mensor 73 User manual

MENSOR MODEL 73 SHOPAIR BOOSTER

Operation Manual - PN 0017946001 A

®

Mensor Model 73

Shop Air Booster System

(750 psi Version)

April 23, 2012

Trademarks / Copyright ©

Mensor is a registered trademark of Mensor Corporation. All other brand and product

names are trademarks or registered trademarks of their respective companies.

© 2010 Mensor Corporation. All rights reserved.

Operation Manual

Mensor Model 73

Shop Air Booster System

GENERAL INFORMATION

The Mensor Model 73 Shop Air Pressure Booster generates 325 psi to 750 psi using a 70 psi

to 150 psi clean dry shop air source.The Model 73 consists of a single 5 to 1 pressure boost

stage with limits for speed control and maximum output pressure control. To achieve the 325

psi output, a minimum supply of approximately 70 psi is required. To achieve 750 psi, a 150

psi supply is required. 150 psi is the maximum input pressure the unit should be subjected to.

The unit is purely a mechanical device and has no electrical requirements.

WARNINGS AND SAFETY PRECAUTIONS

Caution: High Pressure Gas can be extremely dangerous if improperly

handled.

Caution: Unit should be operated, adjusted and maintained by qualified

personnel trained in high pressure pneumatics.

Caution: All Tubing, Fittings and connected devices must have a working

pressure rating equal to or greater than the maximum required

pressure.

Caution: All connections should be in good mechanical condition, i.e. good

threads on fittings, tubing free of kinks or nicks, etc.

Caution: All connections should be properly installed and tightened.

Caution: Small articles exposed to the escaping gas can be propelled at

ballistic speeds to the endangerment of nearby personnel and

equipment.

Caution: Under certain conditions the noise level created by gas exiting

equipment under high pressure can become dangerously high.

Caution: The maximum input pressure to the unit is 150 psi gauge pressure.

The input regulator and the input filter are rated for 150 psi

maximum.

INITIAL SETUP AND CHECKOUT

On initial setup, user should check to insure no shipping damage has occurred to the unit or

the container it was shipped in. Prior to connecting pressure, check all hoses for kinks and

nicks and insure fittings are snug. Verify that the regulator filters are not contaminated with

liquid or particulates. User should verify input pressure (shop air) is within the operating

range of the booster and within the range of any test device connected prior to applying the

input pressure. Although the regulator pressure settings have been set at the factory, the user

should on initial application verify the incoming shop air is 150 psi or less and the input

pressure gauge on the rear of the unit is approximately 50 psi or less. The black regulator

knob should be used to adjust the input pressure either increasing or decreasing the output

pressure as appropriate. The front panel gauge shows the actual output pressure value. Once

the system is operational, the black regulator knob should be used to set the final output

pressure to match the application and the controller full scale. Some final adjustments may be

required to compensate for differences in actual supply pressure.

PORTS, CONTROLS AND ADJUSTMENTS

There are two pressure ports on the rear of the Model 73 chassis. The input pressure port is

designed for a shop air supply which functions as the drive pressure as well as the output

media. It should be clean dry compressed air (or Nitrogen) at a pressure of 70 to 150 psi.

(Absolute Maximum Input Pressure is 150 psi to the rear mounted pressure filter.) This

pressure is regulated down to a typical working pressure of 50 to 150 psi. The second

pressure port is the HIGH PRESSURE OUTPUT port. It is designed for a typical output

pressure of 325 to 750 psi. The mechanical advantage is derived by using differing piston

area sizes to generate high pressures. The output equation is :

Output Pressure = Input Pressure + (Regulated Pressure * 4)

The input port is a 3/8” Swagelok male type tube fitting mounted on the external pressure

filter. The Output port is a ¼” Swagelok male type tube fitting.

Input Pressure Port

The input pressure port labeled

“INPUT PRESSURE” is used to

supply and drive the booster and

is intended to be connected to a

shop air supply of 70 to 150 psi

(150 psi max). The port is a 3/8”

male Swagelok type tube fitting

mounted on the end of a pressure

filter. A 200 psi rear mounted

panel gauge provides an

indication of the regulated shop

air pressure input. If shop air is

not present on the gauge the user

should check to see if the shop

air is present on the input port

and the regulator knob is not fully counterclockwise. The input regulator filter provides basic

filtering of large particles and liquids.It should periodically be checked for excessive

contamination and emptied of liquids. Note: The input pressure supply should have

sufficient capacity (flow) to maintain the input pressure setting. Failure to do so may

cause the booster to short cycle and not be able to achieve the desired output pressure. If

external regulators are in line with the shop air supply, make sure that they do not restrict the

input flow. Also use large diameter supply hoses (3/8” or larger) is recommended.

