mensor PCS 400 User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

2066.01

This Manual contains important

information.

PLEASE READ PRIOR TO USE.

®

PRESSURE CALIBRATION SYSTEM

Operation Manual - PN 0014141001 T1

ISO 9001:2000

FM 59031

WARRANTY

All products manufactured by Mensor®Corporation are warranted to be free of defects in workmanship

and materials for a period of one year from the date of shipment. No other express warranty is given, and

no affirmation of Seller, by words or actions, shall constitute a warranty. SELLER DISCLAIMS ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSES

WHATSOEVER. If any defect in workmanship or material should develop under conditions of normal use

and service within the warranty period, repairs will be made at no charge to the original purchaser, upon

delivery of the product(s) to the factory, shipping charges prepaid. If inspection by Mensor Corporation or

its authorized representative reveals that the product was damaged by accident, alteration, misuse, abuse,

faulty installation or other causes beyond the control of Mensor Corporation, this warranty does not apply.

The judgment of Mensor Corporation will be final as to all matters concerning condition of the product,

the cause and nature of a defect, and the necessity or manner of repair. Service, repairs or disassembly

of the product in any manner, performed without specific factory permission, voids this warranty.

MENSOR CORPORATION MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. Mensor Corporation shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or use

of this material.

PREFACE PCS 400

ii www.mensor.com

WARNINGS AND CAUTION NOTES

IMPORTANT NOTE

Please Notice: The product specifications and other information contained in this manual are subject to

change without notice. Mensor Corporation has made a concerted effort to provide complete and current

information for the proper use of the equipment. If there are questions regarding this manual or the proper

use of the equipment, contact Mensor Corporation at:

TEL 1.512.396.4200 or 1.800.984.4200 (USA only)

FAX 1.512.396.1820

WEB SITE http://www.mensor.com

E-MAIL [email protected]

CAUTION: USE THE PROPER PRESSURE MEDIUM. USE ONLY CLEAN,

DRY NON-CORROSIVE GASES. THIS INSTRUMENT IS NOT DESIGNED

FOR OXYGEN USE.

WARNING: NOT EXPLOSION PROOF!

Installation of this instrument in an area requiring devices rated as intrinsically

safe is not recommended.

WARNING: POSSIBLE INJURY!

The tubing, valves and other apparatus attached to the gauge must be adequate

for the maximum pressure which will be applied, otherwise physical injury to the

operator or bystanders is possible.

WARNING: HIGH SOUND LEVELS!

Pressures from 600 psig and up can generate sound levels above 100 db for brief

periods when they are exhausted directly to atmosphere. If no muffling devices are

attached to the EXHAUST port, then ear protection is advised for personnel in

the vicinity of instruments that will be operated under such conditions.

WARNING: HIGH PRESSURE!

High pressure gases are potentially hazardous. Energy stored in these gases can be

released suddenly and with extreme force. High pressure systems should be assembled

and operated only by personnel who have been trained in proper safety practices.

CAUTION: ESD PROTECTION REQUIRED. The proper use of grounded

work surfaces and personal wrist straps are required when coming into contact

with exposed circuits (printed circuit boards) to prevent static discharge to

sensitive electronic components.

PCS 400 PREFACE

www.mensor.com iii

PACKAGING FOR SHIPMENT

If the product must be shipped to a different location or returned to Mensor for any reason through a

common carrier it must be packaged properly to minimize the risk of damage.

The recommended method of packing is to place the instrument in a container, surrounded on all sides

with at least four inches of shock attenuation material such as styrofoam peanuts.

SOFTWARE LICENSE AGREEMENT

This product contains intellectual property, i.e., software programs, that are licensed for use by the end

user/customer (hereinafter “end user”).

This is not a sale of such intellectual property.

The end user shall not copy, disassemble or reverse compile the software program.

THE SOFTWARE PROGRAMS ARE PROVIDED TO THE END USER “AS IS” WITHOUT WARRANTY OF

ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE ENTIRE RISK OF THE

QUALITY AND PERFORMANCE OF THE SOFTWARE PROGRAM IS WITH THE END USER.

MENSOR AND ITS SUPPLIERS SHALL NOT BE HELD TO ANY LIABILITY FOR ANY DAMAGES

SUFFERED OR INCURRED BY THE END USER (INCLUDING, BUT NOT LIMITED TO, GENERAL,

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES INCLUDING DAMAGES FOR LOSS OF BUSI-

NESS PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION AND THE LIKE),

ARISING FROM OR IN CONNECTION WITH THE DELIVERY, USE OR PERFORMANCE OF THE

SOFTWARE PROGRAM.

FCC RADIO FREQUENCY EMISSION NOTICE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at his or her own expense.

USE SHIELDED CABLES TO CONNECT EXTERNAL DEVICES TO THIS INSTRUMENT TO MINIMIZE

RF RADIATION.

TRADEMARKS

Mensor is a registered trademark of Mensor Corporation. All other brand and product names are

trademarks or registered trademarks of their respective companies. The PCS 400 instrument contains

software licensed from Microsoft Corporation.

©2005, Mensor Corp. All rights reserved.

PREFACE PCS 400

iv www.mensor.com

MENSOR BACKGROUND

HISTORY: Mensor is an ISO-9001:2000 certified manufacturer of precision pressure products. Mensor

was established in 1969 in Houston, Texas as an independent spin-off from the Texas Instruments (TI)

Pressure Instrument Group. As a private corporation, Mensor’s objective was to design and produce high

accuracy, high quality, easy to use pressure instruments. In 1978 Mensor moved to its present location in

San Marcos, on Interstate 35 (the Austin-San Antonio corridor). Two and a half years after the move, the

plant was destroyed by fire on Friday, February 13, 1981. Mensor resolved to come back, and almost

before the ashes had cooled, construction of a new building began on the same site. Six months after the

disaster, Mensor moved into its present facility and began shipping products to customers who had waited

patiently for the recovery.

