Seakeeper 6 User manual

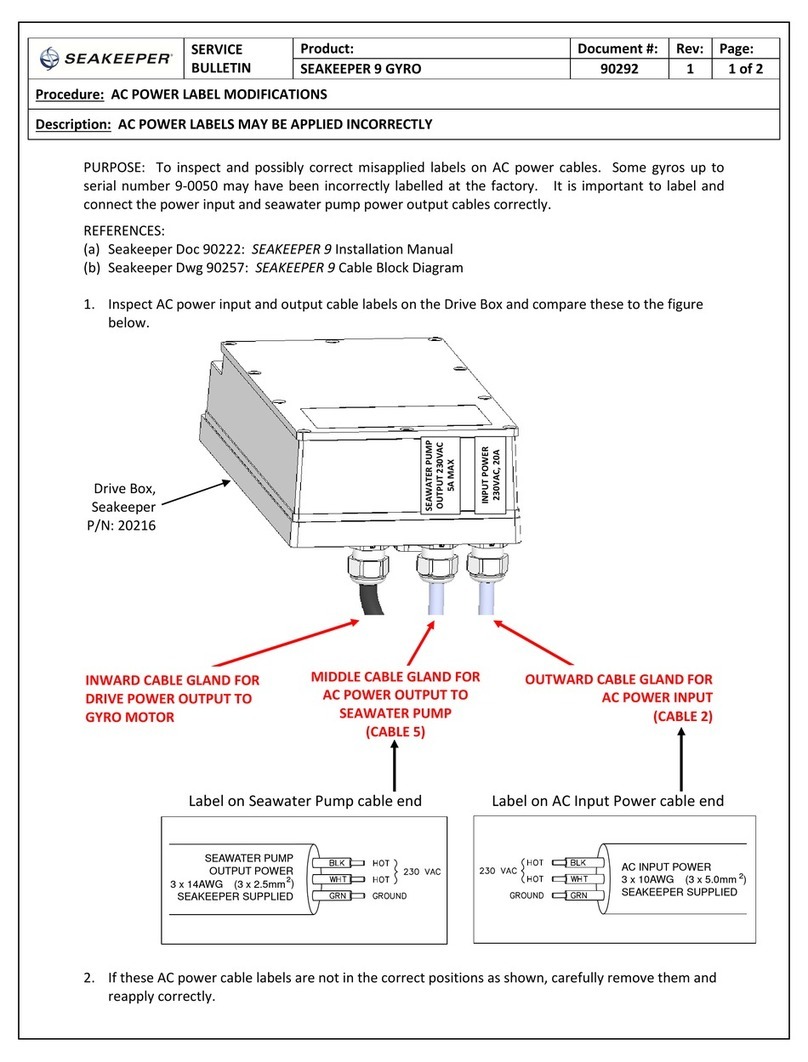

Rev 22 JUNE 2017

INSTALLATION MANUAL

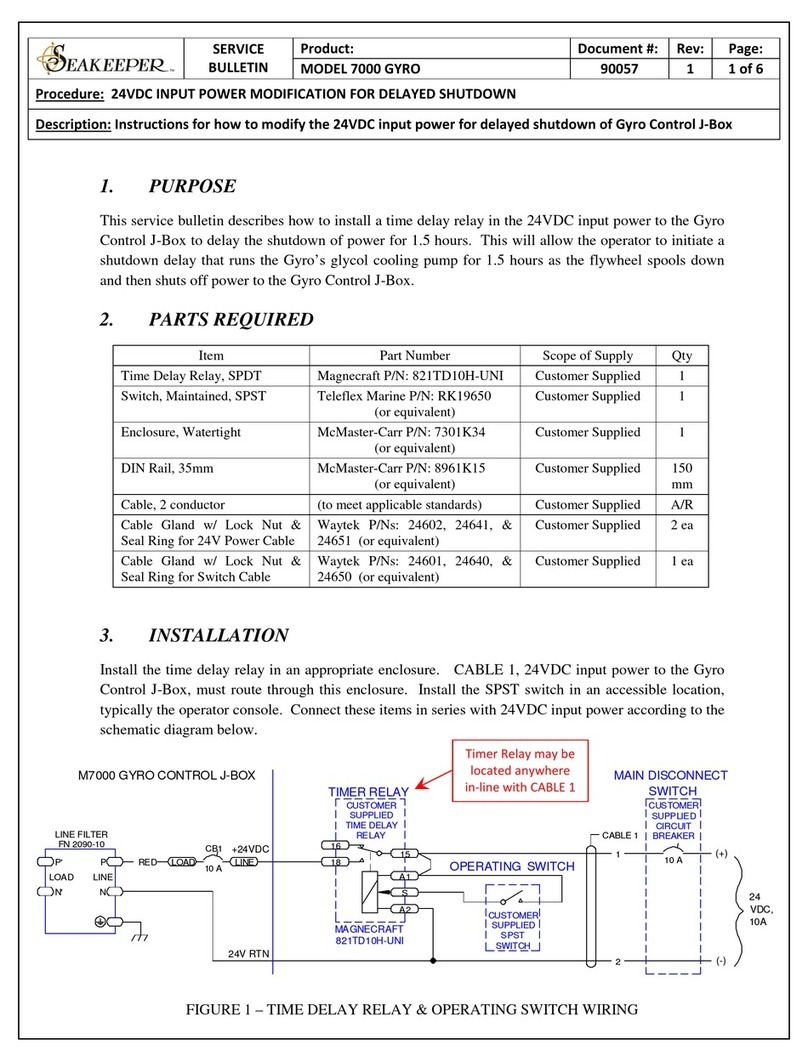

INSTALLATION

MANUAL

Product: Document #: Rev:

SEAKEEPER 6 90402 1

SEAKEEPER 6

INSTALLATION MANUAL

JUNE 2017

Contents:

Section 1 – Mechanical Installation

Section 2 – Electrical Installation

Section 3 – Cooling Installation

Section 4 – Startup

Section 5 – Installation Checklist and Required Supplies

44425 PECAN COURT, SUITE 151

CALIFORNIA, MARYLAND, 20619, U.S.A

PHONE: 410-326-1590

FAX: 410-326-1199

E-MAIL: [email protected]

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 1 of 6

Section 1: MECHANICAL INSTALLATION

1.0 Introduction

This document is intended to give details and guidance to a boat builder or equipment installer to

install the Seakeeper 6 Stabilization System. The Seakeeper is capable of producing loads up to

17 KN (3820 lbs.) at each of the four mounts and careful consideration should be given to

foundation design to insure it is capable of transferring these loads into the hull.

There are two methods of installing the Seakeeper 6:

1) Bolt-In Installation

2) Saddle Installation

It is assumed that the installer is familiar with bonding using high strength adhesives or

mechanical fasteners to marine structures and has performed structural analysis to assure

the structure to which the Seakeeper mounts can properly transfer the loads the Seakeeper

creates into the hull structure. If the installer has any doubt about the ability of the

structure to transfer the loads to the hull then he should contact a licensed naval architect

or marine engineer to do a structural analysis.