High Pressure Output Port

The output pressure port is a ¼” male Swagelok type tube fitting. The actual output pressure

can be monitored with the pressure gauge located on the front panel. The output pressure is a

combination of the raw input supply pressure plus four times the regulated pressure as read on

the Regulator Pressure gauge. It can be adjusted with the black Regulator Adjustment Knob.

OPERATION

While operation of the booster system is quite simple, high pressure gas is dangerous.

NOTE: Operation of this unit and maintenance of this unit should be performed by

qualified personnel only.

1. Connect a low pressure supply such as shop air to the “INPUT PRESSURE” port.

The system requires a minimum of 60 psito obtain 300 psi output.

2. Connect the load (pressure controller) to the ‘HIGH PRESSURE OUTPUT” port.

Be careful to use tubing rated for the boosted working pressure.

3. Slowly apply shop air to the “INPUT PRESSURE” port while monitoring the

“OUTPUT PRESSURE” gauge on the front of the unit.

For most applications, the booster

piston temperatures will not be a

problem. However, if a particular

application causes the booster piston

to operate frequently, the high

pressure end of the booster cylinder

may overheat. Temperatures in the

cylinder above 300 degrees F will

considerably shorten the life of the

piston seal. Temperatures can be

minimized by reducing the drive

speed while still maintaining the output pressure, but at a slower recharge rate. The drive

speed is adjusted by removing the top cover and adjusting the yellow ball valve lever. The

unit is shipped with this lever in the wide open position. Experience has shown, that under

all but the most extreme conditions, temperature problems should be of no concern.

DISCONTINUE OPERATION

To discontinue operation of the booster system:

Rear View

1. Valve off any pressure going to the “INPUT PRESSURE” port. Disconnect the

supply gas if desired. Alternately, the Regulator Pressure knob can be adjusted until

the regulator pressure reads zero.

2. With the input pressure shut off, slowly vent the output pressure by cracking the

output connector to let the pressure slowly release or by continually cycling the

controller between an acceptable control pressure and vent until pressure is drained.

Maintain a safe noise level when venting. Wait until the output gauge reads 0 psi

before disconnecting the controller or load.

TROUBLESHOOTING

This section provides simple operational checks. The Haskel AAD-5 manual attached

contains additional information.

If the unit does not pump…

1. Verify that the “INPUT PRESSURE” has pressure applied.

2. Verify that the regulator pressure knob is slightly open and the Regulator Pressure

gauge reads approximately 50 to 150 psi (just not at zero).

If the unit continually cycles after reaching pressure and the temperature of the gas has

stabilized or when cycling occurs when not being used….

1. Check for leaks in the system. Use a leak detector to track down and correct the

problem.

MAINTENANCE

NOTE: High Pressure Gas can be dangerous. Maintenance of this unit

should be performed by fully qualified personnel only.

Booster Unit:

The control valve and the pilot valves on the Haskel Booster may occasionally need re-

lubrication on units experiencing a high amount of use. Instructions and a special lubricant

are provided in the Haskel manuals in the Appendix.

Drive Pressure Filters

Each booster is equipped with a filter and regulator. The filters should be inspected on a

regular basis. Drain any accumulated moisture or sludge through the drain petcock on the base

of the filter.

Occasionally, clean the internal filter element inside the filter sediment bowl. To access the

element, first disconnect all pressures from the system. Unscrew the filter bowl ring nut by

hand and remove the bowl and filter element screw.

Clean the bowl with either soapy water or kerosene. Clean the element with a cleaning

solvent. Dry all the parts and reassemble. Make sure that the o-ring seal for the bowl is

properly positioned, replace the bowl and tighten the ring nut by hand.

The Haskel recommended maintenance schedule is listed in the appendix.

High Pressure

Output Gauge

Front View

Regulator Adjust

Regulator Gauge

(50 to 150 psi)

Input Pressure

Filter (See

Maintenance

Section)

High Pressure

Output Port

(750 PSI Max.)

Moisture Trap

Release Valve

Speed Adjust Lever

(located inside chassis)

Input Pressure Port

150 psi Max.

Rear View

SPECIFICATIONS

Input Pressure:

Dry Compressed air or Nitrogen at a maximum of 150 PSI (1.03 MPa)

Output Pressure:

Compressed air or Nitrogen up to 750 psi with appropriate supply pressure

Not to exceed 750 psi maximum.

Charge Noise Level:

Approximately 80 dbA intermittent pulses measured at 1 meter

Weight:

45 lbs or 20.4 kg

Size: Rack Mounted 7U Chassis,

19” wide, 10.5” tall, 17.25” deep (482.6 mm x 266.7 mm x 438.15 mm)

(User accessible filter extends depth by an additional 5” or 127 mm in the rear.)