PEOPLE: The key to Mensor’s strength in the marketplace is the concentration of experienced people in

the field of precision pressure measurement and control. The company’s founders previously worked in

various capacities in the Pressure Instrument Group of Texas Instruments, including engineering,

production and marketing. These founders were involved in the design of the original quartz bourdon

pressure gauge at TI. Mensor’s CEO, Jerry Fruit, is co-holder of the patent on using a fused quartz bourdon

tube to accurately measure pressure. Mensor employees have an average tenure of sixteen years. That’s a

lot of pressure experience!

PRODUCTS: Mensor’s portfolio of products consists of an extensive line of precision pressure instru-

ments, including digital gauges, pressure controllers, transducers and pressure calibrations systems. All

of these products feature computer interface capability. These products are used in metrology labs,

calibration labs, research facilities, engineering offices, production test stands, and in other environments

were high accuracy pressure measurement and/or control is required. Many of these products include

customized features to meet a customer’s specific requirement. Mensor products range from about $900

to $30,000.

CUSTOMERS: Typical Mensor customers are pressure sensor manufacturers, aerospace firms, jet engine

manufacturers, electric utilities, nuclear power plants, pharmaceutical firms, calibration laboratories,

government agencies and research organizations.

APPLICATIONS: In many facilities the highest accuracy pressure measuring or pressure controlling

instrument is a Mensor product. A typical application for these Mensor instruments is the calibration of

other pressure devices, such as sensors, transducers, transmitters, gauges and pressure switches. The

Mensor product is used as the pressure standard to verify pressure calibrations or outputs of the device

being produced, checked, tested or certified.

PCS 400 PREFACE

www.mensor.com v

SUMMARY OF CONTENTS

This manual includes the sections listed below.

1INTRODUCTION lists the items that are shipped with a standard instrument, provides

a brief overview of the instrument, and gives advice on an initial power-up.

2INSTALLATION states the mounting options, defines the pressure connections, and

gives examples of the initialization screens

3LOCAL OPERATION is a walk-thru of the display, keypads, transducers, modes of

operation and includes a complete menu tree.

4REMOTE OPERATION explains communicating with an external computer; includes

the commands available over the IEEE-488-STD bus, or via the RS-232 serial port.

5MAINTENANCE shows how to resolve some commonly encountered functional ques-

tions, and contains a list of available spare parts.

6CALIBRATION defines the recommended calibration intervals. Provides separate pro-

cedures for calibrating either absolute or gauge type instruments.

7SPECIFICATIONS lists the specifications for a standard instrument. Special or optional

features may include overriding specifications either in Section 8, Options,orasan

addendum to this manual.

8OPTIONS includes a functional description of the various options available as of this

printing. Also includes additional specifications and remote commands for some of these

options.

9APPENDIX contains a number of useful tables, figures, pneumatic schematics and

additional information.

10 INDEX lists keywords arranged alphabetically and provides text locations.

Rear Cover Pocket

This pocket holds a fold-out Menu Tree and a Quick Reference Card containing several

items of useful information.

At our web site you will find information and specifications on Mensor’s products

and services. From there you can ask questions, or direct comments to our sales

or technical people. Also available are various technical papers relating to pressure

management which you can browse, download or convert to hard copy.