The installer should review the following list of reference drawings to ensure the installation

procedure is fully understood.

Reference Drawings

90389 Seakeeper 6 Hardware Scope of Supply

90392 Seakeeper 6 Installation Template Kit

90398 Seakeeper 6 Installation Details – Bolt in Method

90399 Seakeeper 6 Installation Details – Bond in Method

90397 Seakeeper 6 Cooling Water Schematic

90396 Seakeeper 6 Cable Block Diagram

FIGURE 1 – SEAKEEPER 6

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 2 of 6

Section 1: MECHANICAL INSTALLATION

1.1 Precautions

Seakeeper must only be lifted from the supplied lifting eyes (See Section 1.4).

Seakeeper flywheel is supported by precision bearings. Make certain while unpacking

and lifting Seakeeper assembly to NOT drop or impart mechanical shock as damage to

bearings could result.

While handling / installing Seakeeper assembly, protect exposed hydraulic brake cylinder

rods (See Figure 1) from scratches or damage as this could lead to premature seal failure

and oil leaks.

While handling / installing Seakeeper assembly, do not allow electrical fittings that exit

bottom of Seakeeper enclosure to come in contact with any surface or object as this could

damage the fittings and potentially affect the vacuum integrity of the enclosure.

Exercise care to protect the painted finish as damage to finish could lead to early

appearance degradation of installed Seakeeper.

1.2 Selection of Installation Location

Selection of mounting location of Seakeeper should consider the following desirable

features:

The Seakeeper must be installed aft of amidships to minimize high

acceleration loadings due to hull/wave impacts during operation at

high speed or in large waves.

