elero Insolis 4 User manual

Linear actuator

Insolis 4

04/2016, TN: 2011521

Operating instructions

Please take care of the operating instructions!

EN

EN Translation from the original German version.

All other documents in different languages are translations of the original

version.

Subject to change without notice. All rights reserved in the event of

registrati-on of patents, working models or design patents.

Table of contents

EN

Table of contents

1 General................................................................................................3

1.1 Information on the Assembly Manual .............................................................. 3

1.2 Standards and guidelines................................................................................. 3

1.3 Intended use..................................................................................................... 3

1.4 Foreseeable misuse ........................................................................................ 4

1.5 Warranty and liability ........................................................................................ 4

1.6 Customer Service - manufacturer..................................................................... 5

2 Safety ..................................................................................................6

2.1 General safety notices...................................................................................... 6

2.1.1 Structure of the safety notices.......................................................................... 6

2.2 Safety principles ............................................................................................... 8

2.3 General duties of the operator.......................................................................... 9

2.4 Requirements of the personnel ........................................................................ 9

2.5 Safety notices on technical condition ............................................................. 10

2.6 Safety notices on transport, assembly, installation......................................... 10

2.7 Safety instructions for operation......................................................................11

2.8 Safety notices on electrical installation............................................................11

3 Product description ......................................................................... 12

3.1 General........................................................................................................... 12

3.2 TechnicalSpecications ................................................................................. 13

3.2.1Congurationoftechnicalparameters............................................................ 13

3.2.2 Information on self-locking.............................................................................. 14

4 Assembly ..........................................................................................15

4.1 Fastening on piston side................................................................................. 16

4.2 Installation environment.................................................................................. 17

4.3 Electrical connection variants......................................................................... 18

4.3.1 Electrical connection for variants with 230 V 1 AC ......................................... 18

4.3.2 Electrical connection for variants with 24 DC ................................................. 19

4.3.3 Optional shaft encoder ................................................................................... 20

4.4 General dimension drawing............................................................................ 21

5 Declaration of Incorporation........................................................... 22

Table of contents

6 Waste disposal ................................................................................. 23

6.1 Scrapping ....................................................................................................... 23

6.2 Disposal of electrical and electronic components........................................... 23

3

General

EN

1 General

1.1 Information on the Assembly Manual

The contents structure is based on the life stages of the linear actuator (herein-

after referred to as "device").

The manufacturer reserves the right to make changes to the technical data

stated in this Assembly Manual. In individual cases they may deviate from the

respective device version without the information being categorically changed

or losing validity. The current state of the technical data can be obtained from

the manufacturer at any time. Any claims arising herefrom may not be asserted.

Deviations from the text and image statements are possible and are dependent

on the technical development, equipment and accessories of the device. The

manufacturer shall provide information on any deviant details on special versi-

ons via the sales documentation. Other details shall remain unaffected by this.

1.2 Standards and guidelines

During the design of the device the fundamental requirements for health and

safety were applied and provision was made for the appropriate legislation,

industrial standards and regulations.

ThesafetyelementisconrmedbytheDeclarationofIncorporation(seechapter

"Declaration of Incorporation"). All information on safety in this Assembly Manual

refers to legislation and regulations currently valid in Germany. All information in

this Assembly Manual must be complied with at all times and to the full extent.

In addition to the safety notices in this Assembly Manual, the regulations appli-

cable at the place of installation with regard to accident prevention, environment

protection and occupational safety must be observed and adhered to. The gui-

delines and standards for safety evaluation can be found in the Declaration of

Incorporation.

1.3 Intended use

The device is intended for use in solar tracking systems. Its purpose is position

adjustmentinsolartrackingsystems.Othereldsofapplicationmustbeagreed

in advance with the manufacturer.

The device must not be used in areas where there is a risk of injury to personnel

or in rooms in potentially explosive environments.

4

General

If a direct or indirect hazard to personnel cannot be ruled out, additional measu-

res (e.g. covers, barriers, etc.) must be taken in order to minimise the potential

risk accordingly.

The operator alone is liable for all damage arising from the non-intended use of

the device. The manufacturer assumes no liability for personal injury and ma-

terial damage caused through misuse or procedural errors, improper use and

commissioning.