MENSOR IS ON THE WEB AT www.mensor.com

PREFACE PCS 400

vi www.mensor.com

TABLE OF CONTENTS

Warranty ............................................. ii

Warnings and Caution Notes ...................................iii

Important Note ..........................................iii

Packaging for Shipment ......................................iv

Software License Agreement ...................................iv

FCC Radio Frequency Emission Notice ..............................iv

Trademarks ............................................iv

Mensor Background ........................................ v

Summary of Contents .......................................vi

INTRODUCTION

Did you get Everything? ..................................... 1-1

Initial Inspection ........................................ 1-1

Meet your Model PCS 400 .................................... 1-1

Front Panel ........................................ 1-1

Rear Panel ......................................... 1-2

Electrical Module ..................................... 1-2

Pneumatic Module ..................................... 1-3

Chassis Assembly ..................................... 1-4

Summary of PCS 400 Functions ................................. 1-5

Power Up! ............................................ 1-6

Mensor Service Plus ....................................... 1-6

Calibration Services ....................................... 1-6

Accreditations .......................................... 1-6

PCS 400 Evolution ........................................ 1-6

INSTALLATION

Mounting ............................................ 2-1

Pressure Connections ...................................... 2-1

SUPPLY Pressure Port ................................... 2-1

EXHAUST Pressure Port .................................. 2-1

MEASURE/CONTROL Pressure Port ........................... 2-1

REFERENCE Pressure Port ................................ 2-1

Power On ............................................ 2-2

System Checkout ........................................ 2-2

Control Pressure Check .................................. 2-2

System Leak Check .................................... 2-2

LOCAL OPERATION

Display ............................................. 3-1

Keypad ............................................. 3-1

Numeric Entry ....................................... 3-1

Mode Entry ........................................ 3-1

Menu Operations ..................................... 3-2

Mode Functions ...................................... 3-2

Default Values .......................................... 3-7

Transducer ........................................... 3-7

Address .......................................... 3-7

Active Transducer ..................................... 3-8

MEASURE Mode ........................................ 3-8

PCS 400 TABLE OF CONTENTS

www.mensor.com vii

Autorange ......................................... 3-8

Control Modes ......................................... 3-9

NORMAL Mode ...................................... 3-9

RATE Mode ........................................ 3-9

Multiple Internal Transducers ............................... 3-9

Setup for Control Mode ................................. 3-10

Input a Control Point Value ............................... 3-10

Incrementing the Control Point ............................. 3-10

Regulator Response ................................... 3-10

Optional Control Modes .................................... 3-10

Solenoid Valves Test ..................................... 3-11

Manual Valves Test ...................................... 3-11

Sequences ........................................... 3-11

Operation ........................................ 3-11

Create/Delete Sequence ................................. 3-12

List/Edit Sequence .................................... 3-14

List Mode ...................................... 3-14

Edit Mode ..................................... 3-14

Run Sequence ...................................... 3-15

Dual Passwords ..................................... 3-15

PCS 400 Menu Tree ...................................... 3-17

REMOTE OPERATION

Device Dependent Messages ................................ 4-1

IEEE-488-STD (GPIB) ..................................... 4-1

IEEE Capability Codes ................................... 4-1

Device Address ...................................... 4-1

Termination String Character ............................... 4-1

Service Request ...................................... 4-1

Local Lockout ....................................... 4-1

Status Display ....................................... 4-1

GPIB Interface Messages .................................. 4-1

DCL.......................................... 4-2

GET ......................................... 4-2

GTL ......................................... 4-2

IFC .......................................... 4-2

LLO.......................................... 4-2

SDC ......................................... 4-2

SRQ......................................... 4-2

Serial Poll ...................................... 4-2

PCS 400 Command Set ................................... 4-2

Definitions ...................................... 4-2

Commands ...................................... 4-3

Tests ......................................... 4-4

Queries ........................................ 4-5

PCS 400 Command Responses ................................. 4-7

Error Codes ........................................ 4-8

PCS 200 Emulation ................................... 4-10

Command Set ................................... 4-10

Emulation Responses ............................... 4-11

Command Reference ................................ 4-12

Changing the Mode of Operations ......................... 4-12

RS-232 Serial Communication ................................ 4-16

Cable Requirements ................................... 4-16

Setup .......................................... 4-16

TABLE OF CONTENTS PCS 400

viii www.mensor.com

Parameters ..................................... 4-16

Command Format ................................. 4-17

Command Examples ................................ 4-17

Single and Multi-Drop Cable Illustrations ..................... 4-18

MAINTENANCE

Beyond the Warranty ...................................... 5-1

Program Disk Replacement ................................... 5-1

Module Replacement ...................................... 5-1

Electrical Module ........................................ 5-1

Troubleshooting Guide ..................................... 5-2

Error Symptoms and Solutions .............................. 5-3

Spare Parts List ......................................... 5-6

CALIBRATION

Calibration Environment .................................... 6-1

Pressure Standard ....................................... 6-1

Calibration Medium ....................................... 6-1

Calibration Procedures ..................................... 6-1

Calibrating a Gauge Pressure Instrument ............................ 6-2

Calibrating the A/D ..................................... 6-2

Setting the Sensor Zero .................................. 6-2

Setting the Sensor Span .................................. 6-2

Calibrating an Absolute Pressure Instrument .......................... 6-3

Calibrating the A/D ..................................... 6-3

Setting the Sensor Zero .................................. 6-3

Setting the Sensor Span .................................. 6-4

SPECIFICATIONS

Measure Specifications ..................................... 7-1

Control Specifications ...................................... 7-2

General Specifications ..................................... 7-3

OPTIONS

1 - Rack Mount Kit ....................................... 8-2

2 - Transport Case ....................................... 8-4

3 - Multiple Range Pneumatics Kit ............................... 8-5

3a - Barometric Reference Transducer .......................... 8-5

3b - Two Independent Internal Transducers ........................ 8-5

4 - High Pressure Control Unit ................................. 8-7

5 - TI/Heise/Mensor Model 179 Controller Emulation ...................... 8-7

6 - Vacuum Gauge and Tube .................................. 8-7

7 - Bi-Directional Pressure Control ............................... 8-9

8 - Pressure Emulation Modes ................................. 8-9

8a - Gauge Transducers (Absolute Emulation) without BRT ............... 8-10

8b - Gauge Transducers (Absolute and Vacuum Emulation) with BRT ......... 8-10

8c - Absolute Transducers (Gauge Emulation) with BRT ................ 8-11

9 - External Analog Input ................................... 8-11

10 - Large Volume ....................................... 8-12

11 - BCD Output ....................................... 8-14

12 - Two’s Complement Binary Output ............................ 8-16

PCS 400 TABLE OF CONTENTS

www.mensor.com ix

13 - Servo-Disable ....................................... 8-18

14 - External Measure Mode Switch .............................. 8-18

15 - Measure Mode Signal ................................... 8-18

16 - Low Pressure External Plumbing ............................. 8-19

APPENDIX

Measurement Units - Unitno (Table 9.1) ............................ 9-1

Conversion Factors, PSI (Table 9.2) ............................... 9-2

Conversion Factors, Pascal (Table 9.3) ............................. 9-3

Temperature Conversion (Table 9.4) .............................. 9-4

Solenoid Valve Truth Table (Table 9.5) ............................. 9-5

Head Pressure Correction .................................... 9-6

Gas Density (Table 9.6) .................................. 9-6

Liquid Density (Table 9.7) ................................. 9-6

Head Pressure Calculation (Figure 9.1) .......................... 9-7

Sample Program ........................................ 9-8

Common Remote Commands Quick Reference (Table 9.8) .................. 9-10

Pneumatic Schem - Standard PCS 400 (Figure 9.2) ...................... 9-11

Pneumatic Schem - Dual Range PCS 400 (Figure 9.3) ..................... 9-12

Pneumatic Schem - Dual Range Press w/Baro Ref Transducer (Figure 9.4) .......... 9-13

