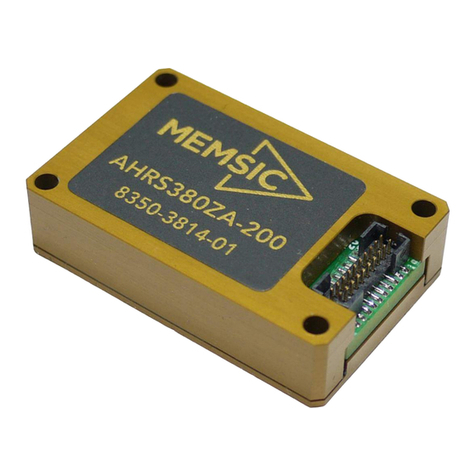

DMU380ZA Series User’s Manual

________________________________________________________________________

Doc# 7430-3810 Rev. 02 Page 2

Overview of the DMU380ZA Series Inertial Systems1.2

This manual provides a comprehensive introduction to the use of MEMSIC’s

DMU380ZA Series Inertial System products listed in Table 2. This manual is intended to

be used as a detailed technical reference and operating guide. MEMSIC’s DMU380ZA

Series products combine the latest in high-performance commercial MEMS (Micro-

electromechanical Systems) sensors and digital signal processing techniques to provide a

small, cost-effective alternative to existing IMU systems.

Table 2 DMU380ZA Series Feature Description

IMU380ZA (-200,-209,-409)

6-DOF Digital IMU, 9-DOF Digital IMU Standard Range, 9-DOF Digital IMU High Range

6-DOF IMU plus Roll and Pitch Standard Range, High Range

9-DOF IMU (3-Axis Internal Magnetometer) plus Roll, Pitch, and Heading Standard Range,

High Range

9-DOF IMU (3-Axis Internal Magnetometer) with interface for External GPS Receiver plus

Position, Velocity, Roll, Pitch, and Heading Standard Range, High Range

The DMU380ZA Series is MEMSIC’s fourth generation of MEMS-based Inertial

Systems, building on over a decade of field experience, and encompassing thousands of

deployed units and millions of operational hours in a wide range of land, marine,

airborne, and instrumentation applications. It is designed for OEM applications.

At the core of the DMU380ZA Series is a rugged 6-DOF (Degrees of Freedom) MEMS

inertial sensor cluster that is common across all members of the DMU380ZA Series. The

6-DOF MEMS inertial sensor cluster includes three axes of MEMS angular rate sensing

and three axes of MEMS linear acceleration sensing. These sensors are based on rugged,

field proven silicon bulk micromachining technology. Each sensor within the cluster is

individually factory calibrated for temperature and non-linearity effects during

MEMSIC’s manufacturing and test process using automated thermal chambers and rate

tables.

Coupled to the 6-DOF MEMS inertial sensor cluster is a high performance

microprocessor that utilizes the inertial sensor measurements to accurately compute

navigation information including attitude, heading, and linear velocity thru dynamic

maneuvers (actual measurements are a function of the DMU380ZA Series product as

shown in Table 2). In addition, the processor makes use of internal magnetic sensor and

external GPS data to aid the performance of the inertial algorithms and help correct long

term drift and estimate errors from the inertial sensors and computations. The navigation

algorithm utilizes a multi-state configurable Extended Kalman Filter (EKF) to correct for

drift errors and estimate sensor bias values.

Another unique feature of the DMU380ZA Series is the extensive field configurability of

the units. This field configurability allows the DMU380ZA Series of Inertial Systems to

satisfy a wide range of applications and performance requirements with a single mass

produced hardware platform. The basic configurability includes parameters such as baud

rate (UART), clock speed (SPI), packet type, and update rate, and the advanced

configurability includes the defining of custom axes and how the sensor feedback is

utilized in the Kalman filter during the navigation process.

The DMU380ZA Series is packaged in a light-weight, rugged, unsealed metal enclosure

that is designed for cost-sensitive commercial and OEM applications. The DMU380 can

be configured to output data over a SPI Port or a low level UART serial port. The port