MEN Mikro Elektronik M24 User manual

Looking for more information?

Visit

us

on the

web

at http://www.artisan-scientific.com for more information:

•

Price

Quotations •

Drivers·

Technical

Specifications.

Manuals and Documentation

Artisan

Scientific

is

You~

Source

for:

Quality

New

and

Certified-Used/Pre:-awned ECJuiflment

•

Tens

of

Thousands

of

In-Stock

Items

•

Hundreds

of

Manufacturers

Supported

•

Fast

Shipping and

DelIve1y

•

Leasing

/Monthly

Rentals

•Equipment Demos

•

Consignment

Service Center Repairs

Experienced Engineers and Technicians

on

staff

in

our

State-of-the-art Full-Service In-House Service Center Facility

InstraView Remote Inspection

Remotely inspect equipment before purchasing with

our

Innovative InstraView-website at http://www.instraview.com

We

bUy

used

equipment!

We

also

offer

credit

for

Buy-Backs

and

Trade-Ins

Sell

your

excess.

underutilized. and idle used equipment. Contact one

of

our

Customer

Service

Representatives todayl

Talk to alive person: 88EM38-S0URCE fB88-887-68721 IContact

us

by

Board-Level Computers

for Industrial Applications

®

User Manual

Embedded Solutions

M24 – 8/16 Binary Inputs

20M024-00 E3 - 2004-03-18

M24 – 8/16 Binary Inputs

MEN Mikro Elektronik GmbH 2

20M024-00 E3 - 2004-03-18

M24 – 8/16 Binary Inputs

The M24 is based on the M-Module ANSI mezzanine standard. It can be used as an

I/O extension in any type of bus system, i.e. CPCI, PXI, VME or on any type of

stand-alone SBC. Appropriate M-Module carrier cards in 3U, 6U and other formats

are available from MEN or other manufacturers.

The M24 has voltage-sensitive inputs. Either 16 channels are available using a 25-

pin D-Sub connector, or 8 channels using a screw terminal with LED display. The

nominal switching threshold is half the supply voltage. Suppressor diodes protect all

inputs against overvoltage.

Interrupt generation can be programmed for each individual channel on each

transition.

The M24 is a high-end M-Module for process input. It is designed for use in critical

applications.

Technical Data

Binary Inputs

• 16 binary inputs with 25-pin D-Sub connector

• 8 binary inputs with screw terminal and LED display

• Input load on ground or supply voltage

• Schmitt trigger characteristics with 2V hysteresis

• Input current 5mA @ 24V typ.

• Input voltage range 12..32V

Input Control

• BIOC (Binary Input/Output Controller)

Switching Voltage and Current

• U low = VBB / (2 - 0.5V)

• U high = VBB / (2 + 0.5V)

• I in = ±5mA (VBB = 24V)

Overload Protection

• Intelligent protection

Miscellaneous

• Debouncing circuit

• Interrupt generation for each channel on each signal edge

Technical Data

MEN Mikro Elektronik GmbH 3

20M024-00 E3 - 2004-03-18

Peripheral Connections

• Via front panel on a shielded 25-pin D-Sub connector (16 inputs) or

• Via screw terminal and LED display (8 inputs)

• Via carrier board (rear I/O)

M-Module Characteristics

• A08, D08, INTA, IDENT

Electrical Specifications

• Isolation voltage:

- 500V DC between isolated side and digital side

- Voltage between the connector shield and isolated ground is limited to 180V

using a varistor; AC coupling between connector shield and isolated ground

through 47nF capacitor

• Supply voltage/power consumption:

- +5V (4.85V..5.25V), 120mA typ.

- +24V (10V..32V), 50mA typ.

• MTBF: tbd.

Mechanical Specifications

• Dimensions: conforming to M-Module Standard

• Weight: 84g

Environmental Specifications

• Temperature range (operation):

- 0..+60°C

- Industrial temperature range on request

- Airflow: min. 10m³/h

• Temperature range (storage): -40..+85°C

• Relative humidity range (operation): max. 95% without condensation

• Relative humidity range (storage): max. 95% without condensation

• Altitude: -300m to + 3,000m

• Shock: 15g/0.33ms, 6g/6ms

• Vibration: 1g/5..2,000Hz

Safety

• PCB manufactured with a flammability rating of 94V-0 by UL recognized manu-

facturers

EMC

• Tested according to EN 55022 / 1999-05 (radio disturbance) and EN 55024 /

1999-05 (immunity) with regard to CE conformity

Software Support

• MEN Driver Interface System (MDIS)

Product Safety

MEN Mikro Elektronik GmbH 5

20M024-00 E3 - 2004-03-18

Product Safety

Electrostatic Discharge (ESD)

Computer boards and components contain electrostatic sensitive devices.