Overhead access or sufficient clearance for removal / re-installation of Seakeeper

for overhaul in future years.

Seakeeper should be installed in a dry space to minimize effects of corrosion.

Clearance for replacement of gimbal angle sensor on gimbal shaft (see Figure 2).

Clearance for filling / purging brake hydraulic oil (see Figure 2).

Clearance for filling water/glycol cooling circuit (see Figure 2).

Clearance for replacement of brake hydraulic cylinders (see Figure 2).

Clearance for routine and regular maintenance including Anode replacement on the Heat

Exchanger (see Figure 2).

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 3 of 6

Section 1: MECHANICAL INSTALLATION

VIEWS SHOWING RECOMMENDED CLEARANCES AROUND SEAKEEPER FOR USE OF HAND-TOOLS, EASE

OF MAINTENANCE, INSTALLATION AND PROPER OPERATION.

FIGURE 2 – INSTALLED SEAKEEPER CLEARANCE CONSIDERATIONS

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 4 of 6

Section 1: MECHANICAL INSTALLATION

FIGURE 3 – TRANSVERSE BEAMS CLEARANCE CONSIDERATIONS

Refer to Figure 3 for recommended clearances to transverse beams. If a transverse beam is

located under the forward brace, it must be 4” (102 mm) from the edge of the saddle beams to

provide the necessary clearance for the swing of the motor power cable during precession.

Clearances aft of the Seakeeper are shown to provide access for maintenance.

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 5 of 6

Section 1: MECHANICAL INSTALLATION

Safety

There is a large torque about the gimbal axis when the Seakeeper is

precessing. Seakeeper cover panels are provided to prevent personnel or

equipment from contacting the Seakeeper while it is in operation. These covers

should not be stepped on, or have anything placed on top. The covers should

always be in place during operation. If it is ever necessary to access the Seakeeper

while the flywheel is spinning, the Seakeeper must be locked at the display to stop

the Seakeeper from precessing. Seakeeper maintenance should not be attempted

unless the Seakeeper is locked and the flywheel has stopped spinning.

The Seakeeper should be treated with the same respect one gives a high speed

rotating propeller shaft or engine shaft.

Noise/Soundproofing

Seakeeper noise has been measured under steady state conditions (no wave load) in

Seakeeper's lab and in our test boat. The steady state noise is typically in the range of 70-75 dB

un-weighted. As the frequencies emitting the highest sound pressures are low (like other marine

machinery), it is recommended that the Seakeeper be installed in a machinery space that is

already treated with soundproofing.

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 6 of 6

Section 1: MECHANICAL INSTALLATION

1.3 Selection of Installation Method

The Seakeeper 6 can be affixed to the hull structure using two methods 1) Use bolt-in installation

or 2) saddle installation. See figures below.

OPTION 1- DIRECT FASTENING OF SEAKEEPER FOUNDATION TO SHIPS STRUCTURE

Option 1 would be applied when a metal structure is available for attachment. The foundation

would fasten directly to hull structure using isolation gaskets and 16x M12-1.75 fasteners.

Depending on the structure to which the Seakeeper is fastened, blind threaded holes or thru-

bolting can be utilized.

OPTION 2- SADDLE INSTALLATION (4 PLACES)

Option 2 would be most commonly used on a hull constructed of glass reinforced plastic (GRP)

or fiberglass. For this option, four 7.5 inch (191 mm) long by 3.38 inch (85.7 mm) deep

saddles are bonded to properly spaced and prepared structural members that are an integral

part of the hull structure. Seakeeper recommends using a structural adhesive with a lap shear

strength of 2000 psi (13.8 MPa) or greater. Careful consideration should be exercised by the

installer while selecting the appropriate adhesive. Compatibility with the Seakeeper’s cast

aluminum A356- T6 saddles, hull structure and pot life are three important factors to consider.

Proper surface preparation in accordance with adhesive manufacturer’s recommendations prior

to installation is very important.

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 7 of 7

Section 1: MECHANICAL INSTALLATION

1.4 Transport and Unpacking

1.4.1 Transport

1) Use a Seakeeper provided shipping crate for transport, part number 10977. Overall

dimensions of a fully packed crate are 40.25”Lx43”Wx40.25”H with a weight of 870

lbs(395kgs).

2) Do not stack Seakeeper shipping crates.

