnect Cord –Connects Feeder/Unwinder to Printer.

10.

Alignment Notch –Fits over Alignment Screw on Printer to keep Printer and

Unwinder aligned.

SECTION 1

GETTING ACQUAINTED

6

RW-1C Winder (Optional)

1.

Speed Control –Turn clockwise to speed up, counterclockwise to slow down.

2.

ON/OFF Switch –Use to turn Winder power ON or OFF.

3.

Fuse –Winder fuse is located here.

4.

Hub Assembly/Guide –Fits 3" cores.

5.

Spindle Lock/Guide –Holds Label Roll in place on Spindle.

6.

Label Roll Spindle –Used to wind Printed Labels around an empty core.

7.

Label Tension Arm –Spring-loaded shaft controls starting and stopping as

tension is maintained or released by media.

8.

Adjustable Media Guide Ring –Slides to fit width of media exiting Printer.

9.

Winder Alignment Notch –Aligns with notch on Spacer Plate mounted on

Printer. Plate is then attached to Winder to keep Printer and Winder properly

aligned and spaced apart.

10.

Tension Control Selector –Increases or decreases spring tension on Label

Tension Arm to accommodate different media widths.

11.

24V, 2.5A External Power Connector* –For connecting printers or equipment

other than Label Printer.

NOTE: External power supply must be a UL Listed power supply.

*Requires disconnecting wire from Winder circuit board and connecting wire from

External Power Connector.

12.

Winder Interconnect Cord –Connects Winder to Printer.

SECTION 1

GETTING ACQUAINTED

7

Control Panel Button/LED Indicators:

3 Control Panel buttons with LED indicators.

POWER (ON/OFF) –Turns Printer power

ON and OFF. Turns off power for cleaning

and maintenance.

PRINT/PAUSE (PAUSE JOB/RESUME) –

Temporarily stops Feed or Resumes Printing.

Press to Pause Job Temporarily.

Printer finishes printing media in progress, then stops and holds. Press once to pause jobs for up to

30 seconds to clear jams or other quick maintenance. (Does not cap printhead).

Press to Resume Printing. Restart printing after a feed error (media jams or out of labels).

CANCEL/CUT (CANCEL JOB) –Stops a Job indefinitely (for maintenance or problems that take longer

to resolve.) Caps Printhead to prevent dehydration and damage. Also Cancels a Job or Cuts the media.

Press to Stop Media Feeding. Press a second time to cancel job.

NOTE: Cancelled Jobs must be reloaded before printing can resume.

Press to Cut the Roll. Once job is finished, pressing this button advances last printed label to

cutter, cuts the roll and retracts media to start position.

LED Sequence

Printer Status

Recommended

Control Panel Options

Power cord plugged

in, Power Switch

ON/OFF

- Power Up

- Inactive

- Inactive

Normal operation:

Downloading

firmware.

Power up.

Power down.

Wait for process to

finish.

- Inactive

- Inactive

- Inactive

Unit powered up.

No job loaded.

Power down.

Load media.

- Power Down

- Load media

- Inactive

Media loaded,

No job pending

Load job or forward

media to attach to

Winder reel (when

loading roll-to-roll)

- Power Down

- 3 sec –Forward

media to Winder

- 3 sec –Retracts

media

SECTION 1

GETTING ACQUAINTED

8

LED Sequence

Printer Status

Recommended

Control Panel Options

Busy Signal:

Maintenance

running

Job loading

Wait for process

to finish.

- Inactive

- Inactive

- Inactive

Job submitted,

printing

Wait for process to

finish.

Power down.

Pause: Printer stops

& holds. (Printhead

not capped.)

Cancel: Forwards,

cuts last label,

retracts to start

position. (Printhead

capped.)

- Power Down

- Pause Printing

- Pause Printing,

Cancel Job

Paused, job pending

Print/Resume:

Press to resume

printing.

Cancel/Cut:

Press to cancel job.

- Power Down

- Resume printing

- Cancel Job

EOR –End of Roll

(Paper Out)

Load new media.

- Power Down

- Reload media

- Cancel Job

Hardware Error:

Tilt Error

Door Open

Service Station Error

Ink Valve Error

Lifter Motor Error

Find and fix error(s).