Electrostatic discharge (ESD) can damage components. To protect the board and

other components against damage from static electricity, you should follow some

precautions whenever you work on your computer.

• Power down and unplug your computer system when working on the inside.

• Hold components by the edges and try not to touch the IC chips, leads, or cir-

cuitry.

• Use a grounded wrist strap before handling computer components.

• Place components on a grounded antistatic pad or on the bag that came with the

component whenever the components are separated from the system.

• Store the board only in its original ESD-protected packaging. Retain the original

packaging in case you need to return the board to MEN for repair.

!

About this Document

MEN Mikro Elektronik GmbH 6

20M024-00 E3 - 2004-03-18

About this Document

This user manual describes the hardware functions of the board, connection of

peripheral devices and integration into a system. It also provides additional

information for special applications and configurations of the board.

The manual does not include detailed information on individual components (data

sheets etc.). A list of literature is given in the appendix.

History

Conventions

This sign marks important notes or warnings concerning proper functionality of the

product described in this document. You should read them in any case.

Folder and file names are printed in italics.

Bold type is used for emphasis.

Hyperlinks are printed in blue color.

The globe will show you where hyperlinks lead directly to the Internet, so you can

look for the latest information online.

Hexadecimal numbers are preceded by "0x", which is the usual C-language

convention, and are printed in a monospace type, e.g. 0x00FFFF.

Signal names followed by "#" or preceded by a slash ("/") indicate that this signal is

either active low or that it becomes active at a falling edge.

Signal directions in signal mnemonics tables generally refer to the corresponding

board or component, "in" meaning "to the board or component", "out" meaning

"coming from it".

Vertical lines on the outer margin signal technical changes to the previous edition of

the document.

Edition Description Technical Content Date of Issue

E1 First edition M. Schmitz 1992-12-15

E2 Second edition M. Schmitz 1995-12-04

E3 Third edition M. Schmitz 2004-03-18

!

italics

bold

hyperlink

0xFF

IRQ

#

/IRQ

in/out

About this Document

MEN Mikro Elektronik GmbH 7

20M024-00 E3 - 2004-03-18

Copyright Information

MEN reserves the right to make changes without further notice to any products herein. MEN makes no

warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does MEN assume any liability arising out of the application or use of any product or

circuit, and specifically disclaims any and all liability, including without limitation consequential or

incidental damages.

"Typical" parameters can and do vary in different applications. All operating parameters, including

"Typicals" must be validated for each customer application by customer's technical experts.

MEN does not convey any license under its patent rights nor the rights of others.

MEN products are not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life, or for any other

application in which the failure of the MEN product could create a situation where personal injury or

death may occur. Should Buyer purchase or use MEN products for any such unintended or

unauthorized application, Buyer shall indemnify and hold MEN and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and

reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that MEN was

negligent regarding the design or manufacture of the part.

All brand or product names are trademarks or registered trademarks of their respective holders.

Information in this document has been carefully checked and is believed to be accurate as of the date of

publication; however, no responsibility is assumed for inaccuracies. MEN will not be liable for any

consequential or incidental damages arising from reliance on the accuracy of this document. The

information contained herein is subject to change without notice.

Copyright © 2004 MEN Mikro Elektronik GmbH. All rights reserved.

Please recycle

Germany

MEN Mikro Elektronik GmbH

Neuwieder Straße 5-7

90411 Nuremberg

Phone +49-911-99 33 5-0

Fax +49-911-99 33 5-901

E-mail info@men.de

www.men.de

France

MEN Mikro Elektronik SA

18, rue René Cassin

ZA de la Châtelaine

74240 Gaillard

Phone +33 (0) 450-955-312

Fax +33 (0) 450-955-211

E-mail info@men-france.fr

www.men-france.fr

UK

MEN Micro Ltd

Whitehall, 75 School Lane

Hartford, Northwich

Cheshire UK, CW8 1PF

Phone +44 (0) 1477-549-185

Fax +44 (0) 1477-549-178

E-mail info@menmicro.co.uk

www.menmicro.co.uk

USA

MEN Micro, Inc.

