MesSen Nord ROHRTEST-4 User manual

ROHRTEST-4 v. 8.8

Tightness test system

for

Sewers, sewage pipes and pipe connections

acc. to EN 1610, SIA 190 / VSA

Separators, Collectors and Shafts

acc. to EN 1610, EN 858-1, EN 858-2, DIN 1999-100, DIN 4040-100,

EN 12566-1, SIA 190 / VSA

Drinking water / waste water pressure pipes acc. to EN 805

MESSEN NORD GmbH

Tightness test systems/ Inspection cameras

Test vehicle equipment / Special software

Zum Forsthof 2

D-18198 Stäbelow

Tel.: + 49 38207 / 656-0

Fax: + 49 38207 / 656-66

e-mail: info@messen-nord.de

Website: www.messen-nord.de

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 2

0. Table of contents Side

1. Application of the test system 4

1.1. Water pressure-test / low-pressure 5

1.2. Water pressure-test / high pressure 5

1.3. Shaft and separator-test in the free-mirror-procedure 6

1.4. Compressed air-test / sleeve-sample 8

2. Technical parameters 11

3.1. General business-parameters 11

3.2. Measuring-equipment WATER / water supply 12

3.3. Measuring-equipment AIR / compressed air-supply 13

3.4. Measuring-equipment VACUUM / hypotension-production 14

3.5. Measuring-equipment HIGH PRESSURE / high pressure-production 15

3.6. Measuring-equipment SHAFT 16

3.7. Measuring-precision of the measuring-facilities / calibration 18

4. Danger-prevention 20

5. Installation 21

5.1. Installation 21

5.2. Installation of the USB-Adapters 22

5.3. Program-configuration 24

5.4. Formation of the individual protocol-head 25

6. Test standards and parameters 27

6.1. Selection of the test procedure and the test standard 27

6.2. Test with water / low-pressure 28

6.2.1. Test parameters for tests of DIN EN 1610 28

(Water, low-pressure)

6.2.2. Test parameters for tests of DIN 1999-100 29

(Water-level-tests for separators)

6.2.3. Test parameters for tests of DIN 4040-100 33

(Water-level-tests for fat-separators)

6.3. Test parameters for tests of DIN EN 805 36

(Water, high pressure)

6.4. Test parameters for tests with compressed air 37

6.5. Test parameters for special-tests 37

6.6. Test parameters for sleeve-tests 38

6.6.1. Tester administration 39

6.6.2. Sleeve-test with reference-measurement 40

6.6.3. Sleeve-tests of ATV/DWA M 143 slices 6 41

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 3

7. Test-transaction 42

7.1. Tests with measuring-equipment WATER 42

7.1.1. Preparatory works 42

7.1.2. Test with measuring-equipment WATER 43

7.2. Tests with measuring-equipment HIGH PRESSURE 44

7.2.1. Preparatory works 44

7.2.2. Test-transaction with measuring-equipment HIGH PRESSURE 45

7.3. Tests with measuring-equipment AIR 46

7.3.1. Preparatory works 46

7.3.2. Transaction of the test with compressed air 47

7.3.3. Test of tube-connections / sleeve-test 48

7.4. Tests with the measuring-equipment SHAFT 49

7.4.1. Preparatory works 49

7.4.2. Transaction of the test with the measuring-equipment SHAFT 50

8. Data-concept 51

8.1. Storage of the test reports 51

8.2. Project-administration 52

8.2.1. Transferred by data-continuances, updating of the project-administration 52

8.2.2. Summary from test reports to lists and overview-tables 52

8.3. Preparation and alteration of test report forms 55

8.3.1. Saving hierachy of test report forms 55

8.4. Data take over from test reports 58

8.5. Configuration of the option "GPS" 59

9. Appliance-maintenance, calibrations and function-tests 60

9.1. Appliance-check 60

9.2. Cleaning of the filter of the measuring-equipment WATER 60

9.3. Changeover to winter-business 61

9.4. Test of the appliance-function, own-control 61

9.5. Cleaning of the measuring-equipment SHAFT 61

Installation:

Test standards (tabular transcriptions, work-leaves)

A) DIN EN 1610

B) LfW 4.3-6

C) ATV/DWA M 143-6

D) DIN 1999-100 / EN 858-1

E) DIN 4040-100

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 4

1. Application of the test system

The test system ROHRTEST-4 allows the computer-aided, automated tightness test

of sewage pipelines, muffs, shafts and separators after the test standards nationally

binding for these installations. In the result of the test, standardized test reports are

produced which document the test course and the test result.

