Merrow Class 70 User manual

INSTRUCTIONS

FOR

SETTING

UP

AND

OPERATING

CLASS

MERROW

MACHINES

r

INTRODUCTION

This

book

is

published

!or

the

guidance

of

those

persons

responsible

for

the

operation

and maintenance of

Merrow

Class

70

Butt-Seaming

Machines.

II

contains

diagrams

and

descriptive

information

concerning

the

most

common

adjustments

necessary

to

assure

maximum

production of

the

highest

quality.

For

individual

problems,

consult

your

nearest

Merrow

Distributor.

The

Merrow

Class

70

Machines

are

designed and

constructed

for

continuous and

per-

fect

operation

at

high

speed

.

The

utility

and

durability

of

Class

70

Machines

are

recog-

nized

features

or

their

design.

Automatic

lubrication,

light, Crcely moving

parts,

and

easily

adjusted

assemblies,

reduce

to a minimum

the

maintenance

required

to

obtain

superb

performance.

Class

70

Machines

overseam

and

trim

simultaneously

and

produce

either

a

one-

thread

or

two-thread

stitch

formation.

By

cutter

adjustments,

the

seam

configuration may

be a

true

butt

seam,

a

gap

seam

or

an

overlap

seam,

while

maintain

ing

the

thinness

necessary

for

a good

fabric

processing

joint.

We

also

make

other

classes

of

machines

including

Class

"MG"

Overstitching

Machines,

Plain

Crochet Machines,

and

Shell

Stitch

Crochet

Machines.

These

machines

are

being used

successfully by

manufacturers

throughout

the

world.

THE

MERROW

a

MACHINE

COMPANY

240

Day St., Newington,

CT

06111

Telephone {860) 666-0109

Fax (860) 666-TT30

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

____

____________

_

HOW

TO

ORDER

Send

parts

order to

your

nearest

Merrow Distributor

or

The

Merrow

Machine

Company,

Newington,

CT

06111, U.S.A.

When

ordering

replacement

parts,

include

the

Style

of

the

machine,

the

Name

of the

part

(see

diagrams

included), and the

letters

and

numbersstamped

on the

part.

(The

stamping

on

a

particular

part

is

insufficient

information

without giving

the

name

of

the

part.)

All

enameled

parts

will be

furnished

in

grey

.

If

difficulty

is

experienced

in

selecting

the

proper

part

number

desired,

we

expect

to

be

able

to

make

proper

selection

from

our

records

if

given

the following

information:

(

1)

The

Name

of

Part

(2)

The

Style

and

Serial

Number

of

Machine

(3)

Special

information

if included below:

(a) Needle Pl

ates

-

specify:

Machine

Style (70-D3B, 70-Y3B,

etc

.). Machine mounting,

(table,

railway,

rotary

stand,

and

the

manufacturer

of

such

mounting).

Type

of

seam

(butt,

gap,

overlap,

etc.),

size

of

needle

used,

(number

of

needle

plate

is

stamped

on

under-

side

of

plate).

(b)

Loopers

-

specify:

upper

or

lower,

one

or

two

thread

stitch.

(Number

of

looper

is

stamped

on

the

shank

near

the

butt

end.)

(c)

Parts

for

Feeding

Mechanism

-

specify:

front

or

rear

feed

if

machi

ne

has

differential

(gathering)

feed

.

When

ordering

replacement

parts

for

chemical

nickel

plated

machines

(styles

70-lD-2

CNP,

and

70-D3B

CNP) follow the

procedure

stated

above,

specifying

on

the

order,

parts

for

chemical

nickel

pl

ated

machine,

or

write

the

letter

"N"

after

the

part

number.

(Example,

Feed

Dog A-81-1!:'J

MERROW

MACHINES

ARI

DISTR

I

IUTID

IY

2

OTHER

MlRROW

MACHINES

• CLASS

MG

OVERSTITCHI

NG

MACHINES

• PLAIN CROCHET MACHINES

• BLANKET HEMMING MACHINES

•

SHELL

STITCH

CROCHET

MACHINES

Oesc,,p11ve

111erature

and

samples

of

st11ches

produced will be

prov1d&d

on request

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

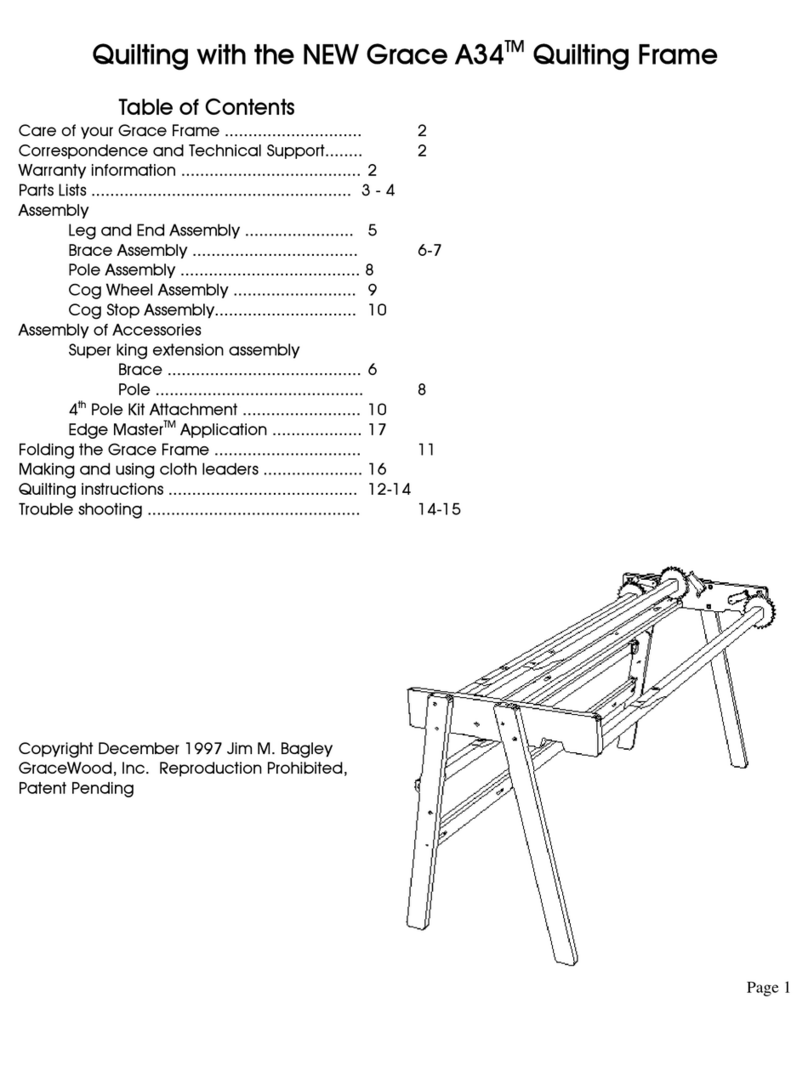

Screw 13

~

Plunger A-198-1

Screw 6

Presser

Bor

----

P.B.

Cotch

P.8. Cotch

loc

k

P.F

. Spring

W.P. Stud M-324-1

Screw 10 ¼

Work Plote

W.P. Plunger M-198-3

W,P.P. Spring 27-42

CLASS

70

INSTRUCTION

BOOK

Heod

Cop

Screws

12)

36

~

11

I

'11

I I I

21

I

INCHES

Heod I I I I I I

1 2 3 4 5

MM

Screws

121

83 ¼

rScrews

14)

99 ¼

Fromc

Oust Shield

Screws

121

5

'I,

FRONT

VIEW

..

Hond Wheel

Gasket

1O,Ring) M-275-9

Hand Wheel

Guard

Screw 103 ¼

Wosher 4 ½,

Screw 4 ¼

Screw 7 ¼

3

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

______________

_ _ _

INSTRUCTIONS

FOR

SETTING

UP

AND

OPERATING

MERROW

CLASS

70

SETTING THE

MACHINE

1.

Upon

removing

the

machine

from

its

box,

observe

its

threading

carefully

and

compare

ii

with

the

threading

diagram

supplied

with

the

machine.

2.

Keep

this

threading

diagram

for

further

reference.

The

matter

of

threading

is

very

important

and

if

difficulty

arises,

the

threading

of the

machine

should

be

compared

with the

individual

threading

diagram

supplied.

Threading

is

simple

but

must

be

accurate.

3.

Secure

the

machine

to

the

table

with the

screw

and

boll

provided.

This

assembly

should

be

parallel

with the

center

line

of

the

motor

and in

such

a

position

that

when the

machine

is

set

on

the

assembly,

the

front

of the

machine

will

be

three

or

four

inches

back

from

the

front

of

the

table

with

Its

hand

wheel

to

the

right

of

the

operator

.

4.

Assemb

le

thread

stand

and

screw

its

base

to

the

table

in

back

of

the

machine.

5.

The

thread

guides

at

the top of

the

thread

stand

should

be

directly

over

the

center

of the

cones

of

thread.

6.

The

thread

should

be wound on

cones

which

should

stand

vertically.

The

thread

from

the

cone

should

lead

to

the top of

the

thread

stand,

through

the

eye

on the

cross

rod

and

over

the

other

leg

of

the

U

shaped

cross

rod.

7. Be

sure

the

thread

will

come

off the

cones

readily

, with

uniform

tension

and

that

it

cannot

catch

under

the

cone

or

be

otherwise

retarded.

8.

Since

oil

has

been

drained

from

the

machines

before

shipping,

the

main

reservoir

must

be

filled

before

the

machine

is

used.

(Note

section

14.)

SPEEDS

The

Styles 70-D3B-2

and

70-Y3B-2

have

a recommended speed

of

2250

stitches

per

minute.

Styles

70-O3B

and

70-Y3B are designed to

run

at

1500-1800

stitches

per

minute, Merrow Styles 70-ABB,

70-AON-l

and

70-ABBY

are

designed to

run

2800-3000

stitches

per

minute.

Style

70-1D-2isdesigned

to

run

4000

stitches

per

minute. While

these

machines

may

run

well

with

littlecare,

they

will

give

better

results with

suitable

attention.

MOTOR

DRIVE

UNIT

9.

To

obtain

full

efficiency,

the

motor

drive

equipment

must

be

kept

in

good

operating

con-

dition

in

order

to

start

and

stop

the

machine

with

minimum

delay.

