Mercury MerCruiser ECM 555 User manual

©2001, Mercury Marine. All rights reserved. Printed in U.S.A. 90-864573 DECEMBER 2001

#36 Service Manual

S/N OM300000 and Above

#36 ECM 555 Diagnostics

Serial Number

0M300000 and Above

www.mercurymarine.com.au

Frankston Road

P.O. Box 80

Dandenong, Victoria 3175 Australia

www.mercurymarine.com

W6250 Pioneer Road

Fond du Lac, WI 54936-1939 USA

www.marinepower.com

(Parc Industriel de Petit-Rechain)

B-4822 Verviers/Belgium

ECM 555 Diagnostics

MC Service Manual #36 12/7/01 12:33 PM Page 1

VIEW

MAIN MENU

90-864573 FEBRUARY 2002 Page i

Notice

Throughout this publication, Dangers, Warnings and Cautions (accompanied by the

International HAZARD Symbol ) are used to alert the mechanic to special instructions

concerning a particular service or operation that may be hazardous if performed incorrectly

or carelessly. OBSERVE THEM CAREFULLY!

These Safety Alerts alone cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus common sense operation,

are major accident prevention measures.

DANGER

Immediate hazards which will result in severe personal injury or death.

WARNING

Hazards or unsafe practices which could result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

Notice to Users of This Manual

This service manual has been written and published by the Service Department of Mercury

Marine to aid our dealers’ mechanics and company service personnel when servicing the

products described herein.

It is assumed that these personnel are familiar with marine product servicing procedures.

Furthermore, it is assumed that they have been trained in the recommended service

procedures of Mercury MerCruiser product, including the use of mechanics’ common hand

tools and the special Mercury Marine or recommended tools from other suppliers.

We could not possibly know of and advise the marine trade of all conceivable procedures

and of the possible hazards and/or results of each method. Therefore, anyone who uses

a service procedure and/or tool, which is not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the products safety will be endangered.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this

manual will be sent to all dealers contracted by us to sell and/or service these products.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins, operation maintenance and warranty manuals and

installation manuals for other pertinent information concerning the products described in

this manual.

Page ii 90-864573 FEBRUARY 2002

Precautions

It should be kept in mind, while working on the product, that the electrical system and ignition

system are capable of violent and damaging short circuits or severe electrical shocks. When

performing any work where electrical terminals could possibly be grounded or touched by

the mechanic, the battery cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed during service they should be covered

to protect against accidental entrance of foreign material which could enter the cylinders and

cause extensive internal damage when the engine is started.

It is important to note, during any maintenance procedure replacement fasteners must have

the same measurements and strength as those removed. Numbers on the heads of the

metric bolts and on the surfaces of metric nuts indicate their strength. American bolts use

radial lines for this purpose, while most American nuts do not have strength markings.

Mismatched or incorrect fasteners can result in damage or malfunction, or possibly personal

injury. Therefore, fasteners removed should be saved for reuse in the same locations

whenever possible. Where the fasteners are not satisfactory for re-use, care should be

taken to select a replacement that matches the original.

Engine Mechanical Components

Many of the engine mechanical components are designed for marine applications. Unlike

automotive engines, marine engines are subjected to extended periods of heavy load

and wide open throttle operation and, therefore, require heavy-duty components. Special

marine engine parts have design and manufacturing specifications that are required to

provide long life and dependable performance. Marine engine parts also must be able to

resist the corrosive action of salt or brackish water that will rust or corrode standard

automotive parts within a short period of time.

Failure to use recommended Quicksilver service replacement parts can result in poor

engine performance and/or durability, rapid corrosion of parts subjected to salt water and

possibly complete failure of the engine.

Replacement Parts

WARNING

Electrical, ignition and fuel system components on MerCruiser Engines and

Sterndrives are designed and manufactured to comply with U.S. Coast Guard Rules

and Regulations to minimize risks of fire or explosion.

Use of replacement electrical, ignition or fuel system components, which do not

comply with these rules and regulations, could result in a fire or explosion hazard

and should be avoided.

When servicing the electrical, ignition and fuel systems, it is extremely important

that all components are properly installed and tightened. If not, any electrical or

ignition component opening would permit sparks to ignite fuel vapors from fuel

system leaks, if they existed.

Failure to use recommended Quicksilver service replacement parts can result in poor

engine performance and/or durability, rapid corrosion of parts subjected to salt water and

possibly complete failure of the engine.

Use of parts other than recommended service replacement parts will void the warranty on

those parts which are damaged as a result of the use of other than

recommended replacement parts.