3) Both Air and Ground transport are acceptable.

4) Seakeeper shipping crates must be transported in environmental conditions between

-20°C and 60°C.

1.4.2 Unpacking Crate

1) Reference Seakeeper Drawing No. 90389, Seakeeper 6 Hardware Scope of Supply for

items that ship with the Seakeeper.

2) Remove electrical components, cables, and misc. items and set aside.

3) Remove packing materials that secure Seakeeper assembly inside the crate.

4) Remove top and angled face cover panels to access lifting eyes

5) Attach spreader bar to the two lifting eyes located on the top of the Seakeeper enclosure.

Stay clear of any other parts on the Seakeeper. Seakeeper 6 weighs 395 kg (870 lbs).

See Figure 4 below.

FIGURE 4 – LIFTING ARRANGEMENT

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 8 of 8

Section 1: MECHANICAL INSTALLATION

1.5 Bolt-In Installation

1.5.1 Check and Preparation of Hull Structure

Refer to Seakeeper Drawing No. 90398, Seakeeper 6 Installation Details – Bolt in Method.

Important dimensional and load information is given in this drawing that will impact the design

details of the structure that will receive the Seakeeper. It is assumed that a proper structural

analysis has been performed for the hull structure to which the Seakeeper will be fastened to

insure proper strength margins for the loads the Seakeeper will create during operation.

The hull structure supporting the Seakeeper should be installed so the Seakeeper is parallel to

the waterline. In addition, the four areas on top of the beams on which the feet of the

Seakeeper foundation and isolation gaskets will rest need to be co-planar within .06” (1.5

mm) to minimize potential distortion of Seakeeper support frame when installed.

Seakeeper provides an installation template kit, P/N 90392, which contains four plates that mimic

the mating surfaces of the four feet located on the Seakeeper’s foundation. These plates have 4

holes located at the same centers as the mounting holes on the Seakeeper. The fixture locates

the hole patterns at the proper spacing both in the fore-aft direction and the port-starboard

direction. See Figures 5 below. Once assembled, the fixture can be used to check clearances

and alignment of the hull structure.

Note: Do NOT use the installation fixture to establish Seakeeper envelope dimensions.

Refer to Drawing No. 90398 for envelope dimensions. A 3-D model of the Seakeeper is

available on the Seakeeper website (www.seakeeper.com) to aid in designing the

Seakeeper foundation and the space around the Seakeeper.

NOTE: MAKE SURE NO OBSTRUCTIONS FROM THE HULL STRUCTURE CAN BE SEEN WITHIN THE INSIDE

OF THE INSTALLATION TEMPLATE KIT (INSIDE THE MARKED RED LINES). SEE SECTION 1, PAGE 9 OF

INSTALLATION MANUAL.

FIGURE 5 –INSTALLATION TEMPLATE KIT, P/N: 90392

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 9 of 9

Section 1: MECHANICAL INSTALLATION

CAUTION: Tight clearances from cable guide bands and brake side gimbal shaft to hull

structure. See below for brake side gimbal shaft clearance. See above figure for

dimensions and reference Seakeeper drawing NO. 90398 for complete Seakeeper

envelope.

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 10 of 10

Section 1: MECHANICAL INSTALLATION

1.5.2 Transfer of Holes to Boat Structure

1) Lower assembled fixture onto hull

structure.

2) The four areas where the feet of

the Seakeeper will rest should be

coplanar to within .06” (1.5mm).

See Figure 9.

3) Align fixture in desired location and

transfer holes from fixture plate to the

foundation structure. Note that holes

in fixture plate are ø0.487” (12 mm).

A transfer punch is supplied with

installation template kit, P/N 90392.

4) Remove fixture and drill and tap

M12X1.75 holes in foundation at

marked locations to mate with holes in

the foundation. Take special care to

drill perpendicular to mounting surface.

Remove any impeding obstructions.

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 11 of 11

Section 1: MECHANICAL INSTALLATION

1.5.3 Installation of Seakeeper

1) Locate and position 4 foundation

spacers, and 4 isolation gaskets

onto hull structure. NOTE: Sealant

or caulk is recommended to be

applied. Apply a small bead

(approximately 4mm wide) of

sealant (silicone or caulk) between

all mating surfaces of each

foundation spacer and each

isolation gasket. This will prevent

water from wicking between the

parts and setting up corrosion.