3740 North Josey Lane, Suite 203

Carrollton, TX 75007

Phone 972-939-2675

Fax 972-939-0055

E-mail sales@menmicro.com

www.menmicro.com

Contents

MEN Mikro Elektronik GmbH 8

20M024-00 E3 - 2004-03-18

Contents

1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Installation Check List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Installing Driver Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Connecting the M-Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Peripheral Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.1 Connection via 25-pin D-Sub Connector . . . . . . . . . . . . . . . 12

2.1.2 Connection via Carrier Board/24-pin Connector . . . . . . . . . 13

2.1.3 Connection via Screw Terminal . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Address Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Binary Input Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1 Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.2 ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.3 Electrical Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Binary Input Output Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.1 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.2 Interrupt Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 M-Module Identification Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Literature and Web Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Board Revisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Component Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MEN Mikro Elektronik GmbH 9

20M024-00 E3 - 2004-03-18

Figures

Figure 1. Screw Terminal Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2. Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 3. Position of Jumper J6 and Resistor Networks NR2 and NR3 . . . . . . . 17

Figure 4. Input Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 5. Position of Capacitor C17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 6. Debounce Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. Component Plan of M24 Hardware Revision 03 . . . . . . . . . . . . . . . . . 24

MEN Mikro Elektronik GmbH 10

20M024-00 E3 - 2004-03-18

Tables

Table 1. Signal Mnemonics of Peripheral Connectors . . . . . . . . . . . . . . . . . . . . 12

Table 2. Pin Assignment of the 25-Pin D-Sub Receptacle Connector . . . . . . . . 12

Table 3. Pin Assignment of the 24-Pin Receptacle Connector. . . . . . . . . . . . . . 13

Table 4. Signal Correspondence between 24-Pin M-Module Connector and 96-pin

Carrier Board Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5. Supported Pins of 60-Pin Plug Connector on Carrier Board . . . . . . . . 15

Table 6. Address Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7. Configuring the Input for Load on GND or VBB . . . . . . . . . . . . . . . . 18

Table 8. Table of Hardware Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Getting Started

MEN Mikro Elektronik GmbH 11

20M024-00 E3 - 2004-03-18

1 Getting Started

This chapter gives some hints for first installation of the M-Module in a system.

1.1 Installation Check List

You can use the following "check list" to install the M-Module on a carrier board for

the first time and to test proper functioning of the board.

The M-Module is completely trimmed on delivery.

Power-down the system.

Install the M-Module carrier board in your system without the M-Module.

Power-up the system.

Test the carrier board.

If O.K., power-down the system and remove the carrier board.

Install the M-Module in slot 0 of the carrier board.

Initially, do not change any jumpers.

Insert the carrier board into the system again.

Power-up the system.

Load a suitable debugger.

Access the base address as set, reading word by word.

If a bus error is occurring now, the M-Module is not plugged properly or the

carrier board is not set up correctly (e. g. D201 PLD must be loaded). Please

refer to the carrier board’s user manual for details.

Write the word 0x0001 to the base address.

Reading from the base address should yield the value 0xyyy9.

1.2 Installing Driver Software

For a detailed description on how to install driver software please refer to the

respective documentation.

You can find any driver software available for download on MEN’s website.

1.3 Power Supply

Power supply to the logic part is done via the carrier board. The necessary voltage is

+5V. The isolated supply voltages (nominal ±24V) must be taken from an external

source. The M-Module cannot operate unless this voltage is connected.

!

Connecting the M-Module

MEN Mikro Elektronik GmbH 12

20M024-00 E3 - 2004-03-18

2 Connecting the M-Module

2.1 Peripheral Interfaces

There are two possibilities for connecting peripherals:

• Connection via 25-pin D-Sub connector.

• Connection via the carrier board.

