MENZL Multitest ND User manual

Multitest ND

Operator's manual

-3-

Contents

Operating and safety instructions............................................................................................................5

General remarks..................................................................................................................................5

Remarks on performing tests..............................................................................................................5

Operating environment.......................................................................................................................5

Malfunction and excessive strain........................................................................................................5

Testing and maintenance ....................................................................................................................5

Care and cleaning ...............................................................................................................................5

Accessories.........................................................................................................................................6

Specifications..........................................................................................................................................7

Scope of delivery................................................................................................................................7

Controls ..............................................................................................................................................8

Introduction.............................................................................................................................................9

The tester ............................................................................................................................................9

Features of the tester...........................................................................................................................9

Scope of possible tests........................................................................................................................9

Performing tests....................................................................................................................................10

Important note on performing tests...................................................................................................10

Normal-pressure equipment..............................................................................................................10

Lung-governed demand valve—leak-tightness without positive medium pressure.....................10

Lung-governed demand valve—leak-tightness without negative medium pressure....................11

Lung-governed demand valve—leak-tightness with medium pressure .......................................11

Lung-governed demand valve—opening pressure.......................................................................12

Mask—leak tightness...................................................................................................................12

Positive-pressure equipment.............................................................................................................13

Lung-governed demand valve—leak-tightness without positive medium pressure.....................13

Lung-governed demand valve—leak-tightness with medium pressure .......................................13

Lung-governed demand valve—closing pressure........................................................................14

Mask—leak tightness...................................................................................................................14

Mask—exhalation-valve opening pressure..................................................................................15

