mensor 9415 User manual

Mensor Model 9415 Multi-Channel Pressure Test System

Mensor LP, 201 Barnes Drive, San Marcos, TX, USA

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

1

Table Of Contents:

Pg 1: Table of Contents

Pg 2: Blank

Pg 3: General Description

Pg 4: General Description

Pg 5: Warnings

Pg 6: Pneumatic Schematic

Setup

Pg 7: Brace Kit Breakdown

Pg 8: Bracing Installation

Pg 9: Tubing Installations Points

Pg 10: Electrical Connectors Installation Locations

Pg 11: Electrical Connectors

Location 1

Pg 12: Location 2

Pg 13: Location 3

Finishing Touches

Pg 14: Upgrade Section

Setup

Pg 15: Vacuum Port Fittings

Pg 16: Removing the Old Power Hub

Pg 17: Disconnect Switch Wiring Change

Pg 18: Electrical Kit Breakdown:

Pg 19: Grounding Rails Installation:

Pg 20: Disconnect Switch Cable Routing

Pg 21: Disconnect Switch Cable Routing

Pg 22: Vacuum Pump Cable Routing

Pg 23: Vacuum Pump Cable Routing

Pg 24: Model 9414 Grounding And Cable Routing

Pg 25: Grounding The 9415:

Pg 26: Tubing

End of Upgrade Section

Pg 27: Operation:

Operation of Model 9414

Pg 28: Operation of Model 9414

Pg 29: Communication Protocol:

Command Set

Pg 30: Normal operation

Normal Shutdown Sequence

Pg 31: Emergency Shutdown Sequence

Notes on Remote Transducers

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

2

“Calibration” of Model 9414 Controller’s Pressure Measuring

Sensors:

Pg 32: “Calibration” of Model 9414 Controller’s Pressure Measuring

Sensors:

Pg 33: “Calibration” of Model 9414 Controller’s Pressure Measuring

Sensors:

Pg 34: Storage and Transportation:

Maintenance:

Pg 35: Maintenance:

Pg 36: General Specifications and Ratings:

Pg 37: General Specifications and Ratings:

Pg 38: Tables:

Pg 39: Tables:

Pg 40: Table 2:

Pg 41: Table 2:

Pg 42: Table 2:

Pg 43-58: Appendix A

Pg 58-60: Appendix B

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

3

Mensor Model 9415

Multi-Channel Pressure Test System

General Description:

The Mensor Model 9415 Multi-Channel Pressure Test System is used for rapid

testing of pressure transducers. It can be a single or dual rack configured with

two, four, or six control channels. The model 9414 (quad or dual) controllers

provide the control channels. For each pair of control channels, there is a Model

9412 pressure tank. The maximum range of this system is 160 psi. Depending

on requirements, a system can be developed with a maximum operating

pressure of 1500 PSI. A Model 9418 Remote Transducer Module with up to four

Mensor CPT6180 remote transducers is used for measurements at the test

device and can have full-scale ranges of up to 160 psi (~11 bar). All internal

transducers have an accuracy of 0.010 % of full scale and a precision of 0.003 %

of full scale. Remote transducers can have accuracies of either 0.010 % of full

scale or 0.01% IS-50 (0.010 % of reading from mid to full scale and 0.005% of

full scale under 50 % of full scale). See General Specifications and Ratings

section near the end of the manual for sizes.

Model 9414

4-Channel

Model 9414

2-Channel

Model 9412

Model 9412

Model 9412

Model 9412

Vacuum Pump

Model 73

Disconnect Switch

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

4

External pressure porting and electrical signal connection pass-thrus are

provided on the left side of the rack when viewed from the front. Pressure ports

include an input for shop air and either two or four output pressure connections to

connect to the Model 9418 Remote Transducer Module or directly to the device

handler (DUT). A cable access port provides entry to the rack for controlling and

reading the remote transducers in the Model 9418 Remote Transducer Module

(25 pin D-sub connector) and a 9 pin D-Sub connector for serial communications

between the rack and a host computer. Sufficient space is allowed for other user

cabling.

The rack will accept AC power (105 to 240 VAC, 47 to 63 Hz.)Power is brought

into the rack via a junction box at the bottom of the rack. The power cord plug on

the input to the rack can be replaced to accept other plugs or can be tied directly

into a main feed. The power cable used is rated for 15 amp service. The Model

9415 system has a power cut off switch located on the top of the left rack which

connects/disconnects the power to the rack’s “Electrical Junction Box”. This box

provides a constant AC power supply to the Model 9414 controllers and houses

electronics for the relay control of the vacuum pump’s AC power supply. The AC

power enters each Model 9414 through a fused and switched “Power Entry

Module” using a standard, NEMA, three-conductor plug. Internally to each Model

9414, the AC power goes directly from the “Power Entry Module” to the front-

mounted, “Emergency Stop” switch which disconnects the AC power going to the

Model 9414’s internal “Switching Power Supply” is rated for 100-240VAC at 47-

63Hz. The switched power is then utilized internally to generate +5 volt DC and

+12 volt DC to control the solenoid valves, electronics, and remote transducers.