When

laying

out

the

motor

drive

equipment,

attempt

should

be

made

to

avoid

driving

from

a

large

pulley

to

a

re

l

atively

smaller

pulley, the

centers

of

which

are

close

together,

as

such

an

arrangement

will

allow

excessive

slippage

of the

belts,

materially

reducing

the

speed

of

the

start

and

stop

of

the

Merrow

Machine.

10. A

V-Belt

Hand

Wheel with an

effective

{pitch)

diameter

of

3-1/3"

{85

mm)

is

supplied

with

70-O3B

and

Y3B Models. On 70-ABB

and

ABBY

machines

the

effective

(pitch)

diameter

is

2-1/8"

(54

mm)

. If

an

individual

motor

is

used,

the

machine

may

be

run

with a

3/8"

(9. 5 mm)

width

endless

V-Belt.

Where

round

belting

is

used,

either

1/4"

(6. 5 mm)

or

5/16"

(8 mm)

round

belting

may

be

used.

11. The top of the Hand Wheel

of

all

Class

70

machines

must

tu

r n away

from

the

operator

.

12.

Consult

your

nearest

Merrow

Distr

ib

utor

to

assure

proper

motor

dr

ive

equipment.

4

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

CLASS

70

INSTRUCTION

BOOK

LUBRICATION

13. GENERAL:

In

the

lubricati

on of the

machine

the

oil

is

metered,

feeding

oil

in

proper

amounts

to

all

bearing

surfaces.

It

is

a one-way oiling action and when the

reservoir

supply

is

used,

the machine

must

be

refilled.

The

reservoir

holds enough

for

forty

hours

of

seaming

.

14. Oil is

fill

ed through a hole

under

the

Cap

Screw

of the Oil

Filler

Assembly

into

the

main

reservoir.

About

8

ounces

(0. 250

litres)

of

a high

grade

turbine

oil

of

about

150 Sayboldt

seconds

at

100°

Fahrenheit

(37. 5°C) is

recommended.

To

drain

the

oil,

dismount

the

machine

and extend

the

feed

mechanism

end

of

the

machine

over

the

end of the table.

After

providing a

means

of

catching

the

oil,

unscrew

the

Oil

Drain

Screw

11-3/ 8 (located

at

the

rear

of

the

machine in the base)

several

turns.

F C. Oil

Tub

e

M-95-,

Au

•y.•A

Upper Shafi

A5:1,y

Goskc1

CO

-Ri

ng)

M275-11 "

~

Oil

Meter-...___

'

,.;:)

"=!J

M 35

0,(

A

lo

El

~

~

F.C

Oa

M••••

Ho

l

dc,

(i

~

Screw 6 ~

-----..

.z I

I

Scr

ow

!i

½r

---...._.

:

= I

,,

I

_,,--:

t

, I

I

I

I

I

r t

I

~

~

,,. Oil

Flhe,/

M,

332

,2

,I

Pump

Pl1,1nger

M,198,2

O.P,

P.

Spring

27

,

.CO

O,P

.P Screw Godcet

M-275-5

0 .

P,P

,

Sc1ow

8

¾.

Oil

Meter M-350

..(

Ato El

~

Gosket

(O-R

i

ngl

-M-275•

11

U.S. O

il

Me,e,

Holder

M,137,5

Goskel (O,Ring)

M,275-17

Filler

Any

. M-329-Au'y,-1

Uppor

Shoft Oil Collecto, M,137,3

I

I I I II I

ltiCHES I I

2 3

MM

I

A I

s

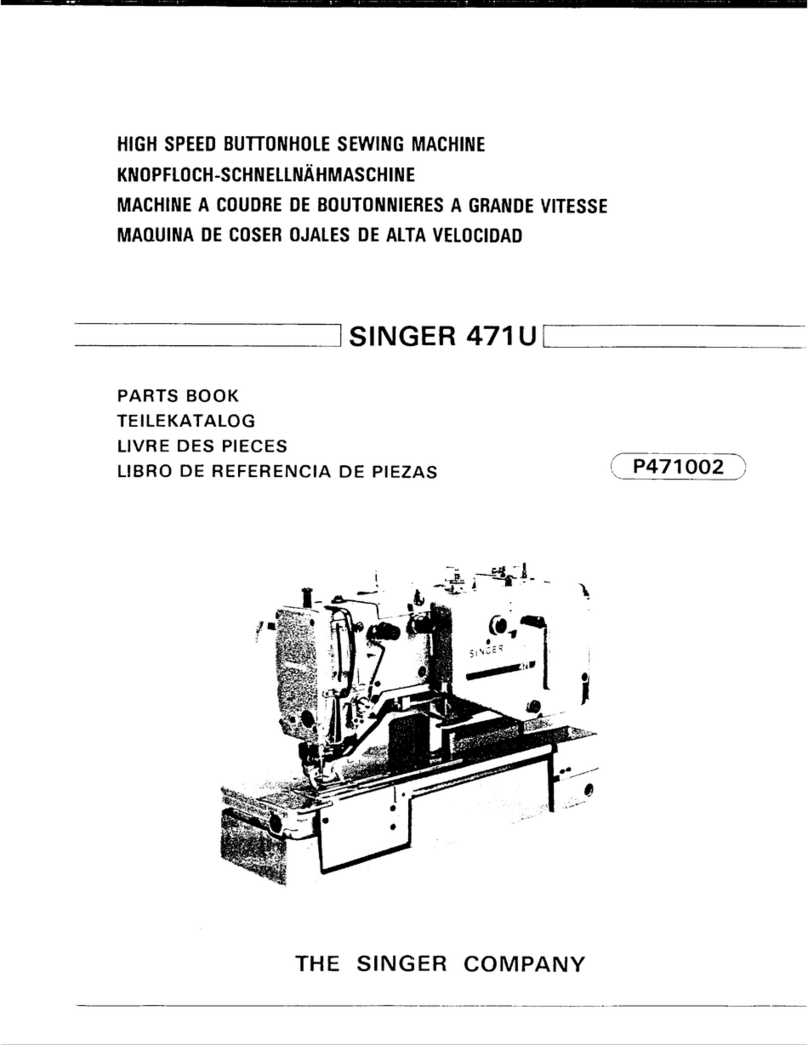

FRAME CAP

AND

UPPER SHAFT

OILING

PARTS 5

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

________________

_

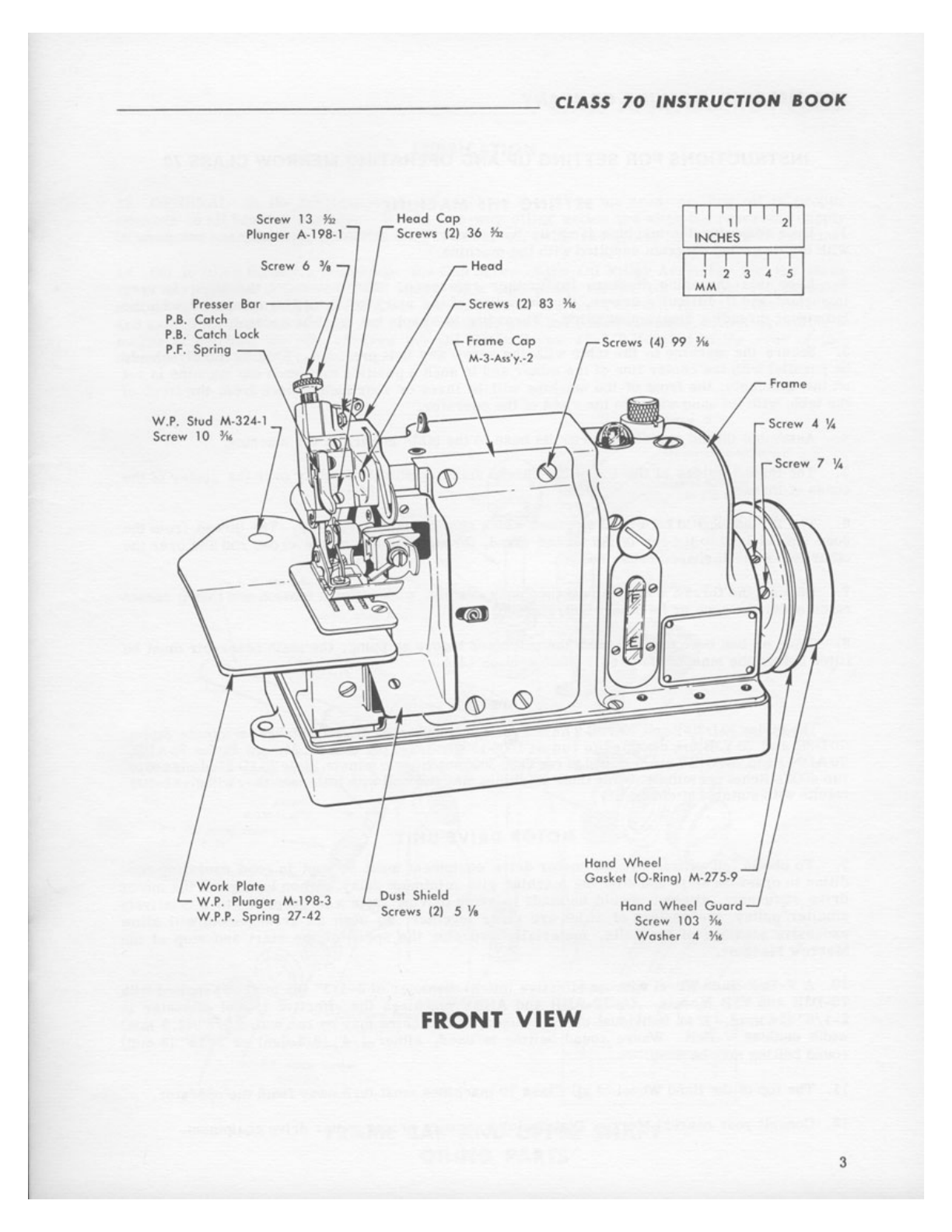

15.

The

oil

coming

up

from

the

reservoir

is

filtered

by a

bronze

screw-type

filter

located

in

the

frame

above

the

Oil

Reservoir

Plate.

16.