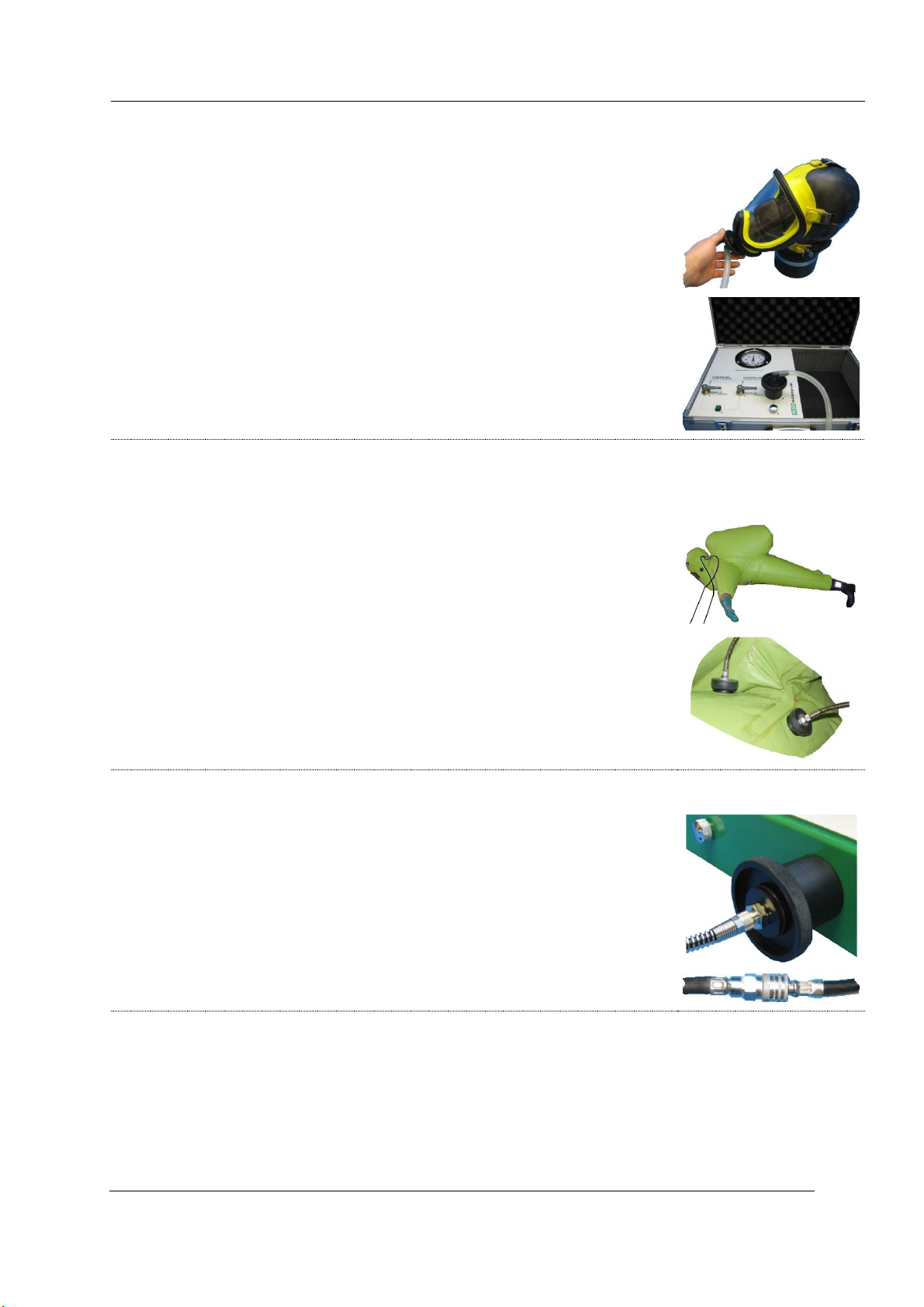

Chemical protective suit...................................................................................................................15

Preparing the suit for testing ........................................................................................................15

Letting the suit pressure stabilize.................................................................................................15

Chemical protective suit—valve testing ......................................................................................16

The dummy head...................................................................................................................................17

Inserting/replacing the battery ..............................................................................................................18

Accessories ...........................................................................................................................................19

Multitest ND

Operator's manual

-5-

Operating and safety instructions

General remarks

The health and lives of people may depend on this tester. All persons who make decisions

regarding its use, who operate, service and maintain it or who check whether it is fully

functional must thoroughly and carefully read, understand and follow the instructions in this

operator's manual. The tester has been tested and has left the factory with all features in

perfect working order.

The information provided in this manual is subject to change without notice. Errors and

omissions excepted.

Remarks on performing tests

Do NOT use thetester for performing tests on pieces of equipment other than those mentioned

in this manual. Never apply medium pressure to a lung-governed demand valve while it is

attached to the tester’s equipment connector. Otherwise, the low-pressure gauge and/or the

lung-governed demand valve may get damaged. For more information on how to test

equipment, please refer to the relevant sections of this manual.

Operating environment

Set the tester up in a dust-free location with as little fluctuations in ambient air temperature

and humidity as possible. Avoid direct exposure to sunlight because it may have a negative

impact on the tester’s accuracy.

Malfunction and excessive strain

Whenever it is likely that the tester is no longer safe for use, make it inoperative and secure it

against any unintentional operation. A service representative of the manufacturer, or a

similarly trained and authorized person, is to diagnose and remedy the cause of malfunction.

Testing and maintenance

The tester itself needs to be tested annually to ensure that it is fully functional and leak-tight

at all pressure levels. Only original replacement parts, fitted by authorized persons, may be

used for repairs. Every 6 years, the tester is to be serviced and recalibrated by the

manufacturer. If the tester gets used a lot, it is recommended that you have it serviced and

recalibrated annually. Where there is a conflict with national provisions and requirements, the

national provisions and requirements shall prevail.

Care and cleaning

Remove dust by carefully wiping the tester's housing with a soft cloth. To get rid of more

stubborn dirt, use a soft, damp cloth and a mild cleaning solution. Never use scourers,

alkaline/acidic detergents, scouring powder or volatile solvents such as alcohol, petroleum

spirits, dilutions or insecticides for cleaning.

Storage

Store the tester at around 20 °C in a dry location that is free from dust and dirt. Keep the tester

protected from direct sunlight. If you do not use the tester for several weeks in a row, you

should remove the battery for environmental and safety reasons.

Multitest ND

Operator's manual

-6-

Accessories

Verify you have received all accessories included in the scope of delivery.