The device must only be operated by trained and authorised specialist staff who

comply with all safety instructions.

The safe and error-free use and operating safety of the device can only be gu-

aranteed on the basis of the intended use according to the information in this

Assembly Manual.

Intended use includes observation of and adherence to all safety instructions

speciedinthisAssemblyManual,aswellasallapplicableregulationsofpro-

fessional associations and the valid legislation regards environment protection.

Adherence to the operating rules prescribed in this Assembly Manual also form

part of the intended use.

1.4 Foreseeable misuse

Installation different from the intended purpose approved by the manufacturer is

considered foreseeable misuse.

1.5 Warranty and liability

In principle, the General Terms & Conditions of Sale and Delivery of the ma-

nufacturer apply. The Terms & Conditions of Sale and Delivery form part of the

sales documentation and are transferred to the operator upon delivery. Liability

claims for personal injury and material damage shall be excluded if they are the

result of one or more of the following causes:

• Opening of the device by the customer (breaking the seal)

• Non-intended use of the device

• Improper assembly, commissioning or operation of the device

• Changes to the design and construction of the device without written per-

mission from the manufacturer

• Operating the device with improperly installed connections and defective or

improperly installed safety and protective equipment

5

General

EN

• Non-compliance with safety regulations and notices in this Assembly Manu-

al

• Exceedingthelimitsofthespeciedtechnicaldata

1.6 Customer Service - manufacturer

The device must only be repaired by the manufacturer in the event of a fault.

The address to send the device to customer service can be found on the inside

of the back page.

If you have not purchased the device directly from elero, please contact the

manufacturer of the machine or the supplier of the device.

Mechanically secure the system before disassembling the device. The device

must not be separated from the system by force.

The serial number must be on hand at the request of customer service. This

can be found on the type plate in the upper right half.

6

Safety

2 Safety

2.1 General safety notices

This Assembly Manual contains all safety notices that must be observed to avo-

id and prevent risks when working with the device in the individual life cycles.

Safeuseofthedeviceisguaranteedwhenallthespeciedsafetynoticesare

adhered to.

2.1.1 Structure of the safety notices

Thesafetynoticesinthisdocumentareidentiedwithsafetysymbolsanddesig-

ned in accordance with the SAFE principle. They contain information on the type

and source of risk, the possible consequences, as well as the prevention of the

risk.

The following table provides a description of the degrees of risk with possible

physical injury, as they are used in this Assembly Manual.

Symbol

Key word

Meaning

DANGER Warns of an accident that will occur if the ins-

tructions are not followed, which may lead to

life-threatening, irreversible injuries or death.

WARNING Warns of an accident that may occur if the

instructions are not followed, which may lead

to serious, perhaps life-threatening, irreversib-

le injuries or death.

CAUTION Warns of an accident that may occur if the

instructions are not followed, which may lead

to minor, reversible injuries.

7

Safety

EN

The following table describes the symbols used in the present Assembly Manu-

al, which are used for the graphic display of danger situations in connection with

the symbol for the degree of risk.

Symbol

Meaning

Risk of electrical voltage or electrical shock:

This symbol refers to risks associated with electrical cur-

rents.

Risk of crushing and killing persons:

This symbol refers to dangers associated where the enti-

re body or individual limbs may become crushed or suffer

injury.

The following table describes the situations used in this Assembly Manual where

damage may occur to the product or refers to important facts, states, tips and

information.

Symbol

Key word

Meaning

CAUTION This symbol warns of possible material damage.

This symbol refers to important facts and states, as

well as to further information in this Assembly Ma-

nual.Furthermore,itreferstospecicinstructions

which give additional information on or provide

assistance in performing a process in a simpler

manner.

The following is an example of the structure of a safety notice:

DANGER

Type and source of hazard

Explanation of the type and source of hazard

• Measures to avoid danger.

8

Safety

2.2 Safety principles

The device is built according to state-of-the-art technology and the generally

accepted safety standards. The device is safe to operate. During the design of

the device, the fundamental requirements for health and safety were applied

and provision was made for the appropriate legislation, industrial standards and

regulations.ThesafetyofthedeviceisconrmedintheDeclarationofIncorpo-

ration.