- Power Down

- Clear Error,

Resume Job

- Clear Error,

Cancel Job

IDS Error:

Ink Out

Ink Tank missing

Printhead missing

Replace Ink Tank(s)

and/or Printhead.

Reseat Ink Tank(s)

and/or Printhead.

Press “Refresh Ink

Tanks” or “Circulate”

in Toolbox.

- Power Down

- Clear Error,

Resume Job

- Clear Error,

Cancel Job

Any other errors

Find and fix error(s)

- Power Down

- Pause Printing

- Pause Printing

SECTION 1

GETTING ACQUAINTED

9

Printer Default Printing Modes

Printer has three default Printing Modes “Roll-to-Roll”, “Roll-to-Cut”, and “Fanfold”. What is connected

or disconnected from Printer determines what mode Printer will operate in and disables or enables

automatic function of Cutter.

NOTE: These defaults will override any presets built into job being run. Before starting to print a job

make sure Printer, Unwinder and Winder are set up correctly for that particular job.

PRINT MODE

UNWINDER

WINDER

CUTTER

Roll-to-Roll

Powered

ON/Connected to

Printer

Powered

ON/Connected to

Printer

Disabled. (Still cuts manually by

pressing 'CANCEL' button.)

Roll-to-Cut

Powered

ON/Connected to

Printer

Powered OFF or

Disconnected from

Printer

Enabled for automatic cutting

Fanfold

Powered OFF or

Disconnected from

Printer

Powered OFF or

Disconnected from

Printer

Enabled for automatic cutting

See Section 2 –Installing Printer, “Loading Labels”for how to load Roll and Fanfold Labels

SECTION 2

INSTALLING PRINTER

10

SECTION 2 –Installing Printer

Contents of Packaging

1.

M1C Printer

2.

UW-1C Unwinder (Optional)

3.

RW-1C Winder (Optional)

Includes Printer/Winder Spacer Plate, 2 shims

4.

Ink Tanks –Cyan, Magenta, Yellow, Black, Black

5.

Printhead

6.

Adjustable Media Guide

7.

AC Power Cord

8.

USB Cable

9.

Operator Manual

10.

Driver Software CD

Before using Printer:

Choose a location for Printer (plus optional UW-1C Unwinder and RW-1C Winder if used)

Unpack Printer (plus optional UW-1C Unwinder and RW-1C Winder if used)

Pull Transport Tab from Service Station and remove Shipping Tape

Install Printer/Winder Spacer Plate on Printer (if RW-1C Winder used)

Plug in Printer and connect it to computer

Install Printer Driver

Install Ink Tanks

Install Printhead

Align Printer with UW-1C Unwinder and RW-1C Winder (If used)

Connect UW-1C Unwinder and RW-1C Winder to Printer (If used)

Load Labels (Roll or Fanfold) and Set Up Feed on Printer

Choose a Location

Place Printer on a sturdy level worktable or cabinet at least 9" from any walls. Use Bubble Gauge

mounted on Print Engine (or a small level) to make sure Printer is level. Surface should be large

enough to accommodate Printer, and UW-1C Unwinder and RW-1C Winder if used, in a line together.

Protect Printer and optional Unwinder/Winder from excessive heat, dust, and moisture. Avoid placing

it in direct sunlight.

Unpacking and Setup

Remove Printer, and optional UW-1C Unwinder and RW-1C Winder if used, and all parts from

cartons. Remove all packing tape.

SECTION 2

INSTALLING PRINTER

11

Remove Service Station Transport Tab

1. Open Top Cover.

2. Release two latches (one on either side of Print

Engine). Open top half of Clamshell by lifting both

levers at same time.

CAUTION

HOLD ONTO BOTH LATCHES WHEN OPENING AND CLOSING

PRINT ENGINE CLAMSHELL COVER TO PREVENT DAMAGE.

DO NOT ALLOW CLAMSHELL TO DROP OR SLAM CLOSED.

TO PREVENT DAMAGE TO INK LINES, A STOP LIMITS RAISING

CLAMSHELL MORE THAN 60°.

3. Remove cardboard Transport Tab [A]

from Service Station.

SECTION 2

INSTALLING PRINTER

12

Install Printer/Winder Spacer Plate (Optional Winder):

1. Remove all four Printer feet.

NOTE: To prevent ink from

spilling or leaking, lift Printer

only as high as needed to

remove/replace feet.