90-864573 FEBRUARY 2002 Page iii

Models Covered in This Manual

Sterndrive (MCM) Serial Number

4.3L MPI Alpha and Bravo

5.0L MPI Alpha and Bravo

350 MAG MPI Alpha and Bravo

0

M

3

0

0

0

0

0

a

n

d

A

b

o

v

e

350 MAG MPI Alpha and Bravo Horizon

0

M

3

0

0

0

0

0

an

d

A

b

ove

MX 6.2 MPI

MX 6.2 MPI Horizon

Inboard and Tow Sports (MIE) Serial Number

350 MAG MPI Inboard

350 MAG MPI Horizon Inboard

MX 6.2 MPI Inboard 0M310000 and Above

MX 6.2 MPI Horizon Inboard

350 MAG MPI Tow Sports

Page iv 90-864573 FEBRUARY 2002

THIS PAGE IS INTENTIONALLY BLANK

1

2

3

5

8

General Information

Troubleshooting

Wiring Diagrams

90-864573 FEBRUARY 2002 Page v

Service Manual Outline

Section 1 - General Information

Section 2 - Troubleshooting

Section 3 - Wiring Diagrams

Page vi 90-864573 FEBRUARY 2002

SECTION 1A - GENERAL INFORMATION

How To Use This Guide 1A-2..............

Abbreviations 1A-3.......................

Special Tools 1A-4.......................

Precautions 1A-10........................

Service Precautions 1A-12...............

General Specifications 1A-14...............

4.3 liter (262 cid) 1A-14.................

5.0 liter (305 cid) 1A-14.................

5.7 liter (350 cid) 1A-15.................

6.2 liter (377 cid) 1A-15.................

General Information 1A-16.................

Electrostatic Discharge Damage 1A-16....

Wiring Harness Service 1A-16............

Wiring Connector Service 1A-17..........

Intermittents 1A-18.....................

Electronic Control Module

(ECM) and Sensors 1A-20.................

General Description 1A-20...............

Computers and Voltage Signals 1A-20....

Analog Signals 1A-20...................

Digital Signals 1A-22....................

Engine Control Module (ECM) 1A-23......

Engine Guardian System 1A-24.............

General Description 1A-24...............

Warning Chart 1A-25....................

General Reference Charts 1A-28............

Manifold Vacuum / Pressure 1A-28.......

Vacuum Gauge vs MAP Sensor 1A-29....

Centigrade to Fahrenheit Conversion 1A-30

SECTION 2A - TROUBLESHOOTING

Troubleshooting

Without A Diagnostic Tool 2A-2............

Troubleshooting

With A Diagnostic Tool 2A-3..............

Troubleshooting Worksheet 2A-4...........

ECM Calibration Label 2A-4............

Data Collection 2A-5...................

PCM 555/ECM 555

Scan Tool Worksheet 2A-5.............

Preliminary Checks 2A-8..................

Visual / Physical Checklist 2A-8.........

On-Board Diagnostic

(OBD) System Chart 2A-9.............

Fuel Pressure Gauge Setup 2A-11........

Symptom Charts 2A-12....................

Chart A-1 Engine Cranks Over

But Will Not Start 2A-12.................

Chart A-2 Main Power Relay Test 2A-13...

Chart A-3 Fuel System Electrical Test 2A-14

Chart A-4 Fuel System Diagnosis 2A-15...

Chart A-5 Ignition System Test 2A-17.....

Chart A-6 Hard Start Symptom 2A-19.....

Chart A-7 Engine Surges Symptom 2A-22.

Chart A-8 Lack Of Power, Sluggish

or Spongy Symptom 2A-24..............

Chart A-9 Detonation /

Spark Knock Symptom 2A-26...........

Chart A-10 Hesitation, Sag

or Stumble Symptom 2A-29.............

Chart A-11 Cuts Out

or Misses Symptom 2A-31..............

Chart A-12 Rough, Unstable or

Incorrect Idle and Stalling Symptom 2A-33

Chart A-13 Poor Fuel

Economy Symptom 2A-35..............

Chart A-14 Dieseling or

Run-On Symptom 2A-37................

Chart A-15 Backfire Symptom 2A-38......

Symptom Quick Reference Chart 2A-40......

Engine Fault Quick Reference Chart 2A-43...

Injector Balance Test 2A-47................

Test Procedure 2A-47...................

Test Example 2A-49....................

Mercury MerCruiser

Scan Tool Flowchart 2A-50..............

Digital Diagnostic Terminal Flowchart 2A-51

90-864573 FEBRUARY 2002 Page vii

SECTION 3A - WIRING DIAGRAMS

Sensor Locations 3A-2....................

Engine Harness Legend 3A-4..............

Wire Splice Description 3A-4............

Wire Color Code Abbreviations 3A-4.....

ECM Pinout 3A-5......................

ECM 555 EFI System Engine

Wiring Diagrams 3A-6....................

Typical Starting System 3A-6............