All details pertaining to safety relate to the regulations from the European Union,

which are valid at this time. In other countries the operator must ensure that the

appropriate laws and national regulations are adhered to.

In addition to the safety notices in this Assembly Manual, the generally applicab-

le regulations regarding accident prevention and environmental protection must

be observed and complied with.

The device must only be used when in perfect working order, for its intended

use, and in compliance with the safety notices in this Assembly Manual. The

device is designed for the application stated in the chapter "Intended use". In the

event of non-intended use, injury to the life and limbs of the user or a third party

may result or the device may be impacted or other material damage caused.

Accidents or near misses during use of the device which led or could have led

to personal injuries and/or damage in the work environment must be reported

directly to the manufacturer with immediate effect.

AllsafetynoticesspeciedintheAssemblyManualandonthedevicemustbe

adhered to. In addition to these safety notices, the operator must ensure that all

national and international regulations applicable in the respective country of use,

as well as other binding regulations on operational safety, accident prevention

and environment protections, are complied with. All work on the device must

only be performed by trained and authorised personnel who have received the

appropriate safety instructions.

9

Safety

EN

2.3 General duties of the operator

❏The operator is obliged to only operate the device in a good and operatio-

nally safe working condition. He must ensure that, in addition to the safety

notices in the Assembly Manual, the generally accepted safety and accident

preventionregulations,thespecicationsofDINVDE0100andtheprovisi-

ons on environment protection in the respective country of application, are

observed and complied with.

❏The operator is responsible that all work with the device is performed by

trained and authorised personnel who have received the appropriate safety

instructions.

❏Ultimately responsible for accident-free operation is the operator of the

device or the personnel authorised by the operator.

❏Theoperatorisresponsibleforcompliancewithtechnicalspecications,in

particular for the compliance with static loads.

Non-compliance of static loads may cause loss of the support or hol-

ding function.

2.4 Requirements of the personnel

❏Each person who is commissioned to work with the device must read and

understand the Assembly Manual in its entirety before he/she carries out

the respective work. This also applies if the assigned person has previously

worked on such a device or was trained to do so.

❏All work on the device must only be performed by trained and authorised

personnel who have received the appropriate safety instructions. Before

starting any operations, personnel must be made aware of the hazards

involved in handling the device.

❏Allpersonsmustonlyperformworkaccordingtotheirqualications.The

areasofresponsibilityoftherespectivepersonnelmustbeclearlyspecied.

❏Any personnel who have been commissioned to work with the device must

have no physical limitations, limitations on attention or judgement, whether

temporary or permanent (e.g. due to overtiredness).

❏Minorsorpersonswhoareundertheinuenceofalcohol,drugsormedica-

tion, are prohibited from working with the device, as well as performing all

assembly, disassembly and cleaning work.

❏Personnel must wear the suitable personal protective gear appropriate to

the work and present work environments.

10

Safety

2.5 Safety notices on technical condition

❏The device must be checked before installation for damage and proper

condition.

❏The operator is obliged to only operate the device in a good and operatio-

nally safe working condition. The technical condition must always comply

with legal requirements.

❏If risks to persons or changes in the operational behaviour are detected, the

device must be shut down immediately and the incident reported to superi-

ors or operator.

❏The device may only be connected to the energy supply lines intended and

designed for this purpose. The permissible type of voltage and operating

voltage are stated on the type plate.

❏Nochanges,extensionsorretrottingmaybeperformedtothedevicewit-

hout the approval of the manufacturer.

❏If wear is detected on the trapezoidal or ball screw spindle or on the spindle

nut, the device must be brought to the manufacturer for maintenance.

2.6 Safety notices on transport, assembly, installation

Responsibility for the transport of the device principally rests with the respective

transport company. The following safety requirements must be complied with

during transport, assembly and installation of the device.

❏When transporting the device, it should be secured according to the instruc-

tions accompanying the means of transportation employed.

❏For the transport, only hoisting gear and lifting devices must be used that

are dimensioned in such a way that you can safely accept the forces during

loading, unloading and assembly of the device.

