Merg Servo4-F Driver Kit 75 Instruction Manual

Servo4-F Driver Kit 75 – Building Instructions June 2012

These are the Kit Building Instructions for the updated Kit 75 Servo4-F Driver Module for controlling model aircraft servos used to actuate turnouts and

signals on your layout. This revised kit incorporates extra components identified as desirable from experience of the original module and includes pull-

up/down resistors for the output servo control lines to counter servo twitch on power-up, separated 5v regulators for the microcontroller and servos to

counter noise and brown-outs, and a full wave bridge rectifier for the power input. Do take a few minutes to read right through these Instructions. It

is also recommended that the builder has read through Technical Bulletin A38/1 which provides a technical introduction to the Servo4 driver board and

how it is configured by using Kit 76, the Servo Setting Box, or an IBM PC. Pay particular attention to the warnings about connecting power

supplies on page 3.

Kit Contents

Ref Component No. in

kit

Ref Component No. in

kit

Ref Component No. In

kit

R6 1K ¼W resistor 1 R4 100K ¼W resistor 1 R3 2K2 - 8 pin ResNet 1

R5 10K - 5 pin Resnet 1 D1 Diode 1N4002

Black plastic body-silver band

1

D2 D3 Diode 1N4148

glass body-black band

2

R1 R2

R7

10K ¼W resistor 3 C1 1000uF/16v electrolytic

capacitor

1 C2, C4 100uF/16V electrolytic

capacitor

2

C3 4.7uF or 10uF/16v

tantalum capacitor

1 U3 78L05CV 100mA TO92 voltage

regulator IC

1 U2 7805 1A TO220 voltage

regulator IC

1

BR1 DIL Bridge rectifier 1A 1 (U1) 14 pin DIL socket for U1 1 J6 3-way 3.5mm term blk 2

J1 2-way 5mm term block 1 J7 9-way D-type pcb skt 1

J2-J5,

LK1, LK3

18 pin 2.54mm PCB

Header

1 LK2,

ICSP

50mm 24swg tinned Copper

wire

1 Printed Circuit Board

‘Servo4 rev F’

1

LK1,

LK3

2.54mm jumper link 2 J8 6 pin 2.54mm PCB ICSP

header

1 U1 PIC 16F630 (SRV4)

microcontroller

1

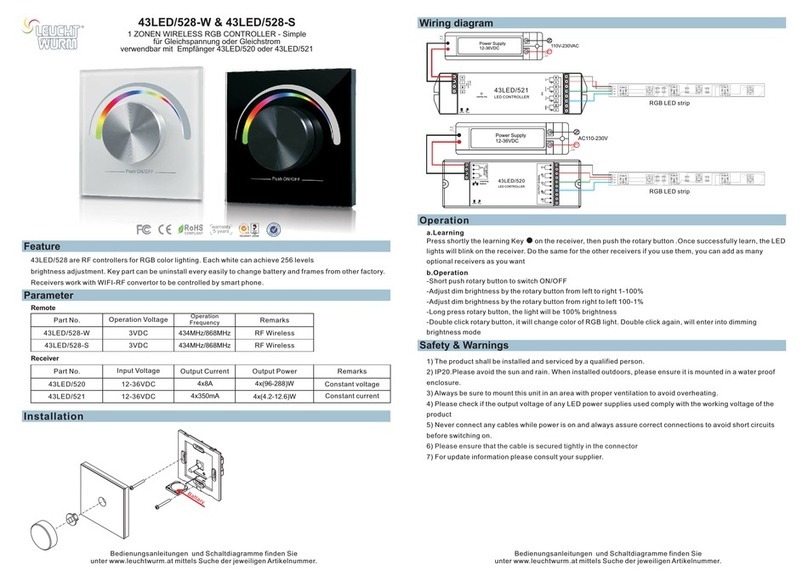

Circuit Diagram of the Servo4 Driver Board

‘Static’ caution. Before opening any kits, touch a nearby radiator, tap, or other earthed metal and then try to stay seated while the kit is

opened and assembly undertaken. Leave the ‘SRV4 microcontroller’ on its protective conductive foam until ready to install.