Multitest ND

Operator's manual

-7-

Specifications

Dimensions:

550 x 200 x 370 mm (w x h x d)

Medium-pressure compressed-air

connectors:

euro coupling

Power supply:

1.5V battery

Power adapter:

1.5V DC 1A

Weight:

10.00 kg

Gauge

Pressure range

Accuracy class

Low pressure

+/-20 mbar

1.6%

Scope of delivery

The scope of delivery includes:

•Multitest ND

•mask testing hose

•dummy head complete with filling valve

•adapters (may vary depending on the order placed)

•sealing plug for hose of lung-governed demand valve

•timer

•silicon spray

•1.5V battery (type D cell)

•operator's manual

Multitest ND

Operator's manual

-8-

Controls

1

low-pressure gauge

5

pump push-button

2

suction-pump lever

6

equipment connector

3

pressure-pump lever

8

battery compartment (on the side of the tester)

4

relief valve

9

jack for power adapter (1.5V)

20

dummy head

30

mask testing hose

21

push-button valve

30a

round thread to be attached to equipment

connector

22

relief valve for dummy head

30b

round thread to be attached to mask

23

clamp

Multitest ND

Operator's manual

-9-

Introduction

Constantly increasing demands with regard to the performance and operational safety of

respiratory protective equipment call for a sustained effort to continually optimize equipment

testers.

Combining pinpoint accuracy with utmost operator friendliness and a stylish design, the Menzl

“Multitest ND” tester meets all the requirements of state-of-the-art equipment testing.

The tester

The “Multitest ND” tester is suitable for testing respiratory protective masks and lung-governed

demand valves at low pressure. In its basic configuration, it can be used for performing tests

on pieces of normal-pressure equipment with round-thread connectors. Thanks to a wide

range of adapters (see accessories), it is also possible to test positive-pressure equipment as

well as different makes of chemical protective suits.

Features of the tester

One battery (type D cell) is required for operating the tester. A compressed-air supply is not

needed. Optionally, the tester can be powered via a 230V/1.5V mains adapter. The low

pressure for leak-tightness tests and functional tests is provided by the tester's built-in pump

and shown on the low-pressure gauge. Chemical protective suits get inflated via the filling

hose's push-button valve, which features a plug-in nipple that is compatible with the plug-in

safety coupling. The dummy head can be inflated with compressed air from either an SCBA

or a compressed-air supply line.

Scope of possible tests

- all leak-tightness tests, opening-pressure tests and closing-pressure tests

- all tests performed at low pressure

- all tests done with a suction pump or a pressure pump

Multitest ND

Operator's manual

-10 -

Performing tests

For the time intervals against which leak-tightness tests and functional tests are to be carried

out, refer tothe manual provided by the equipment manufacturer. Always perform tests against

the specifications found in the relevant equipment manual.

Important note on performing tests

Do NOT apply medium pressure to the lung-governed demand valve while it is attached to

the equipment connector.

Be sure to strictly adhere to the following sequence of steps in order to prevent the tester and the

lung-governed demand valve from being damaged:

- Detach the lung-governed demand valve from the equipment connector.

- Apply medium pressure to the lung-governed demand valve.

- Attach the pressurized lung-governed demand valve to the equipment connector.

Normal-pressure equipment

Lung-governed demand valve—leak-tightness without positive medium

pressure

Attach the lung-governed demand valve to the equipment

connector.

Seal the connecting nipple of the lung-governed demand valve.

Move the “pressure pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “pressure pump” lever to the “CLOSED”

position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Multitest ND

Operator's manual

-11 -

Lung-governed demand valve—leak-tightness without negative medium

pressure

Attach the lung-governed demand valve to the equipment

connector.

Seal the connecting nipple of the lung-governed demand valve.

Move the “suction pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “suction pump” lever to the “CLOSED” position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Lung-governed demand valve—leak-tightness with medium pressure

IMPORTANT: Be sure to strictly adhere to the sequence of steps!

Detach the lung-governed demand valve from the equipment

connector.

Attach the connecting nipple of the lung-governed demand valve to the

SCBA.

Open the breathing-air-cylinder valves.

Attach the lung-governed demand valve to the equipment

connector.

Move the “pressure pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “pressure pump” lever to the “CLOSED”

position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Multitest ND

Operator's manual

-12 -

Lung-governed demand valve—opening pressure

IMPORTANT: Be sure to strictly adhere to the sequence of steps!

Detach the lung-governed demand valve from the equipment

connector.

Attach the connecting nipple of the lung-governed demand valve to the

SCBA.

Open the breathing-air-cylinder valves.

Attach the lung-governed demand valve to the equipment

connector.

Move the “suction pump” lever to the “OPEN” position.

Press the pump push-button.

Perform the test against the specifications provided by the equipment

manufacturer.

Mask—leak tightness

Strap the mask onto the dummy head.

Connect the testing hose to the tester and the mask.

Move the “suction pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “suction pump” lever to the “CLOSED” position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Multitest ND

Operator's manual

-13 -

Positive-pressure equipment

Lung-governed demand valve—leak-tightness without positive medium

pressure

Attach the lung-governed demand valve to the equipment

connector.