You find a complete list of the test-specific system-components under 2. System-

components / delivery capacity:

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 5

System-components Test procedures

Control unit, integrated AIR/VACUUM (RT-ST04) This unit is required for all Test procedures,

contains measuring-equipment for AIR / VACUUM

tests, supplie unit, data-transformers and test

controller for all measuring-facilities

Tests acc. to EN 1610 (L) i.e.

External measuring equipment AIR (RT-EXTL) External Filling and measuring unit for testing high

pipe dimensions, application directly at the pipe

fastener, makes filling procedure fast and save

Tests acc. to EN 1610 (L) i.e.

Measuring-equipment SHAFT (RT-SP04) Shaft and separator-tests acc. to EN 1610,

ATV/DWA M 143/6, EN 858-1, EN 858-2, DIN

1999-100, DIN 4040-100 i.e.

Measuring-equipment WATER (RT-WA04) Allows water loss tests by automatic supplying

and measuring the lost water. Unit can keep up a

given pressure or a level in connection with

external sensors.

Tests acc. to EN 1610 (W) i.e.

External water pressure sensor

(RT-EXTW)

Allows in connection with RT-WA04 the water loss

test by keep up the water start level. Apllication of

the pressure sensor directly at the pipe fastener.

Tests acc. to EN 1610 (W) i.e.

External water pressure sensor

(nozzle model) (RT-EXTWR)

Allows in connection with RT-WA04 the water loss

test by keep up the water start level. Apllication of

the pressure sensor at the drain outlet.

Tests acc. to EN 1610 (W) i.e.

Measuring-equipment HIGH PRESSURE

(RT-HD04)

Tests of DIN EN 805 as well as. the former Norm

DIN 4279 (water, high pressure)

Air-distribution-unit (RT-LV04) Muffs and stand-tests with compressed air after

ATV/DWA M 143/6, DIN EN 1610, Control of the

tests and blister-pressure for Max. 4 Fasteners as

well as a Junction test fastener

Junction test fastener (RT-MU04) Manually driven reel with connection-management

100 m to the Junction test fasteners over only one

hose-management with interior-lying main lead for

measuring-sensor, air-control and observation-

camera

Optional fade-in of the Test parameter into the

video-picture

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 6

1.1. Water pressure-test / low-pressure

Configuration A: Water pressure test at the closed system (fastened pipe)

Standards: EN 1610 „W“

DIN 1986 Teil 30

DWA M 143 Teil 6

SIA 190 / VSA

ÖNORM B2503

Special test procedure „W“

Control unit

RT-ST04

Measuring unit WATER

RT-WA04

Connection cable

RT-VK10

Test

connection

Water

supply

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 7

Water pressure-test / low-pressure

Configuration B: Water pressure test at the open system (open water column)

Standards: EN 1610 „W“

DIN 1986 Teil 30

DWA M 143 Teil 6

SIA 190 / VSA

ÖNORM B2503

Special test procedure „W“

Test

connection

Water

supply

Control unit

RT-ST04

Measuring unit WATER

RT-WA04

Dispatcher box

RT-VBOX

External pressure sensor

RT-EXTW

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 8

1.2. Water pressure-test / high pressure

Test standards: EN 805

DIN 4279 (become obsolete)

Special test procedure "H"

Control unit

RT-ST04

Measure equipment HIGH

PRESSURE RT-HD04

High pressure pump

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 9

1.3. Shaft and separator-test in the free-mirror-procedure

Configuration A: Shaft - / separator-test of automatic water-addition

Configuration B: Separator-test with automatic water-addition

Control unit

RT-ST04

Measure equipment

WATER RT-WA04

To the

Shaft

Water

supply

Connection

cable RT-VK10

Dispatcher

box RT-VBX

Control unit

RT-ST04

Measure equipment

SHAFT

Sensor cable

RT-SK10

Measure equipment

SHAFT RT-SP04

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 10

Configuration C: Separator-test with several level-probes

Test standards: EN 858

DIN 1999-100

DIN 4040-100

EN 1610 "W"

