Sentry IS Card Reader User Manual Page 5 of 35 2017r0

Contents

Introduction........................................................................................................................6

System Overview.................................................................................................................6

Power / Comms Options......................................................................................................6

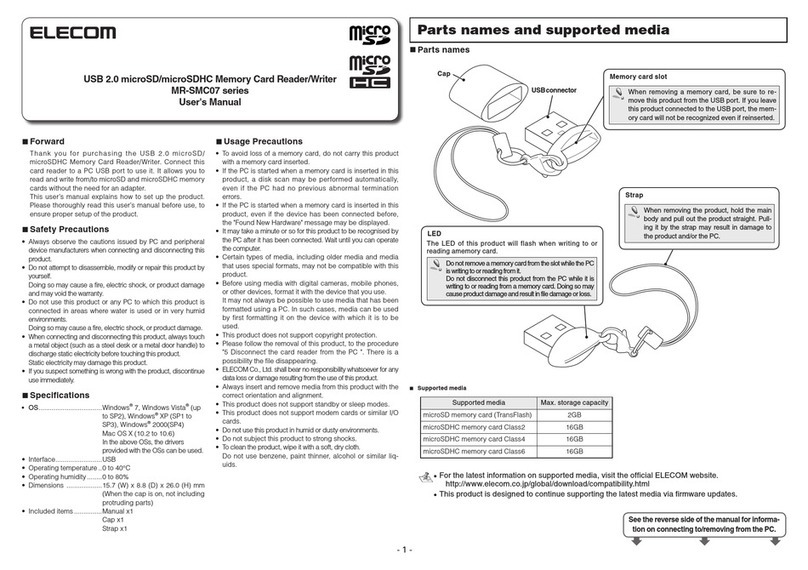

Base Unit............................................................................................................................. 6

Reader Types....................................................................................................................... 7

Enclosure Material...............................................................................................................7

Certification Standard...................................................................................................... 8

Installation..........................................................................................................................9

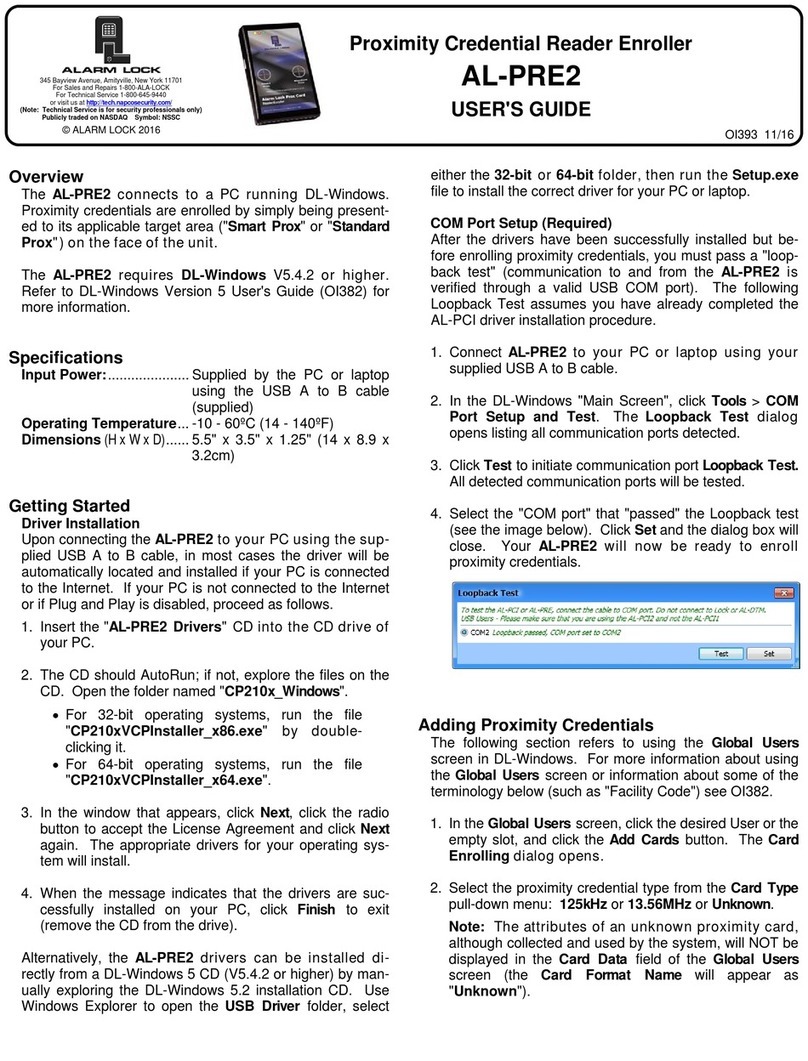

Overview............................................................................................................................. 9

Mounting the Sentry Card Reader.......................................................................................10

Weatherproofing.................................................................................................................. 10

Hazardous Area Connections...............................................................................................10

Twisted Pair Cabling............................................................................................................11

Safe Area Requirements...................................................................................................... 11

Safe Area Connections.........................................................................................................12

Internal Overview................................................................................................................12

Operation............................................................................................................................13

Power On.............................................................................................................................13

Set Up & Configuration.......................................................................................................14

Configuring the Reader Card Type......................................................................................14

Operating Mode...................................................................................................................15

Configuration String............................................................................................................16

Example Configuration String.............................................................................................17

Telemetry Block Structure................................................................................................18

Multi Drop...........................................................................................................................18

Data Only.............................................................................................................................18

Escape Sequences................................................................................................................19

Card Data ............................................................................................................................19

System Options.................................................................................................................. 20

Option 1 : IS Sentry in Standalone mode...........................................................................20

Option 2 : IS Sentry in MultiDrop Mode........................................................................... 20

Option 3 : IS Sentry in Standard Modbus Mode................................................................. 21

Option 4 : IS Sentry in Mercury 2+ Modbus Compatibility Mode..................................... 23

Option 5 : Safe Area Sentry.................................................................................................24

Option 6 : Wiegand D1/D0 Output Mode........................................................................... 25

Hazardous Area I/O............................................................................................................. 26

Appendix A Wiring Diagrams...........................................................................................27

Appendix B Specifications................................................................................................34

Appendix C Link Settings.................................................................................................35