NetworkDiagnostics-LocalandRemoteAccess

SurfaceMountTechnology(SMT) forHighReliabilityandRepeatability

FaultTolerantSelf-HealingRingorLinearBusTopology

Multiple-MasterCapability

2x16CharacterLCDDisplayoneachModem

AsynchronousDataRatesupto125KbpsNRZ

UsesDigitalFPGATechnology

DataProtocolIndependent

RS-232D,RS-422,RS-485(2and4wire)andTTL

TrueTri-StateSensing(notimeoutsneeded)

SingleHandshake–RS-232D(RTS&CTS)

or2Channel125KbpsDataMultiplexer

FullHandshakingAvailable–RS-232D

DataRe-clocked&RegeneratedateachModem

99NodeCapability

IndividuallyAddressableModems

Anti-streaming(on/offorvariabletime)

LocalandRemoteLoopBackTest

LocalDryContactAlarm (N.O.)

BuiltInDualInputPowerRedundancy

AlarmedBatteryBackup

Dual Input: 12 VDC - 35 VDC, 9 VAC - 24 VAC

HotSwappableInputPower

FullyCompatiblewithSpectraSmart™PCBasedNetworkManagement

Build In BER Tester w/GUI

ESDInputProtection

ExceedsNEMATS-1/TS-2andCaltransSpecifications

FEATURES:

•

•

•

•

•

•

•

•

•

•

•

DESCRIPTION:

The2300Misastateoftheartselfhealing,counterrotatingmulti-dropdata

modemdesignedtoprovidetheuserwithtroublefreedatatransmissionin

bothringandstringconfigurations.Inadditiontobeingequippedwithallofthe

expectedfeatures, localandremotediagnosticcapabilitiesareincludedin

eachmodem.Theuser-friendlydiagnosticsmenucanbeaccessedviatwo

smallbuttonslocatedonthefrontpanel.Thesebuttonsareusedforscrolling

throughthe menufunctions.Thestatusofanyothermodemcanbeviewed

on the SpectraSmartTM System. Field technicians can perform local and

remotediagnostics without theaid of aPC. Parameters viewableon the

LCDdisplayareinternalmodemtemperature,powersupplyvoltages,opti-

calringstatus,locationoffiberbreaks,unitfailures andmanyothercritical

parameters.Ifaparameterisexceeded,aflashinglightandaudiblealarm

areactivatedatallmodems.Bothprimaryandsecondaryringsaremoni-

toredsimultaneouslybythenetworkdiagnostics.Iftheprimaryringisbro-

ken,the LCD will display theaddressofthemodemsoneachsideof the

breakprovidingquicktroublefree identification.Intheeventofafault,cus-

tomer data will automatically be transferred to the secondary ring.

SpectraSmartTM PC,awindowsbasedGUIdriven network management

system can be connected to the Master Primary and Master secondary

modemsviaanRS-232orRS-485cable.WhenaPCisused,theGUIwill

displaytheentireNetworkandachangeofcoloratthetroublelocation.The

SpectraSmartTM softwareworksinconjunctionwiththeLCDdisplaylocated

ontheindividualmodems. When operating normallythe PrimaryMaster

modemmonitorsquantityandnumericalsequenceofslavemodemsonthe

ringandeachmodemstoresthelastfivealarms,whichcanbedisplayedon

thelocalLCDdisplay.The2300Mfamilycombinessophisticatedself-heal-

ingringtopologyandcomputerbasedlocalandremotediagnosticstopro-

vide your network with round the clock monitoring. The self-healing ring

immediatelydetectsfaultsandreroutescommunicationstokeepyournet-

workoperationalwhilethebuiltindiagnosticsreducesthetimerequiredby

technicianstoanalyze,locateandrepairthefault.

