Merlin HSGC User manual

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 1

Merlin HSGC

OGS HOMESAFE GAS CONTROL

INSTALLATION & OPERATION INSTRUCTIONS

Please read these instructions carefully and retain for future use.

These instructions can be downloaded in electronic form on the product website.

oceaniagassafety.com

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 2

Contents

Important Warning Statements .............................. 3

Installation ...................................................... 4

Typical Application & Location ...........................................4

Mounting & Cabling ............................................................4

Circuit Board Terminals ......................................................5

Wiring –Power ...................................................................6

Wiring –Gas Valve..............................................................6

Wiring –Pressure sensor ...................................................6

Wiring –Devices.................................................................6

Basic Operation ................................................ 7

Basic Maintenance............................................. 8

Specification .................................................... 8

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 3

Important Warning Statements

Where this symbol is used, the manual must be consulted to understand the nature of any

potential hazards and how to avoid them.

Before any installation, use or maintenance read this manual carefully.

The information contained within this manual should be referenced for typical installation and operation only.

For site specific requirements that may deviate from the information in this guide –contact your supplier.

If the equipment is used in a manner not specified by the manufacturer, the safety and protection provided by the

equipment may be impaired.

Installation must be in accordance with recognised standards in the country concerned.

When metal conduit is used provision shall be provided by the installer for bonding in accordance with the NFPA70.

This product is designed for indoor operation only unless used in conjunction with a weatherproof cover.

Cables must be protected against mechanical damage.

The internal fuse should be replaced only with the same type. Anti-surge fuse 3.15A 250Vac 5x20.

This product is not designed to detect smoke, fire or other gases and should NOT be used as such.

This device requires a continual supply of electrical power –it will not work without power.

A switch or circuit breaker must be fitted, it must be accessible and marked as the disconnecting device!

This device should not be used to substitute proper installation, use and / or maintenance of fuel burning appliances

including appropriate ventilation and exhaust systems.

Seek fresh air supply and contact your local gas emergency service should you suspect a gas leak.

This device may not fully safeguard individuals with specific medical conditions. If in doubt, consult a doctor /

physician.

Any parts that form part of the connections/installation must have a minimum fire-retardant rating of UL 94V-2!

Your product should reach you in perfect condition, if you suspect it is damaged, contact your supplier.

Manufacturer’s Warranty Statement

Warranty coverage: The manufacturer warrants to the original consumer purchaser, that this product will be free of defects in

material and workmanship for a period of twelve months (1 year) from date of purchase.

The manufacturer’s liability hereunder is limited to replacement of the product with repaired product at the discretion of the

manufacturer. This warranty is void if the product has been damaged by accident, unreasonable use, neglect, tampering or other

causes not arising from defects in material or workmanship. This warranty extends to the original consumer purchaser of the

product only.

Warranty disclaimers:Any implied warranties arising out of this sale, including but not limited to the implied warranties of

description, merchantability and intended operational purpose, are limited in duration to the above warranty period. In no event

shall the manufacturer be liable for loss of use of this product or for any indirect, special, incidental, or consequential damages, or

costs, or expenses incurred by the consumer or any other user of this product, whether due to a breach of contract, negligence,

strict liability in tort or otherwise. The manufacturer shall have no liability for any personal injury, property damage or any special,

incidental, contingent, or consequential damage of any kind resulting from gas leakage, fire, or explosion. This warranty does not

affect your statutory rights.

Warranty Performance: During the above warranty period, your product will be replaced with a comparable product if the defective

product is returned together with proof of purchase date. The replacement product will be in warranty for the remainder of the

original warranty period or for six months –whichever is the greatest.

Information on waste disposal for consumers of electrical & electronic equipment.

When this product reaches the end of its life it must be treated as Waste Electrical & Electronics Equipment

(WEEE). WEEE marked products must not be mixed with general household waste, but kept separate for the

treatment, recovery and recycling of the materials used. Please contact your supplier or local authority for

details of recycling schemes in your area.

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 4

Installation

Typical Application & Location

Installation must be in accordance with recognised standards in the country concerned.

The HOMESAFE Gas Control (HSGC), is designed to isolate the gas supply to the property if gas leak or

dangerously low gas pressure has been detected or the smoke alarm or building fire panel is activated.