Check foundation spacers and

isolation gasket alignment by test

fitting bolts without any

obstructions.

2) Lower Seakeeper into position

onto foundation beams and align

over drilled holes.

3) Install Seakeeper supplied M12X1.75 –

70mm fasteners– apply a moderate coat

of removable thread locker to the threads

of each bolt and include a small bead of

marine sealant under each washer

before installation.

4) Torque all fasteners to 65 ft-lbs (88 N-m).

5) Proceed to electrical and cooling portion

of the installation.

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 12 of 12

Section 1: MECHANICAL INSTALLATION

1.6 Saddle Installation

Seakeeper recommends Plexus MA590 adhesive for bonding the saddles to the GRP hull

structure. Plexus MA590 is a two-part methacrylate structural adhesive that has characteristics

conducive to this type of installation. Details of the bonding procedure in this manual will involve

the Plexus MA590 product, but that should not exclude other suitable adhesives the installer

chooses to use. See Sheet 5 of Seakeeper drawing no. 90399 for loads information and

recommended adhesive properties.

1.6.1 Initial Check and Preparation of Hull Structure

Refer to Seakeeper Drawing No. 90399, Seakeeper 6 Installation Details – Bond In Method.

Important dimensional and load information is given in this drawing that will impact the design

details of the structure that will receive the Seakeeper as well as selection of the adhesive to bond

the Seakeeper into the hull.

The foundation “saddles” of the Seakeeper are designed to be bonded directly to the composite

hull structure of the vessel to effectively distribute gyroscopic loads. A complete bond is

required between the inside surface of the saddles and the hull structure. Seakeeper

recommends having a minimum of 7 cartridges (225mL), 1 bottle Plexus PC-120

Primer/Conditioner, and 2 manual adhesive guns on hand for installation. Two workers should

apply the adhesive at the same time to finish the installation before the adhesive starts to cure.

To aid in determining the quantity of adhesive required, the interior surface area (bonding

surfaces) of each saddle is 58.2 in2 (375 cm2) for a total bonded surface area for all four saddles

of 232.5 in2 (1500 cm2).

The hull structure supporting the Seakeeper should be installed so the Seakeeper is parallel to

the waterline. The four areas on top of the beams that the saddles will bond to need to be

co-planar within .13” inches (3 mm) for consistent adhesive bond gap. In addition, the four

areas on top of the saddles on which the feet of the Seakeeper foundation will rest need to

be co-planar within .06” (1.5 mm) to minimize potential distortion of Seakeeper support

frame when installed.

Note that any paint or gel-coat present in bond area should be removed so that adhesive

will bond directly to laminate fibers and resin.

Seakeeper provides an installation fixture template, P/N 90392 that locates the saddles at the

proper spacing both in the fore-aft direction and the port-starboard direction. See Figures 6, 7 &

8 below. Once assembled with the provided saddle fittings, the fixture can be used to check saddle

clearances and alignment of the hull structure. The fixture will allow the builder / installer to lay-

up and adjust the foundation dimensions to create a low-clearance fit between the Seakeeper

foundation saddles and the hull structure. Shear strength of the adhesive will be maximized if the

cured thickness between the vessel structure and Seakeeper saddles is at the thinner end of the

adhesive manufacturer’s recommended range. Therefore, the fixture should be used to confirm

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 13 of 13

Section 1: MECHANICAL INSTALLATION

that the overall dimensions of the foundations are square and level and that the adhesive gap is

within Seakeeper’s maximum recommended thickness of .13” or 3mm.

Note: Do NOT use the installation fixture to establish Seakeeper envelope dimensions.

Refer to Drawing No. 90399 for envelope dimensions. A 3-D model of the Seakeeper is

available on the Seakeeper website (www.seakeeper.com) to aid in designing the

Seakeeper foundation and the space around the Seakeeper.

NOTE: MAKE SURE NO OBSTRUCTIONS FROM THE HULL STRUCTURE CAN BE SEEN WITHIN THE INSIDE

OF THE INSTALLATION TEMPLATE KIT (INSIDE THE MARKED RED LINES). SEE DRAWING NO. 90399.