❏Onlythepointsdenedonthepalletanddevicecanbeusedasliftingand

hoisting points.

❏If work is required on high parts or work units, these must be secured

against falling with suitable equipment. Work equipment for lifting loads

must secure the loads against undesired displacement or free falling or

unintentional unhooking.

❏Standing under suspended loads is prohibited.

❏A protective helmet must be worn when loading with hoisting gear.

❏In principle, assembly and installation may only be conducted by trained

andqualiedpersonnel.

11

Safety

EN

2.7 Safety instructions for operation

❏The operator of the device is obligated to ensure the safe and proper state

of the device before the initial commissioning.

❏This is also necessary during the operation of the device at regular intervals

determined by the operator.

❏In the event of a fault, misuse and/or if control components are not con-

nected correctly, this can cause the supporting and retaining function of the

device to be impaired.

❏No radial and/or torsional forces must be allowed to act on the device.

2.8 Safety notices on electrical installation

❏All work on electrical connections must only be performed by authorised

electricians in accordance with the applicable regulations and provisions of

thetradeassociation,inparticularthespecicationsinaccordancewithDIN

VDE 0100. Furthermore, the national statutory regulations of the respective

country of application must be observed.

❏In the event of defects such as loose connections or defective or damaged

cables, the device must not be operated.

❏In the event of faults with the electrical equipment, the device must be shut

down immediately.

❏The device must be switched off before inspection, assembly and disas-

sembly work.

❏The device must not be hosed down with a high-pressure cleaner or a

steam blaster.

The following must be checked before connecting the device to the power

supply:

❏Are all electrical connections, safety devices, safeguards, etc. properly

installed, connected and earthed?

❏Istheintendedpowerconnectiondesignedaccordingtothespecications

in the electrical circuit diagram (voltage type, voltage level)?

❏Has the supply line been isolated?