Pneumatic Schem - Dual Abs Press w/Baro Ref Transducer (Figure 9.5) ........... 9-14

Pneumatic Schem - Two Independent Transducers (Figure 9.6) ............... 9-15

PCS 400 Sequence Program Script .............................. 9-16

INDEX ........................................... 10-1

REFERENCE LIST OF FIGURES AND TABLES

Figures:

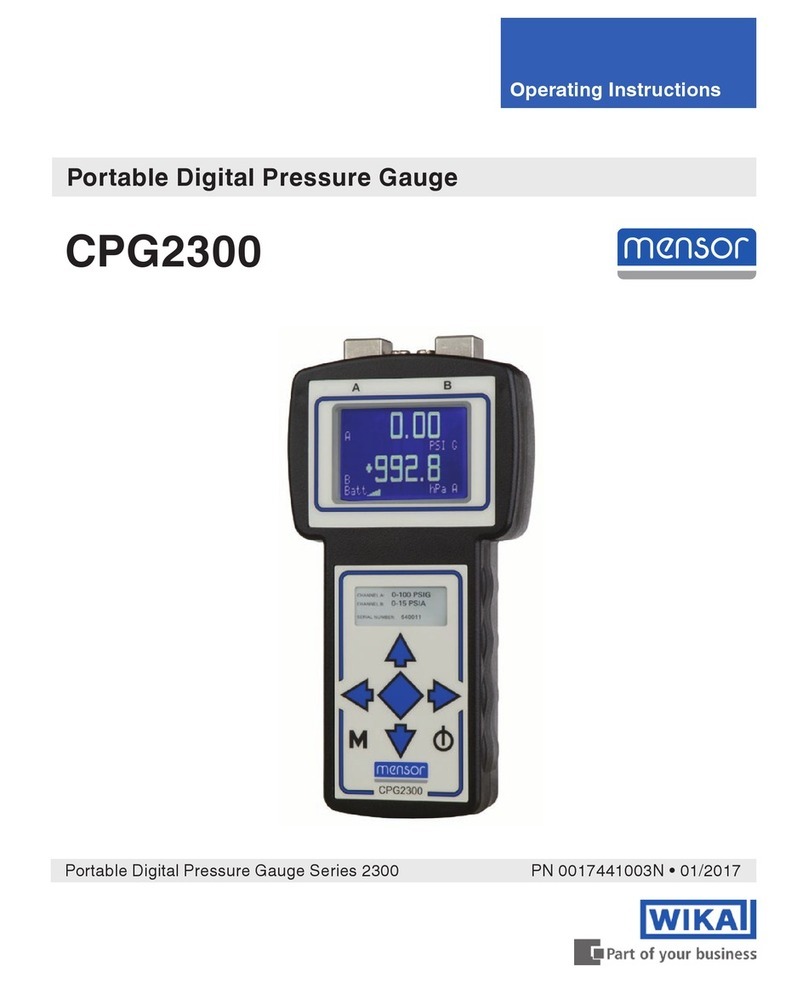

Figure 1.1 – Front Panel .................................. 1-1

Figure 1.2 – PCS 400 Rear View .............................. 1-2

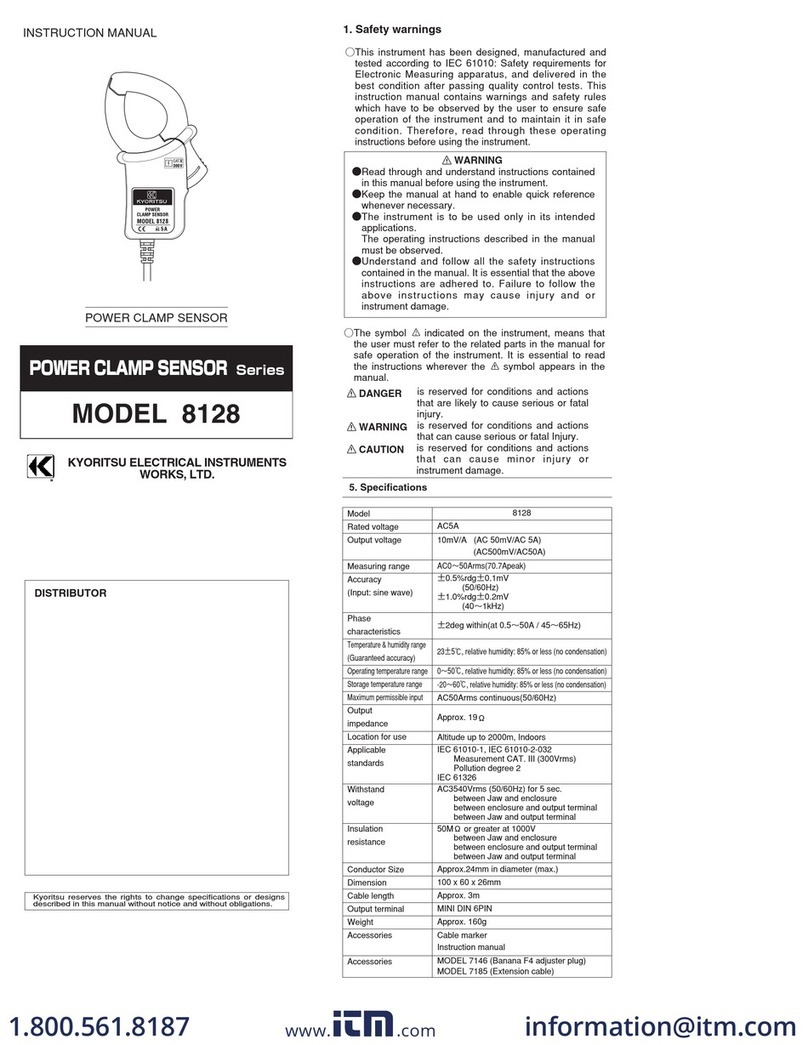

Figure 1.3 – Internal Electrical Module-Top View ..................... 1-2

Figure 1.4 – Pneumatic Module-Top View ......................... 1-3

Figure 1.5 – Chassis Assy-Top View ............................ 1-4

Figure 3.1 – Keypad .................................... 3-1

Figure 3.2 – PCS 400 Menu Tree ............................. 3-17

Figure 4.1 – Single Drop Cable ............................. 4-18

Figure 4.2 – Multi-Drop Cable .............................. 4-18

Figure 5.1 – Chassis Assy-Top View ............................ 5-2

Figure 6.1 – Calibration Setup-Gauge Pressure ...................... 6-2

Figure 6.2 – Calibration Setup-Absolute Pressure ..................... 6-3

Figure 7.1 – Dimensional Outline ............................. 7-3

Figure 8.1 – Rack Mount Dimensions ........................... 8-2

Figure 8.2 – Rack Specifications .............................. 8-3

Figure 8.3 – Slide Specifications .............................. 8-3

Figure 8.4 – Transport Case ................................ 8-4

Figure 8.5 – High Pressure Control Unit .......................... 8-7

Figure 8.6 – Rear Panel Vacuum Gauge Connector .................... 8-8

Figure 8.7 – VT-6 Gauge Tube Wiring ........................... 8-8

Figure 8.8 – Large Volume Option (<1000 cc’s external) ................ 8-13

Figure 8.9 – Large Volume Option (>1000 cc’s external) ................ 8-13

Figure 8.10 – BCD Output/Analog Input Connector ................... 8-15

TABLE OF CONTENTS PCS 400

x www.mensor.com

Figure 8.11 – Two’s Complement Binary Output .................... 8-17

Figure 8.12 – PCS 400 Rear View ............................. 8-18

Figure 8.13 – Pneumatic Connections for Low Pressure ................. 8-19

Figure 8.14 – Pneumatic Module for Low Pressure ................... 8-20

Figure 9.1 – Head Pressure Calculation .......................... 9-7

Figure 9.2 – Pneumatic Schematic-Standard PCS 400 .................. 9-11

Figure 9.3 – Pneumatic Schematic-Dual Range PCS 400 ................. 9-12

Figure 9.4 – Pneumatic Schematic-Dual Gauge Pressure with Baro Ref Transducer . . 9-13

Figure 9.5 – Pneumatic Schematic-Dual Absolute Pressure with Baro Ref Transducer . 9-14