Special test procedure „W“

1.4. Pipe test with compressed air / measuring equipment AIR/VAKUUM

Measure equipment

SHAFT RT-SP04

Measure equipment

SHAFT RT-SP04

Control unit

RT-ST04 with

2 add. Meas.ports

Sensor cable

RT-SK10

Measure equipment

SHAFT RT-SP04

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 11

Test standards: EN 1610, Verfahren „L“

DWA M 139

DIN 1986/30, DWA M 143/6

ÖNORM B2503

SIA 190 / VSA

Special test procedure „L“

1.5. Pipe test with compressed air / external measuring equipment AIR

Control unit

RT-ST04

Air

distribution unit

RT-LV04

Compressed air

supply

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 12

Test standards: EN 1610, Verfahren „L“

DWA M 139

DIN 1986/30, DWA M 143/6

ÖNORM B2503

SIA 190 / VSA

Special test procedure „L“

Compressed air

supply

External measuring

equipment AIR

Control unit

RT-ST04

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 13

1.6. Compressed air tightness test for pipe junctions

Test standards: ATV/DWA M 139

ATV/DWA M 143-6

EN 1610

ÖNORM B2503

SIA 190 / VSA

Special test procedure „L“

Control unit

RT-ST04

Video

Data Box

RT-DBOX

RT-LV04

Compressed air

control unit

Compressed air

supply

Junction test reel

RT-MU04,

house length 100 m,

cable, meter counter and

videotextgenerator integrated

Junction test

fasteners with

integratred

camera

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 14

1.7. Water tightness test for pipe junctions

Test standards: ATV/DWA M 139

ATV/DWA M 143-6

EN 1610

ÖNORM B2503

SIA 190 / VSA

Special test procedure „W“

Control unit

RT-ST04

Video

Data Box

RT-DBOX

RT-LV04

Compressed air

control unit

Compressed air

supply

Kompressor

Junction test reel

RT-MU04,

house length 100 m,

cable, meter counter and

videotextgenerator

integrated

Junction test

fasteners with

integrated camera

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 15

2. Technical parameters

2.1. General business-parameters for all system-components

Power supply 12V DC (motor vehicle-shelf-net, 16A)

230V 50 Hz (6 A)

Supply takes place over the control unit ST04

Electric connection 12V: Motor vehicle-socket for included cables

230V: Net-socket

External measuring-facilities:

Connection to measuring-equipment

over special-cables

Business-conditions Temperature:

1 ... 40°C, no direct sun-radiation

Humidity:

Control unit until 90 percent of rel. Humidity

not-condenses

Measuring-facilities WATER, HIGH PRESSURE and

SHAFT IP65, the function of the measuring-equipment

SHAFT restricted with moisture-effect.

Transportation and camps- Temperature:

conditions: 1 ... 60°C, measuring-facilities WATER and HIGH

PRESSURE can through complete emptying of water

(business-means), Condensation, or through

replenishing with motor vehicle-frost-protection

sufficient concentration frost-certainly is done.

Humidity:

until not-condenses relative humidity 90 percent

Package:

Appliance-casings are as transportation-package

(Package-service, been not suitable. Additional

protection against push and pressure necessary.

Stack-bar-ness:

Appliance-casings are unpackaged until Max. 3

Appliances stack-bar.

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 16

2.2. Measuring-equipment WATER / water supply

Operating parameters

Business-medium: Water, fine-filtered

Entrance-pressure-area: - 0,1 ... + 0,5 bar

Exit-work-pressure: Max. 1 bar

Exit-pressure-proof-ness: Max. 2,5 bar, over it irreversible damage

Maximum-flow: 400 l/h

Water supply

Since the measuring-equipment WATER possesses an integrated pump, only a

pressure-loose water-connection is required. The entrance-pressure can .0.1 bar. To

suck in from until tank more deeply situated to 1 m, until +0.5 amount cash (tank lies

until to 5 m higher than the measuring-equipment).

RESPECT! Infringements of the maximum entrance-pressure can lead to

irreversible damages of the appliance as well as to the user's

endangering.