The Model 9414 is fused on both the hot and neutral AC lines entering the unit.

The Mensor 6180 transducer(s) in the

remote transducer module (Model

9418) utilize RS-485 for

communications with the Model 9414

Quad Pressure Controller(s). Control

of the isolation solenoids (if equipped)

is done internally in the 9414

controller and provided to the Remote

Transducer Module through the same

25 pin D-sub connector as the RS-

485 communications. The RS-485

port communicates with the remote

transducers at 19200 Baud with 8

data bits, 1 stop bit, and no parity.

Communications between the Model

9414 Dual Pressure Controller and

the user’s computer are on a 9 pin D-

Sub connector at 57,600 Baud, 8 data

bits, 1 stop bit, and no parity. See

Appendix A for a list of the command sets.

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

5

Precautions:

The maximum working pressure of the system is 300psi (~20

bar), however, the limitation of the downstream equipment is

annotated on the controllers and needs to be adhered to

The system contains large pressure storage tanks that can

hold large amounts of kinetic energy. User should bleed all

pressure stored in the tanks before servicing, removing

pressure hoses, or removing instruments. Normal shutdown

and emergency shutdown should start the process, but due

to the size of the tanks, and desire to maintain a safe

discharge rate, this operation may take an extended period of

time to achieve. Utilize the pressure gauges on the front of

the 9412 Module to ensure pressure has been released from

each tank.

The system uses normal power line AC voltages. User

should remove the AC power cord from mains when

servicing inside enclosures.

Due to the internal pressures and voltages used within the

9415 system, only qualified and properly trained personnel

should service this system.

The emergency shutdown electrical system is limited in

capacity to approximately 6 amps of power. It is intended to

shut down the pressure portion of the system (Model 9414)

and slowly release pressure from the pressure tanks in the

Model 9412(s).

User should orient the system in a way that the Emergency

Shutoff Button, the power cord connection, and the pressure

valves on the side of the rack, if so equipped, should also be

accessible to the operator for rapid shutdown.

Special handling and carrying techniques are required as

some individual components in the system exceed 18 kg. A

“TWO MAN LIFT” should be employed.