APPENDIX

Haskel Operating and Maintenance Instructions

Mensor Corporation

201 Barnes Drive

San Marcos, Texas 78666-5994

Phone: 512.396.4200

Fax: 512.396.1820

Web site: www.mensor.com

E-mail: sales@mensor.com

Table of contents

Popular Extender manuals by other brands

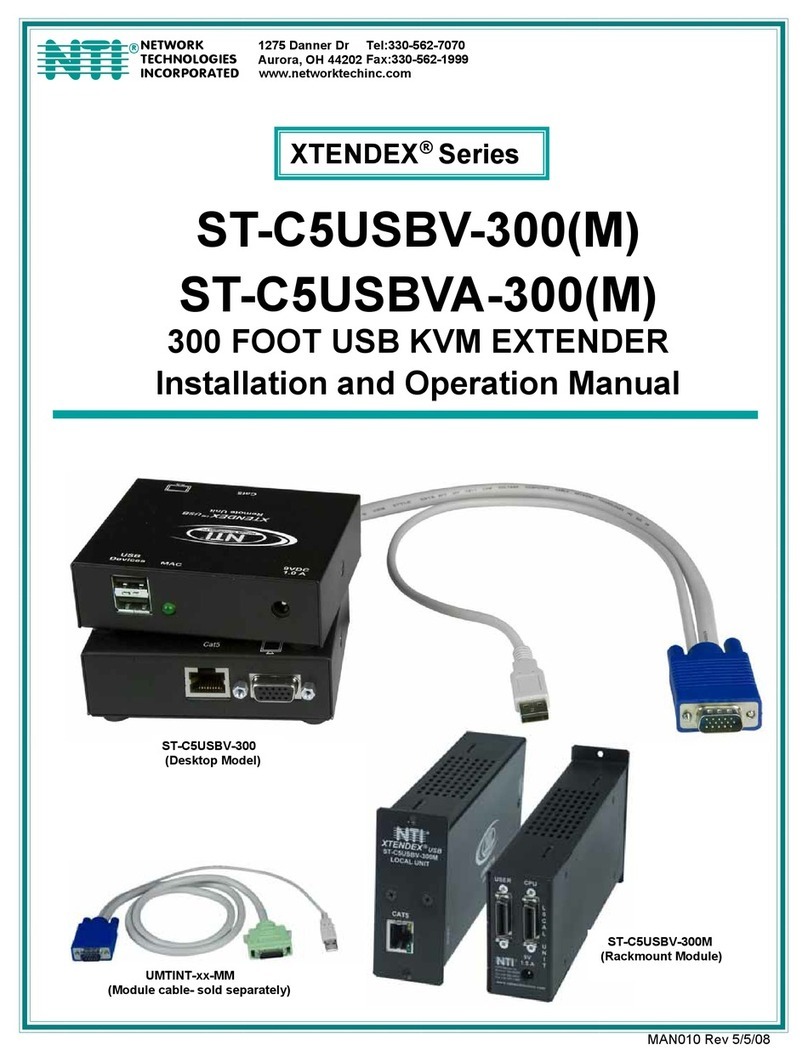

Network Technologies

Network Technologies ST-C5USBV-300M Installation and operation manual