Assembly

1. Fit resistors R6* (1K); R1, R2 and R7 (10K ) and R4 (100K). Beware these resistors look very similar to the untrained

eye and in poor light. Also, depending on supplied stocks, could be either 3-band resistors with a light cream body or 4-

band resistors with a blue body. The following table illustrates the differences:

75Servo4-F Bldinst2c.doc 1 of 4 Issue 2c June 2012

Servo4-F Driver Kit – Building Instructions contd

75Servo4-F Bldinst2c.doc 2 of 4 Issue 2c June 2012

Value 3-band colours 4 band colours

1K - R6 Brown-black-red Brown-black-black-brown

10K - R1, R2, R7 Brown-black-orange Brown-black-black-red

100K - R4 Brown-black-yellow Brown-black-black-orange

2. Fit diodes D1 (1N4002) and D2 & D3 (1N4148), observing polarity. (Match the end band on the diode to the band on

the overlay.)

3. Fit the 14-pin Dual-in-line (DIL) socket, with the 'bite' corresponding to the bite shown on the printed overlay. Do NOT

fit the SRV4 microcontroller yet.

4. Fit R3, the 8-pin 2K2 'Resnet' package, black and marked B 222G. This Resnet may be fitted either way round.

5. Fit R5, the 5-pin 10K 'Resnet' package, black and marked A103G. This Resnet must be inserted with the marked

common pin at the top of the legend next to the ‘R5’ marking.

6. Fit the DIL Bridge rectifier BR1, aligning its top legend with that on the pcb

7. Locate the 18 pin pcb header strip and cut carefully into 1 x 2 pin header for LK3 and 5 x 3 pin headers for J2, 3, 4, 5

and LK1 with a sharp pair of sidecutters (there will be one pin remaining). This strip can be brittle and shatter if you

attempt to do this with blunt tools or your fingers.

8. Insert the 5 x 3-way headers J2, J3, J4, J5 and LK1 into the pcb and solder carefully. (Tip - Before fitting, paint a black

strip along the board edge close to the outermost pins of J2 - J5 as a reminder to connect the servo plugs right way

round). Also insert and solder the 2 way header LK3.

9. J8 is the header for In-Circuit Serial Programming (ICSP) of the SRV4 PIC and may be omitted if you do not need this

facility. It plays no part in the Servo4 operation. However, if required, gently remove pin no. 3 from the 6 pin strip with

long-nosed pliers and solder into the J8 position on the pcb. (Note – you will also need to install the long wire link that

runs adjacent to J6)

10. Fit C3, the 4.7uF (or 10uF) Tantalum capacitor. Polarity is vital. The longer marked lead next to the ‘+’ on the legend.

11. Fit the TO92 78L05 regulator U3 which has a black transistor-like body. Ensure correct polarity, aligning its curved

face with that on the legend.

12. Fit the 2-way 5mm terminal block J1 with cable entries towards the right board edge.

13. Assemble the 6-way terminal block J6 by slotting together the 2 x 3.5mm terminal blocks. Insert in the pcb and solder

ensuring that the wire entry holes are to the left!

14. Fit C2 and C4, the 100uF/16V capacitors. Polarity is vital. The negative lead is marked by a silver stripe on the

capacitor body and is generally the shorter one. The longer lead therefore must be fitted adjacent to the ‘+’ on the pcb.

15. Fit the 9-way D-type connector J7. Fixing screws are optional: if you make it difficult to connect the mating plug for

programming or re-programming in situ maybe you should add fixing screws (not supplied) as a precaution!