Seal the connecting nipple of the lung-governed demand valve.

Move the “pressure pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “pressure pump” lever to the “CLOSED”

position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Lung-governed demand valve—leak-tightness with medium pressure

IMPORTANT: Be sure to strictly adhere to the sequence of steps!

Detach the lung-governed demand valve from the equipment

connector.

Deactivate the positive-pressure function of the lung-governed

demand valve.

Attach the connecting nipple of the lung-governed demand valve to the

SCBA.

Open the breathing-air-cylinder valves.

Attach the lung-governed demand valve to the equipment

connector.

Move the “pressure pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “pressure pump” lever to the “CLOSED”

position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Multitest ND

Operator's manual

-14 -

Lung-governed demand valve—closing pressure

IMPORTANT: Be sure to strictly adhere to the sequence of steps!

Detach the lung-governed demand valve from the equipment

connector.

Activate the positive-pressure function of the lung-governed

demand valve.

Attach the connecting nipple of the lung-governed demand valve to the

SCBA.

Open the breathing-air-cylinder valves.

Attach the lung-governed demand valve, with its positive-pressure

function activated, to the equipment connector.

Release pressure via the relief valve for 5 seconds.

Perform the test against the specifications provided by the equipment

manufacturer.

Mask—leak tightness

Strap the mask onto the dummy head.

Connect the testing hose to the tester and the mask.

Move the “suction pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “suction pump” lever to the “CLOSED” position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Multitest ND

Operator's manual

-15 -

Mask—exhalation-valve opening pressure

Strap the mask onto the dummy head.

Connect the testing hose to the tester and the mask.

Move the “pressure pump” lever to the “OPEN” position.

Press the pump push-button.

Perform the test against the specifications provided by the equipment

manufacturer.