12

Product description

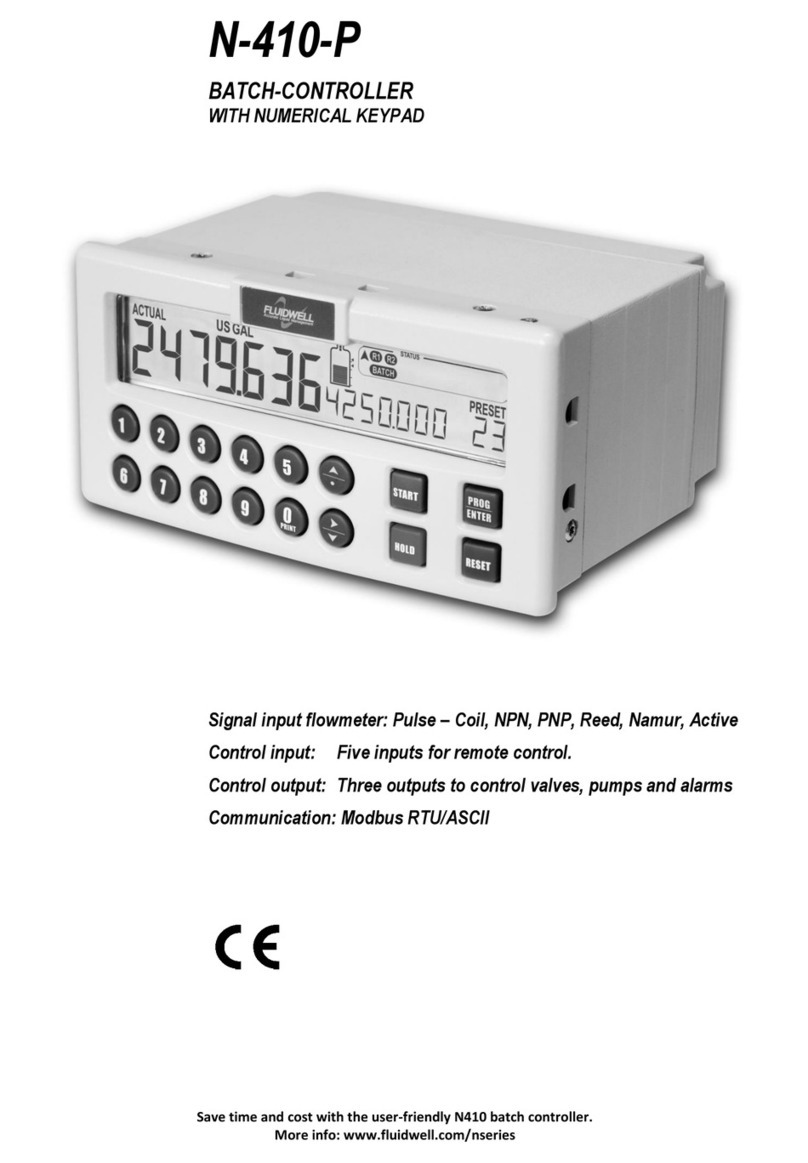

3 Product description

3.1 General

The device is an electromechanical linear actuator. It performs linear move-

ments.

Abb. 1 Components of the device

1 Fastening on the piston side (head of toggle link)

2 Limit switch extended

3 Limit switch retracted

4 Fixing on the housing (articulated lug)

5 Connection cable

13

Product description

EN

3.2 Technical Specications

All information in this chapter refers to an ambient temperature of 20 °C.

3.2.1 Conguration of technical parameters

Technical Specications Direct voltage (DC) Alternating voltage

(AC)

Rated voltage 24 V DC 230 V AC, 50 Hz

Peak demand, dynamic (N) 25.000

Load peak statically retrac-

ted (N)

up to 80.000 1)

Load peak statically exten-

ded (N)

up to 25.000

Stroke speed (mm/s) approx. 1.3

Stroke lengths (mm) up to 1000

Rated current 7 A 2) 2.2 A 2)

Power 168 W 506 VA

Duty cycle KB 14 min

Fastening on piston rod Head of toggle link

Fixing on housing Articulated lug

Housing and piston ma-

terial

Aluminium, anodised

Length of connection cable 1.50 m 3)

Protection class IP 65

Operating temperature

range

-20 °C to +60 °C

Airborne noise emission < 70 dB(A) 4)

Weight up to 40 kg

Tab. 1 Technical parameters

1) Special model with dimension B = 155 mm up to 60,000 N only

2)

If voltage surge protection devices are used, the exact current draw of the unit must be calcu-

lated prior to installation.

3) Depending on the customer's requirement - between 1.5 m and 5.0 m is possible.

4) 1 m distance; 1.6 m above unit; nominal operation; measuring tolerance 10 %

14

Product description

3.2.2 Information on self-locking

WARNING

Risk of injury through loss of self-locking.

Crushing and fatal injuries possible.

• Use device with brakes.

CAUTION

Possible damage to the device or customer system through loss of self-locking.

• Use device with brakes.

There is a difference between dynamic and static self-locking for the devices.

Dynamic self-locking consists of movement and static self-locking consists of

the shutdown of the device. Self-locking of the devices is dependent on different

factors, such as:

• Angle of elevation of spindle and nut

• Surfaceroughnessofanksofspindleandnut

• Sliding speed.

Self-lockingcanbenegativelyinuencedbyanumberoffactors.Forexample:

• Shocks or vibrations

• Load

• Heating.

In theory, a self-locking spindle can not replace a brake. For this reason, it is

excluded to assume warranty obligations regarding the self-locking.

Self-locking does NOT meet the relevant safety standards.

Observe the usual duty of care for technical products to minimise further risks.

15

Assembly

EN

4 Assembly

WARNING

Risk of injury by weather conditions.

Skin may suffer frostbite or burns.

• Wear personal protective gear.

WARNING

Risk of injury through incorrectly dimensioned receptors.

Crushing and fatal injuries possible.

• Useonlyxingmaterialsuitableforthedimensionofthereceptors.

• The counter receptors (customer) must be at least designed for the forces for

which the device was designed.

WARNING

Risk of injury through loss of support and holding function.

Crushing and fatal injuries possible.

• Observe static loads.

WARNING

Risk of injury by electrical current.

Electric shock possible.

• Electrical work must only be performed by an authorised electrician.

