Important

note:

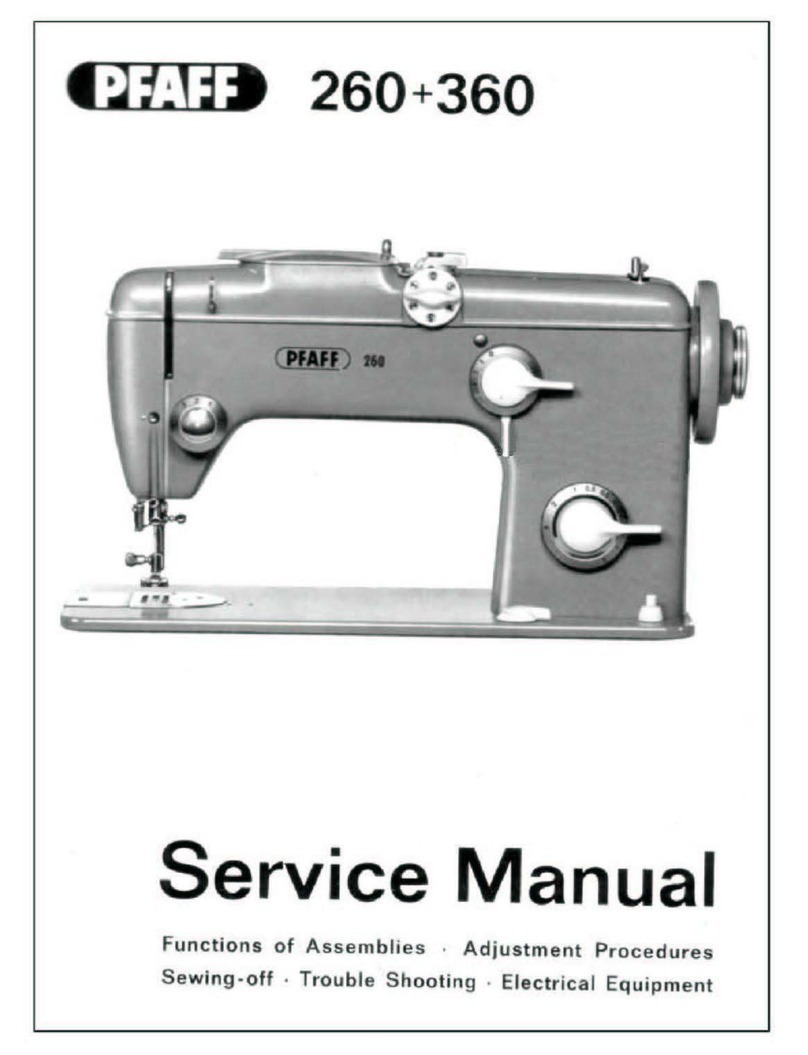

ThisServiceManual applies also to the Raff 441-0 and 442-0. Deviations in the illustrations do not

affect

the

adjustment of the machines.

The

Sen/ice

Manual is

based

on a two-needle machine.

When adjusting a single-needle machine,

simply

ignore the adjustment procedure for the left

needle and the left sewing hook. A separate Service

Manual

is available for adjusting the

Pfaff

441-R

(0)-705/03: -755/03.

Tools,

gauges

and

other

items required for adjusting

Raff

machines

442-R, 441-0

and

442-0

1

set

of

screwdrivers

with

blades

from

2

to

10

mm

wide

1

set

ofwrenches withopeningsfrom 7 to 14 mm wide

1

set

of alien keysfrom 2 to 6 mm

1feed dog

gauge,

part No.

91-129995-05

1adjusting

gauge,

part No. 91

-129573-91

1C-clamp,

part

No.

880137/00

1

metal

rule

1wrapper of needles: system 134 (for7 mmfabric clearance)

system

134-35

(for 9 mm fabric clearance)

2strips of white

paper

Sewing thread and testing material

Technical

data

Maximumsewing

speed:

5000 s.p.m.

Balance

wheel:

65

mm

eff.

dia.

Drive:

clutchmotor0,550 kW(% HP)

lever-operated Stop motor0,550 kW(% HP)

electronic-stop-motor 0,550 kW(%HP)

Needle system: 134 (for7 mmfabric clearance)

134-35

(for 9 mm fabric

clearance)

Fabric

clearance:

7

or

9

mm