16. Fit C1, the 1000uF electrolytic capacitor, observing correct polarity as in 14. above.

17. Fit the TO220 7805 5v Voltage Regulator U2, with metal tab face towards edge of board.

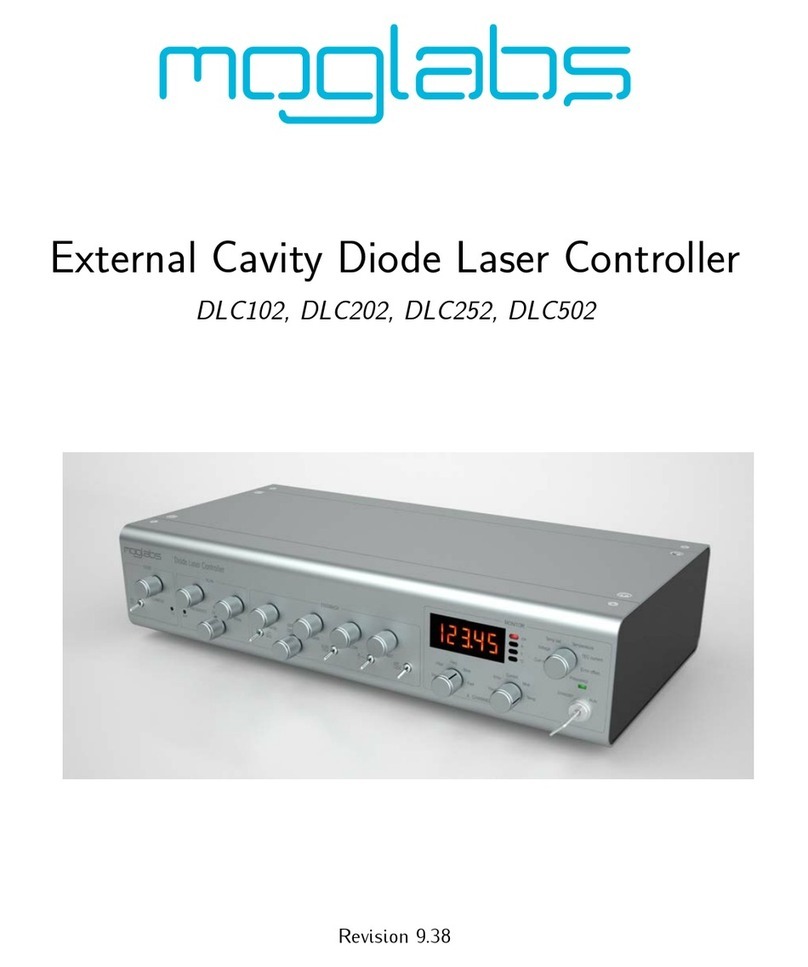

The assembled board should look like the

diagram to the left. Using a good light and a

magnifying glass, check all the solder pads under

the board for solder bridges, whiskers, and dry

joints.

(Soldered joints should resemble a neat 'Mount Fuji' in

miniature. If it looks like a small tomato with a stalk the

joint is very probably 'dry'. Apply a hot iron and a small

amount of solder and re-check.

75Servo4-F Bldinst2c.doc 3 of 4 Issue 2c June 2012

Testing.

You will need a standard analogue or digital multimeter to test this module.

Switch your meter to a resistance range. Connect the black meter probe to terminal 5 of J6 and test for

continuity of the 0v rail around the board by touching the red probe on the outer pins of J2-J5, pin 14 of U1 DIL skt

and pin 5 of the D-connector J7. Continuity is confirmed with a reading of 0 ohms on a digital meter or full scale

needle deflection on an analogue meter

Connect either a 12Vdc supply or a 9Vac supply to J1. Please be aware that lightly loaded power supplies

can deliver substantially higher voltages than specified. If this occurs then Servo4 components will be

damaged, particularly capacitor C1 (eg using that auxiliary output on a Gaugemaster controller is known to

overload C1) so please measure your intended source with a multimeter BEFORE connecting your servo4

module. The specification for input of 12Vdc or 9Vac is not to be ignored. When happy with the power

supply, switch your multimeter to a Vdc range and check the voltage on the middle pins of J2 – J5 against the pins

nearest the edge of the board. It should be 5V. Check that the main regulator U2 is not getting hot which would

indicate a short somewhere. If it does, disconnect power immediately and troubleshoot. If all is OK, remove power.