The controller can be easily manually reset once gas supply, smoke or fire alarm is back to normal status.

Mounting & Cabling

If mounting direct to wall - ensure the wall surface is flat to prevent base distortion!

Where suitable cable glands/conduits are used for wire entry, use 20mm (3/4 inch) separated by at least 20mm!

Fill any holes drilled to maintain integrity of the equipment!

Any parts that form part of the connections/installation must have a minimum fire-retardant rating of UL 94V-2!

Restrain the hazardous live wiring from accidental loosening to prevent wires from moving after installation and

touching parts of opposite polarity or at low voltages!

A switch or circuit breaker must be fitted, it must be accessible and marked as the disconnecting device!

Isolate the equipment from all hazardous live power sources before opening the cover!

1. Carefully remove the front cover from the unit by using an M3 socket wrench.

2. Using the rear base - mark mounting holes to the wall or align with an appropriate gang/pattress box.

3. Fixing straight to wall –drill 0.2” (5mm) hole, insert plugs and use the four screws (No.4 Pozi) provided.

Alternatively –Fix direct to a vertical 2-gang/double electrical pattress box.

4. There are pre-fractured areas for cable entry on the rear of the base and pilot holes positioned on the top

and bottom of the enclosure suitable for entry points up to ¾” (20mm). Drill out as necessary ensuring all

swarf is removed from the box and holes have smooth edges.

5. Secure the front cover with all M4 bolts and insert security caps provided.

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 5

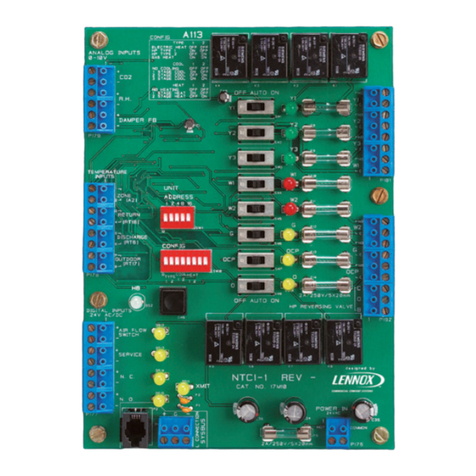

Circuit Board Terminals

Damage to PCBs when creating cable entry points may void any warranty!

Take care when making connections to high voltage connectors!

Any damage attempting to remove the circuit board may void any warranty!

All Class 2 wiring is to be installed within flexible tubing to maintain segregation between circuits!

Wiring of different circuits shall be separated by means of routing, clamping or barrier!

A switch or circuit breaker must be fitted, it must be accessible and marked as the disconnecting device!

For field connections use wires suitable for at least 167°F (75°C)

Any parts that form part of the connections/installation must have a minimum fire-retardant rating of UL 94V-2!

Terminals are pluggable for ease of wiring and therefore subject to misplacement resulting in a hazardous condition!

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 6

Wiring –Power

Supply 100-240V~ Wired to the [POWER/LINE IN] terminal using a 3A switched fused spur.

Wiring –Gas Valve

Use earth terminals for gas valves not considered class II apparatus!

Connecting two valves to both mains 240V~ and 24V~ simultaneously is considered misuse!

A gas solenoid valve should be powered using one of the terminals marked [VALVE OUT].

Terminals offer control via 100-240VAC. When wired to a normally closed gas solenoid valve, the

controller can be used to isolate the gas supply either by; pressing the Off button or if a smoke detector or

fire panel is in an alarm condition or gas supply pressure is below 0.5kpa (5mBar) >10 seconds.

Wiring –Pressure sensor

Screw the pressure sensor into the downstream port of your gas solenoid valve.

Pressure sensor (optional) is wired to the [PRESSURE SENSOR] connector as pictured and screwed into

the downstream port of the gas solenoid valve. The sensor will check integrity of gas pipework and will

monitor the gas supply pressure. If pressure proving is not needed, the DIP switch on the circuit board

marked [PROVE DISABLE] must be turned ON to disable this feature.

Turn switch ON to disable gas proving and use of

the pressure sensor - if not required.

It is factory set as: OFF (Enabled)

Screw the sensor into the valve downstream port.

Wiring –Devices

Cable lengths wired to this volt free contact will depend on cable condition and thickness.