Table 1. Signal Mnemonics of Peripheral Connectors

2.1.1 Connection via 25-pin D-Sub Connector

Table 2. Pin Assignment of the 25-Pin D-Sub Receptacle Connector

Connector types:

• 25-pin D-Sub receptacle according to DIN41652/MIL-C-24308, with thread bolt

UNC 4-40

• Mating connector:

25-pin D-Sub plug according to DIN41652/MIL-C-24308, available for ribbon

cable (insulation piercing connection), hand-soldering connection or crimp con-

nection

Signal Direction Function

D0..D15 in Binary inputs 0 to 15

GND - Ground

VBB - Supply voltage

1GND14GND

2 GND 15 D0

3D816D1

4D917D2

5 D10 18 D3

6 D11 19 D4

7 D12 20 D5

8 D13 21 D6

9 D14 22 D7

10 D15 23 VBB

11 VBB 24 VBB

12 VBB 25 VBB

13 VBB

114

13 25

Connecting the M-Module

MEN Mikro Elektronik GmbH 13

20M024-00 E3 - 2004-03-18

2.1.2 Connection via Carrier Board/24-pin Connector

When a carrier board with a 96-pin DIN 41612 PCB connection is used for

peripheral signals (for example a 6U VMEbus board), these are fed to the M-

Module through the 24-pin receptacle connector. You can connect up to four 21-pin

connectors to the 96-pin connector (cf. carrier board manual). When these

connectors are used, for each M-Module three pins of the DIN 41612 PCB

connector cannot be used. The pin numbers for the 96-pin connector shown below

are valid for M-Module slot number 3. If other M-Module slots (2, 1 or 0) are used,

the value 8, 16 or 24 must be added as appropriate.

Table 3. Pin Assignment of the 24-Pin Receptacle Connector

Connector types:

• Two 12-pin receptacles, high-precision, 2.54mm pitch, for square pins

∅0.635mm gold, 6.9mm height

• Mating connector:

Two 12-pin plugs, 2.54mm pitch, square pins ∅0.635mm gold

Table 4. Signal Correspondence between 24-Pin M-Module Connector and 96-pin

Carrier Board Connector

23 - 24 -

21 VBB 22 -

19 VBB 20 VBB

17 D7 18 D15

15 D6 16 D14

13 D5 14 D13

11 D4 12 D12

9D310D11

7D28D10

5D16D9

3D04D8

1GND2GND

ABC

1GND GND D0

2D8D1D9

3D2 D10 D3

4D11 D4 D12

5D5 D13 D6

6D14 D7 D15

7 VBB VBB VBB

8 - VBB VBB

23

12

24

1

ABC

Connecting the M-Module

MEN Mikro Elektronik GmbH 15

20M024-00 E3 - 2004-03-18

2.2 Host Interface

The M-Module supports the following signals of a 60-pin carrier board interface

plug connector:

Note: Only two rows—A and B—of the 60-pin connector are mounted on the M24!

Table 5. Supported Pins of 60-Pin Plug Connector on Carrier Board

Connector types:

• Three 20-pin receptacles, high-precision, 2.54mm pitch, for square pins

∅0.635mm gold, 6.9mm height

• Mating connector:

Three 20-pin plugs, 2.54mm pitch, square pins ∅0.635mm gold

ABC

1/CS GND -

2A01 +5V -

3A02 - -

4A03 - -

5A04 GND -

6- - -

7- - -

8A07 - -

9- D00 -

10 - D01 -

11 - D02 -

12 - D03 -

13 - D04 -

14 - D05 -

15 - - -

16 - - -

17 - /DS0 -

18 /DTACK /WRITE -

19 - /IRQ -

20 /RESET SYSCLK -

1

20

ABC

Address Organization

MEN Mikro Elektronik GmbH 16

20M024-00 E3 - 2004-03-18

3 Address Organization

When using the driver software supplied, you do not need to be familiar with the

hardware of the M-Module in detail. However, familiarity with the address

organization of the board is essential if you wish to write your own software for the

M-Module or do low-level development.

The 256-byte I/O area of the M-Module is hardware-mapped. The address at which

individual functions can be addressed from the carrier board is computed from the

base address of the M-Module plus the address in the following table.