The

Upper Shaft

Pump

provides

a continuous

oil

flow

to

assure

proper

lubrication

without

the

use

of

wicks.

The

Pump

is

operated

from

an

eccentric

groove

in

the

main

Upper

Shafi.

The

Upper Shafi

Pump

draws

oil

from

the

main

reservoir

and

forces

ii through

the

Oil

Bubbler

Pipe

to

the

Oil

Bubbler

Pipe

Cap.

Some

oil

is

bypassed

from

the

Oil

Bubbler

Pipe

to

the

F. C.

Oil

Meter

Holder

and

to

the

Upper

Shaft

Oil

Meter

Holder.

17. FRAME CAP LUBRICATION:

F.C

.

Oil

Feeder

Tube

supplies

oil

to

the

upper

and

lower

looper

carrier

assemblies

and

the

cam

roll

bearings.

The

oil

flows

to

the

F.C.

Oil

Feeder

Tube

through

an

oil

meter

which

is

enclosed

in

the

F.

C.

Oil

Meter

Holder.

The

F . C.

Oil

Meter

Holder

is

located

in

the

frame

beside

the U.S.

Oil

Pump

Screw.

18.

UPPER

SHAFT LUBRICATION:

The

oil

bypassed

through

the

Oil

Bubbler

Pipe

fills

up the

Upper

Shafi

Oil

Meter

Holder

cavity

and

a

limited

amount

flows

through

an

oil

meter

in

the

Holder.

The

oil

drops

into

the

Upper

Shaft

Oil

Collector

and

is

fed

past

the

Oil

Distributor

Rod

located

in

the

Upper

Shaft.

This

action

distributes

the

oil

to

the

bearing

surfaces

of

the

main

shafts

on

the

left

end

of

the

machine,

the

Needle

Carrier

Assembly,

the

Upper

Cutter

Carrier

Assembly,

and

the

Feed

Mechanism.

19. Some of

the

oil

not fed into the

Oil

Bubbler

Pipe

is

forced

along

the

outside

of the

Upper

Shaft,

to

the

face

of the

Upper

Cam

Boss

.

20. LOWER SHAFT LUBRICATION:

The

Lower

Shaft

is

lubricated

by

oil

flowing into

the

Lower

Shaft

Oil

Meter

Holder

through

an

oil

meter

to

the

Lower

Shaft.

This

Meter

Holder

is

located

in the

frame

between

the

right

Upper

and

Lower

Shaft

Holes.

(Note Section 73,

line

i.)

Oil

METERS

21.

There

are

four

grades

available

for

various

rates

of

oil

flow.

22.

Oil

Meters

in

the

machine

are

selected

at

the

factory

to

provide

proper

lubrication

for

normal

machine

uses.

23. If

the

machine

is

to

be

used

in

wet

locations

or

wet

cloth

is

to

be

sewn,

then

the

F.

C.

Oil

Meter

and

U.S.

Oil

Meter

should

be

changed

to

grade

"A"

(coarse)

.

24.

The

following

precautions

are

recommended:

6

a.

Never

allow

the

oil

level

to

go

below

the

empty

"E"

line

on

the

Oil

Gage.

b.

Occasionally

clean

the

lint

around

the

Feed

Dogs

and

from

behind

the Dust

Shield

(do

not

use

compressed

air}

.

c .

Clean

screen

on

the

Oil

Filler

Assembly

if

filling

the

machine

becomes

difficult.

1.

To

clean

the

screen,

unscrew

this

assembly

from

the

machine

and

clean

with

compressed

air

or

a

solvent.

d.

The

Inlet

Oil

Filter

is

located

inside

the

main

reservoir.

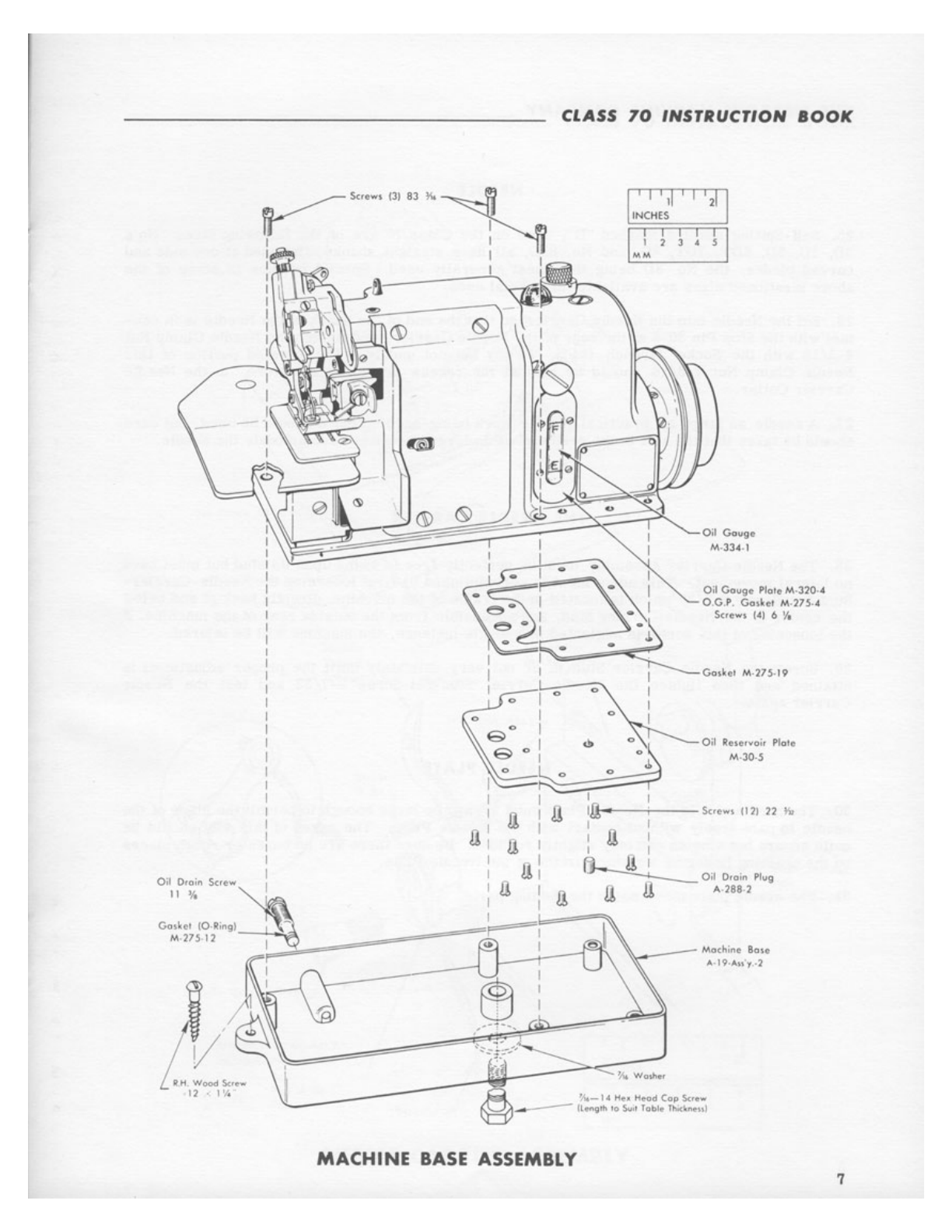

This

may

be

replaced

by

removing

the

Oil

Reservoir

Plate

and

unscrewing

the

filter.

It

may

be

cleaned

by

soaking

in

solvent

and

blowing

through

ii

with

compressed

air

from

the

inside

out.

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

CLASS

70

INSTRUCTION

8OOK

~Sc,ew,

131

83

II.~

I

I

(S) I

I

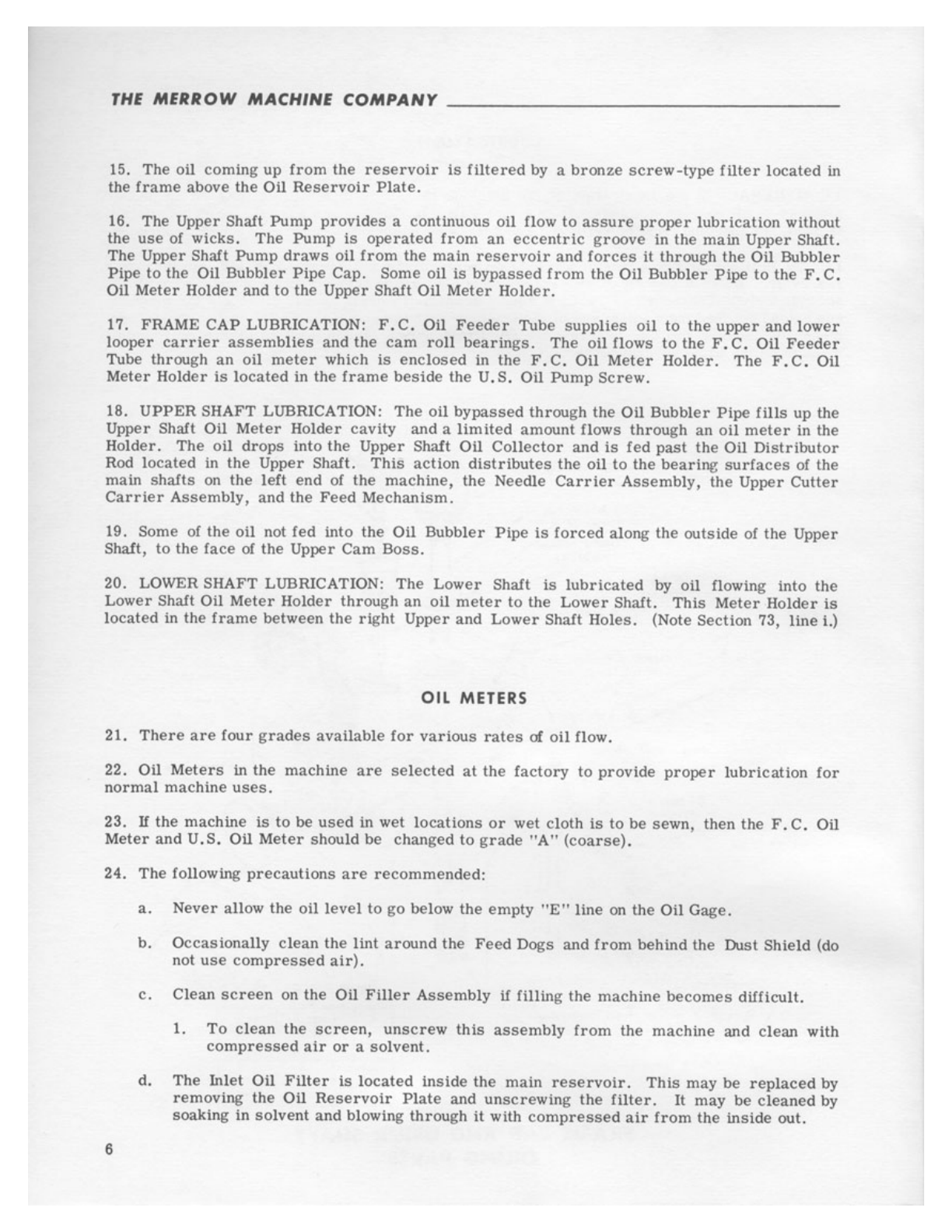

MACHINE

BASE

ASSEMBLY

0

0

1

1 J I II J I

2!