Figure 9.6 – Pneumatic Schematic-Two Independent Transducers ........... 9-15

Tables:

Table 3.1 – Default Values ................................. 3-7

Table 3.2 – Min/Max Rate ................................. 3-9

Table 4.1 – Valid Output Format ............................. 4-7

Table 4.2 – Error Codes ............................... 4-8-4-9

Table 4.3 – Emulation Responses ............................ 4-11

Table 4.4 – Data Bits Format .............................. 4-16

Table 5.1 – Error Symptoms and Solutions ..................... 5-3-5-5

Table 5.2 – Spare Parts .................................. 5-6

Table 7.1 – Minimum/Maximum Slew Speed ....................... 7-2

Table 8.1 – Effects of mode switching (Gauge Transducer) ............... 8-10

Table 8.2 – Effects of mode switching (Absolute Transducer) .............. 8-10

Table 8.3 – Characters for Display Resolution ...................... 8-16

Table 9.1 – Measurement Units (unitno) .......................... 9-1

Table 9.2 – Conversion Factors, PSI ............................ 9-2

Table 9.3 – Conversion Factors, Pascal .......................... 9-3

Table 9.4 – Temperature Conversion Chart ........................ 9-4

Table 9.5 – Solenoid Valve Truth Table .......................... 9-5

Table 9.6 – Gas Density .................................. 9-6

Table 9.7 – Liquid Density ................................. 9-6

Table 9.8 – Quick Reference List of Common Remote Commands ........... 9-10

PCS 400 TABLE OF CONTENTS

www.mensor.com xi

U

ser

'

s

N

otes:

TABLE OF CONTENTS PCS 400

xii www.mensor.com

INTRODUCTION

DID YOU GET EVERYTHING?

In addition to this manual you should have:

·PCS 400

·Power cord

·Four 1/8 inch NPT fitting adapters

·Any accessories ordered

·An envelope containing a Calibration

Certificate

INITIAL INSPECTION

Your new Mensor instrument was thoroughly

tested and inspected at the factory, and it was free

of dings, dents and scratches when it was packaged

for shipment. Please examine it now for signs of

shipping damage. Report any apparent damage to

the carrier immediately.

MEET YOUR MODEL PCS 400

The Model PCS 400 Pressure Calibration System is

a self-contained, computerized, high accuracy

pressure management system integrated into a

single, compact unit. The system is comprised of a

front panel assembly, a rear panel, an electrical

module, a pneumatic module, and a chassis to tie

it all together. The system functions either as a

bench-top or a rack mounted instrument. It can

operate in local mode to accept front panel input,

or in remote mode to communicate with external

devices. A brief description of the major elements

of the system follows.