The HSGC can be connected to devices with an open/close circuit via the [FIRE/SMOKE] volt free terminal.

This terminal has a factory fitted link installed (normally closed circuit) and when open will shut off the gas

supply via the solenoid valve.

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 7

Basic Operation

Isolate the equipment from all hazardous live power sources before opening the cover!

When power is supplied to the controller, the LED on the logo will illuminate Red. To turn the equipment

off, disconnect electrical power supply.

Controller Status LED

The LED changes colour when the controller enters five (5) different states as follows.

Gas On. Green LED remains illuminated when gas is being supplied/valve is open.

Testing. Green LED will flash when HSGC is checking integrity of gas pipework.

Test failed. Amber LED remains illuminated when gas proving test fails.

Pressure low. Amber LED will flash when gas supply pressure drops below 0.5kpa (5mBar).

Fire/Smoke Alarm. Illuminated when either a smoke detector or fire panel is in alarm condition.

The gas is shut off until the alarm condition has been investigated, rectified, and reset.

Press ON to reset the controller.

HOMESAFE GAS CONTROL INSTALLATION & OPERATION MANUAL

Rev 02 8

Basic Maintenance

Keep your gas controller in good working order - follow these basic principles.

✓Remove any dust/debris from the outer enclosure regularly using a slightly damp cloth.

✓Never use detergents or solvents to clean your device.

✓Never spray air fresheners, hair spray, paint or other aerosols near the device.

✓Never paint the device.

Specification

General

Model:

OGS HOMESAFE –HSGC

Size: (H x W x D)

5.95 x 4.37 x 1.97” (151 x 111 x 50mm)

Housing Material:

ABS PA765 (Flame Rating UL94 V-1)

Mounting:

Wall/Surface Mounted. Indoor use only –Outdoor using weatherproof cover.

Weight:

11.2 oz (0.32g) Approx

User Interface

Visual Indicators:

LED.

Audible Buzzer:

>60dB @ 3.28ft (1m). Quiet conditions.

Buttons:

Gas On / Gas Off

Language:

English

Power Supply

Power Consumption:

1.2W Max

Power Input:

100-240V~ 50-60Hz

Internal Fuse:

Anti-Surge 3.15A @ 250Vac

Equipment

Overvoltage Category:

II

Pollution Degree:

3 (Unit Only)

Environmental

Ingress Protection:

Not formally evaluated. IP4X Determined by inspection.

Operating:

-10 ~ 50°C / 14 ~ 122°F 20 ~ 95% RH (non-condensing)

Storage:

0 ~ 50°C / -13~122F° up to 95% RH (non-condensing)

Altitude Rating:

2000m

Wiring

Typical

Min. 18AWG / 75°C min / Tinned copper.

Compliance

Electrical Safety

CE / UKCA / IEC BS EN 61010-1

Electromagnetic Compatibility

EN 61326-1: 2013

Every effort is made to ensure the accuracy of this document; however, OGS can assume no responsibility for any errors or omissions in this

document or their consequences. OGS would greatly appreciate being informed of any errors or omissions that may be found in the content of

this document. For information not covered in this document, or if there is a requirement to send comments/corrections, please contact OGS

using the contact details.

Oceania Gas Safety

Head office:

Tuakau, Waikato New Zealand

Tel: +64212386990

Email: info@oceaniagassafety.com

Oceania Gas Safety is the owner of this document and reserves all rights of modification without prior notice.

Table of contents

Other Merlin Controllers manuals

Popular Controllers manuals by other brands

Comtrol

Comtrol RocketPort PCI Series Quick Installation Reference Card

Sealey

Sealey SGA4.V2 instructions

Anolis

Anolis ArcControl SU user manual

Drive.web

Drive.web smarty dw24 Series Installation & operation manual

EASTHOUSE

EASTHOUSE EM-1701A-C10 operating instructions

Sony

Sony DualSense CFI-ZCT1W instruction manual

Dectron

Dectron DRY-O-TRON Supervisaire DS 010 Operation manual

Springtree

Springtree SM-8 User manual and installation guide

Mitsubishi Electric

Mitsubishi Electric melsec-k instruction manual

Watlow

Watlow DIN-A-MITE Style B user manual

Megmeet

Megmeet MC200E Series Quick start user manual

Channel Vision

Channel Vision P-0920 instructions