I

INCHE;

.

11 I I I I

M~

1 J 4 S

Oil

Gouge

M·33.t 1

Oil Gouge, Plate M-

320

4

0 .G P

Goi\e1

M ?75.

.,t

Screw, (4) 6 ¼

Oil

Retervo

ir Pfolc

M-30-S

7

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

________________

_

NEED

LE

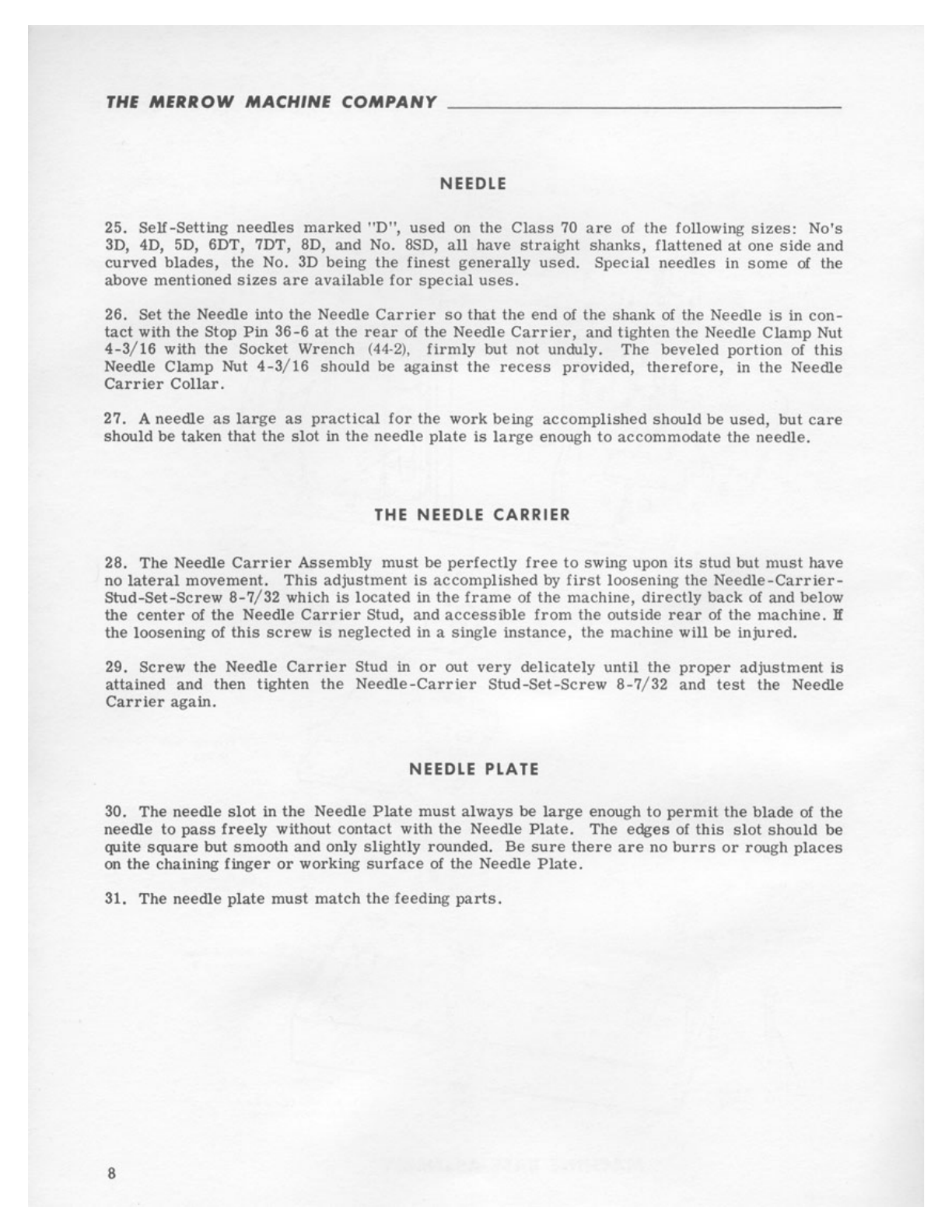

25. Self-Setting

needles

marked

"D",

used

on

the

Class

70

are

of

the

following

sizes:

No's

3D,

4D, 5D, 6DT, 7DT, 8D, and No. 8SD,

all

have

straight

shanks,

flattened

at

one

side

and

curved

blades,

the

No.

3D

being

lhe

finest

generally

used.

Special

needles

in

some

of

the

above mentioned

sizes

are

available

for

special

uses.

26. Set

the

Needle into

the

Needle

Carrier

so

that

the

end

of

the

shank

of the Needle

is

in

con-

tact

with

the

Stop

Pin

36-6

at

the

rear

of

the

Needle

Carrier,

and tighten

the

Needle

Clamp

Nut

4-3/16

with

the

Socket Wrench

(44-2),

firmly

but

not

unduly.

The

beveled

portion

of

this

Needle

Clamp

Nut

4-3/16

should be

against

the

recess

provided,

therefore,

in

the

Needle

Carrier

Collar.

27. A

needle

as

large

as

practical

for

the

work

being

accomplished

should

be

used,

but

care

should

be

taken

that

the

slot

in

the

needle

plate

is

large

enough

to

accommodate

the

needle.

THE NEEDLE CARRIER

28.

The

Needle

Carrier

Assembly

must

be

perfectly

free

lo

swing upon

its

stud

but

must

have

no

latera

l movement.

This

adjustment

is

accomplished

by

first

loosening

the

Needl

e-Carrier-

Stud-Set-

Screw

8-7/32

which

is

located

in

the

frame

of

the

machine,

directly

back

of and below

the

center

of

the

Needle

Carrier

Stud, and

accessible

from

the

outside

rear

of

the

machine

. If

the

loosening of

this

screw

is

neglected

in

a

single

instance,

the

machine

will

be

injured.

29.

Screw

the

Needle

Carrier

Stud in

or

out

very

delicately

until

the

proper

adjustment

is

attained and

then

tighten

the

Needle-Carrier

Stud-

Set-Screw

8-7

/32 and

test

the

Needle

Carrier

again.

NEEDLE PLATE

30.

The

needle

slot

in the

Needle

Pl

ate

must

always

be

large

enough

to

permit

the

blade

of

the

n

eedle

to

pass

freely

without

contact

with

the

Needle

Plate

.

The

edges

of

this

slot

should

be

quite

square

but

smooth

and

only

slightly

rounded.

Be

sure

there

are

no

burrs

or

rough pl

aces

on

the

chaining

finger

or

working

surface

of the Needle

Plate.

31. The

needle

plate

must

match

the

feeding

parts.

8

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Wor

k Plote

Support

Screws

t2)

52

¾6

Needle

Thread

'\.

Ta

keup

'\.

Set Screw 12

½l

N.C. link Ass

'y

,

Screw j

--

1

~

1 -- -

t

--

- -

--

.

--

-

--

--

Need

le

Cor,icr

Stud

~

Needle

Conier

A.ss'y,

includes: N.C.

Collar

Bolt

N

ut

4 ¼

Pin

•..•

CLASS

70

INSTRUCTION

BOOK

.

--·

Com Timing

Screw

St0toge

\J

Hole

..

;1

Screw

3-#8

lii''

' ' '

I I

,I

'2'