Chemical protective suit

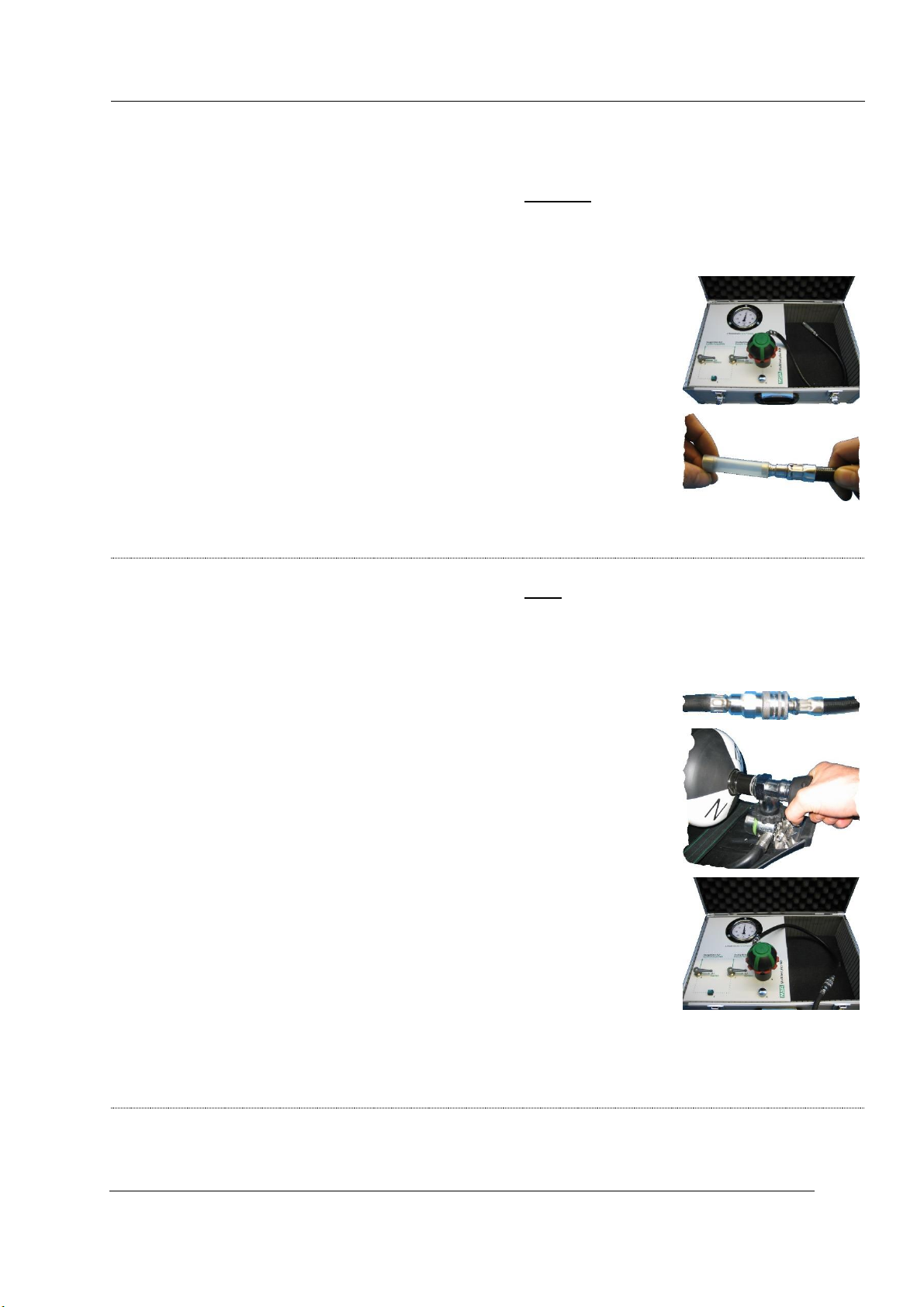

Preparing the suit for testing

Unfold the suit on a workbench or the clean floor.

Remove all valve chambers.

Remove all exhalation-valve disks.

Connect the testing hose to the exhalation valve.

Attach the testing hose to the tester's equipment connector.

Connect the filling hose to the exhalation valve.

Connect the filling valve to the medium-pressure supply.

Seal all other exhalation valves of the suit.

Letting the suit pressure stabilize

Use the filling valve to adjust the pressure to the level that is required for

testing according to the suit manufacturer.

CAUTION: Never increase the pressure in the suit beyond the

required stabilization pressure. Otherwise, seams and joints may

get damaged.

Perform the test against the specifications provided by the equipment

manufacturer.

Multitest ND

Operator's manual

-16 -

Chemical protective suit—valve testing

Connect the testing hose to the inside part of the valve.

Attach the testing hose to the tester's equipment connector.

Move the “suction pump” lever to the “OPEN” position.

Press and hold the pump push-button.

Let the pressure build up until it is slightly higher than the level required

for testing and move the “suction pump” lever to the “CLOSED” position.

Release the pump push-button.

Release pressure via the relief valve until the level required for testing is

reached.

Perform the test against the specifications provided by the equipment

manufacturer.

Repeat these steps for every single valve of the suit!

Multitest ND

Operator's manual

-17 -

The dummy head

General remarks

For optimal results during mask testing, inflate the dummy head to the size of a normal human head

(see images) via the filling hose mounted to the dummy head's base. The filling hose is equipped with

a push-button valve that can be connected to a medium-pressure supply (e.g. the medium-pressure

hose of an SCBA). Inflate the dummy head by pressing the push-button.

The dummy head is

insufficiently inflated.

The dummy head is ideally

shaped for testing masks.

The dummy head is inflated too

much.

CAUTION: Inflating the dummy head too much may damage it.

Taking care of the dummy head

In order to prevent premature wear and tear, protect the dummy head from direct exposure to sunlight

and cover it with a protective hood if it is not used for an extended period of time. Once a week, apply

plenty of silicon spray and let it work into the (uncovered) dummy head overnight.

Article number of silicon spray (500 ml) 1800-015

Multitest ND

Operator's manual

-18 -

Inserting/replacing the battery

The built-in battery compartment is located on the side of the tester. One battery (type D cell) is

needed for powering the tester's internal pump. To insert or replace the battery, proceed as

follows:

Remove the battery-compartment cover

Turn the battery-compartment cover to the left with a flat-blade screwdriver or a coin and remove it.

Replace the battery

Remove the empty battery and insert a new one. Always observe the correct polarity!

Put the battery-compartment cover back on

Put the battery-compartment cover back on and turn it to the right with a flat-blade screwdriver or a

coin to lock it in place.

Jack for power adapter

Next to the battery compartment, there is a jack for a power adapter (230 V AC / 1.5 V DC, 1A).

Always verify that the output voltage (1.5 V) and polarity of the power adapter are correct. Plug the

power adapter's DC cord into the tester's DC jack. The use of a power adapter automatically

disconnects the battery.