Table 6. Address Map

Address D15..D8 D7..D0

0x00 -Input Register 0 (r/w)

0x02 -Input Register 1 (r/w)

0x04 -Input Register 2 (r/w)

0x06 -Input Register 3 (r/w)

0x08 -Input Register 4 (r/w)

0x0A -Input Register 5 (r/w)

0x0C -Input Register 6 (r/w)

0x0E -Input Register 7 (r/w)

0x10 -Input Register 8 (r/w)

0x12 -Input Register 9 (r/w)

0x14 -Input Register 10 (r/w)

0x16 -Input Register 11 (r/w)

0x18 -Input Register 12 (r/w)

0x1A -Input Register 13 (r/w)

0x1C -Input Register 14 (r/w)

0x1E -Input Register 15 (r/w)

0xFE -Interrupt Register (r)

M-Module Identification Register (r/w)

Functional Description

MEN Mikro Elektronik GmbH 17

20M024-00 E3 - 2004-03-18

4 Functional Description

4.1 Binary Input Circuit

The M24 M-Module can accept 16 binary inputs. The inputs constitute a load

connected to ground or to the supply voltage. This is configurable through a jumper.

Figure 2. Input Circuit

4.1.1 Inputs

Since the input may take the form of a passive switch contact or be fed by open-

collector outputs, the M24 M-Module must constitute a load connected either to the

supply voltage (VBB) or to ground (GND). The selection of VBB or GND applies

to all inputs and is made by means of jumper J6. The load resistances are made up of

two resistor networks (NR2 and NR3). The standard resistance is 4.7kΩ. This means

that with a supply voltage of 24V there is a current of approximately 5mA. If these

resistors are removed completely, the input resistance of the circuit is approx.

100kΩ.

Figure 3. Position of Jumper J6 and Resistor Networks NR2 and NR3

GND

VBB

RL = 4.7 kOhms

100 kOhms22 Ohms

36V

Input

Functional Description

MEN Mikro Elektronik GmbH 18

20M024-00 E3 - 2004-03-18

4.1.1.1 Load on Ground or Supply Voltage

Table 7. Configuring the Input for Load on GND or VBB

4.1.1.2 Signal Switching and Debouncing

Each input has a Schmitt trigger. This ensures proper switching even when the input

signal is noisy. Hysteresis is typically 1V. The nominal switching voltage is always

exactly half the supply voltage of the electrically isolated part of the circuit, that is

12V nominal with a 24V supply.

Figure 4. Input Waveform

For eliminating the "bounce", which typically occurs when switches are opened or

closed, so-called bounce eliminators are included. These digital components

monitor the stable input state of a signal for a certain time before passing this state

to the output.

The debouncing time is 4.5 cycles of a reference frequency determined by capacitor

C17, the frequency being approx.

Jumper Setting Load on

GND

VBB

J6

3

2

1

J6

3

2

1

V

H

VBB/2

VBB

GND

V

IN

V

OUT

V

IN

V

OUT

15.

1000000 C17⋅

---------------------------------------

Functional Description

MEN Mikro Elektronik GmbH 19

20M024-00 E3 - 2004-03-18

The standard value for C17 is 1nF, which yields a frequency of 1500Hz,

corresponding to a debouncing time of 3ms. The debouncing time can be altered by

changing the capacitor. If this capacitor is removed completely, the debouncing time

is approx. 50µs, which means that signals up to 20kHz can be registered.