I

NC

H

ES

I I I

2 3 4 5

MM

NEEDLE

CARRIER ASSEMBLY 9

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

________________

_

LOO

P

ER

S

ETTING

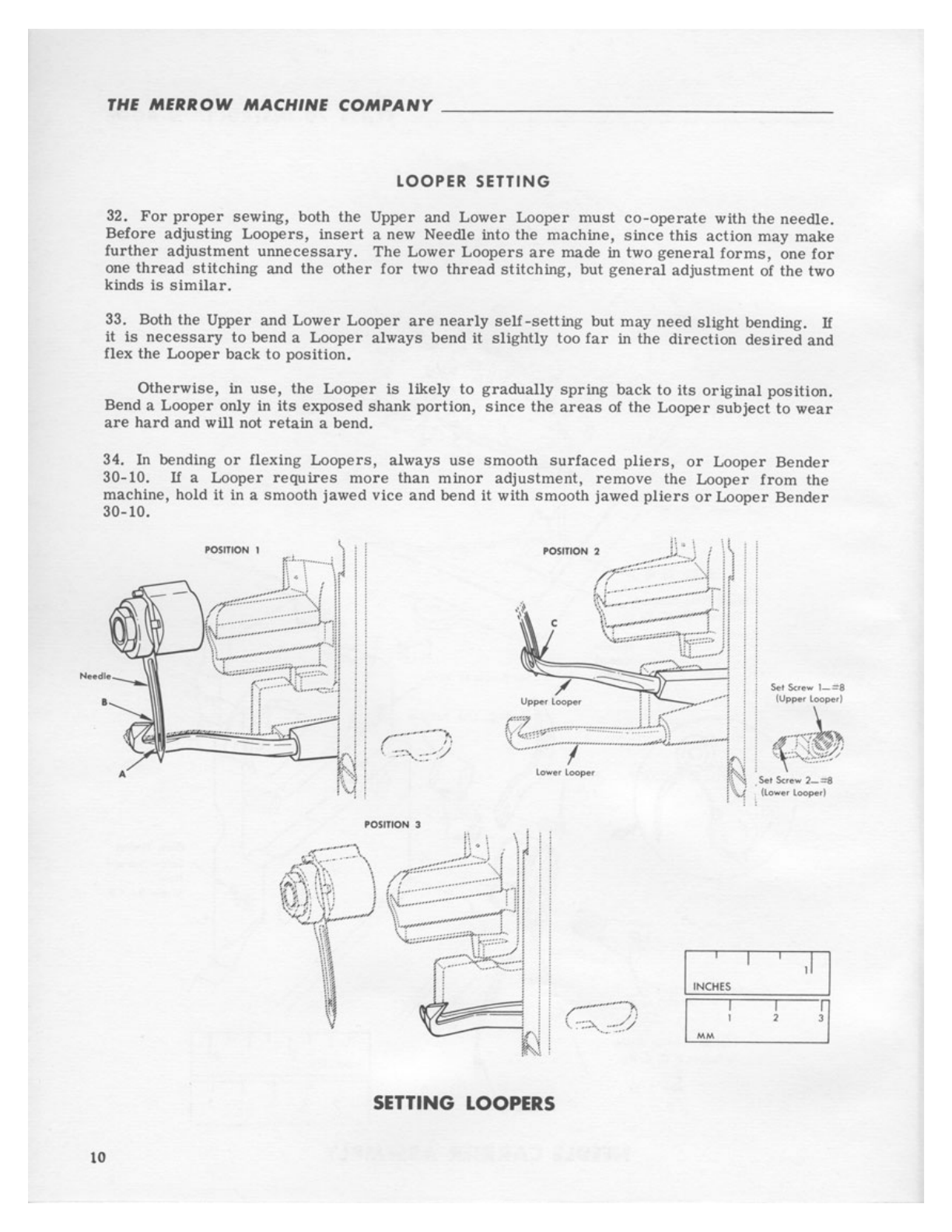

32.

For

proper

sewing, both

the

Upper and Lower

Looper

must

co-operate

with

the

needle.

Before adjusting

Loopers,

insert

a new Needle into

the

machine,

since

this

action

may make

further

adjustment

unnecessary.

The

Lower

Loopers

are

made in two

general

forms,

one

for

one

thread

stitching

and the

other

for

two

thread

stitching,

but

genera

l

adjustment

of the two

kinds

is

similar.

33. Both

the

Upper and Lower

Looper

are

nearly

self-setting

but may need

slight

bending. If

it

is

necessary

to

bend a Looper always bend

it

slightly

too

far

in

the

direction

desired

and

flex

the

Looper

back

to

position.

Otherwise,

in

use,

the

Looper

is likely

to

gradually

spring

back

to

its

original

position.

Bend a Looper only in

its

exposed

shank

portion,

since

the

areas

of

the

Looper

subject

to

wear

are

hard

and

will

not

retain

a bend.

34.

In

bending

or

ilexing

Loopers,

always

use

smooth

surfaced

pliers,

or

Looper

Bender

30-10. If a Looper

requires

more

than

minor

adjustment,

remove

the Looper

from

the

machine, hold it in a

smooth

jawed

vice

and bend it with

smooth

jawed

pliers

or

Looper

Bender

30-10.

I

IN

C~ES

,I

I

r-A

I I

~

-

/·

1 i

'

~

..

:··:

.

./

MM

SETTING LOOPERS

10

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

CLASS

70

INSTRUCTION

SOOK

35.

Steps

to

Setting

Loopers:

a.

Swing the

Presser

Foot

Assembly

out or

position

and

remove

the

Needle

Plate,

Lower

Looper

Thread

Tube,

Feed

Dogs,

and

Dust Shield

for

accessibility.

Remove both

Loopers

by

means

of

the

Set

Screws

provided.

b.

The

Lower Looper

is

best

set

and

adjusted

before

the

Upper

Looper

is

placed

in

the

machine

and

after

the

Needle

has

been

properly

set

in.

1.

First

loosen

the

Lower

Looper

Screw

which

is

accessible

through

the

hole

in

the

front

of

the

Frame

Cap. As

this

Screw

is

just

to

the

left

of

the

Upper

Looper

Screw,

be

sure

to

loosen

the

proper

screw.

36.

Insert

the

Lower

Looper

pushing

it

in

as

far

as

it will go, and

tighten

the

Set

Screw

against

the

flat

of

the

Looper.

37. Slowly

turn

the

Hand Wheel away

from

the

operator.

The

Needle on

its

downward

stroke

should gently

contact

the

shank

of

the

Lower

Looper

at

point

"A"

. When

properly

set,

the

point

or

the

Lower Looper

must

make

gentle

but

firm

contact

with

the

Needle

at

point

"B",

but

should not deflect

the

Needle. If

necessary,

bend

the

Looper.

38.

The

Upper

Looper

is

secured

to

the Upper

Looper

Carrier

by a

Screw

accessible

through

the

right

hand

end

of

the opening through

the

front

of

the

Frame

Cap

.

Insert

the Upper

Looper,

pushing

it

into

the

Upper

Looper

Carrier

as

far

as

it

will go, and tighten

the

Set

Screw

against

the

flat

on

the

Upper

Looper.

39. Slowly

turn

the Hand Wheel away

from

the

operator.

The

Upper

Looper

should not

strike

the Needle but

the

point of Needle

should

pass

close

to

the

back

side

of

the

Upper

Looper

at

point

"C"

.

To

effect

this

adjustment

the

Looper

can

be

sprung

up

or

down,

as

well

as

sidewise.

40.

Turn

the

Hand Wheel

until

the

throat

of

the

Upper

Looper

is

about

to

pass

the

left

end

of

the Lower

Looper

on

the

upstroke.

When

properly

adjusted,

the

throat

of

the

Upper

Looper

should

pass

just

clear

of

the

left

end

of

the

Lower

Looper

on

the

up and down

stroke

as

shown

in

illustration

position

#3.

41.

Finally,

turn

the Hand Wheel

completely

around

and

see

that

the

Loopers

and

Needle

are

properly

adjusted

to

each

other.

After

adjustment,

check

to

be

sure

the

Set

Screw

holding

each

Looper

is

properly

tightened.

THREADING

42.

To

thread

the

machine,

follow the

Threading

Diagram

provided

with

each

machine.

A

duplicate

may be obtained upon

request

provided

that

the

style

and

serial

number

of

the

ma-

chine

is included with

the

request.

The

matter

of

threading

is

important

and although

simple,

it

must

be

accurate.

43. When

threading

the

Looper

Threads,

it will

be

found convenient

to

use

a

threading

wire.

With

the

thread

or

yarn

inserted

in

the

eye

of

the

threading

wire,

pass

the

wire

through

the

thread

eyes

and

tension

discs

as

shown on

the

threading

diagram

.

To

place

the

Lower

Looper

in position

to

be

threaded,

turn

the

Hand Wheel

until

the Needle

is

in

its

highest

position.

Then, it

will

be

possible

to

pass

the

threading

wire

through both the

L.

L.

Thread

Tube

and

the

Lower

Looper

simultaneously.

44.

The

machine

is

ready

to

"chain"

after

threading

the

needle

or

needle

and

looper

as

shown

on

the

threading

diagram.

45.

It

is

generally

advisable

to

keep

tension

on

the

thread

as

light

as

necessary

to

produce

good

results.

11

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

Upper

Cutter

u.c.

Holder

Clamp~

U.C.

Holder Screw

U.C.

Holder Clomp

A-97-1

Upper Cutter

lower

Cutter Holder

6-6S-U

l.C. Holder Support Assembly

Includes, L.C.H. Clomp M-66,3

l.C.H.C. Screw

86

¼i,

l.C.H. Supporl Shim

U.C.

Clomp

INCHES

I I

2 3

MM

Threod Culler

6·121-A

.........

e·,·"

\

::----

·

f

i

i

:

:

~

..

j._.

;'/q

\,/

!

I

s

..

)~

~

~-

:

..

:;::::;:~::=-::::;:;.

--..:1..

....

:,.

~-~

~

:::