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

6

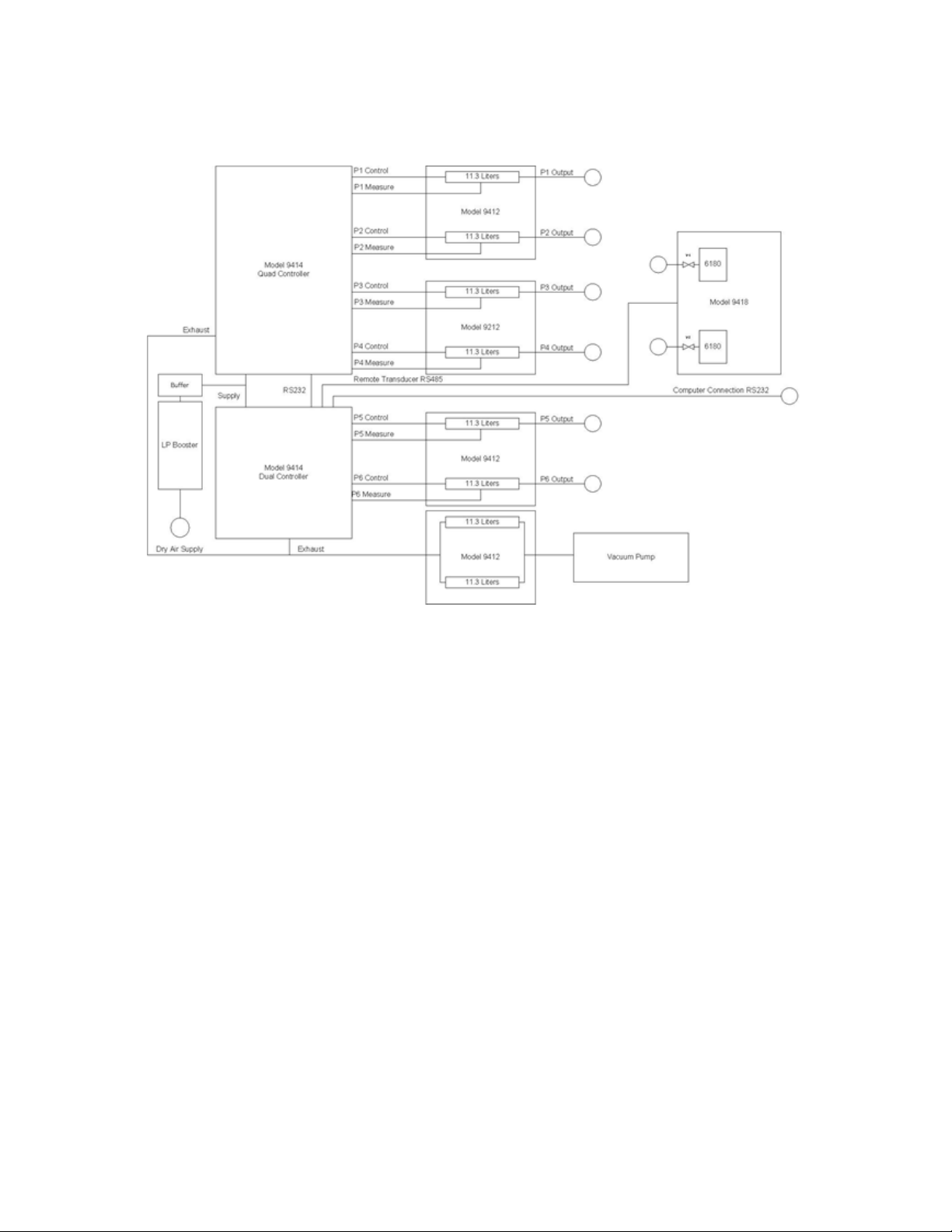

Pneumatic Schematic

Setup:

The initial installation should include removing any packing material used in

shipment and inspecting that fittings and screws are snug and that hoses and

electrical cords are not chaffed or cut. The system rack is mounted on casters

and should be installed on a level surface with adequate airflow to keep the

system within its 15 to 45 C optimum operating temperature range. The

emergency shutoff button on the 9414 controller, the rack power connection, and

the safety valves on the side of the rack, if so equipped, should be accessible to

the operator. Wheel chocks or threaded feet/supports should be used where

appropriate to keep the unit in place. The system operates on line voltages

between 105 and 240 VAC, 47 to 63 Hz. A dry, clean, compressed air or

nitrogen supply is required for operation.

The quad pressure output ports are located on the side of the rack and are

labeled P1, P2, P3, and P4 Outputs. If a dual channel system is ordered, only

P1 and P2 will be available. If a six-channel system is ordered, P5 and P6 will be

available. The fittings on the side panel are ¼” tube fittings. Sufficient ¼” flexible

tubing is provided to allow four 6 to 10 foot (~2 meters) pressure hoses to

connect between the rack and pressure selection valves in either the Model 9418

Remote Transducer Module or the handler.

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

7

First, remove the side panels on the left and right side of the

rack with the main power disconnect switch. This is

accomplished by turning the fasteners on the side panel

and removing the panel. If a rear door is installed it should

be opened for easier access.

Then, using the supplied allen wrench, loosen the vacuum

pump’s shipping locks; the vacuum pump is located on the

bottom of the rack with the vented front panel. Refer to the

instruction package with the allen wrench for more details

on this step.

Reinstall the panel on the left side and leave the panel off on the right side.

Remove the left side panel of the other rack (the one without the main power

disconnect switch). If a rear door is installed, open that one as well. Proceed to

bolt the racks together using the braces provided.

Brace Kit Breakdown:

Brackets (2)

10-32 Screws (8)

Lock Washer (8)

Flat Washer (8)

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

8

Bracing Installation:

The first bracket should be installed above the 20 rail indentation. Each screw

should have a lock washer followed by a flat washer which then contacts the

bracket.

20 Rail Indentation

2 Rail Indentation

10-32 Screw

Lock Washer

Flat Washer

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

9

The next bracket should be installed above the 2 rail indentation. Each screw

should have a lock washer followed by a flat washer which then contacts the

bracket.

Tubing Installations Points:

Do not disconnect any tubing. All tubing that needs to be attached will have one

loose end. All loose ended tubing will be in the rack that doesn’t have the main

power disconnect.

Grab the vacuum line (3/8”

Yellow Tube) labeled

“Vacuum”coming off the B1

and B2Model 9412 and

connect it to the vacuum

pump port.

Grab the remaining vacuum

line (3/8” Yellow Tube)

labeled “P1 Exhaust”coming

off the 9414 Quad and

connect it to the port labeled

“Exhaust”on the P1 side of

the Model 9414 Quad.

Grab the air supply line (1/4”

Black Tube) labeled “P1

Supply”coming off the 2-

Channel Model 9414 supply

Tee and connect it to the port

labeled “Supply”. This port is

located on the P1 side of the

Model 9414 Quad.