Figure 5. Position of Capacitor C17

Figure 6. Debounce Timing

Clock

Input

Output

Table of contents

Other MEN Mikro Elektronik Control Unit manuals

Popular Control Unit manuals by other brands

Reece

Reece VADA V-PC quick guide

Posital Fraba

Posital Fraba KIT CONTROL BOX WITH GUI manual

ARI

ARI 1108 Installation, Inspection & Maintenance instructions

Johnson Controls

Johnson Controls M300CJ-R Installation and maintenance instructions

Monacor

Monacor ATT-212/WS instructions

ArduCAM

ArduCAM CMOS MT9D111 user guide

Nice

Nice MINDY A02 Instructions and warnings for the fitter

Conductix-Wampfler

Conductix-Wampfler 0815 Series installation instructions

National Instruments

National Instruments SCXI-1112 user manual

MyGate

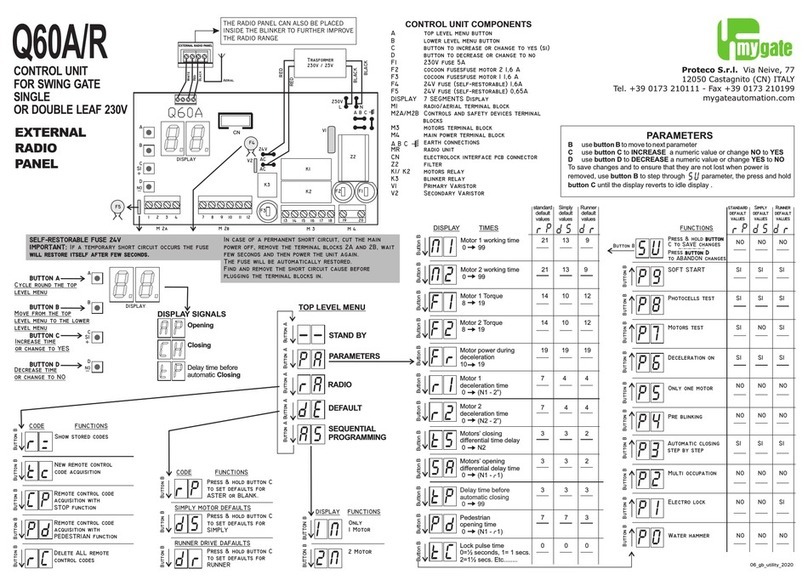

MyGate Q60A/R manual

Danfoss

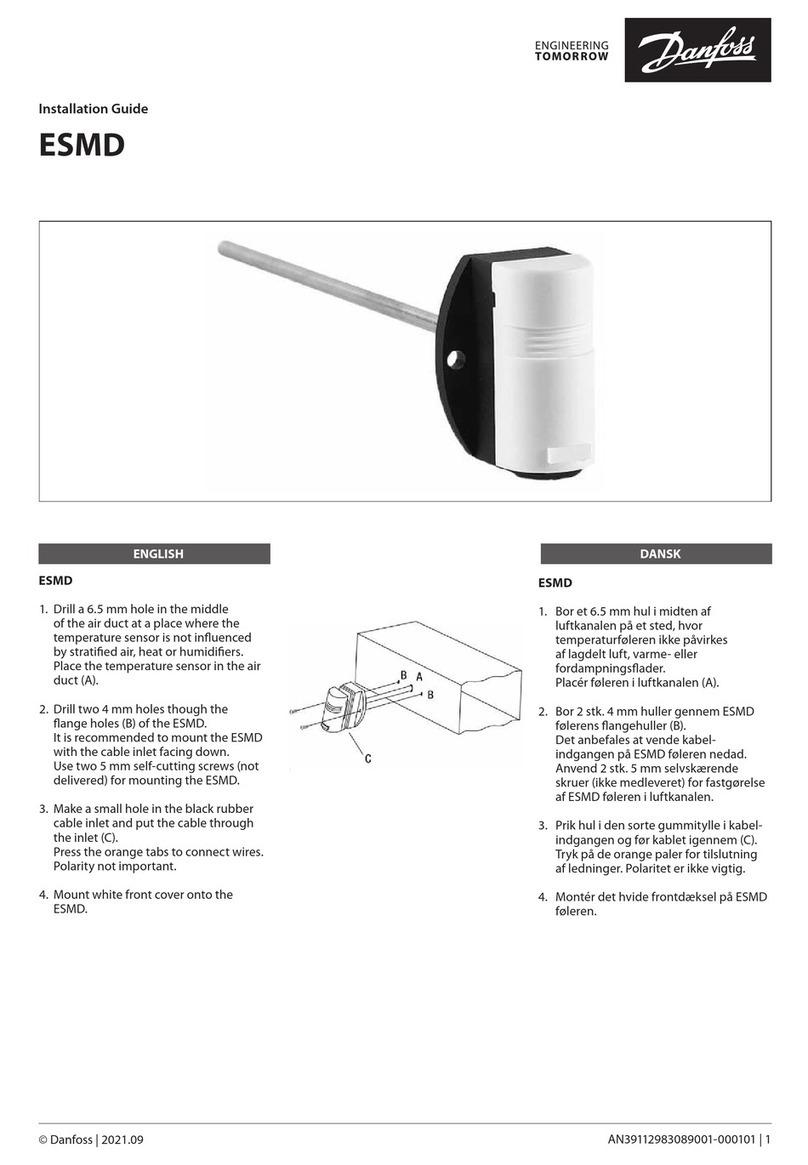

Danfoss ESMD installation guide

Lucent Technologies

Lucent Technologies Stinger OC3-ATM Guide