Move Printer to edge of bench or

table to remove feet.

2. Install long edge of Spacer Plate

under Exit End of Printer. Reinstall

2 feet to secure Plate to Printer.

3. Install 1 washer/spacer on both remaining feet and reinstall on Printer. (This will keep Printer

level.) See “Position Winder”in “Aligning Unwinder and Winder”.

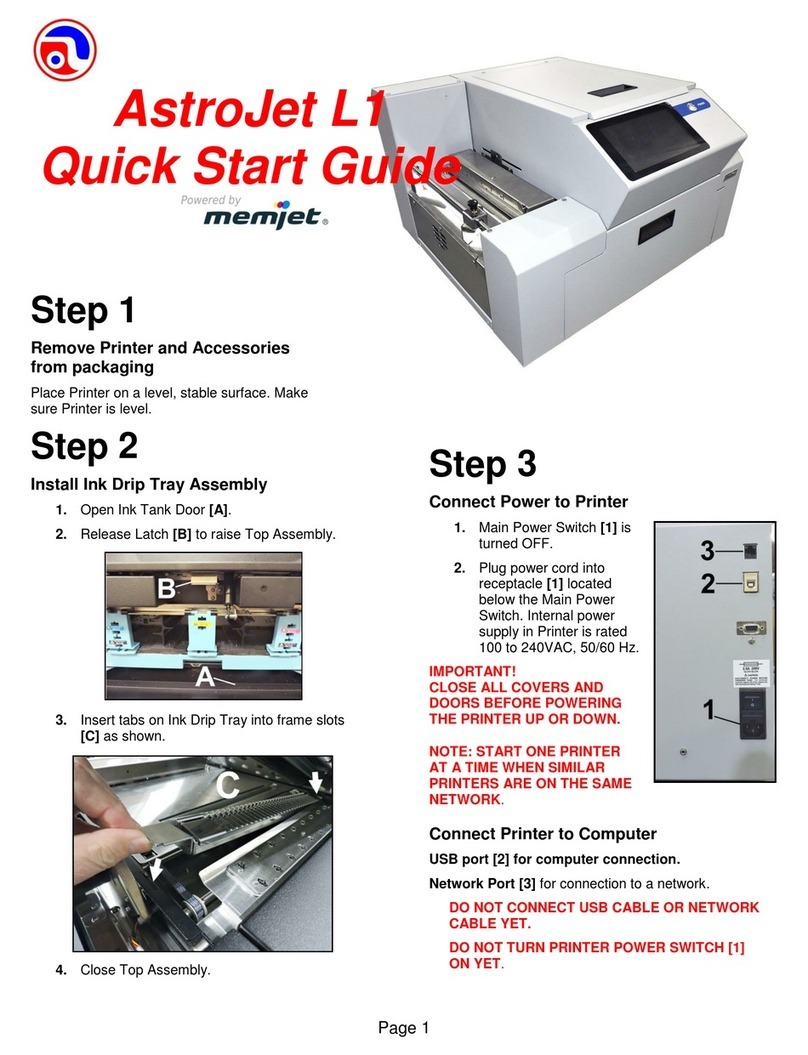

Connecting Printer

Plugging in Printer

Plug power cord into receptacle [1] on non-operator side of Label Printer. Internal power

supply in Printer is rated 115 to 240VAC, 50/60 Hz.

CAUTION

DO NOT USE ADAPTER PLUGS OR EXTENSION CORDS TO

CONNECT LABEL PRINTER TO WALL RECEPTACLE.

DO NOT USE OUTLETS CONTROLLED BY WALL SWITCHES.

DO NOT USE OUTLETS THAT SHARE THE SAME CIRCUIT WITH

LARGE ELECTRICAL MACHINES OR APPLIANCES.

Connecting to Computer

Label Printer connects to computer through USB port [3].

Network port [2] is provided for operating in a network environment.

Unwinder Interconnect port [4] is located just below USB port.