Grab the air supply line (3/8”

Black Tube) labeled “Shop

Air”coming off the Model 73

and connect it to the rear of

the “Shop Air Input port

located on the I/O Port

Panel.

Grab the P5 output line (1/4”

Blue Tube) labeled “P5

Output”coming off the 9412

and connect it to the rear of

the “P5 Output Port”located on the I/O port panel.

Grab the P6 output line (1/4” White Tube) coming off the 9412 labeled “P6

Output”and connect it to the rear of the “P6 Output” located on the I/O

port panel.

Ensure that all tubing connections are secured tightly, to ensure an air tight seal,

before proceeding.

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

10

Electrical Connectors Installation Locations:

There are three major electrical connectors that need to be plugged in and one

grounding wire that will need to be secured to the chassis grounding bus. Do not

unplug anything. All wiring that needs to be attached will have one loose end. All

loose ended wiring will be in the rack that doesn’t have the main power

disconnect. Ensure that the AC power cord is removed from any mains during all

electrical work.

Location 1

Location 2

Location 3

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

11

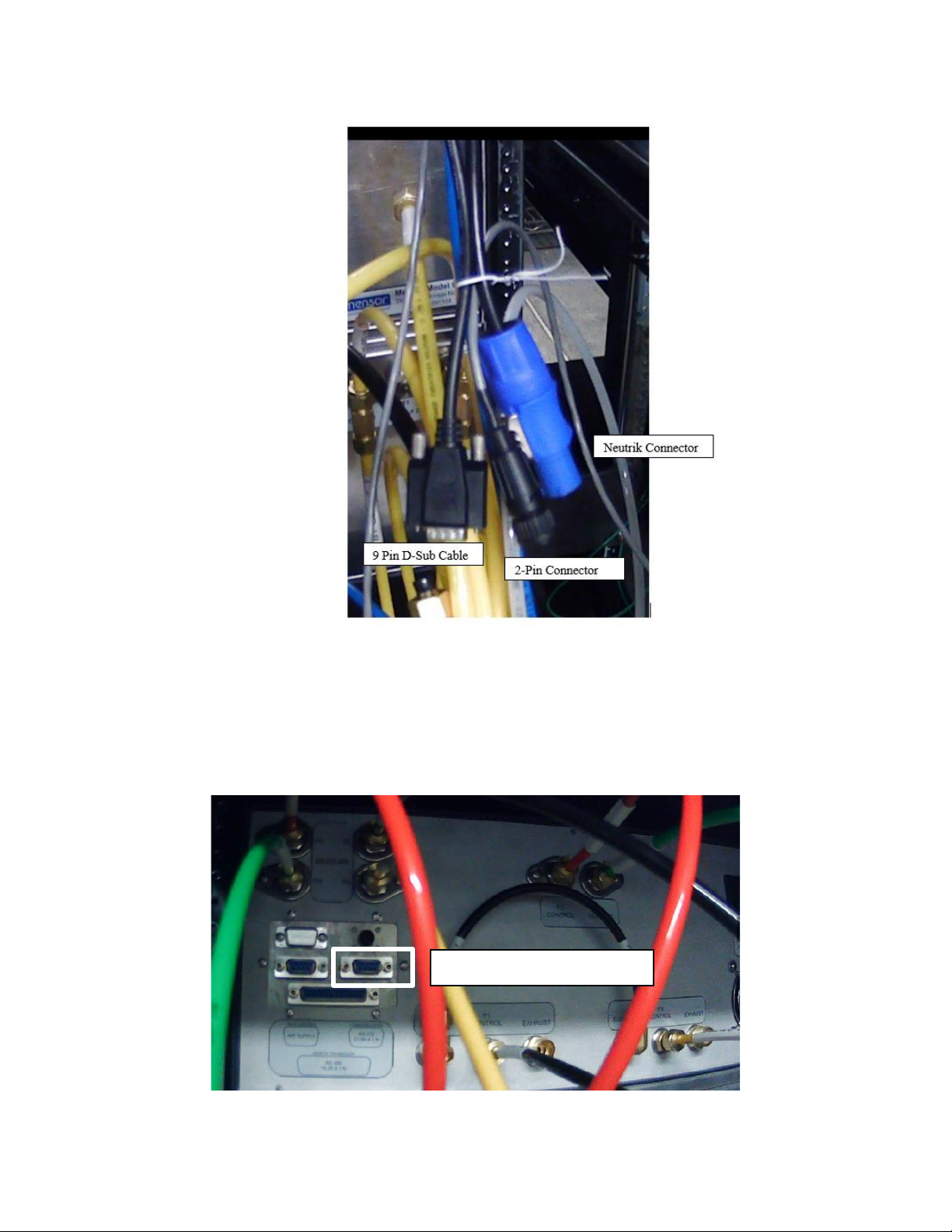

Electrical Connectors:

The “Neutrik Connector” is responsible for providing AC power to the 4-

Channel Model 9414.