About the capability of the installation not through pressure-garbages in the hose-

managements as well as it is recommended to the connections to reduce not to

exceed a maximum hose-length of 10 m and a minimal cross-section of 10 mm, not

to under-stride.

2.3. Measuring-equipment AIR / compressed air-supply

Operating parameters

Business-medium: Air

Entrance-pressure-area: 0,1 ... 2,bar 0 above atmospheric pressure

Exit-work-pressure: Max. 0,6 bar

Exit-pressure-proof-ness: Max. 1,5 bar, over it irreversible damage

Maximum-vacuum-stream: 500 l / min (normal-gas)

Protection against damages through over pressure

The form of the filling control unit is on Max. 2 bar to restrict cash, a form is

recommended by about. 0,5-1,0 bar. The pressure-restriction takes place with a

mechanical pressure control as well as. Pressure minimizer, which becomes rear for

the compressor.

For the duration of the test operation, the upholding the form is necessary at the

compressed air-entrance of the filling control unit.

RESPECT! Heed section 4 about the danger-prevention with the contact with

compressed air.

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 17

2.4. Measuring-equipment VACUUM / hypotension-production

Operating parameters

Business-medium: Air

Entrance-pressure-area: 0,0 ... 1,bar below atmospheric pressure

Exit-work-pressure: Max. 1,bar below atmospheric pressure

Maximum-vacuum-stream: 500 l / min (normal-gas)

Hypotension-production

The production of the hypotension can be gone in for which with customary pressure

(so-called ejectors, jet-procedures) with compressed air or water as energy-bearers

or but with vacuum-suction pumps takes place.

2.5. Measuring-equipment HIGH PRESSURE / high pressure-production

Operating parameters

Business-medium: WATER, fine-filtered

Work-pressure-area: 0 ... 25 bar

Pressure-proof-ness: Max. 40 bar, over it irreversible damage as well as.

Endangering

High pressure-production

The connection to the measuring-equipment HIGH PRESSURE takes place

accordingly following illustration:

Pressure liniter

<= 25 bar

to the test object

to the control unit

High pressure

pump

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 18

2.6. Measuring-equipment SHAFT

There are two different test procedures for the use of the ROHRTEST-measurement

uipment SHAFT:

a, level-alteration-measurement

On this occasion the level-alteration is recorded opposite the zero-water-stand at

beginning of the test and is calculated the water-loss-quantity with help of the shaft-

geometry. The pressure-alteration yielding itself through the level-alteration amounts

to at most 5 mbar.

Measuring-area: 50 mm level-alteration

Appliance-technology: Control unit ST04,

Measuring-equipment SHAFT

b, water-loss-compensation

With this Test procedures, the water-level is stopped steadily at the zero-water-stand

over the entire test procedure. The addition of water-losses takes place

automatically, the loss-installment is recorded over the test procedure.

Measuring-area: 0.02 .. 400 l/h loss-installment (loss of 0 is recognized)

Appliance-technology: Control unit ST04,

Measuring-equipment WATER,

Measuring-equipment SHAFT

Zero-water-stand

Measuring

equipment SHAFT

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 19

The measuring-equipment SHAFT (ROHRTEST SP04) possesses the admission

of the LGA Würzburg for the test of fusible-ness-separators of the Prüfnorm

DIN in 1999-100.

We like to send you a copy of the certificate on demand.

Technical parameters

Connection: over connection-cables at reason-appliance ROHRTEST 4,

Supply with protection-small-tension of the reason-appliance,

maximum cable-length 80m

Denseness- DIN EN 1610, method "W"

tests: DIN 1999-100

DIN 4040-100

DIN 4261-1

DIN EN 12566-1

Special-tests (free parameters)

Measuring-area: Max. 50 mm level-alteration

entspr. Max. 39 l loss of DN 1000

entspr. Max. 25 l loss of DN 800

Dissolution: 0.01 mm level-alteration

Precision: +/-0.2 mm with expired or not existing calibration

+/-0.1 mm with valid calibration, See section 3.7

+/-0.03 mm with parallel temperature measurement and valid

calibration, See section 3.7

Please heed:

The stated measuring-precision is gained by the measuring

instrument under unfavorable conditions only 15 min after positioning

and switching on in the span required for this stabilization-process

being main from the temperature-difference between the place of the

storage as well as the transportation and the place of the use

dependent.