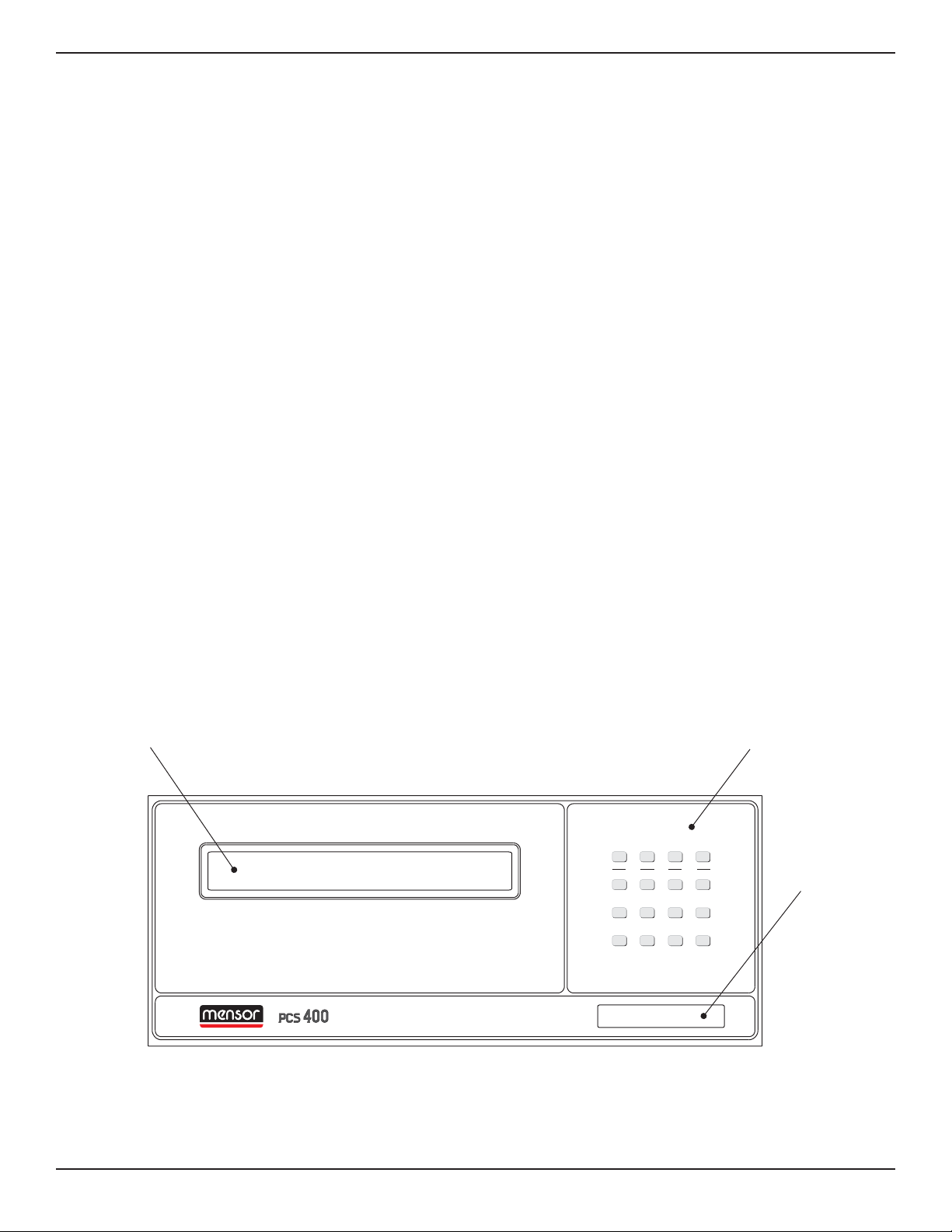

Front Panel

The front panel (figure 1.1) includes a forty char-

acter per line, two line display, a four by four

membrane keypad, and a transparent window for

the pressure range label. The keypad includes

fifteen dual-function keys, plus a sixteenth key,

labeled 2nd, which toggles the function of the other

fifteen. All sixteen keys provide both tactile and

audible feedback.

Keypad

Display

Pressure

Range

0-600 PSIA

2nd

F1 F2 F3

1

0

=

5

_

3

.

7

2

9

6

4

+

8CE

METRIC ENG GPIB SERIAL

CAL TEST LIMITS HELP

STBY CONT VENTMEAS

UNITS COMM

PRESSURE CALIBRATION SYSTEM

Figure 1.1 - Front Panel

PCS 400 INTRODUCTION

www.mensor.com 1-1

Rear Panel

The rear panel (figure 1.2) includes access to the

line-fuse holder, the power cord socket, the system

power switch, a ventilator fan opening, and several

communication connectors. All of these items are

grouped on the electrical module side of the rear

Electrical Module

The internal electrical module (figure 1.3, shown

with its cover removed) is self contained and can

be replaced as a unit. It consists of the input power

module, a fan, a power supply, a computer assem-

bly, a 3.5 inch disk drive and a flash disk.

panel. The pneumatic side exposes the four fitting

ports of the pressure manifold, and may have ad-

ditional electrical connectors to support optional

functions.

Input Power

Module

Power Supply/

Fan

Disk Drive

Backplane

CPU BOARD

GPIB

PRINTER DRIVER

SOLENOID DRIVER

PLA

Figure 1.3 - Top View of Internal Electrical Module

Power

Switch

Power

Connector

Line

Fuses

Communication

Ports

Pressure

Ports

MEASURE/

CONTROL

REFERENCE EXHAUST SUPPLY

IEEE STD 488 PORT

SH1, AH1, T6, L4,

SR1, RL1, PP0,

DC1, DT1, E2, C0

SERIAL PORT

FUSE: 250V/1.5A

“This equipment complies with the requirements in

Part 15 of FCC Rules for a Class A computing device.