FIGURE 6 – EXPLODED VIEW OF SADDLE INSTALLATION FIXTURE

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 14 of 14

Section 1: MECHANICAL INSTALLATION

FIGURE 7 – SADDLE INSTALLATION FIXTURE ON NOTIONAL HULL STRUCTURE

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 15 of 15

Section 1: MECHANICAL INSTALLATION

1.6.2 Fiberglass Hull Preparation

1) Position installation fixture (Fig 8) on hull girders noting recommended clearances for

maintenance from Figure 2. Check that the screws fastening the saddles to the installation

fixture are tight (Fig 6).

2) Mask hull area (Fig 9) around foundation saddles for easy clean-up and to create outline

of surface area to receive adhesive as (Fig 8). Insure that the bond gap is within

Seakeeper’s recommended thickness, or 3mm if using Plexus MA590.

3) Raise fixture clear of foundation. Check all four mounting areas are co-planar to within

.13” (3 mm) to each other, as well as parallel to the water line plane, as shown in Fig 8.

FIGURE 8 - INSTALLING FIXTURE ON HULL

FIGURE 9 - MASKING PERIMETER OF SADDLES

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 16 of 16

Section 1: MECHANICAL INSTALLATION

4) Thoroughly clean with alcohol or acetone all areas of girders to be bonded to remove any

contaminates. Use new paper towels for cleaning, not shop rags.

5) Remove any paint or gel-coat from bond surfaces so that adhesive will bond directly to

laminate fibers and resin as shown in Figure 8.

6) Thoroughly sand girder bond surfaces with 80 grit sandpaper. (IMPORTANT –

BOND STRENGTH MAY BE REDUCED IF THIS STEP IS SKIPPED.)

7) Wipe surfaces clean from dust with alcohol or acetone using new paper towels, not shop

rags.

8) Re-position installation fixture on girders and double-check that the adhesive gap is within

the adhesive manufacturer’s maximum recommended thickness. Seakeeper recommends

a maximum gap of 3mm if using Plexus MA590.

Note if bonding saddles to a metal structure, contact Seakeeper for hull preparation

instructions.

FIGURE 10 – COPLANAR PROPERTIES OF FOUNDATION

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 17 of 17

Section 1: MECHANICAL INSTALLATION

1.6.3 Seakeeper Saddle Preparation

1) Ensure that screws fastening saddles to the installation fixture are tight (Fig 6).

2) Check that each saddle contains 2 plastic screws which will insure an adhesive gap of

.080” (2 mm) on top surface of hull as shown in Figure 11.

3) Thoroughly clean with alcohol or acetone the inside surfaces of Seakeeper foundation

saddles to remove any contaminates as shown in Figure 11. Use new paper towels for

cleaning, not shop rags.

4) Thoroughly sand all saddle inside surfaces with 80 grit sandpaper. (IMPORTANT –

BOND STRENGTH MAY BE REDUCED IF THIS STEP IS SKIPPED.)

5) Wipe surfaces clean from dust with alcohol or acetone using new paper towels, not shop

rags.

6) If using Plexus MA590 adhesive, apply Plexus PC-120 surface conditioner to inside

surfaces of Seakeeper foundation saddles in accordance with manufacturer instructions.

These instructions are located at the end of this section. If using an alternate adhesive,

check with manufacturer if any surface conditioner/etch is required for the aluminum

saddles.

FIGURE 11 - SADDLE CLEANING

INSTALLATION

MANUAL

Product: Document #: Rev: Page:

SEAKEEPER 6 90402 1 18 of 18

Section 1: MECHANICAL INSTALLATION

1.6.4 Bonding Saddles to Hull

Note: If using Plexus MA590 adhesive, the Seakeeper saddles should be installed when PC-

120 is confirmed dry.

1) Assemble Plexus cartridge into either the manual or pneumatic gun as shown. Remove cap

on cartridge and attach mixing tip. For pneumatic gun, start with low air pressure and increase

until desired flow rate is achieved.

2) Cut tip of mixing wand as shown in photo.

3) Prepare a second mixing wand as shown in photo below by attaching the simple flexible

nozzle to the end of the mixing tip. Set aside for now as this will be used to inject adhesive

into the sides of each saddle after the fixture / saddles are in position.

4) Install provided rubber plugs in six holes of each

saddle. The plugs will limit the adhesive being forced

out of the injection holes in step 6 below.

Pneumatic Gun

Mixin

g

Ti

p

Flexible Nozzle

Adhesive Gun

Mixin

g

Ti

p

Other manuals for 6

2

Table of contents

Other Seakeeper Marine Equipment manuals