This module is provided with a subsidiary 5V voltage regulator U3 which supplies power to the onboard SRV4 PIC

U1 in order to minimise the effects of any noise generated by the servos. It may be connected in either of two

ways, only one of which must be chosen:

a. to the main power supply through J1, as above, in which case LK2 C-2 must be made with a wire link and the

main power supply then powers the whole module, or

b. to an optional independent external 12Vdc supply (such as available from some CBUS modules or the DCC

Steady State Decoder kit 53) connected at J6 (positive to J6/6 and negative to J6/5, diode D1 protects against

incorrect connection), in which case link LK2 C-1 must be made. The main power supply at J1 then only powers

the servos whilst the subsidiary power supply at J6 only powers the PIC.

With power off, install your required link at LK2. Reapply power and check that regulator U3 is not getting hot. If it

does, switch the power off immediately and troubleshoot.

When satisfied and with power connected, use the multimeter to check for 5Vdc as follows. With the black lead of

your meter to J6/5, check with the red meter lead at the positive terminal of C3, at pins 6 and 8 of 'D' connector J7

and pins 1 and 4 of the empty DIL socket for U1.

If all is well, disconnect power supply, ground yourself (touch a water pipe or radiator, for example) and insert the

SRV4 microcontroller U1, ensuring that it is correctly orientated ('bite' to 'bite') and that all legs are entered into the

socket. Press firmly home. Switch the power back on and recheck the voltages as above.

If all is OK your Servo4-F board is completed. Please read the notes on connecting servos before proceeding.

Notes on Connecting Servos

Servo Cable Colours

While the Futaba colour coding appears to be the most common, be aware that other manufacturers and re-

badgers use other colours. If you view the cable with the black to the right, the core should be as follows:

Manufacturer Control Positive + Negative 0v

Futaba white Red black

Hitec yellow Red black

JR Radio Orange Red brown

Tower Pro SG90 Orange Red brown

Unhelpfully, Airtronics buck the near standard: view the cable with red to the left.

Control

red black Black or white

Servo4 Power-up

Whilst the Servo4-F module is capable of driving most model aircraft servos, some brands have a tendency to

twitch on power-up thus possibly straining connecting links to layout accessories. It has been determined that this

feature can be ameliorated by applying either a pull-up voltage bias or a pull-down voltage bias to the servo

Servo4-F Driver Kit – Building Instructions contd

75Servo4-F Bldinst2c.doc 4 of 4 Issue 2c June 2012

module output control lines. The Servo4-F module has these options available through installing one of the jumper

plugs at LK1. Linking LK1 centre pin to ‘+’ applies a pull-up bias or centre pin to ‘-‘ a negative bias.

(Note 1 - this link applies bias to all connected servos at this module)

(Note 2 – The TowerPro SG90 servo available in the Kit Locker requires a pull-up bias).

If your servos do not twitch on power-up then link LK1 may be omitted completely.

Servo Chatter or Buzz

It has been noticed that some servos buzz or chatter when constrained at the applied limit of travel and this is due

to the pulse drive being maintained once the servo has come to rest. The Servo4-F module is provided with the

option that either the pulse drive is removed approximately 2 seconds after reaching the limit of travel (omit jumper

LK3), or is maintained (install jumper LK3). It should be appreciated that the setting of LK3 is only read by the

SRV4 microcontroller on power-up and so adding or removing it whilst the Servo4-F is powered effects no change

in behaviour.

(Note – some brands of servos return to their mid position if the pulse drive is removed).

Servo Selection

As shown above, it may therefore be necessary for you to experiment with your selected servos before deciding on

the link options available. Please remember that your Servo4-F module must be disconnected from all power

sources whilst installing links.

Although the Servo4-F module caters for most situations encountered at the time of writing, it has not been

possible to provide for individual options at each output and all servos connected to one module are subject to the

options selected. Therefore the best advice must be try to keep to one supplier and always read the instructions.