The “2-Pin Connector” signals the vacuum pump to turn on/off.

The “9 Pin D-Sub Cable” is responsible for communication between the

two Models 9414.

Location 1:

Insert and secure the “9 pin D-Sub Cable”into the back of the Model

9414.

9 Pin D-Sub Cable Connection

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

12

Location 2:

Insert the black “2-Pin Connector”into the black port labeled “Vacuum

Relay”. Be cognizant of the orientation of the connectors’ and sockets’

keying for correct polarity.

Insert the blue “Neutrik Connector”into the blue port label “Dual

Controller”. Ensure the connector is secured by inserting the connector,

rotating clockwise, and confirming that the metal slide lock is locked.

2-Pin Connector Connection

Neutrik Connector Connection

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

13

Location 3:

There will be a loose green wire. The loose end of this wire should

be secured to the chassis grounding bus shown above. The ground

terminal will be located near the vacuum pump between the two

racks.

Finishing Touches:

Connect the existing model 9418 to

the back of the dual Model 9414’s

I/O electrical panel with the

provided cable (DB 25 M-F cable).

Connect a source of clean, “Shop

Air”, to the supply port on the I/O

port panel.

Connect the completed model

9415’s AC power cable to the

mains.

The remote transducer module

Model 9418 should be mounted

close to the devices under test to

minimize the pressure exchanges and maximize the operational speed of the

system. The 9418 is electrically connected to the Model 9415 system using the

25 pin d-sub cable provided. Pneumatic connections between the 9418 and the

device under test should be short and with minimal volume. The actual mounting

location is left to the user’s discretion.

Grounding Terminal

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

14

Upgrade Section:

*This section is only applicable if a unit is being upgraded and meets the material

prerequisites.*

Prerequisites Material Assumptions:

A model 9418

A rack with a 9414 Quad, 9412, 9412, a vacuum pump, and an

emergency disconnect installed

Materials Provided:

A rack with a model 73, 9412, 9414 Dual, and a secondary 9412

Labeled Tubing

Electrical Junction box

Wires and cables

Fittings

Bracing

Setup:

Begin by removing any packing material used in

shipment and inspecting that fittings and screws are

secure and that hoses and electrical cords are not

chaffed or cut. After the unit has been confirmed to be

sound, proceed to install the Model 9414 Dual into the

top slot of the rack. There should be a total of four

screws holding the unit in.

Once the Model 9414 is secure, remove the left panel

and right panel of the rack and open the rear door if

one is installed. The removed left panel will have a

labeled I/O for different channel pressure connections.

Remove the right panel and left panel on the existing

rack and open the rear door, if one is installed. Set

aside the blank right panel for later use. The two racks

can now be bolted together using the provided

bracing. Refer to the “Brace Kit Breakdown:” &

“Bracing Installation:” sections above for greater detail.

Install the panel with the various ports and legend on the left side of the newly

bolted together rack system. Install the blank panel that was set aside on the

other side. Once done it should resemble the following images.

Screw Locations

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

15

Left Side: Right Side:

Vacuum Pressure Relief Valve Upgrade:

.5 PSI Relief Valve

1”x ½” Reducer

1/2” FNPT x 3/8” Tube Tee

3/8” Coupler

¼” NPT x 3/8” Elbow

1” Vacuum Flange

¼” NPT Adapter

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

16

Additional fittings will need to be installed on the vacuum pump. Note that Teflon

tape should be used for all connections. Begin by installing a ¼” NPT Adapter

with a 1” Vacuum Flange on to the end of the vacuum pump. This will be followed

by a ¼” NPT x 3/8” elbow. A 3/8” coupler will need to follow the end of the elbow

which then connects to a ½” FNPT x 3/8 Tube Tee. This Tee will then connect to

a ½ ”x 1” Adapter that terminates with a .5 PSI Relief Valve. Refer to the image

above for the ideal orientation of the components.

Removing The Old Power Hub:

*The machine should be powered down and unplugged.*

Before the updated electronics can be installed, the old ones must be removed.

The old power hub should be located beside the vacuum pump. Begin by

unplugging all connections. There are two main cables coming off the power hub.

Follow these cables and unplug/unscrew their terminations. More information on

removing the terminations is provided ahead. After all of the cables have been

freed, the two bolts holding the panel in place can be unscrewed. The panel with

the attached electrical junction boxes can then be removed.