Turning Power ON and OFF

Powering Up Printer:

1. Press Main Power Switch on Side Panel.

2. Press Power Button on Control Panel.

Powering Down Printer:

CAUTION

WHENEVER POWERING DOWN UNIT, ALWAYS:

1. PRESS POWER BUTTON ON CONTROL PANEL.

2. WAIT FOR PRINTER TO STOP PROCESSING.

3. THEN PRESS MAIN POWER SWITCH ON SIDE PANEL.

SECTION 2

INSTALLING PRINTER

13

Install Printer Driver

For Printer software to operate properly, check that computer system meets these minimum requirements:

Operating System: Windows 8/8.1, Windows 10 (Desktop Mode only). Windows XP, Windows

Vista, Windows 7. Supports 32 and 64 bit systems. (You must have administrative privileges on

system.) NOTE: Win 8, 8.1 and Windows 10 will only work in desktop mode. No Win 8 or 10 metro

apps will be supported (applications that work in a Windows 8 or 10 only environment).

Microprocessor: Pentium II, 2 GHz minimum (Pentium Dual Core, 2.5 GHz or better, is optimal)

System memory: 2 GB minimum; or as recommended for your operating system.

Free hard-disk space: At least 10 GB.

Web Browser: Firefox recommended; Chrome, Safari, and Opera also supported.

CD/DVD drive.

USB port (2.0/3.0): (Ports will be identified as “USB” or “Enhanced” in Device Manager)

Microsoft .Net Framework version 3.5 (for 32 bit systems) or Microsoft .Net Framework version 4

(for 64 bit systems) must be installed. NOTE: Even if you have a higher .NET Framework version

installed; version 3.5 or 4 must also be installed, or Toolbox will not open.

IMPORTANT: Before installing Printer software (Toolbox and Driver), temporarily disable all

antivirus programs and firewalls. In addition, you must be logged onto system with full administrative

privileges (admin rights).

NOTE: If installing over USB, do not plug in USB cable until prompted.

Install Over USB Connection

This is the procedure for installing the Print Driver over the USB connection. The procedures for installing

the Print Driver over a network connection follow.

1. Check that Printer is plugged in and turned OFF.

Disconnect USB connection if already plugged

in.Install disk (supplied) in your CD drive to

download driver.

Install Printer Software. Click “Install Printer

Software”to start.

2. License Agreement. Check “I accept…” then

click “Next>”.

SECTION 2

INSTALLING PRINTER

14

3. Printer Connections. Click “Configure

to print using USB”. Click “Next>”.

4. Installing Printer Software.

5. Connect Device Now.

Switch Printer ON and connect USB

cable. Don’t click on either button.

Software will then finish installing.

6. Finished software installation. Do not

check Print Test Page as Printer is not set

up yet. You can also set printer to be

default printer. To complete process,

restart computer. Click “Reboot”.

SECTION 2

INSTALLING PRINTER

15

Install Over Network Connection, Version A

Use this procedure to install the Print Driver over the Network connection. This procedure works for

almost all networks that allow automatic assignment of the IP address (factory default). NOTE: Copy the

12-digit Hardware ID number listed on the Printer(s) on the label located just below the Ethernet

port so you can identify the Printer(s) in a later step.

1. Check that Printer is plugged in and turned ON. Make

sure the Ethernet (network) cable is plugged into the

Ethernet port on the Printer. Install disk supplied with

Printer in your CD drive. When AutoPlay Window

opens, click “Run Setup.exe”to start.

2. Install Printer Software. Make sure computer

system meets minimum requirements and you

followed other instructions listed on screen.

Click “Install Printer Software”.

3. License Agreement.

Check “I accept…” then click “Next>”.

SECTION 2

INSTALLING PRINTER

16

4. Printer Connections. Click “Configure to print

using the Network”. Make sure the Printer is

connected to the Network. Then click “Next>”.

5. Printers Discovered. A list of available Printers

opens. Check the Printer column to verify you

have an MC-Series printer. Check the Hardware

ID column and match the number listed to the

number you copied previously from the Printer

label. Select that Printer. Click “Next>”.

NOTE: If the Printer does not appear on the

list, the IP address may have to be assigned

manually. See “Install Over Network

Connection, Version B”.

6. Installing Printer Software.

Software download begins.

7. Would You Like to Install This Device

Software? Click “Install”.

8. Finished software installation. Do not check the

Print Test Page as Printer is not set up yet. You

can check “Set this printer as the default printer”

at this time. Click “Next>”.

Table of contents

Other Memjet Label Maker manuals