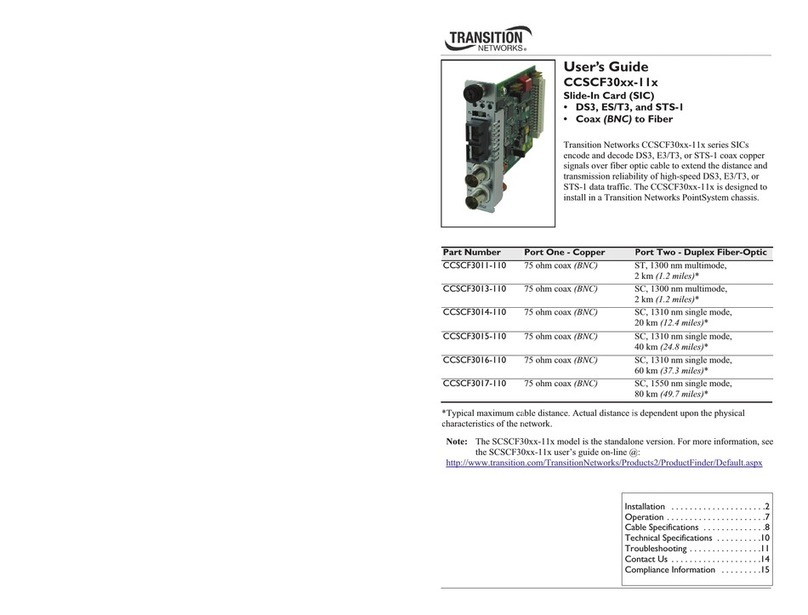

Transition Networks

Transition Networks CCSCF3011-110 user guide

Atlona

Atlona AT-AVGA-SR user manual

G&D

G&D CATVision Installation and operation

Texecom

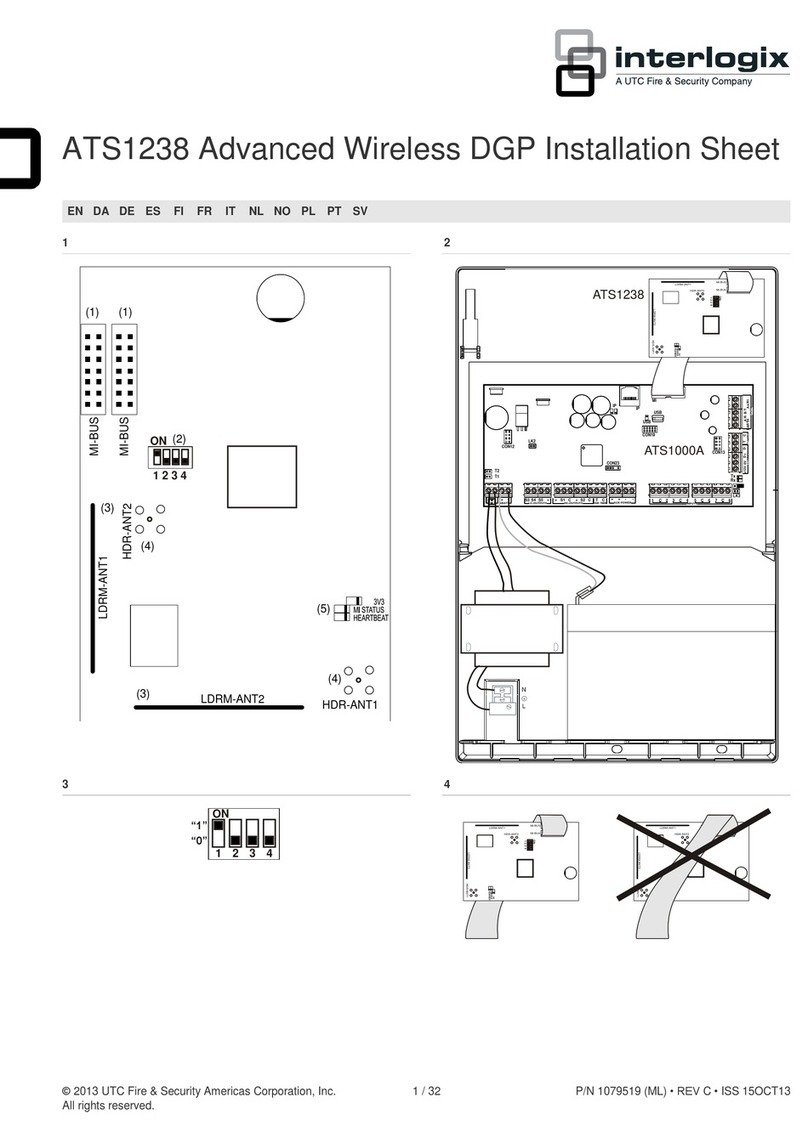

Texecom Premier Elite 32XP-W installation manual

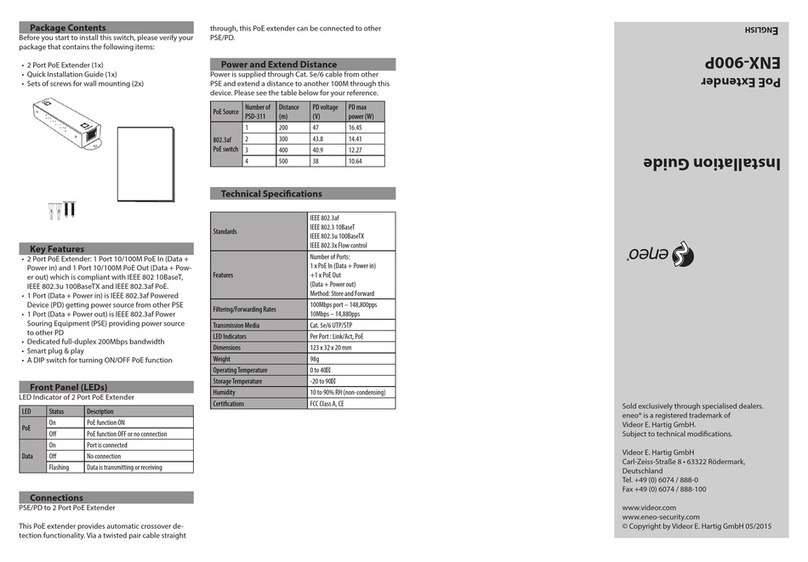

Eneo

Eneo ENX-900P installation guide