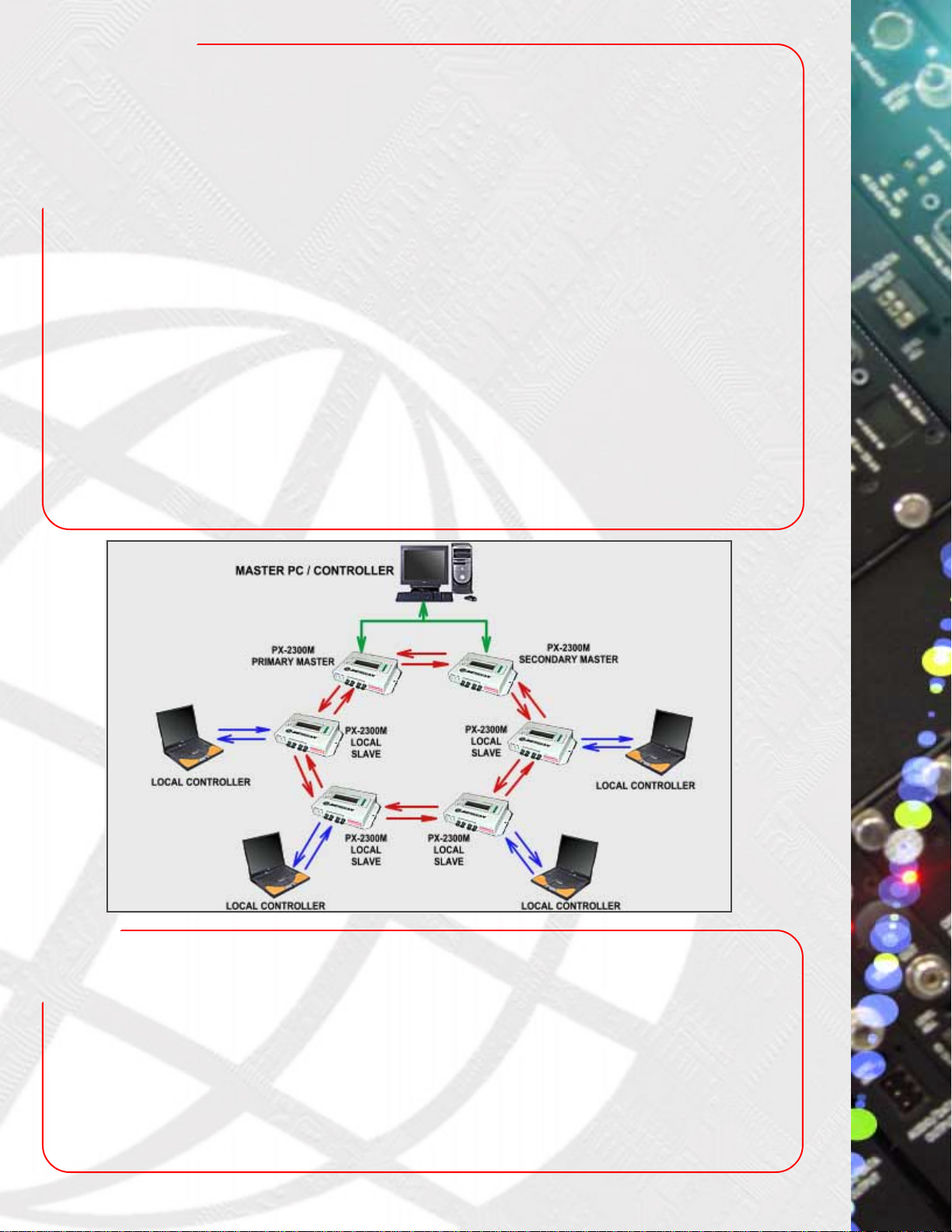

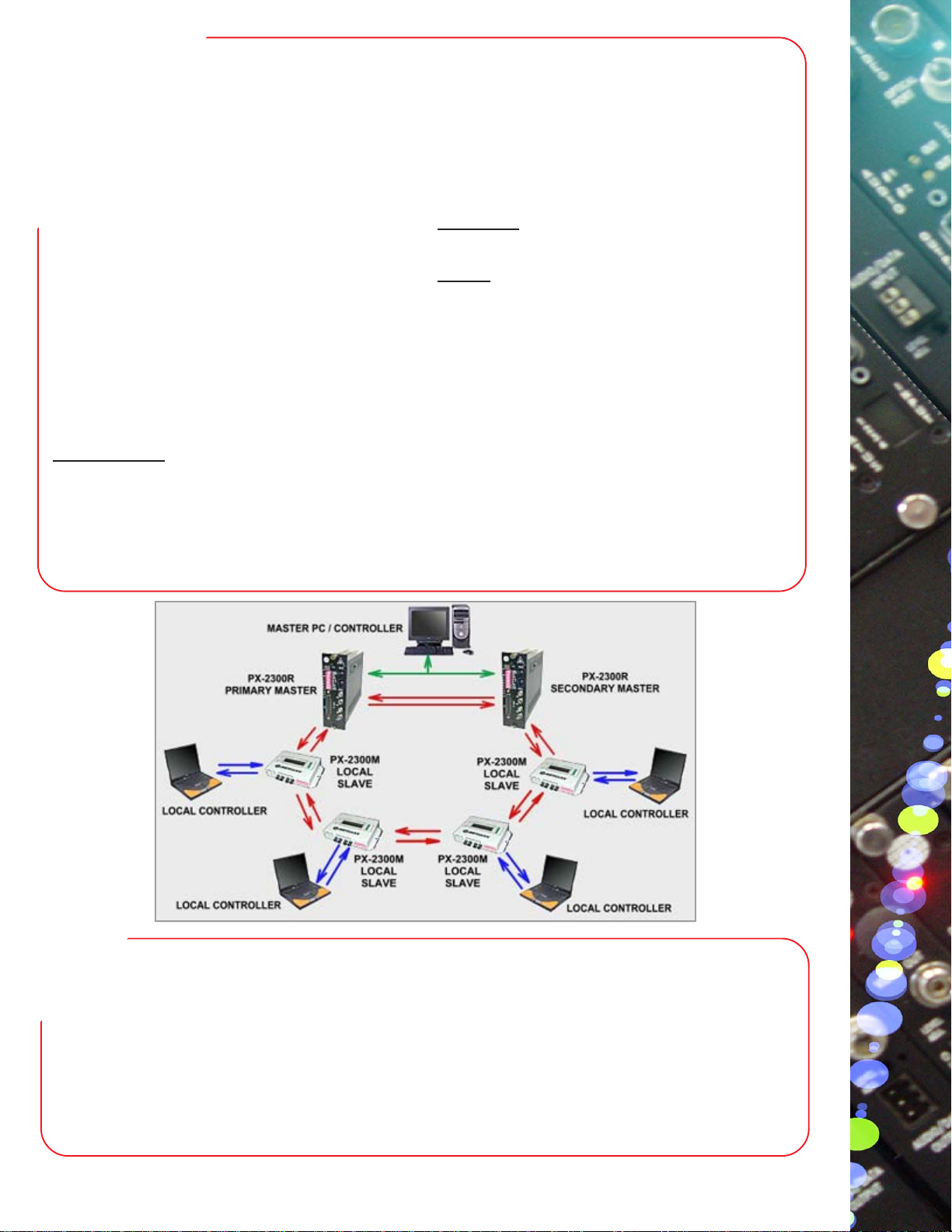

CONFIGURATIONS:

Themodemscanbeinstalledasastringorcounterrotatingfaulttolerant

rings.TheswitchselectablefeatureallowseachmodemtobesetasaMas-

terPrimary,MasterSecondaryoraSlave.TheMasterPrimaryandMaster

Secondary modems are connected to the PC by an RS-232 or RS-485

cableandprovideredundancyifMasterPrimaryortheopticalringisbro-

ken.

APPLICATIONS:

DataMultidropSelf-Healing

OpticalRingModem

SERIES2300M

CardAccessControl

SecurityTelemetrySystems

SCADA System

ComputerNetworks

ProcessControlSystems

ITS

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

DATA

DATA

DATA

DATA

DATA

DATA

DATA

DATA