Wake, Horn and Tachometer Circuits 3A-8

Fuses, IAC and Relays 3A-9............

MAP/T, CPS and TPS 3A-10.............

ECT, Seawater Pump and

Oil Pressure Sensors 3A-11.............

Gear Indicator and Shift Interrupt 3A-12...

Fuel Injector Control Circuits

and Diagnostic Circuits 3A-13...........

Ignition System 3A-14...................

CAN, Fuel Level, Paddle Wheel

and Temperature Circuit 3A-15..........

Transom Harness 3A-16.................

Transom Connector (Engine Side) 3A-17..

Transom Harness (Transom Side) 3A-18..

Slave Solenoid Circuit 3A-19.............

Altenator Output Circuit 3A-20............

Engine 12 Volt Ground Circuit 3A-21......

Single Circuit Diagrams 3A-22..............

Seawater Pump Circuit 3A-22............

Diagnostics Circuit 3A-23................

Engine Coolant Temperature Circuit 3A-24.

IAC Circuit 3A-25.......................

MAP/T Circuit 3A-26....................

Throttle Position Circuit 3A-27............

Oil Pressure Circuit 3A-28...............

Knock Sensor Circuits 3A-29.............

Harness To Paddle Wheel

Connector Circuit 3A-30................

Fuel Level Circuit 3A-31.................

Fuel Pump Relay Circuit 3A-32...........

Control Area Network (CAN) Circuit 3A-33.

Wiring Diagrams 3A-34....................

Page viii 90-864573 FEBRUARY 2002

THIS PAGE IS INTENTIONALLY BLANK

1

A

GENERAL INFORMATION

SERVICE MANUAL NUMBER 36

90-864573 FEBRUARY 2002 Page 1A-1

SECTION 1A - GENERAL INFORMATION

Table of Contents

How To Use This Guide 1A-2..............

Abbreviations 1A-3.......................

Special Tools 1A-4.......................

Precautions 1A-10........................

Service Precautions 1A-12...............

General Specifications 1A-14...............

4.3 liter (262 cid) 1A-14.................

5.0 liter (305 cid) 1A-14.................

5.7 liter (350 cid) 1A-15.................

6.2 liter (377 cid) 1A-15.................

General Information 1A-16.................

Electrostatic Discharge Damage 1A-16....

Wiring Harness Service 1A-16............

Wiring Connector Service 1A-17..........

Intermittents 1A-18.....................

Electronic Control Module

(ECM) and Sensors 1A-20.................

General Description 1A-20...............

Computers and Voltage Signals 1A-20....

Analog Signals 1A-20...................

Digital Signals 1A-22....................

Engine Control Module (ECM) 1A-23......

Engine Guardian System 1A-24.............

General Description 1A-24...............

Warning Chart 1A-25....................

General Reference Charts 1A-28............

Manifold Vacuum / Pressure 1A-28.......

Vacuum Gauge vs MAP Sensor 1A-29....

Centigrade to Fahrenheit Conversion 1A-30

GENERAL INFORMATION SERVICE MANUAL NUMBER 36

Page 1A-2 90-864573 FEBRUARY 2002

How To Use This Guide

This diagnostic guide is separated into 3 sections: General Information, Troubleshooting

and Wiring Diagrams.

General Information covers:

General wiring information

Engine Guardian description

Warning chart

Troubleshooting covers:

Basic scan tool information

Symptom trouble chart

Fault chart

Wiring diagram covers:

Engine electrical harness

Circuit diagrams

Troubleshooting covers possible electrical and mechanical causes for engine faults on the

scan tool. In wiring diagrams, the single circuit diagrams cover each sensor and subset of

the electrical system of the engine. These two sections will help the technician pinpoint

problems occurring in the electrical system.