Unplug Cables

Unscrew Bolts

Unplug/Unscrew Terminations

Unplug/Unscrew Terminations

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

17

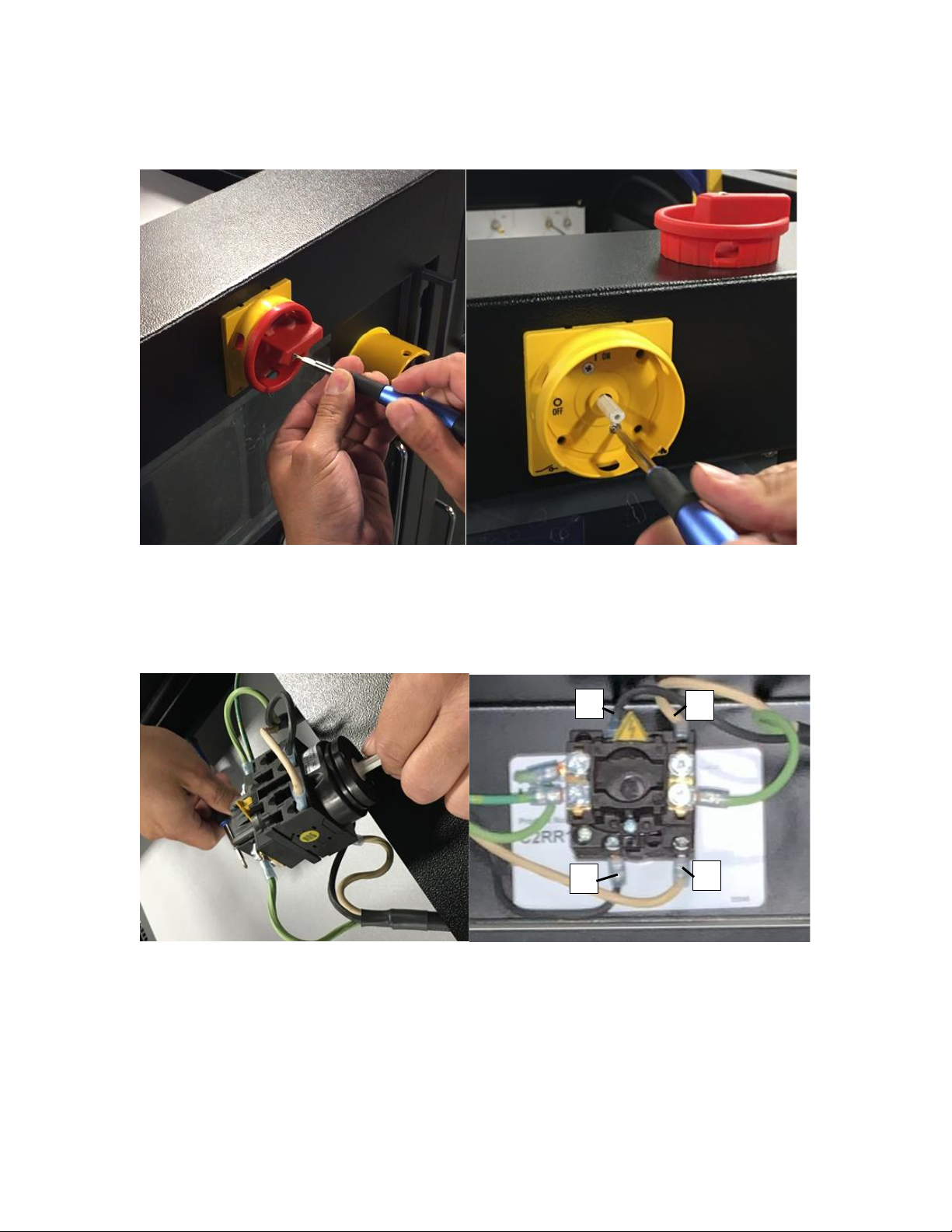

Disconnect Switch Wiring Change:

Remove the top panel of the rack with the disconnect switch. There shoud be a

total of 6 phillips screws holding the panel in place. Unscrew the red dial and

remove it from the switch. Unscrew the last two screws holding the switch’s

yellow body in place. The yellow body can be pulled off and the switch can be

pushed into the rack.

Unscrew the wires 2 and 4 from the switch. Both wires 2 and 4 can be

determined by markings on the rear of the switch. Due to the existing ground

connecting the original grouning to the mains ground, the cabe should not be

removed. Instead, the removed wires should be secured and stowed out of the

way.

Use the two-wire cable provided to connect to the 2 and 4 connections on the

switch. Ensure that the brown lead connects to 2 and the blue lead connects to 4.

1

3

4

2

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

18

After the switch has been rewired, it can be reinstalled. The reinstallation process

is the inverse of the removal process. Note that the switch should be reinstalled

with the yellow triangle on top and that the wire routing of the new cables will be

shown in a later section. Ensure to reinstall and secure the top panel that was

suggested to be removed in the previous steps.