Using your Servo4-F module

Having completed and tested the module, you will now install it in its chosen position and connect to the servos

and subsequently their accessories. Suitable 3-way servo extension leads are available from commercial sources if

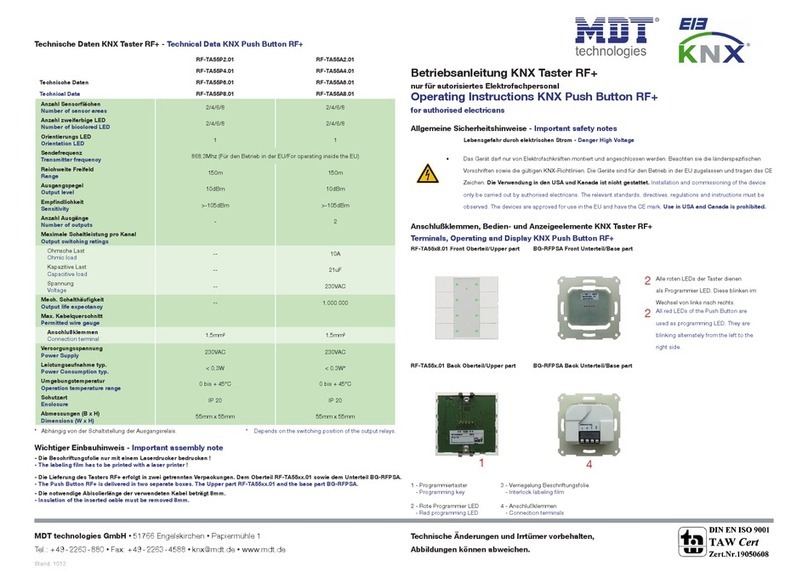

required. The simplest method of servo control is established by connecting the required input terminal (1 – 4) on

block J6 to common pin 5 (marked ‘0’ on the pcb), ‘off’ being one servo position and ‘on’ the other. This is

illustrated in the diagram below which shows control of the first servo connected to J2. Servos 2 – 4 are connected

to J3 – J5 respectively. Speed of travel is set as ‘S1’ being servo movement on closure of the switch and ‘S2’ as

movement at switch opening. The servo travel limits and speed require configuring as described below.

OFF ON

Panel switches may also be replaced by relay contacts or outputs from other driver modules in the MERG Kit range

such as the DCC Steady State Decoder (kit 53 – see TB DCC 11/19 for details), and the CAN_ACC5 and

CAN_ACC8 modules from the CBUS range.

Configuring your Servo4-F module

Configuring the servo4-F module for the required limits of travel (On and Off) and travel speed (S1 and S2) can be

accomplished by using the Servoset box (kit 76) or the PC Servoset software available for download from the

MERG website. Both of these devices connect through a standard RS232-type serial link connected at J7*.

Selected settings are ‘saved’ in the SRV4 microcontroller. For details please refer to Technical Bulletin A38/1 for

Programming and Putting to Use.

*At the time of writing, resistor R6 (1K) and its connection to pin 2 of J7 performs no function and has been

included to facilitate bi-directional communication with the SRV4 microcontroller should it be required in the future.