.:·1>~

;#'··

Thread Tube

Clomp

Screw

---~

Needle

Plate Screw 7

¾,

Needle

Plate

Thread Tube

Thread Tube Clomp

6,184-8

12

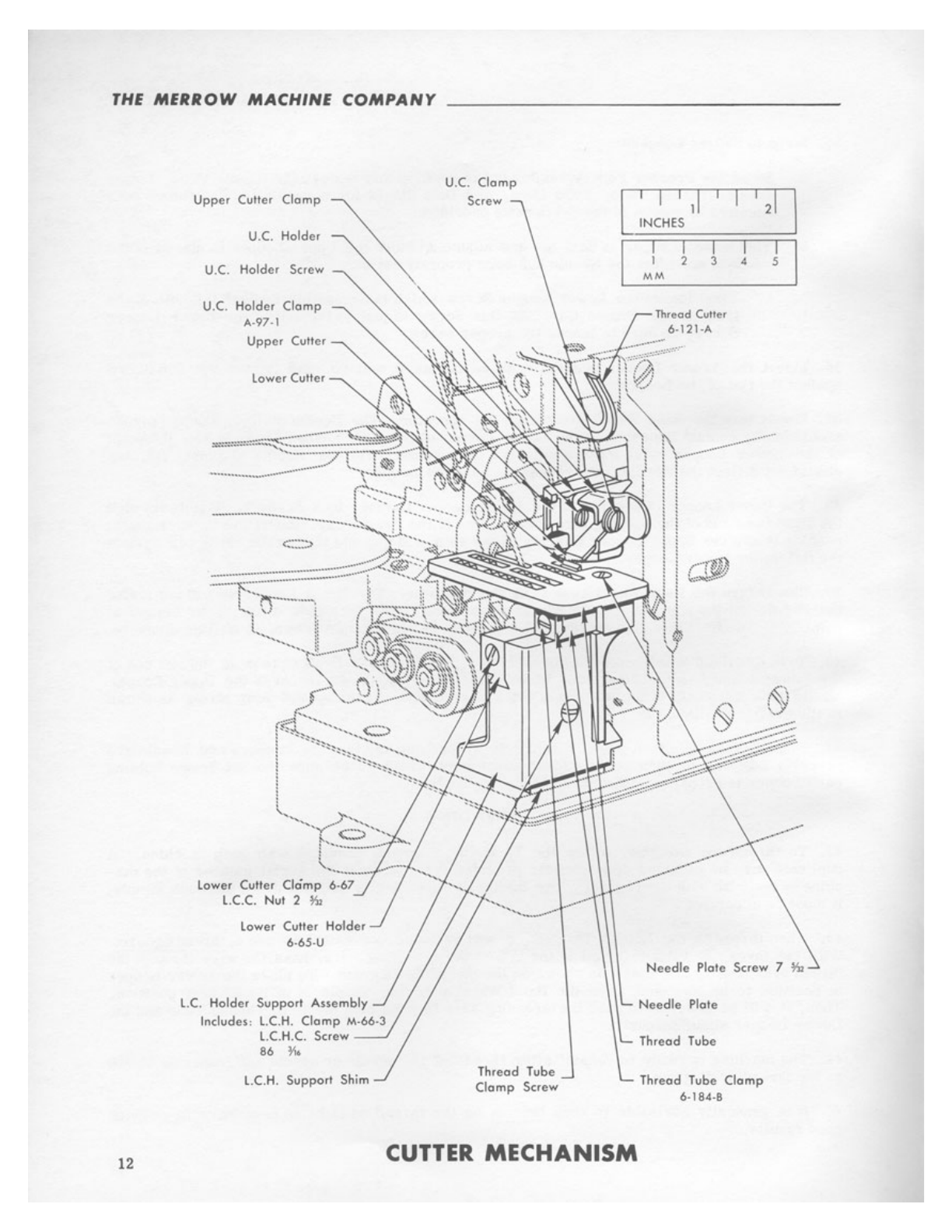

CUTTER

MECHANISM

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

CLASS

70

INSTRUCTION

BOOK

UPPER

AND

LOWER

CUTTER

46. GENERAL:

The

upper

and

lower

cutter

may be

adjusted

up and down

and

laterally

to

the

right

or

left.

47.

The

position of

cutters

determines

the

width of

the

fabric

within

the

seam

. When a

butt

seam

is

desired,

the cutting

surfaces

should

be

positioned

approximately

in

the middle

of

the

Needle

Flate

Chaining

Finger.

When a gap

seam

is

desired,

the

cutting

surfaces

shouldbe

positioned

as

for

a

butt

then

moved

to

the

left

about

1/2

the width of

the

gap

required.

Lap

seams

are

created

by

setting

the

cutting

surfaces

to

the

right

of

the

butt

seam

posit

ion.

The

position of the

cutters

will

vary

with

the

thickness

of

fabric

and

some

trial

settings

should be

made

to

determine

the

correct

position

for

each

weight

of

material.

Loosely

woven

materials

require

a

wider

setting

than light

fabrics.

48.

The

L.

C.

Holder

slides

in the L. C.

Holder

Support

Assembly

providing

lateral

movement

to

the

Lower

Cutter

. Do not allow the

Lower

Cutter

to

push too tightly

against

the

Upper

Cutter.

If

more

than a light

pressure

is

required,

it

usually

indicates

that

the

cutters

are

dull

and

should

be

sharpened.

ADJUSTMENT

49. Set

the

cutting

edge

of

the

Lower

Cutter

slightly

above the

upper

surface

of

the

Needle

Plate

by

means

of

the

L. C. C. Nut

2-5

/32.

Do

not

set

this

cutter

high enough

to

contact

the

lower

surface

of

the

Presser

Foot.

50.

Clamp

the L.

C.

Holder

to

the

width of

trimming

desired

by

Screw

86-3/16.

Turn

the

machine

over

by hand and

set

the

Upper

Cutter

so

that

in

its

lowest

position

its

cutting

edge

is

a

little

below

the

top

edge

of

the

Lower

Cutter.

This

adjustment

is

made

by

U. C.

Clamp

Screw

and

U.C.

Holder

Screw.

51. Loosen L. C. H.

C.

Screw

86-3

/

16

and

turn

the Machine

over

by hand.

The

downward

pro-

jection

at

the

rear

of

the Upper

Cutter

should

be in

contact

with

the

lower

Cutter

at

all

times.

52.

Press

the

L,

C.

Holder lightly

to

hold

the

cutters

together

and tighten the

L.

C.H.

C.

Screw

86-3/16

.

SHARPENING

THE

CUTTER

S

53.

The

Upper

and

Lower

Cutters

must

be

sharpened

in a

Cutter

Grinder, which

has

a

Jig

to hold

the

cutters

at

the

proper angle.

Those

customers who do

not

have

a Merrow

Cutter

Grinder

can

have

dull cutters

sharpened

by

sending

them to your distributor

or

to

the

Merrow Machine Company,

Newington, Connecticut 06111.

54. When using

the

Merrow

Cutter

Grinder,

be

sure

that

the

retaining

groove

for

the

cutter

is

perfectly

clean

before

inserting

the

cutter

and

clamping

the

cutter

into

the

cutter

holder.

The

cutter

should

be

carried

entirely

across

the

grinding

face

of

the

wheel,

to

prevent

the

wheel

from

becoming

worn

unevenly and

requiring

replacement

so

that

cutters

may

be

sharpened

properly.

55. Very

little

need

be

ground

off

the

cutters

. If

too

much is

ground

at

one

passage

across

the

face

of

the

wheel,

the

temper

of

the

cutter

will

be

drawn

and

its

cutting quality

greatly

im-

paired.

56.

The

cutter

should

not

be

discolored

by

grinding.

13

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

________________

_

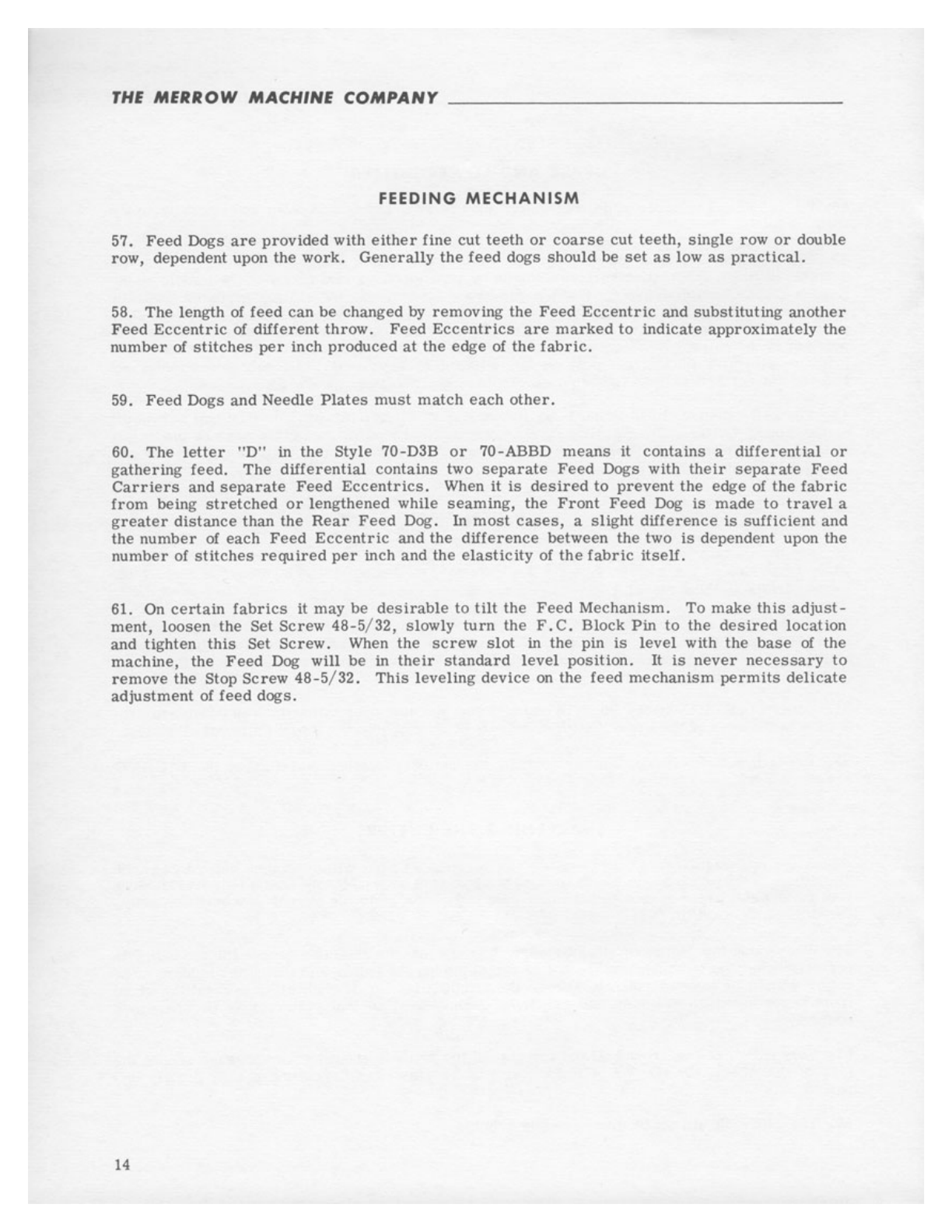

FEEDING

MECHANISM

57.

Feed

Dogs

are

provided

with

either

fine

cut

teeth

or

coarse

cut teeth, single row

or

double

row, dependent upon

the

work.

Generally

the

feed

dogs

should

be

set

as

low

as

practical.

58.

The

length of

feed

can be changed

by

removing

the

Feed

Eccentric

and

substituting

another

Feed

Eccentric

of

different

throw.

Feed

Eccentrics

are

marked

to

indicate

approximately

the

number

of

stitches

per

inch

produced

at

the

edge

of

the

fabric.

59.

Feed

Dogs and Needle

Plates

must

match

each

other.

60.

The

letter

"D" in

the

Style

70-D3B

or

70-ABBD

means

it

contains

a

differential

or

gathering

feed.

The

differential

contains two

separate

Feed

Dogs with

their

separate

Feed

Carriers

and

separate

Feed

Eccentrics.