WARNING

Risk of life-threatening injury caused by faulty electrical connection.

Electric shock possible.

• Check the proper connection of the PE cable before the initial commissio-

ning.

CAUTION

Damage to the device through radial and/or torsional forces.

• No radial and/or torsional forces must be allowed to act on the device.

16

Assembly

CAUTION

Damage to the device through blocking of the piston rod.

• The linear pathway of the piston must always be freely moveable.

• The pivoting range of the device must be kept free.

CAUTION

Damage to device through loss of support and holding function.

• Observe static loads.

The device was manufactured with the circuit diagram ordered by you. The

designation can be found in the sales documentation or the circuit diagram enc-

losed with the delivery.

In the standard delivery (tool setting), the piston rod is already slightly exten-

ded. The minimum and maximum dimensions are available on the dimension

drawing (see chapter "General dimension drawing").

4.1 Fastening on piston side

CAUTION

Damage to device through torsional forces.

• No torsional forces must impact on the device.

• Do not adjust the head of the toggle link.

CAUTION

Damage to the device through too small screw-in depth of head of toggle link.

• Default screw-in depth of the head of the toggle link must not be changed.

The position of the fastening on the piston side (head of the toggle link) is

sealed and must not be changed.

17

Assembly

EN

4.2 Installation environment

CAUTION

Damage to the device by exceeding standard tolerances.

• The steel construction must be designed to conform to the tolerances accor-

ding to DIN ISO 2768-1/-2 and ISO 13920 (B).

If the deviation in the steel construction is greater than the tolerances according

to DIN ISO 2768-1/-2 and ISO 13920 (B), this will require the deviation to be

compensated as follows by suitable building design measures by installation of

the device at the latest:

1. Mount the device in the steel construction in table position.

2. Increase the distance of the two top pick-up positions (e.g. fork) and install

a longer bolt.

3. Fixthecompletelyretracteddevicetothepivotmountingrstandthento

the joint rod head.

4. Use the wide design of the top fastening to compensate for a centre offset

over the wider fork on the building with a longer bolt.

18

Assembly

4.3 Electrical connection variants

Variants 230 V AC

Variants 24 V DC

WS 9902 GS 9805

WS 9905 GS 9806

Tab. 2 Electrical connection variants

4.3.1 Electrical connection for variants with 230 V 1 AC

WARNING

Risk of life-threatening injury caused by faulty electrical connection.

Electric shock possible.

• Check the proper connection of the PE cable before the initial commissio-

ning.

CAUTION

Damage to the device through faulty electrical connection.

• Do not connect connection N to 230 V/50 Hz.

• Avoid simultaneous application of voltage to conductors „R“ and „V“.

CAUTION

Damage to the device through overload of the potential-free outputs.

• The potential-free outputs for the response of the end positions can only be

operated with maximum 24 V DC/1 A ohmic load.

Valid signals for response only arise after applying the operating voltage.

Drive position

Signal of response outputs

Device switched off Both closed "1"

Device retracts or extends Both open "0"

Device moves to retracted end

position

Retracted, closed "1",

extended, open "0"

Device moves to extended end

position

Retracted, open "0",

extended, closed "1"

Tab. 3 Function of the response contacts

Table of contents

Other elero Controllers manuals

elero

elero ExitSafe 28 388.0001 User manual

elero

elero MemoTec-868 User manual

elero

elero Combio-915 JA User manual

elero

elero VarioTec-868 DC User manual

elero

elero BoxControl Compact User manual

elero

elero InDrive M30/1.6 RH Product guide

elero

elero Compakt User manual

elero

elero Patio User manual

elero

elero Picolo 0 User manual

elero

elero Vario 1 User manual

Popular Controllers manuals by other brands

Schumacher Electric

Schumacher Electric BATTERY EXTENDER BE01254 owner's manual

DOLD

DOLD DMP 96 A operating instructions

BENSHAW

BENSHAW RediStart RB2 user manual

praher

praher Solar Control SC04 user manual

KMC Controls

KMC Controls KMD-5831 Installation & operation guide

BRIDGEWERKS

BRIDGEWERKS Magnum 220RM user manual