GENERAL INFORMATION

SERVICE MANUAL NUMBER 36

90-864573 FEBRUARY 2002 Page 1A-3

Abbreviations

amp Amperes in. hg Inches Of Mercury

BARO Barometric Pressure INJ Injector

Bat Battery Positive Terminal, Bat-

tery or System Voltage kPa Kilopascal

B+ Battery Positive Voltage KS Knock Sensor System

Bps Beeps kV Kilovolts

CAM Camshaft mA milliamperes

cond Condition MPR Main Power Relay

cont Continuous MAP Manifold Air Pressure

Crank Crankshaft MAT Manifold Air Temperature

CAN Control Area Network mohms Milliohms

CKT Circuit mSec Millisecond

CMP Camshaft Position Sensor N/C Normally Closed

Conn Connector N/O Normally Open

CPS Crankshaft Position Sensor OBD On-Board Diagnostic Test

Cyl Cylinder PCM Propulsion Control Module

DDT Digital Diagnostic Terminal RAM Random Access Memory

Deg Degrees REF HI Reference High

Diag Diagnostic REF LO Reference Low

DIS Distributorless Ignition System RFI Resistance Frequency Interval

DLC Data Link Connector ROM Read Only Memory

Dtc Diagnostic Trouble Code RPM Revolutions per Minute

DMM

DMT

DVOM

Digital Multimeter SW Switch

ECM Electronic Control Module TACH Tachometer

ECT Engine Coolant Temperature TERM Terminal

EFI Electronic Fuel Injector TPS Throttle Position Sensor

EMCT Exhaust Manifold Coolant

Temperature VVolts

EST Electronic Spark Timing VAC Vacuum

GND Ground VDC Volt Direct Current

IAC Idle Air Control VOA Volt/Ohm/Amp Meter

IGN Ignition WOT Wide Open Throttle

GENERAL INFORMATION SERVICE MANUAL NUMBER 36

Page 1A-4 90-864573 FEBRUARY 2002

Special Tools

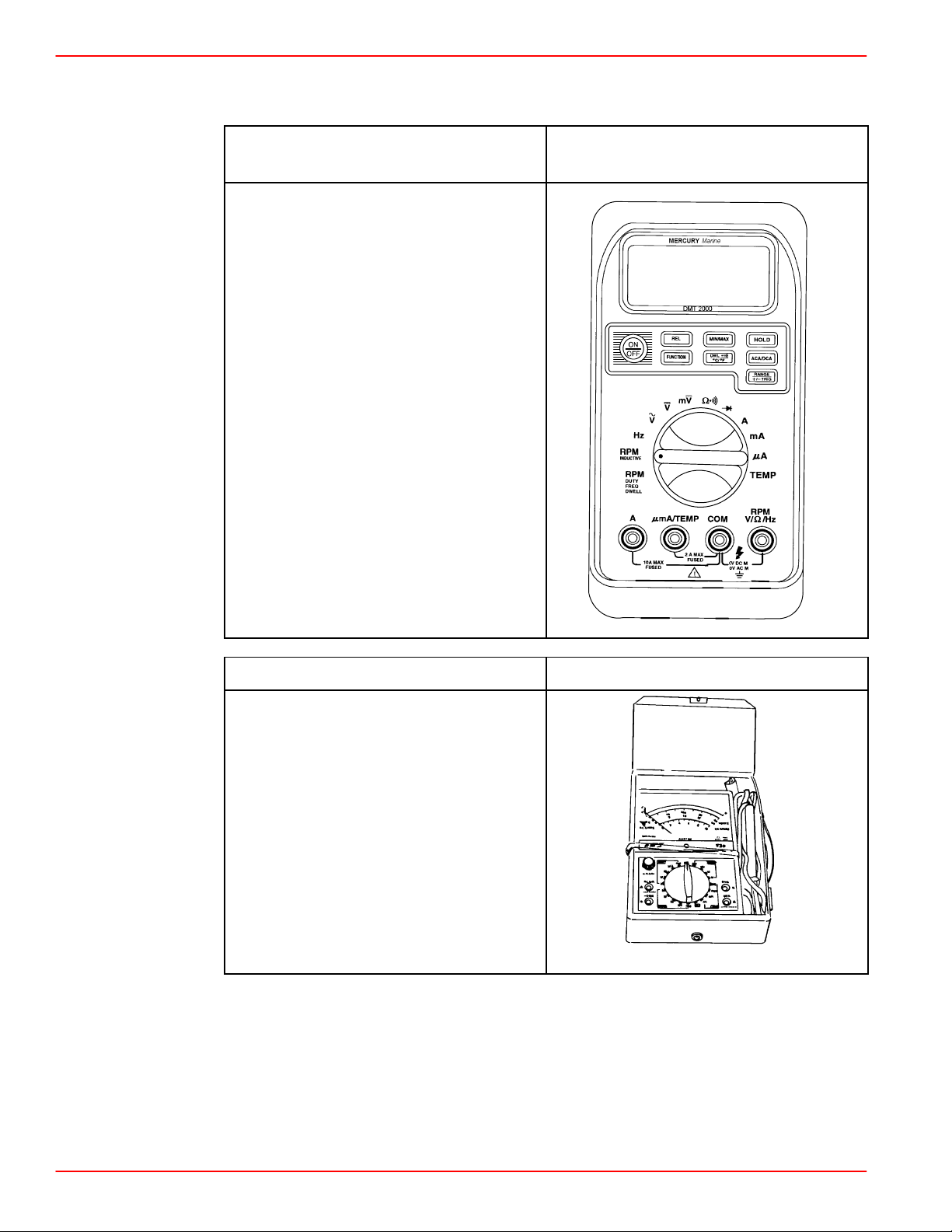

DMT 2000A Tachometer /

Multi-Meter Kit 91-854009A3

Description:

Measures rpm on both 2 and 4 cycle

marine engines, records the maximums

and minimums simultaneously and will

read accurately in high RFI

environments.