Operation of this equipment in a residential area may

cause unacceptable interference to radio and TV

reception requiring the operator to take whatever

steps are necessary to correct the interference.”

Optional Connectors

as required

Figure 1.2 - Rear View

The drive is accessible by removing the rear panel

which is attached by seven screws. Note that the

plug-in printed circuit cards are not necessarily in

the order illustrated.

INTRODUCTION PCS 400

1-2 www.mensor.com

Pneumatic Module

The pneumatic module (figure 1.4) includes a pri-

mary Silicon Pressure Transducer (SPT) consist-

ing of a sensor inside a rugged aluminum housing,

and three piggy-backed circuit board assemblies

mounted to the outside. These boards contain the

signal conditioning and calibration constants for

the SPT. The pneumatic module also includes a

Reed Valve Regulator (RVR) pressure controller, an

auxiliary transducer, a manifold, and all of the

interconnecting plumbing. The pneumatic module

also has the cables required to connect it to the

electrical module. In addition, this module may

include as options, one or two additional

transducers (3 SPTs maximum), shown at address

#01 and #02.

The electrical and pneumatic modules are each

self-contained and can be replaced individually.

System accuracy is maintained when any compo-

nent is replaced because the transducer’s calibra-

tion data resides on the transducers.

The only moving parts in the PCS 400 are the fan,

the disk drive mechanism, the pneumatic flow

controller diaphragms and valves, and the solenoid

valve plungers. There are no internal user adjust-

ments or setup switches.

Shown configured with three SPTs (maximum)

Manifold

Regulator Auxiliary

Transducer

L1

L2

L3

L4

L5

L6

S

PT #01

Secondary

(Optional)

SPT #02

Baro Ref

(

O

p

tional

)

SPT #00

(Primary)

Figure 1.4 - Top View of Pneumatic Module

PCS 400 INTRODUCTION

www.mensor.com 1-3

Chassis Assembly

The chassis assembly acts as the housing for the system. Each of the major components is easily removed

and replaced using basic hand tools. The layout of the internal system is illustrated in the figure below.

Front

Rear

Electrical

Module

Interior

(shown with the

cover removed)

Pneumatic

Module

Figure 1.5 - Top View of Chassis Assembly

INTRODUCTION PCS 400

1-4 www.mensor.com

SUMMARY OF PCS 400 FUNCTIONS

Below is a list giving a brief description of the various functions available to the PCS 400. This listing begins

with descriptions of the three function keys on the bottom row, progresses from [1] through [9] in numerical

order, then ends with [CE], [+] and [-]. The listing begins with the key cap inscription shown in brackets,

followed by the mode legend for the key in capital letters, and finally a sentence or so of descriptive text.

Detailed explanations for all of the functions, and how to access them, are provided in Section 3, Local

Operation. Additional information can also be found in Section 4, Remote Operation.

KEY FUNCTION DESCRIPTION

[0] F1 Function key F1 is used only with certain options.

[.] F2 Sequences: Macros which can be created, edited, run and deleted.

[=] F3 Function key F3 is used only with certain options.

[1] CALIBRATION Allows the user to calibrate transducers and some functions

of the instrument.

Sensor Zero Calibrate A/D Baro Cal

Sensor Span Calibrate Auxiliary Sensor Save Control Settings

[2] TEST Provides the means to quickly test various internal electrical and

pneumatic functions or components. (Does not apply to HPCU.)

All Tests Regulator Display Solenoid Valves

Sensor Internal Leak Keypad Program Memory

Source Pressure System Leak Program

[3] LIMITS Allows the operator to select certain items or functions and set

parameters.

Active Transducer Cont Stable Window & Delay Restore Defaults

Control Limits Press/Rate/Peak Chg Passwords

Filter Display Resolution

[4] METRIC Allows the user to convert pressure reading to the metric units

selected from a list. The selected units will be displayed with any

mode that displays pressure readings.

[5] ENGLISH Allows the user to convert pressure readings to selected English units.

[6] GPIB Provides a means to set up parameters for use with GPIB communi-

cations.

Address Termination Character

[7] STANDBY Places instrument in the “Standby Mode”. The last measured or

controlled pressure will be displayed.

[8] MEASURE Measures the pressure at the “Measure/Control” pressure port.

[9] CONTROL Generates a pressure in response to a command point set via the

keypad or a remote command.

PCS 400 INTRODUCTION

www.mensor.com 1-5

[CE] VENT Vents the “Measure/Control” pressure port to atmosphere.

[+] HELP Displays instrument name, software version, chassis serial

number and full scale range.

[–] SERIAL Provides a way to set the parameters to be used with RS-232

communications.

Address Termination Character Data Format

Baud Single/Multi Drop

[2nd] 2nd Toggles keypad between numeric and mode functions.

POWER UP!

You can confirm that your PCS 400 is operational

right now. Simply apply power to the power con-

nector on the rear of the instrument, remove any

plastic plugs from the PRESSURE and REFER-

ENCE ports and turn the power switch ON. When

the PCS 400 is turned on it goes through an initiali-

zation process which includes scanning the inter-

nal configuration for file code errors.

About one minute after power is applied the full

display will come on. With no pressure connected,

an absolute instrument of sufficient range will dis-

play atmospheric pressure, while a gauge instru-

ment will display at or very near zero pressure. In

any case the pressure will be displayed in the

measurement units that were specified when the

instrument was ordered.