Delivery capacity: Measuring-equipment "shaft" with tripod and level unit,

extension-tubes 0,5 m and 1,0 m, Calibration report

ROHRTEST-4, v. 8.8 MESSEN NORD GmbH

page 20

2.7. Measuring-precision of the measuring-facilities / calibration

Measuring-

equipment

Einstellgenauigkeit

Test pressure /

level

Measuring-precision

pressure - / level-

waste

Measuring-precision

water-loss

AIR / VACUUM +/- 5 mbar +/- 1 mbar -

WATER +/- 10 mbar +/- 2 mbar 5% from the

measurement in the

area 0,02-400 l/h

HIGH

PRESSURE

+/- 200 mbar +/- 15 mbar 5% from the

measurement in the

area 0,02-400 l/h

SHAFT +/- 0,2 mm Up to +/- 0,03 mm

See section 2.6!

-

Calibration of measurement equipments AIR, WATER, HIGH PRESSURE

The measuring-facilities of the system ROHRTEST are basing on high-quality

sensors for pressure and water flow which are subjected extensive tests before

delivery.

In order to support the users of the installation in the proof of the precision opposite

her/its/their clients, all measuring-facilities are calibrated. The Calibration reports

belong to the delivery capacity of the respective installations.

Through the application of DKD-certificated calibration equipment the retracing of the

measurements to the German national norm is given.

A repetition of the calibration is recommended by the manufacturer in distances of 1

years, please contact for this purpose your supplier as well as. the appliance-

manufacturer.

Influence of the atmospheric pressure on the pressure-measurements

Through this, measuring-proceeding would use, the recorded test pressure remains

independently from the atmospheric pressure, d.h. Weather-changes, on the agenda

wind and similar factors don't have any influence on the test result.

Since the water-loss as well as. Pressure-waste from a leaky tube-wall as well as. a

tube-connection dependent on the difference-pressure of inner and outside-pressure

is, the test pressure (inner-pressure) should be put in relatively to the atmospheric

pressure (outside-pressure).

In order to enable this, the functions "Calibration atmospheric pressure" are existing

for the measurement equipments AIR, WATER and HIGH PRESSURE. By

implementation of these functions, the exact reference of the test pressure to the

current environment-atmospheric pressure is guaranteed directly before beginning of

the tube-test.

Table of contents

Popular Test Equipment manuals by other brands

Agilent Technologies

Agilent Technologies InfiniiVision 3000 X-Series Programmer's guide

Elma

Elma 9400 manual

Anritsu

Anritsu LMR Master S412E Programming manual

Precision Rated Optics

Precision Rated Optics PRO-6350 Operation guide

BGS technic

BGS technic 40105 instruction manual

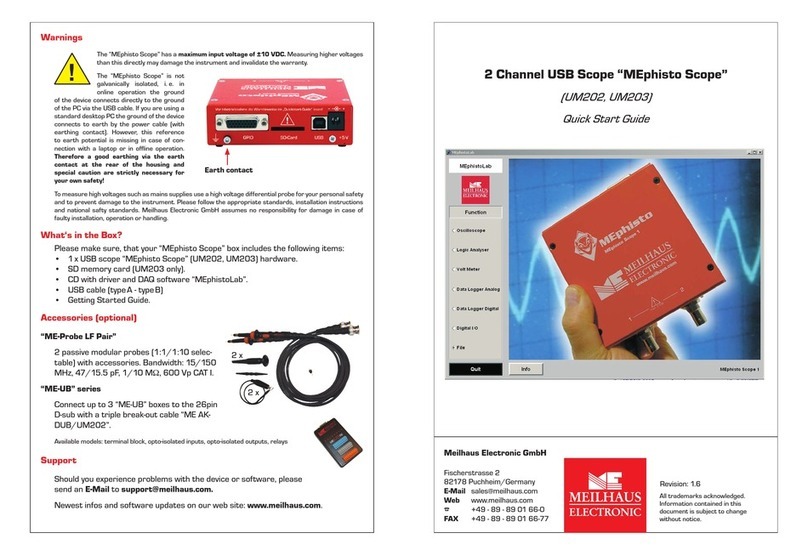

Meilhaus Electronic

Meilhaus Electronic MEphisto Scope UM202 quick start guide