Replacement Components:

91-854010-1 8 ft (2.4 m) Inductive

Pick-Up

91-854011-1 Temperature Probe

91-854012 Ferrite Core

91-854013-1 Interface Module

91-854014-1 Hard Carrying Case

91-854015-1 User’s Guide

91-802651 Test Leads

Optional Accessories:

84-854016T 8 ft (2.4 m) Inductive

Pick-Up Extension

91-802650 Clamp-On Current Probe

91-89045-1 Direct Voltage Adaptor

77959

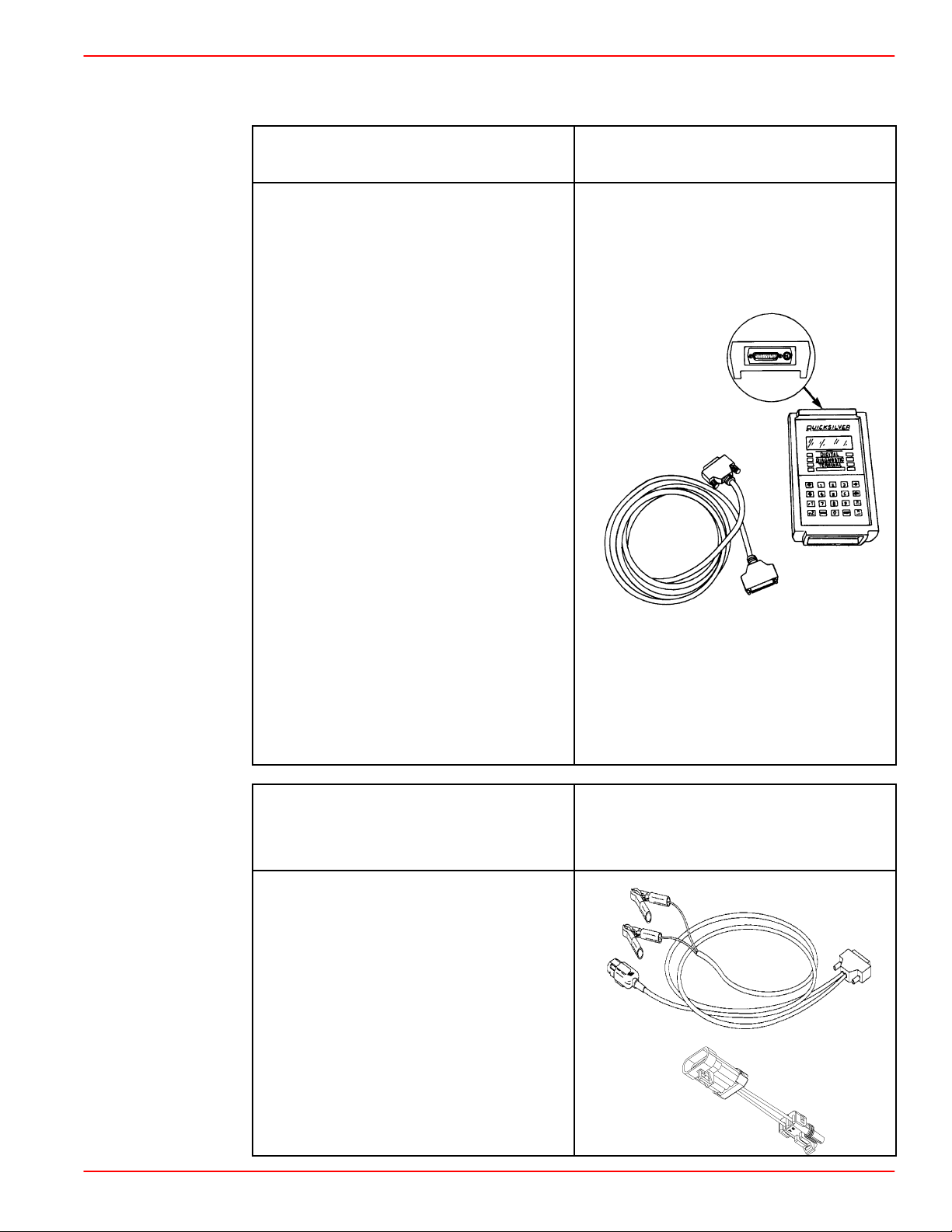

DVA / Multi-Meter Kit 91-99750A1

Description:

Tests the electrical and ignition systems;

consists of a VOA meter with built-in

direct voltage adaptor.