When it

is

desired

to

prevent

the

edge of

the

fabric

from

being

stretched

or

lengthened while

seaming,

the

Front

Feed

Dog is made

to

travel

a

greater

distance

than the

Rear

Feed

Dog. In

most

cases,

a

slight

difference

is

sufficient

and

the

number

of

each

Feed

Eccentric

and

the

difference

between

the

two

is

dependent upon

the

number

of

stitches

required

per

inch and

th

e

elasticity

of

the

fabric

itself.

61. On

certain

fabrics

it

may

be

desirable

to

tilt

the

Feed

Mechanism

. To

make

this

adjust-

ment,

loosen

the

Set

Screw

48-5

/32, slowly

turn

the

F.C.

Block

Pin

to

the

desired

location

and tighten

this

Set

Screw.

When

the

screw

slot

in

the

pin

is

level

with

the

base

of

the

machine,

the

Feed

Dog

will

be

in

their

standard

level

position.

It

is

never

necessary

to

remove

the Stop

Screw

48-5

/32.

This

leveling

device

on the feed

mechanism

permits

delicate

adjustment

of

feed

dogs

.

14

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

CLASS

70

INSTRUCTION

BOOK

f("t-d

Conif'r

Spoc~r

6-313A

Feed

Come,

(R)

M-74-3

foodO~(RI\

~1--@iP--

',

NUT

-

2¾.

-----

-

~

--

f C l Bu\hing

UH

--

~-

--

M-79-J

-

f~cd

f«c-nlt,c

ffl

NUJ

7"'

\

feed

f«fflJ,o(

(RJ

M.'76

'1

l

Feed

Comer

l,...~

!RI

M-76-1

Sc.rcw

II

I>,

FEED

MECHANISM

(DIFFERENTIAL)

FCt.8otttn

6•77•A

feed

Dog

if)

I I I

INCHES

I

7

MM

,I

lowu

Shoh

I

,I

I

I I I I

l • 5

15

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

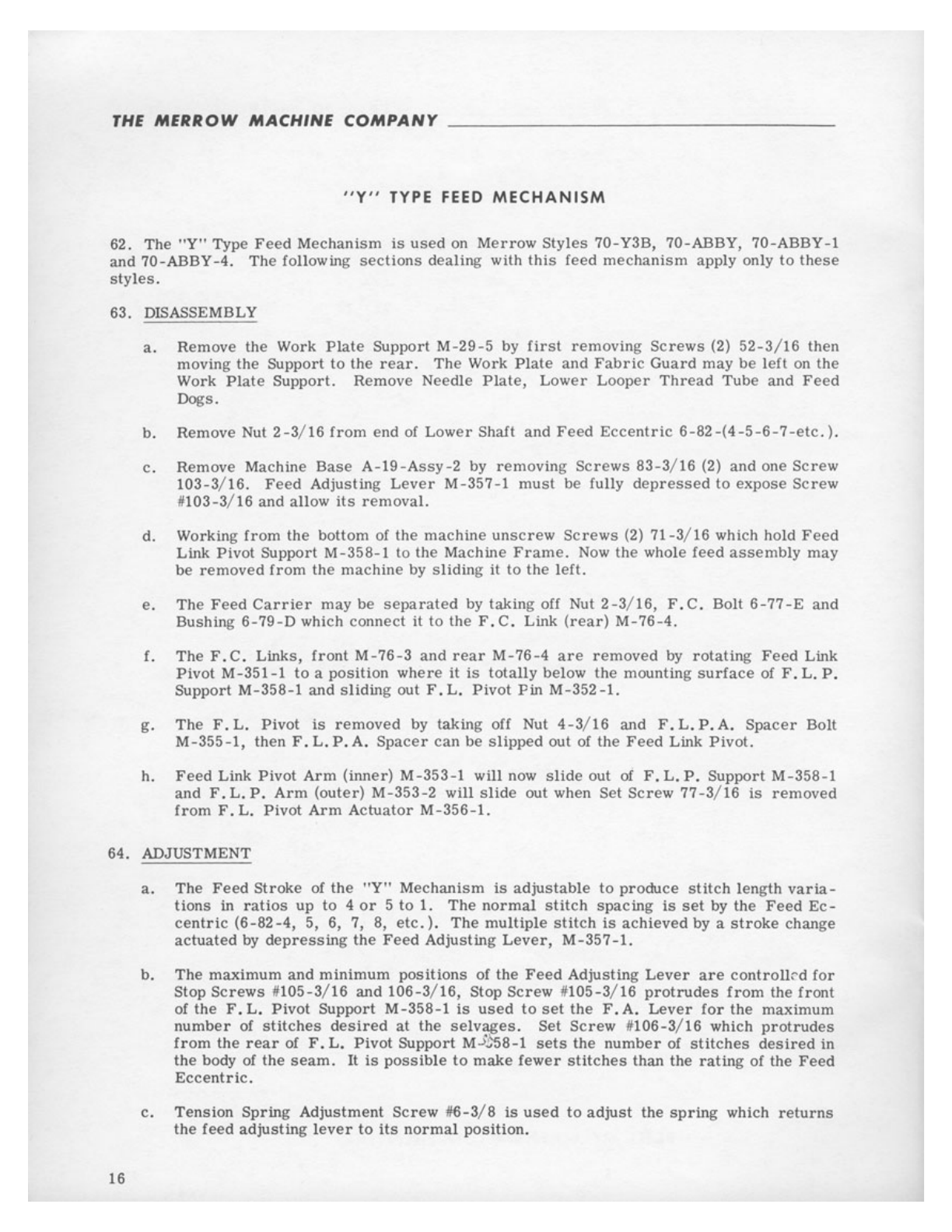

"Y"

TYPE

FEED

MECHANISM

62

.

The

"Y"

Type

Feed

Mechanism

is

used

on

Merrow

Styles

70-Y3B, 70-ABBY, 70-ABBY-1

and 70-ABBY-4. The following

sections

dealing

with

this

feed

mechanism

apply

only

to

these

styles.

63. DISASSEMBLY

a.

Remove the Work

Plate

Support

M-29

-5

by f

ir

st

removing

Screws

(2) 52

-3

/16

then

moving

the

Support

to

the

rear.

The

Work

Plate

and

Fabric

Guard

may

be

lefl

on the

Work Pl

ate

Support.

Remove

Needle

Plate,

Lower

Looper

Thread

Tube

and

Feed

Dogs.

b. Remove Nut

2-3

/16

from

end

of

Lower

Shaft

and

Feed

Eccentric

6-82-(4-5

-6-

7-etc.).

c.

Remove

Ma

ch

in

e

Base

A-19-Assy-2

by

removing

Screws

83-3

/

16

(2)

and

one

Screw

103-3/16.

Feed

Adjusting

Lever

M-357-1

must

be

fully

depressed

to

expose

Screw

11103-3/16

and

allow

its

removal.

d. Working

from

the bottom of

the

machine

unscrew

Screws

(2)

71-3

/16 which hold

Feed

Link Pivot

Support

M-358-1

to

the

Machine

Frame.

Now

the

whole

feed

assembly

may

be

removed

from

the

machine

by

sliding

it

to

the

l

eft.

e.

The

Feed

Carrier

may

be

separated

by

taking off Nut

2-3

/16,

F.C.

Bolt

6-77-E

and

Bushing

6-79-D

which

connect

it

to

the F .C. Link

(rear)

M-76-4

.

f.

The

F. C. Links,

front

M-76-3

and

rear

M-76-4

are

removed

by

rotating

Feed

Link

Pivot

M-351-1

to

a

position

where

it

is

totally

below

the

mounting

surface

of

F.

L.

P.

Support M

-358-1

and

sliding

out

F . L.

Pivot

Pin

M-352-1.

g.

The

F.

L. Pivot

is

removed

by taking off Nut

4-3

/

16

and

F.

L.

P.A.

Spacer

Bolt

M-355-1,

then

F . L. P. A.

Spacer

can

be

slipped

out of the

Feed

Link

Pivot.

h.

Feed

Link Pivot

Arm

(inner)

M-353-1

will now

slide

out

of

F.

L.

P.

Support

M-358-1

and

F.

L.

P.

Arm

(outer)

M-353-2

will

slide

out

when Set

Screw

77-3

/16

is

removed

from

F.

L.

Pivot

Arm

Actuator

M-356-1.

64. ADJUSTMENT

16

a.

The

Feed

Stroke

of the

"Y"

Mechanism

is

adjustab

le

to

produce

stitch

length

varia-

tions

in

ratios

up

to

4

or

5

to

1.

The

normal

stitch

spacing

is

set

by

the

Feed

Ec-

centric

(6-82-4,

5,

6,

7,

8,

etc.)

.

The

multiple

stitch

is

achieved

by a

stroke

change

actuated

by

depressing

the

Feed

Adjusting

Lever,

M-357-1.

b.

The

maximum

and

minimum

positions

of

the

Feed

Adjusting

Lever

are

cont

r

oll:--d

for

Stop

Screws

1110

5-3

/16

and

106-3/16,

Stop

Screw

11

105-3

/16

protrudes

from

the

front

of the F .

L.

Pivot

Support

M-358-1

is

used

to

set

the

F.

A.

Lever

for

the maximum

number

of

stitches

desired

at

the

se

l

vages

.

Set

Screw

11106-

3

/16

which

protrudes

from

the

rear

of F .

L.

Pivot

Support

M->j58-l

sets

the

number

of

stitches

desired

in

the

body of the

seam.

It

is

possible

to

make

fewer

stitches

than

the

rating

of

the

Feed

Eccentric.

c.

Tension

Spring

Adjustment

Screw

116-3/8 IS

used

to

adjust

the

spring

which

returns

the

feed

adjusting

lever

to

its

norma

l

position.

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

CLASS

70

INSTRUCTION

BOOK

>

.,

~··

1

,~

'':

f/;

lo)

~ ·

.

.,_

f

••

Hd

~•;;;'

:pqw

•:•

.. ..

I'I I

,I

I

NCHES

" Y"

FEED

MECHANISM

17

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

Preuer

Foot

Sc,~

....

18

v.

Prcncr Fool

Ar,u

Screw 102

~

PRESSER

FOOT

ASSEMBLY I I I

INCHES

PF

. Fi

nger

Screw 8

Y•

I I

2 3

P.F. Brockel

A

,316•3

I

s

PRESSER

FOOT

AND

PRESSER

FOOT

FINGER

65.

