Contents

1 Introduction................................................................................................5

2 Manual.......................................................................................................6

2.1 Lettering..............................................................................................6

2.2 Text boxes...........................................................................................6

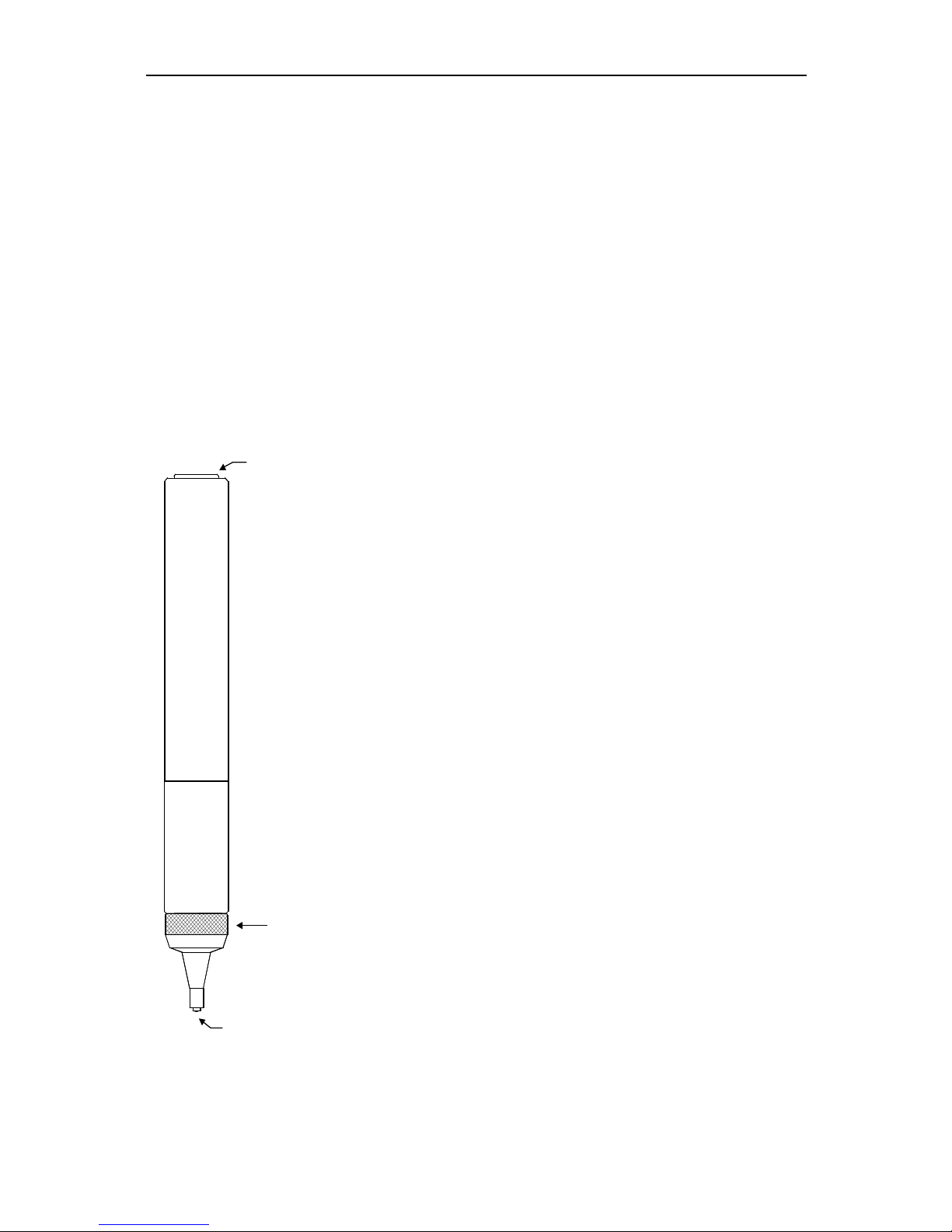

3 The test probes..........................................................................................7

3.1 Probe selection...................................................................................7

3.2 Probe handling....................................................................................7

4 eneral working instructions.....................................................................9