73609

GENERAL INFORMATION

SERVICE MANUAL NUMBER 36

90-864573 FEBRUARY 2002 Page 1A-5

Special Tools (continued)

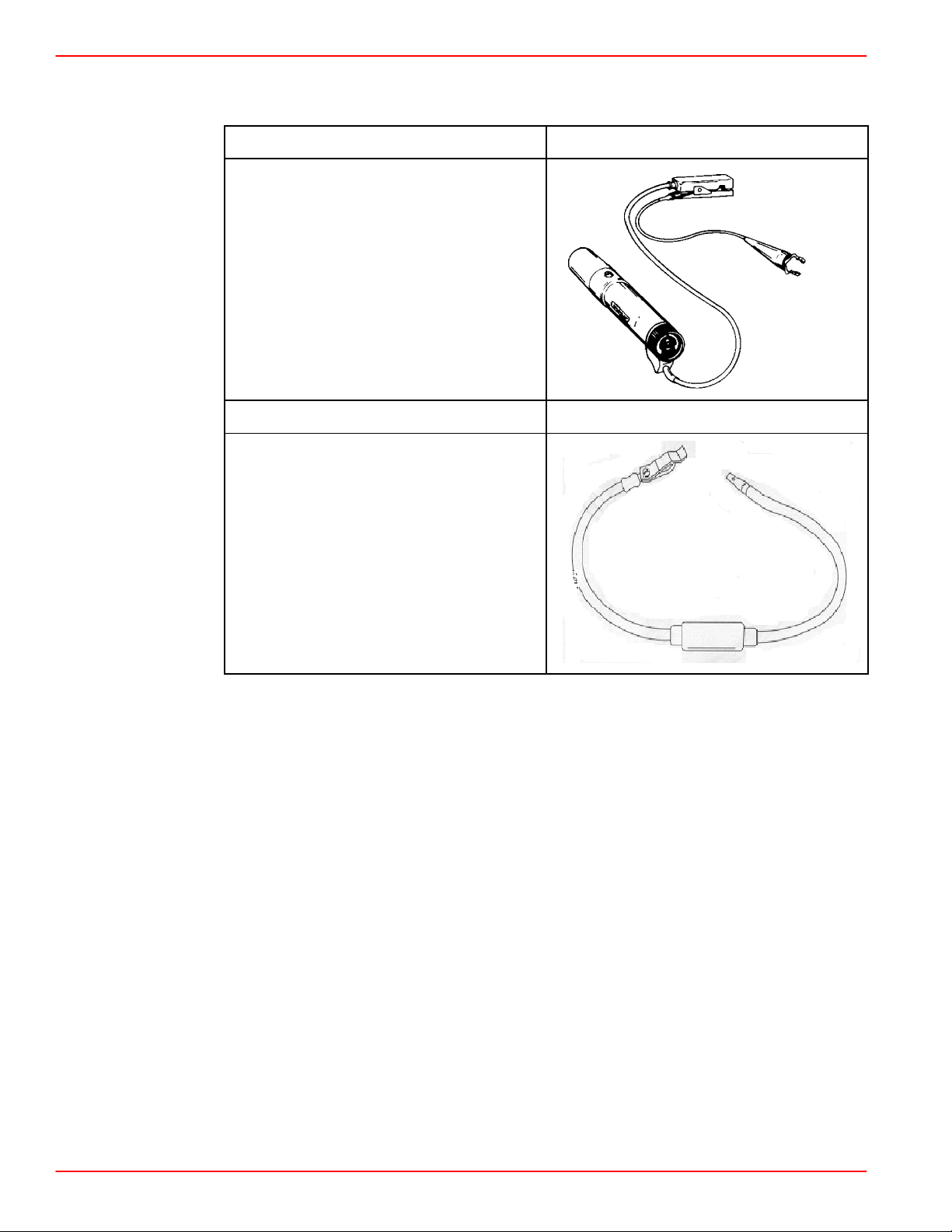

Digital Diagnostic Terminal

DDT 91-823686A2

Description:

Display problem codes stored in the

ECM. It also allows the monitoring of

various circuits and components in the

fuel injection system. Must order the

91-803999 cartridge for MEFI 1, MEFI 2

and MEFI 3 ECM models 91-880118A2

cartridge for ECM 555 and PCM 555

models.