Popular Controllers manuals by other brands

PlaneWave Instruments

PlaneWave Instruments EFA instructions

Wolf

Wolf WRS-K Installation and operating instructions

KNX

KNX Push Button RF+ operating instructions

elero

elero Insolis 4 operating instructions

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-F FX5 user manual

Johnson Controls

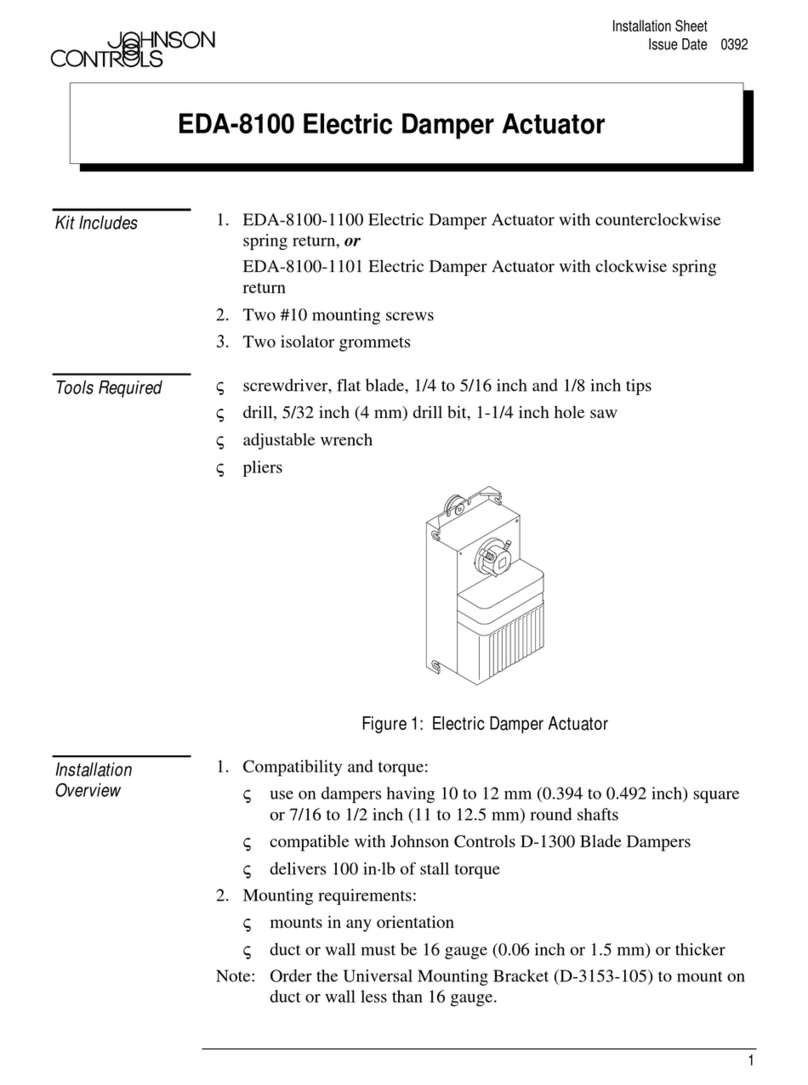

Johnson Controls EDA-8100 Installation sheet