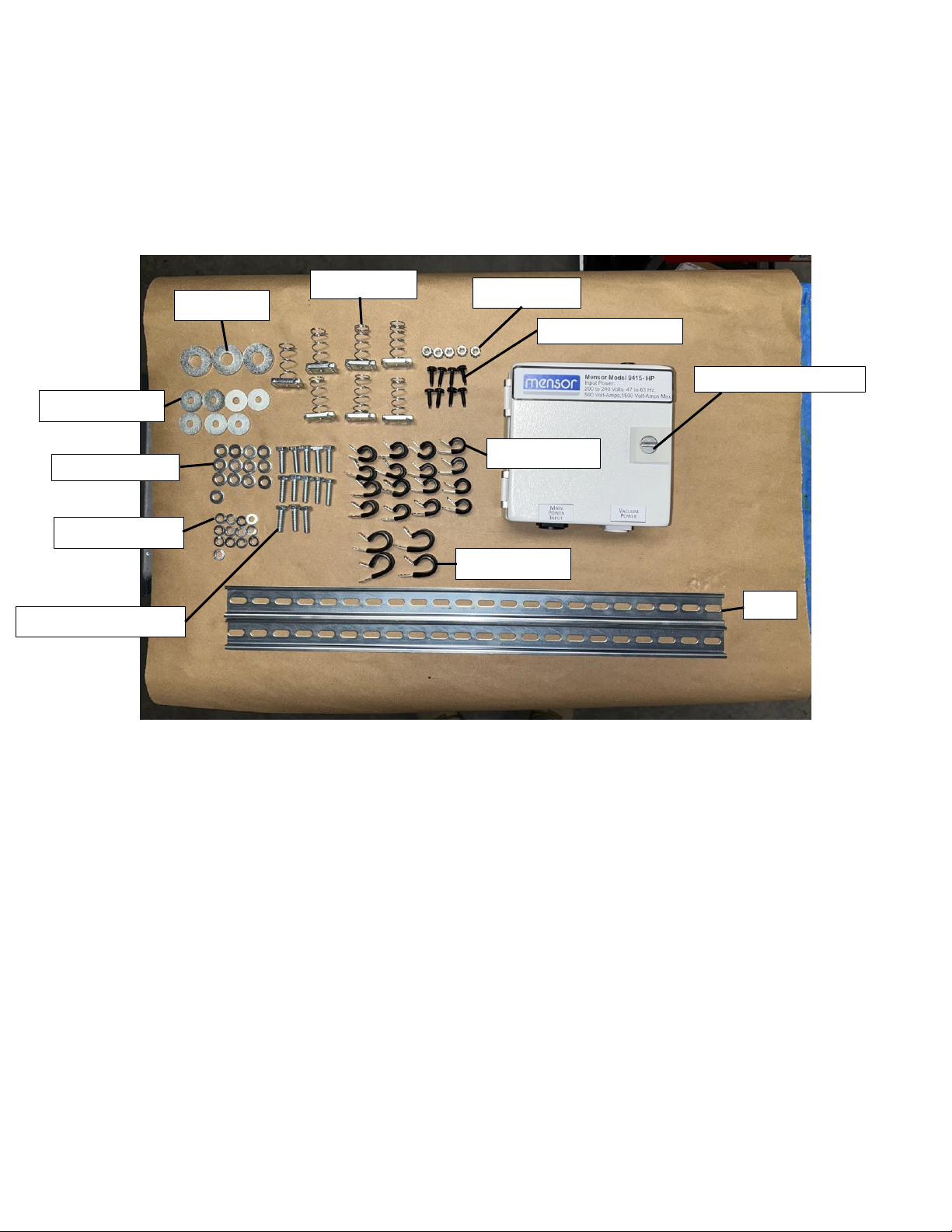

Electrical Kit Inventory:

Quantity:

½” Washer (3)

¼” x 1” Washer (7)

¼” Lock Washer (13)

¼” x 1” Hex Head Bolt (13)

¼” Rail Nut (7)

¼” Lock Nut (5)

10-32 Black Screws (8)

3/8” P-clamp (16)

5/8” P-clamp (4)

Rail (2)

Electrical Junction Box (1)