84-825003A1 Replacement 10 ft (3 m)

25-pin Harness

91-8404805 Optional Heavy Duty

Carrying case

Accessories:

An additional harness assembly may be

required when using the DDT, refer to

the following:

91-822560A13 Harness Assembly /

Diagnostic Tester

91-861540A1 Adaptor Harness

91-822560A7 Outboard Adapter

Harness

91-84-822560A5 EFI Outboard Adaptor

91-822560T12 Scan Tool Harness

Adaptor

91-822560A2 Harness Assembly /

Diagnostic Tester

74214

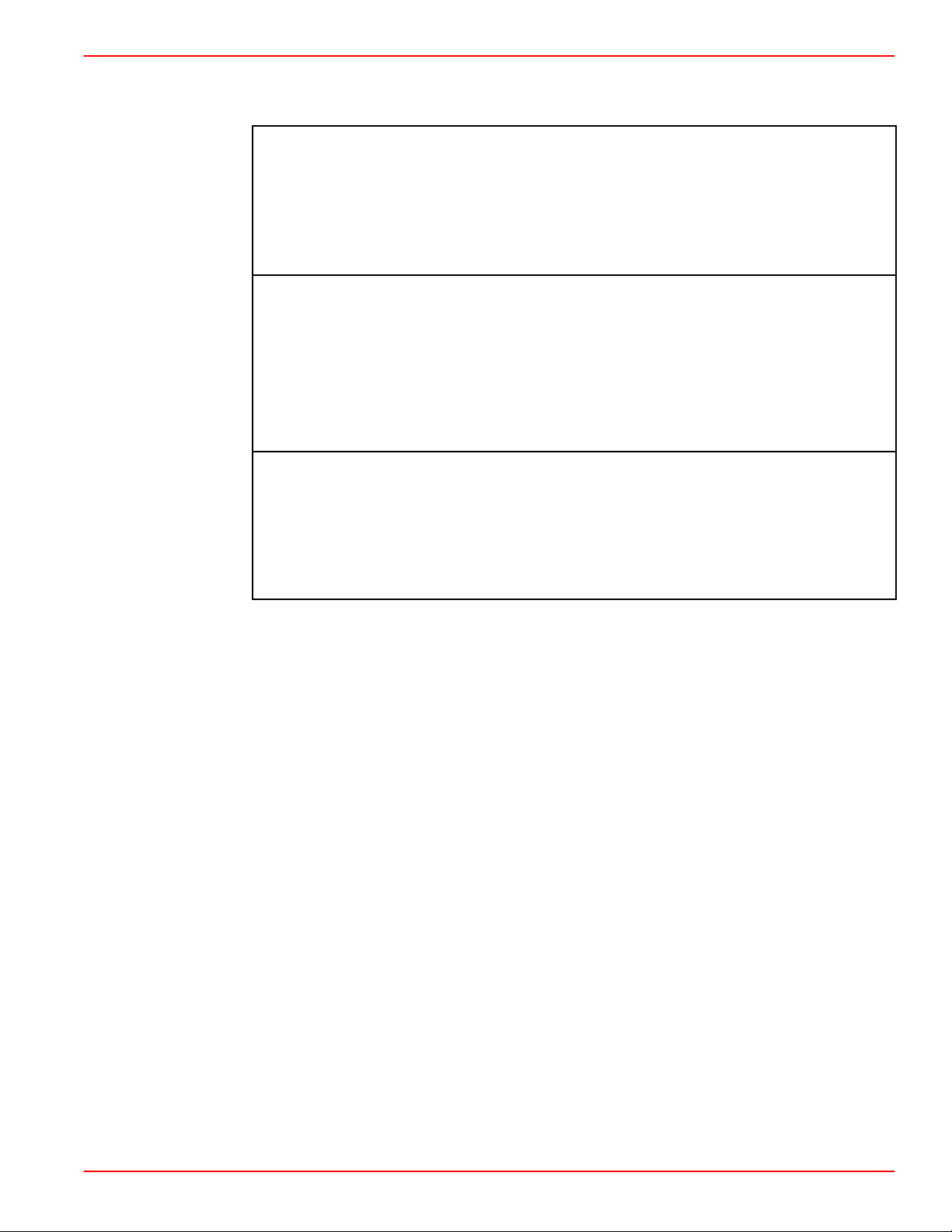

EFI Outboard Harness

Adaptor

Scan Tool Harness Adaptor

84-822560A5

84-822560T12

Description:

84-822560A5 Outboard Harness

Adaptor may be used with

91-823686A32 DDT Scan Tool for PCM

555 and ECM 555 models.

Use the Harness Adaptor 84-822560T12

For PCM 555 Models to adapt the 4-pin

Mercury MerCruiser connector to the

2-pin 84-822560A5 Outboard Harness.

84-822560A5

84-822560T12 78034

78069

GENERAL INFORMATION SERVICE MANUAL NUMBER 36

Page 1A-6 90-864573 FEBRUARY 2002

Special Tools (continued)

Fuel Pressure Gauge Adaptor

Kit 91-803135

Description:

Allows updating 91-16850A 2 and older

Fuel Pressure Gauge Kits. Adapts the

gauge to fit either the Mercury

MerCruiser or the GM Shrader valve.

This Adaptor Kit is included with the

Fuel Pressure Gauge Kit 91-881833A2.