Hobby-Wing

Hobby-Wing QUICRUN WP 1080 G2 BRUSHED user manual

AutomationDirect

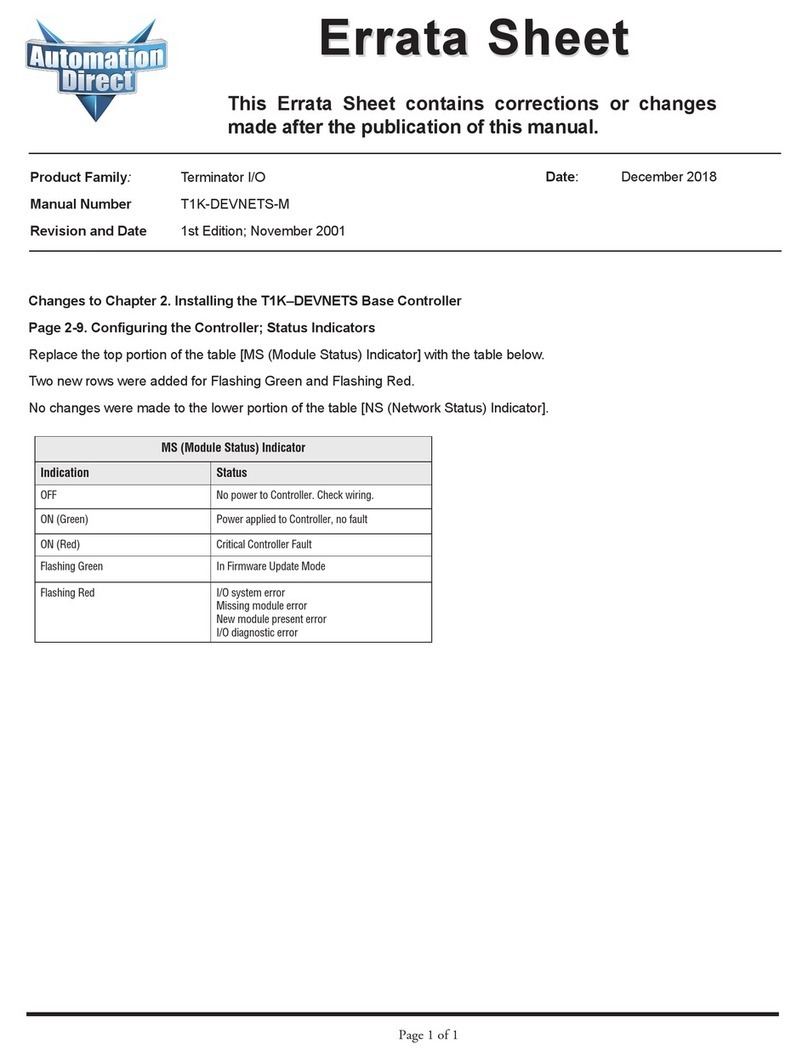

AutomationDirect T1K-DEVNETS user manual

Bender

Bender CC611 manual

LMI Technologies

LMI Technologies Liquitron DC4000 Series instruction manual

Mircom

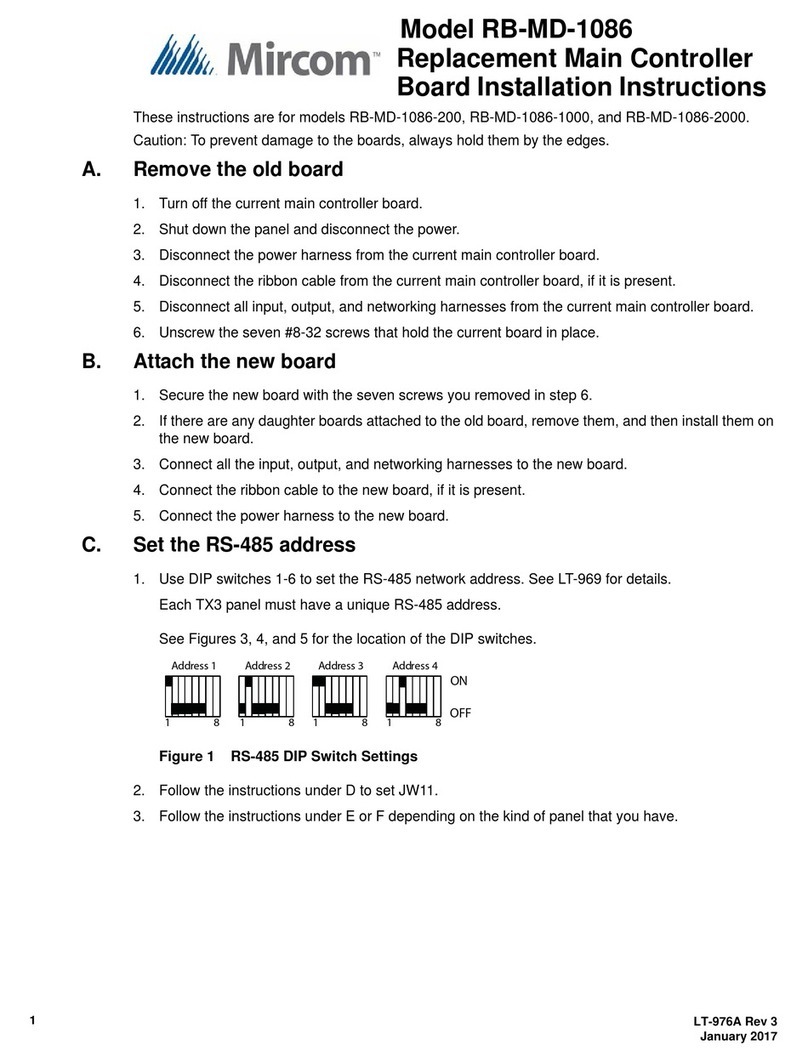

Mircom RB-MD-1086 Series installation instructions

CHROMOFLEX

CHROMOFLEX Pro Series instruction manual