Rail

5/8”P-Clamp

½” Washer

¼” x 1” Washer

¼” Lock Washer

10-32 Black Screw

3/8”P-Clamp

¼”Lock Nut

¼” x 1” Hex Head Bolt

¼” Rail Nut

¼” Washer

Electrical Junction Box

Mensor Model 9415 Multi-Channel Pressure Test System Manual Rev. I

19

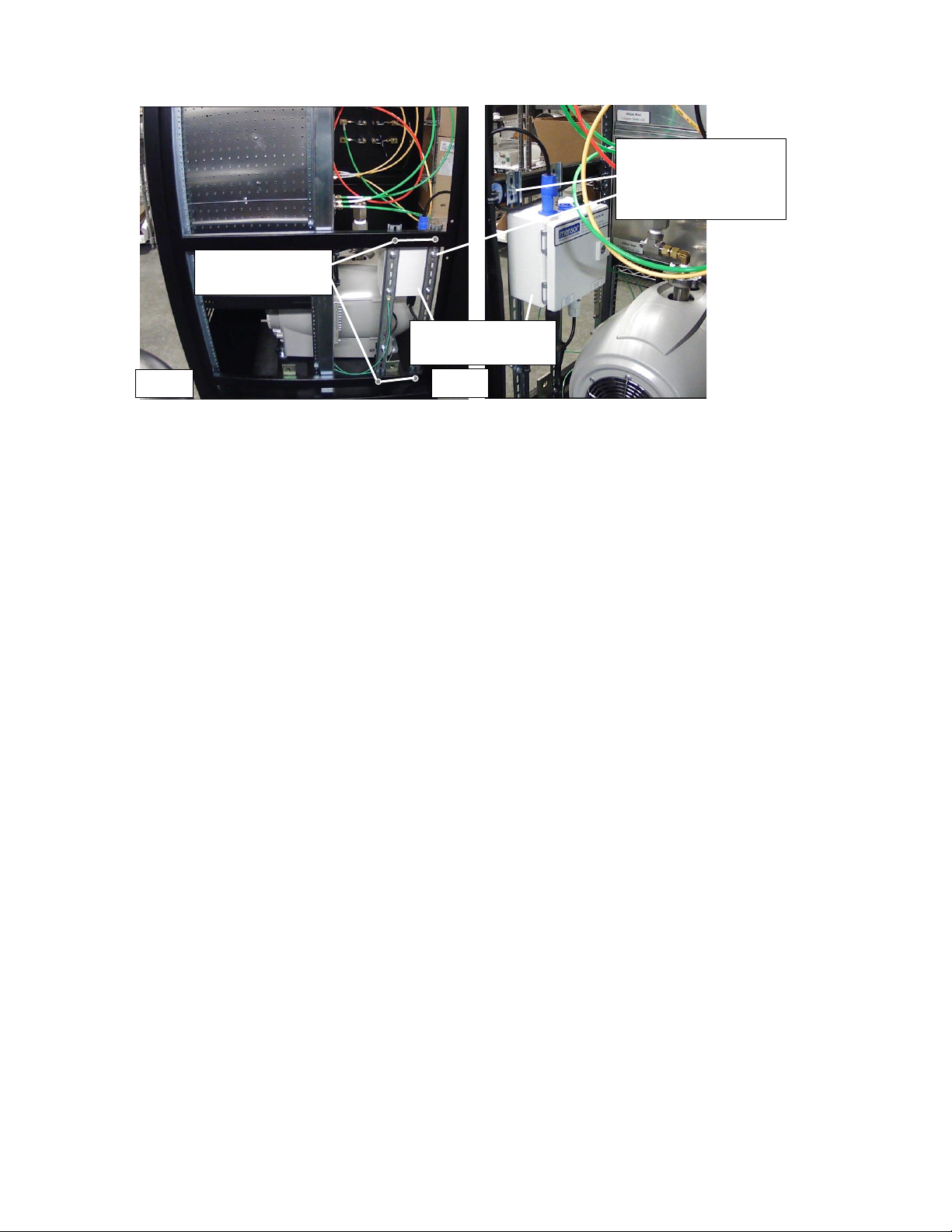

Grounding Rails Installation:

Slide 2 rail nuts into the middle and bottom rack channels as shown in the image

above. Note that this rack should be the one with the vacuum pump installed.

Use a ¼” x 1” Hex Head Bolt followed by a ¼” Lock Washer and a ¼” Washer,

then attach the Rail to each Rail Nut. The bolt should only be hand tightened to

the point that the rail is held upright, but can still slide around in the rack’s

channel. Refer to the images above as needed.

Next, attach the Electrical Junction Box to the rails. Slide the rails as needed to

get the alignment right. The Electrical Junction Box should be attached near the

top of the rails as shown in the above image. Use a ¼” x 1” Hex Head Bolt

followed by a ¼” Lock Washer and then a ¼” Washer, to bolt the Electrical

Junction Box in place in each of its four rear mounting holes. After the Electrical

Junction Box has been installed, proceed to tighten the Rail Nuts. Note that the

Electrical Junction Box should be near the rear of the rack as shown in the image

above.

Rail Nuts

Installation Points

¼” x 1” Hex Head Bolt

¼” Lock Washer

¼” Washer

Rail

Electrical Junction

Box

Front

Rear

Table of contents

Other mensor Test Equipment manuals