This confirms that the unit is ready to use. If this

is your first time to use a PCS 400 please review the

Warnings and Cautions information inside the

front cover. Then take the time to familiarize your-

self with the Installation and Operation sections of

this manual and the ‘Menu Tree’ provided there. Te

tree illustrates the command structure and the

functions available from the front panel keypad.

MENSOR SERVICE PLUS

If you have problems using your PCS 400 and you

don’t find the answer in your manual, contact

Mensor at 1.800.984.4200 (USA only), or

1.512.396.4200 for personal assistance, or at any

of the on-line addresses listed in the front of the

manual. We are ready to help.

Mensor’s concern with the welfare of this instru-

ment is not limited to the warranty period. We

provide complete repair services beyond the war-

ranty, as explained in Section 5, Maintenance.

CALIBRATION SERVICES

In addition to servicing our own products Mensor

can perform a complete pressure calibration serv-

ice, up to 20,000 psi, for all of your pressure

instruments. This service includes a Calibration

Certificate and a record of traceability to the pres-

sure standards of the National Institute of Stand-

ards and Technology (NIST).

ACCREDITATIONS

MensorCorp.isregisteredtoBSENISO

9001:2000. The calibration program at Mensor is

accredited by A2LA, as complying with both the

ISO/IEC FDIS 17025:1999 and the ANSI/NCSL

Z540-1-1994 standards.

PCS 400 EVOLUTION

Since its introduction in the PCS 400 has undergone

a continuous process of evolution. Many changes

have been in response to special application re-

quirements expressed by our customers. Once they

are designed these ‘specials’ are either incorpo-

rated into the standard system, or made available

as options to other users with similar require-

ments. All customers are welcome to discuss their

unique requirements. We may already have a solu-

tion, or we can provide one.The system has proven

to be extremely flexible in this way because of the

modularity of both the software and the hardware.

INTRODUCTION PCS 400

1-6 www.mensor.com

INSTALLATION

MOUNTING

The instrument can be set up on a table-top or it

can be rack-mounted. For rack-mount installation,

see the instructions in Section 8, Options.

The special sensor used in the PCS 400 is relatively

insensitive to tilt and vibration. However to further

assure stability and accuracy, excessive motor or

machinery vibration of the mounting surface

should be avoided.

PRESSURE CONNECTIONS

NOTE: When making up connections to

the o-ring adapter use a back-up wrench

to prevent over-stressing the threads in

the manifold block.

The pressure ports on the rear manifold block are

female 7/16 - 20 SAE/MS straight threads per

MS16142 and SAE J514 table 14. They require a

tube fitting boss seal with an o-ring per MS33656.

Mensor provides female 1/8 NPT adapter fittings

with the instrument. The pressure connection can

be made to these adapters with the proper mating

hardware. We recommend the use of either Loctite

Hydraulic Sealant or fresh teflon tape on the

threads of the male pipe fitting. Do not use sealants

on fittings sealed with an o-ring. The integrity of the

seal is particularly important since even micro-

scopic leaks can cause errors in measurements.

Figure 9.2 is a pneumatic schematic of the internal

plumbing (see figures 9.3 through 9.6 in the Appen-

dix for additional pneumatic schematics showing

optional configurations).

Table 9.5 in the Appendix shows the status of

solenoid valves L1 through L6 during different

operating conditions. Requirements for connecting

to the various ports on the PCS 400 manifold are

given below.

SUPPLY Pressure Port

Connect a pressure source to the SUPPLY port of

the PCS 400. This pressure will be used to derive

the CONTROL pressure output at the MEAS-

URE/CONTROL port. The supply pressure must be

greater than the highest control pressure that will

be commanded which is usually the full scale (FS)

range of the instrument.

EXHAUST Pressure Port

The EXHAUST pressure port is either left open to

atmosphere or connected to a vacuum pump in

order to control at pressures below atmospheric

pressure. A vacuum pump will also improve con-

trol for positive pressures below 0.25 psig.

MEASURE/CONTROL Pressure Port

The MEASURE/CONTROL port is a bi-directional

port. It can receive an unknown pressure to be

measured, or upon command it can output a con-

trolled pressure to external devices. In the MEAS-

URE mode, solenoid valve L5 is closed (see table

9.5, Solenoid Valve Truth Table, in the Appendix).

This isolates the regulator from the port but leaves

the measure path open to the transducer(s). In

CONTROL mode, L5 is opened to allow the regu-

lated pressure output to reach the same port.

For optimum CONTROL performance the external

system connected to this port should consist of a

total volume between 0.01 and 0.5 liters. External

volumes less than 0.01 liter will decrease control

stability, and volumes greater than 0.5 liter will

increase overshoot and control times.

REFERENCE Pressure Port

If an optional Barometric Reference Transducer

(BRT) is included in the PCS 400, the REFERENCE

port might be internally connected to its pressure

port. If there is no BRT then the REFERENCE port

is either connected to the reference port(s) of the

gauge pressure transducer(s), or internally plugged

on absolute units. Refer to the Appendix section of

the manual for the appropriate pneumatic sche-

matic diagram that applies to your instument.

CAUTION: HIGH NOISE LEVELS.

As pressure decreases compressed gas will

escape out the EXHAUST port. For ranges

above 600 psi high noise levels may result

during such pressure releases. To overcome

objectionable exhaust noise either install a

muffler or route the port to a remote

location.

PCS 400 INSTALLATION

www.mensor.com 2-1

Table of contents

Other mensor Test Equipment manuals