Multitest ND

Operator's manual

-19 -

Accessories

Adapters for

respiratory protective masks

MSA Auer plug-in connector

330-048

MSA Auer plug-in connector AutoMaXX

330-152

Threaded connector M 45x3

330-050

Dräger plug-in connector

330-049

Interspiro plug-in connector

330-051

Interspiro Clic

330-168

Plug-in connector ESA

330-178

Adapters for

lung-governed demand valves

MSA Auer plug-in connector

330-011

MSA Auer plug-in connector AutoMaXX

330-149

Threaded connector M 45x3

330-012

Dräger plug-in connector

330-013

Interspiro plug-in connector

330-014

Interspiro Clic

330-162

Plug-in connector ESA

330-175

Adapters for

chemical protective suits

MSA Auer testing adapter

330-335

Dräger testing adapter

330-295

Interspiro testing adapter

330-294

MSA Auer sealing adapter

330-164

Dräger sealing adapter

330-500

Interspiro sealing adapter

220-372

Dräger valve testing adapter

330-501

Interspiro valve testing adapter

330-502

Equipment for testing

chemical protective

suits (CPS)

Testing hose with connecting adapter for Auer CPSs

330-039

Filling hose with connecting adapter for Auer CPSs

330-041

Valve testing unit with valve testing adapter for Auer

CPSs

330-235

Fastening straps for

helmet-mask

combinations (HMC)

MSA Auer (old and new)

330-120

Heros

180-162

Dräger

330-210

HMC stainless steel

support

Main unit (MSA Auer, Dräger)

330-233

HMC MSA Auer old

330-127

HMC Heros

330-128

Other accessories

Protective hood for dummy head

340-001

Silicon service spray

1800-015

Medium-pressure hose with connectors 600 mm

330-202

Software

Please do not hesitate to get in touch with us if you have

any questions or would like to learn more about the

functionality of our software products, their range of

possible applications or their use in networked

environments.

Inventory management

330-005

Barcodes

Handheld barcode scanner

330-154

Base for handheld barcode scanner

260-044

Front-adhesive barcode labels (pack of 100)

330-220

Back-adhesive barcode labels (pack of 100)

330-219

Multitest ND

Operator's manual

-20 -

Cylinder pressure gauge

For checking the pressure levels of 200-bar and 300-

bar breathing-air cylinders. Easy to operate. Pull-back

depressurization mechanism.

330-023

Ultrasonic cleaner

For the optimal cleaning and disinfecting of masks and

lung-governed demand valves in a minimum of time.

Masks do not need to be disassembled. Comes

complete with an immersion basket and a lid.

for 2 masks

60-103

for 6 masks

330-148

for 9 masks

330-156

TM Speed mask drying cabinet

For drying up to 12 respiratory protective masks in

approximately 1 hour. All-automatic operation,

controlled by an adjustable timer. Masks are dried at a

maximum of 50 °C by means of a hot-air blower.

330-399

RDT 09 mask washing machine

For cleaning, disinfecting and drying up to 9 respiratory

protective masks in approximately 4 hours. PLC-

controlled, all-automatic operation. Disinfectant gets

added automatically. Freely adjustable concentration

level (0.5% to 5%). Masks are dried at a maximum of

50 °C by means of a hot-air blower.

330-487

Detergent EW80 clean

For cleaning respiratory protective masks, chemical

protective suits and gloves. Tested and approved for

use with Dräger and MSA Auer equipment by the

Deutsche Gesellschaft für Hygiene und Mikrobiologie

(German Society for Hygiene and Microbiology), testing

authority of DMT - Gesellschaft für Forschung und

Prüfung Gmbh.

1 litre

330-449

Disinfectant EW80 des

For disinfecting respiratory protective masks, chemical

protective suits and gloves. Tested and approved for

use with Dräger and MSA Auer equipment by the

Deutsche Gesellschaft für Hygiene und Mikrobiologie

(German Society for Hygiene and Microbiology), testing

authority of DMT - Gesellschaft für Forschung und

Prüfung Gmbh.

1 litre

330-417

5 litres

330-418

Metering unit DMZ 01

For adding a preset amount of disinfectant, detergent or

decontaminant. The concentration level can be freely

adjusted from 0.5% to 2%.

330-550

This manual suits for next models

1

Table of contents

Other MENZL Test Equipment manuals