The

Presser Foot

on

the

Style 70-D3B

may

be tilted

to

accommodate certain fabrics. To

make

this

adjustment,

loosen Screw

2~5

/32,

tilt

foot

to

desired

angle

and

tighten

Screw

2~5/32.

Afterlifting

the

Presser Foot Latch,

the

Presser Foot Arm

with

its

Presser Foot

may

be

swung

to

one

side

providing

accessibility

to

the

Needle

and

Loopers.

66.

The

Presser

Foot

Finger

should

be

positioned

upon

the

Presser

Fool

so

that

its

left

edge

just

covers

the

right

edge

of

the

slot

in the

needle

plate.

If

the

point of

the

needle

is

slightly

deflected

to

the

right,

it

should

not hit

the

Presser

Foot

Finger.

67.

Ordinarily,

use

as

little

pressure

on

the

Presser

Foot

as

is

practical,

the

degree

of

pressure

being

adjustable

by

the

Screw

6-3/8.

This

screw

is

held

in

adjustment

by

Set

Screw

13-5

/

32

at

the

right

side

of

the

Head.

68.

The

Presser

Arm

on

70-D3B

and

70-Y3B

Machines

is

mounted

to

the

P.A.

Pivot

by

Screw

102-3/16.

Screw

102-3

/16

is

tightened

until

the

Presser

Arm

swings

freely

without up

and

down

play.

Screw

1-#5

is

now

tightened

to

lock

Screw

102-3

/16.

18

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

I I I 11

INCHE

S

MM

CLASS

70

INSTRUCTION

BOOK

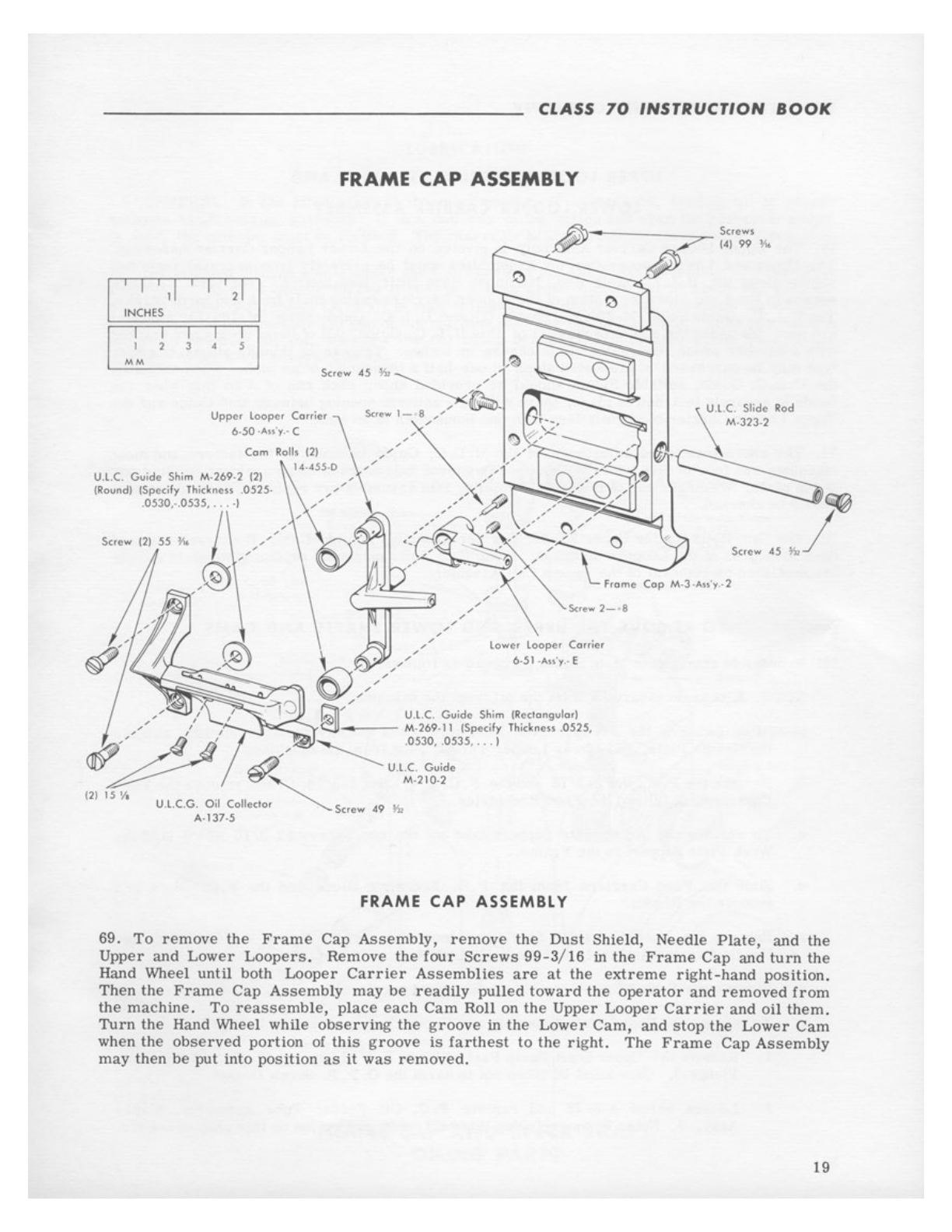

FRAME

CAP ASSEMBLY

Lowe, l

oo

per Carrier

6-51-Au'y.- E

FRAME

CAP AS

SEMBLY

69.

To

remove

the

Frame

Cap

Assembly,

remove

the

Dust Shield, Needle

Plate,

and

the

Upper

and

Lower

Loopers

. Remove

the

four

Screws

99-3/16

in

the

Frame

Cap

and

turn

the

Hand Wheel

until

both

Looper

Carrier

Assemblies

are

al

the

extreme

right-hand

position.

Then

the

Frame

Cap

Assembly

may

be

readily

pulled

toward

the

operator

and

removed

from

the

machine.

To

reassemble,

place

each

Cam

Roll

on

the

Upper

Looper

Carrier

and

oil

them.

Turn

the

Hand Wheel while

observing

the

groove

in

the

Lower

Cam,

and

stop

the

Lower

Cam

when the

observed

portion

of

this

groove

is

farthest

lo

the

right.

The

Frame

Cap

Assembly

may

then

be

put into

position

as

it

was

removed

.

19

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THE

MERROW

MACHINE

COMPANY

UPPER

LOOPER

CARRIER

ASSEMBLY

AND

LOWER

LOOPER

CARRIER

ASSEMBLY

70.

The

Upper

Looper

Carrier

Assembly

is

pivoted on the

Lower

Looper

Carrier

Assembly.

The

Upper

and

Lower

Looper

Carrier

Assemblies

must

be

perreclly

free

to

travel

their

full

stroke

along the

U.

L. C. Slide Rod, bul

must

have

little

lost

motion.

The

U.

L.

C. Guide

serves

to

limit

the

sidewise

motion or the

Looper

Carriers

during

their

back

and

forth

stroke.

The U. L.

C.

Guide Shim

M-269-2

(round) (2) and U.

L.

C. Guide Shim M-269-11

(square)

are

provided

under

the

points

of

support

of

this

U.

L.

C.

Guide. All of

these

Shims

are

marked

with a

number

which

designates

its

thickness

in

inches.

Thicker

or

thinner

shims

of

either

type

may

be

purchased

in

graduated

steps

of

one-half

a thousandth of

an

inch.

When

adjusting

the

U.

L.

C. Guide,

suitable

Shims

shou

ld

be

provided

under

each

end of

il

so

that

when the

Guide

is

securely

fastened

in

place,

there

will

be

a

uniform

opening between

this

Guide

and

the

Upper

Looper

Carrier

of

slightly

less

than one thousandth of an

inch.

71.

The

above

mentioned

adjustment

of

the

U. L.

C.

Guide

is

made

at

the

factory

and

most

machines

run

four

or

five

years

without

readjustment

unless

there

be an

accident

spoiling

one

of the

parts.

Whenever any of

the

parts

compiling

this

assembly

are

replaced,

this

adjustment

shou

ld

be

checked.

72.

The

Cam

Rolls

for

the

Upper

Looper

Carrier

Assembly

are

identical.

If

excessive

up

and

down

looseness

of the

Loopers

develops,

these

Cam

Rolls

may

need

replacing

which

is

simply

accomplished

by

removal

of

the

Frame

Cap

Assembly.

TO

REMOVE

THE

UPPER

AND

LOWER

SHAFTS

AND

CAMS

73. In

order

to

remove

the

Main

Shafts,

proceed

as

follows:

20

NOTE:

It

is

unnecessary

to

drain

the

oil

from

tile

machine.

a.

After swinging

the

Presser

Foot

Assembly

out of the way

for

accessibility,

remove

the Needle

Plate,

and

Lower

Looper

Thread

Tube

from

the Machine.

b. Remove

the

F.

E.

Nut

2-3/16

and

the

F.

C. L. (r) Nut

2-3/16

. Then

remove

the

Feed

Carrier

Link

(r)

and

the

Feed

Eccentrics.

c.

To

remove

the

Work

Plate

Support

take

out

the

two

Screws

52-3/16

which hold the

Work

Plate

Support

to

the

Frame.

d.

Slide

the

Feed

Carriers

from

the

F.

R.

Eccentric

Block

and

the

F.

C. Block

and

remove

the

Blocks.

e.

Remove

the

Needle

Carrier

Stud

after

loosening

the

Set

Screw

8-7/32.

Slide

the

Needle

Carrier

Assembly

and

the

N.

C.

Link

Assembly

from

the

machine.

f.

Remove

the

Frame

Cap

Assembly

as

d

escribed

previously.

g.

To

remove

the

Upper Shaft

Assembly

and

Upper

Cam,

proceed

as

follows:

1. Remove

the

Upper Shaft

Pump

Parts

(Screw

8-7/16,

Spring

27-40, and

Oil

Pump

Plunger).

Care

must

be

taken

not

to

harm

the

0.

P.P.

Screw

Casket.

2.

Loosen

Screw

5-9/32

and

remove

F.C.

Oil

Feeder

Tube

Assembly,

M-95-

Assy.

-4.

Note: When

replacing

this

part,

point

projection

on

this

tube downward.

This manual suits for next models

8

Table of contents

Other Merrow Sewing Machine manuals