© RESOL 07192 HMK2.monen.indd

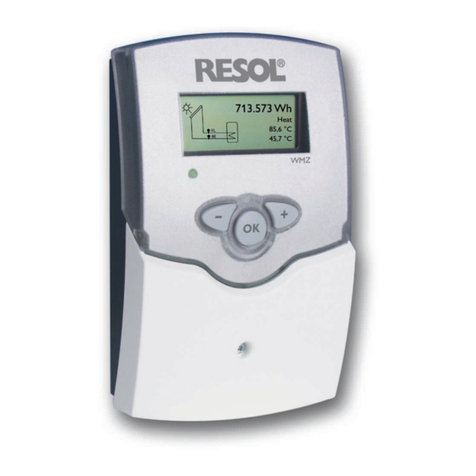

HKM2

|2

Security instruction............................................................ 2

Application examples ........................................................ 4

1. Installation................................................................ 5

1.1 Wall mounting.............................................................................5

1.2 Electrical connection.................................................................5

1.3. Connecting terminals................................................................6

2. Sensor types ............................................................. 7

3. Function survey........................................................ 8

3.1 Heating circuit.............................................................................8

3.2 Timer ............................................................................................8

3.3 Remote control ..........................................................................8

3.4 Switch-off heating circuit..........................................................8

3.5 Rapid heating-up.........................................................................8

3.6 Feed flow set temperature ......................................................9

3.7 Mixer regulation .........................................................................9

3.8 Domestic water priority ..........................................................9

3.9 Blocking protection of the heating circuit pump ...............9

3.10 Anti-freeze function...................................................................9

3.11 Store after-heating .....................................................................9

4. Operation and Adjustment................................... 10

4.1 Control parameters................................................................ 10

4.1.1 Feed flow set temperature ................................................... 11

4.1.2 Ambient temperature ............................................................ 11

4.1.3 Remote contol correction .................................................... 11

4.1.4 Feed flow set temperature ................................................... 11

4.1.5 Store temperature .................................................................. 11

4.1.6 Nightly temperature lowering.............................................. 11

4.1.7 Daily correction....................................................................... 11

4.1.8 Maximum feed flow temperature........................................ 12

4.1.9 Heating curve........................................................................... 12

4.1.10 Mixer runtime.......................................................................... 12

4.1.11 Summer operation.................................................................. 12

4.1.12 Domestic water priority ....................................................... 12

4.1.13 Timer ......................................................................................... 12

4.1.14 HKM expert ............................................................................. 13

4.1.15 Manual operation .................................................................... 14

4.1.16 LED-Blinking codes................................................................. 14

5. Commissioning ......................................................14

6. Tips for fault localization ......................................14

6.1 Cause and solution ................................................................. 15

Contents

Security advice

Please pay attention to the following security advice in order

to avoid danger and damage to people and property.

Instructions

Attention should be paid

- to the statutory provisions for prevention of industrial

accidents,

- to the statutory provisions for environmental protection,

- to the Health and Safety at Work Act 1974

- to Part P of the Building Regulations 2005

- to BS7671 Requirements for electrical installations and

relevant safety regulations of DIN, EN, DVGW,TRGI,TRF

and VDE.

This instruction is exclusively addressed to authorised

skilled personnel.

- Only qualified electricians should carry out electrical

works.

- Initial installation should be effected by named qualified

personnel

Declaration of conformity

We, RESOL Elektronische Regelungen GmbH, D-45527

Hattingen, declare under our sole responsibility that our

product HKM2 complies with the following standards:

EN 55 014-1

EN 60 730-1

According to the regulations of the above directives, the

product is labelled with :

89/336/EWG

73/ 23/EWG

Hattingen, 07.07.2006

RESOL Elektronische Regelungen GmbH,

ppa. Gerald Neuse