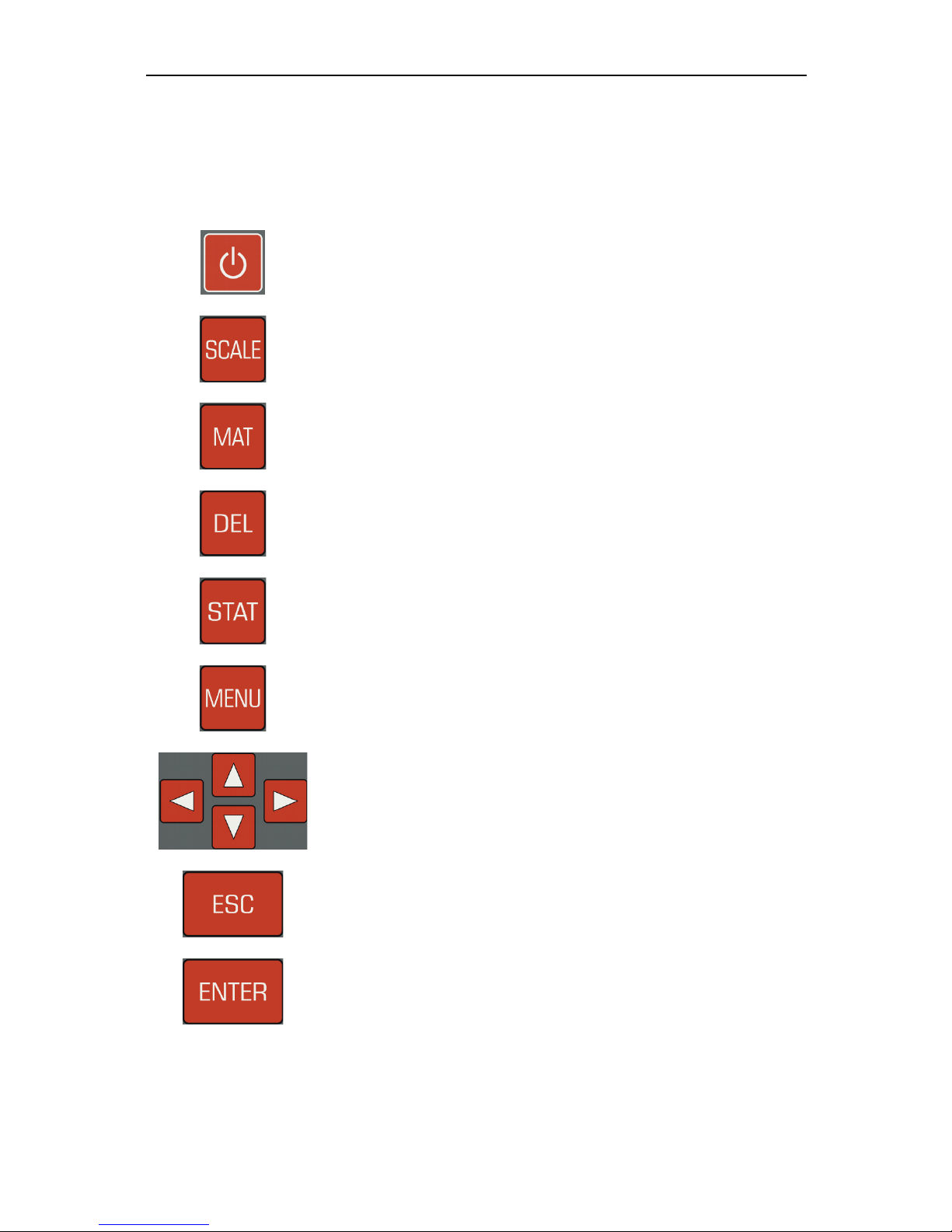

4.1 Key functions.......................................................................................9

4.2 Status bar............................................................................................10

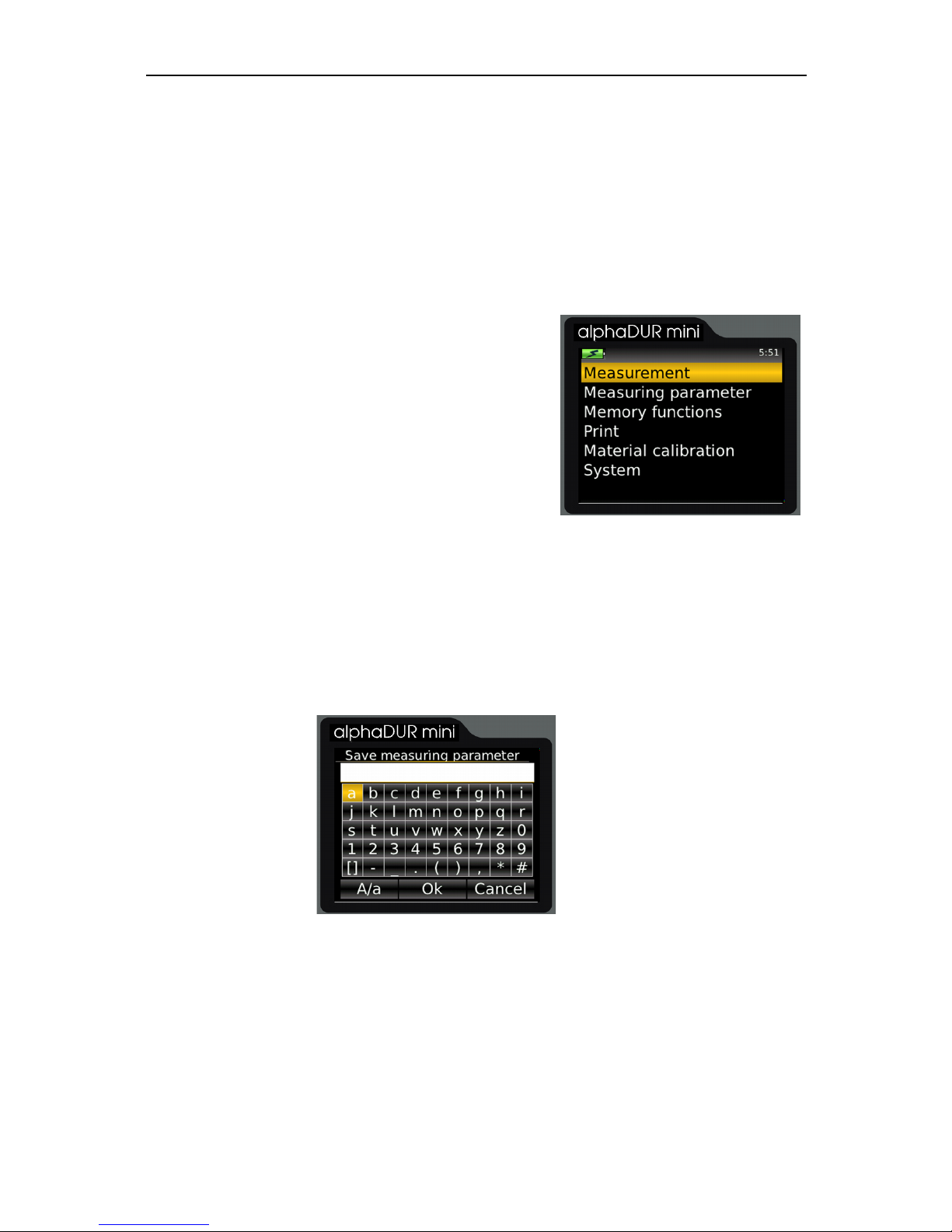

4.3 The menus..........................................................................................10

4.4 Text entry.............................................................................................10

4.5 The number field.................................................................................12

5 Measurement.............................................................................................13

5.1 Specimen requirements......................................................................13

5.2 Measuring parameter..........................................................................14

5.3 Measuring procedure..........................................................................15

5.4 Measuring window..............................................................................15

5.4.1 Key assignment of the measuring window...................................16

5.5 Statistics..............................................................................................17

5.5.1 Display of statistics.......................................................................17

5.6 Instant printout....................................................................................19

6 Measuring parameter................................................................................20

6.1 Description..........................................................................................20

6.2 Managing sets of measuring parameter..............................................21

6.2.1 Editing measuring parameter........................................................21

6.2.2 Saving measuring parameter........................................................21

6.2.3 Loading measuring parameter......................................................22

6.2.4 Deleting a set of measuring parameter.........................................22

7 Hardness conversion.................................................................................23

8 Material calibration....................................................................................23

9 Memory functions......................................................................................26

9.1 Creating a new series.........................................................................27