Fuel Pressure Gauge Kit 91-881833A2

Description:

Use to test the fuel pump pressure,

includes:

91-803135 Fuel Pressure Gauge

Adaptor Kit

91-806901 Fuel Pressure T-fitting

91-881833A1 160 psi Gauge 73814

Fuel Shut Off Tool 91-805918A1

Description:

Use in fuel system pressure tests on the

return line. 74227

Fuel Shut Off Tool 91-805918A3

Description:

Use in fuel system pressure tests at the

fuel rail.

Not available at time of printing.

GENERAL INFORMATION

SERVICE MANUAL NUMBER 36

90-864573 FEBRUARY 2002 Page 1A-7

Special Tools (continued)

Harness Assembly /

Diagnostic Tester 91-822560A13

Description:

25-pin to 4-pin Adaptor harness. For

PCM 555 and ECM 555 models (4-pin

connectors, no additional harness

required).

74214

Mercury MerCruiser DDT

Cartridge Version 1.2 91-880118A2

Description:

Use on PCM 555 and ECM 555 models.

78036

Scan Tool Kit / Version 4.0 Note in Description

Description:

Hand-held Scan Tool updated for 2001.

(refer to Service Bulletin 2001-1). Use

with models:

MCM/MIE EFI (TBI) and MPI Gasoline

MCM/MIE 496/8.1S MPI PCM 555

1997 and Newer MCM/MIE Carbureted

Models with Thunderbolt Ignition System

MCM/MIE D-Tronic Diesel

NOTE: Tool must be ordered from Rinda

Technologies, Inc.

72428

GENERAL INFORMATION SERVICE MANUAL NUMBER 36

Page 1A-8 90-864573 FEBRUARY 2002

Special Tools (continued)

Portable Timing Light 91-99379

Description:

Checks the ignition timing, powered by 2

D-cell batteries.

73664

Spark Gap Tester 91-63998A1

Description:

Spark Gap Tester

GENERAL INFORMATION

SERVICE MANUAL NUMBER 36

90-864573 FEBRUARY 2002 Page 1A-9

Special Tools (continued)

Rinda Technologies

4563 N. Elston Ave.

Chicago, IL 60630

Phone: 773-736-6633

Fax: 773-736-2950

Email: [email protected]

Mercury Marine

W6250 Pioneer Road,

P.O. Box 1929

Fond Du Lac, WI 54935-1939

Phone: 920-929-5589,

800-487-8736

www.MERCURYMARINE.com

OTC

28635 Mound Rd.

Warren, MI 48092-3499

Phone: 586-574-2332,

800-328-6657

www.servicesolutions.spx.com

GENERAL INFORMATION SERVICE MANUAL NUMBER 36

Page 1A-10 90-864573 FEBRUARY 2002

Precautions

WARNING

Electrical, ignition and fuel system components on your Mercury MerCruiser are

designed and manufactured to comply with U.S. Coast Guard Rules and Regula-

tions to minimize risks of fire and explosion.

Use of replacement electrical, ignition or fuel system components, which do not

comply with these rules and regulations, could result in a fire or explosion hazard

and should be avoided.

WARNING

Avoid injury or death and power package damage from an electrical shock, fire or

explosion. Always disconnect both battery cables from the battery before servicing

the power package.

WARNING

Be careful when cleaning flame arrestor and crankcase ventilation hose; gasoline

is extremely flammable and highly explosive under certain conditions. Ensure that

ignition key is OFF. Do NOT smoke or allow sources of spark or open flame in area

when cleaning flame arrestor and crankcase ventilation hose.

WARNING

Be careful when changing fuel system components; gasoline is extremely flam-

mable and highly explosive under certain conditions. Ensure that ignition key is

OFF. DO NOT smoke or allow sources of spark or flame in the area while changing

fuel filter. Wipe up any spilled fuel immediately.

GENERAL INFORMATION

SERVICE MANUAL NUMBER 36

90-864573 FEBRUARY 2002 Page 1A-11

Precautions (continued)

WARNING

Make sure no fuel leaks exist, before closing engine hatch.

WARNING

Avoid gasoline fire or explosion. Improper installation of brass fittings or plugs into

fuel pump or fuel filter base can crack casting and/or cause a fuel leak.

Apply Loctite 565 Pipe Sealant with Teflon to threads of brass fitting or plug. Do

NOT USE TEFLON TAPE.

Thread brass fitting or plug into fuel pump or fuel filter base until finger-tight.

Tighten fitting or plug an additional 1-3/4 to 2-1/4 turns using a wrench. Do NOT

OVERTIGHTEN.

Install fuel line. To prevent overtightening, hold brass fitting with suitable

wrench and tighten fuel line connectors securely.

Check for fuel leaks.

CAUTION

Overheating from insufficient cooling water will cause engine and drive system

damage. Ensure that there is sufficient water always available at water inlet holes

during operation.