Tektronix 3S3 User manual

Other Tektronix Test Equipment manuals

Tektronix

Tektronix AMM768 User manual

Tektronix

Tektronix TG8000 User manual

Tektronix

Tektronix 2445A User manual

Tektronix

Tektronix MultiPaq VX4101A Service manual

Tektronix

Tektronix 2465 User manual

Tektronix

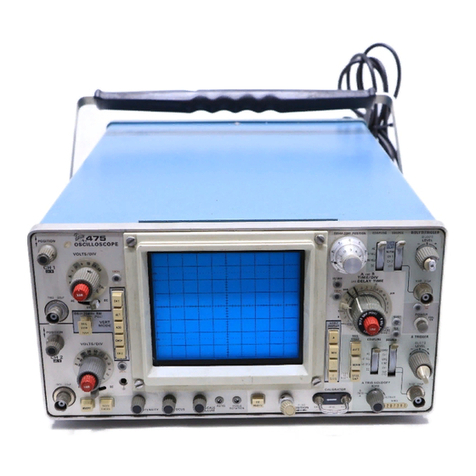

Tektronix 475 User manual

Tektronix

Tektronix 524AD series User manual

Tektronix

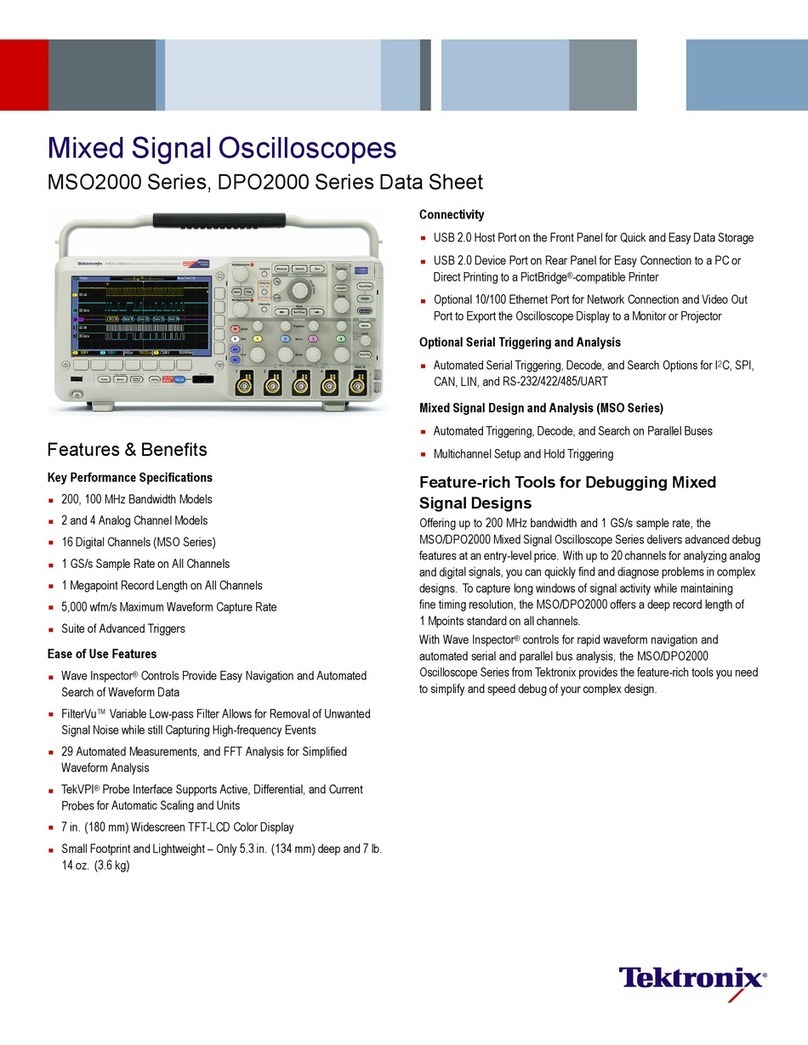

Tektronix MSO2000 Series User manual

Tektronix

Tektronix KEITHLEY S530 User manual

Tektronix

Tektronix MTS4000 MPEG Manual

Tektronix

Tektronix Keithley 2302 Operator's manual

Tektronix

Tektronix 492 Service manual

Tektronix

Tektronix P5100A Use and care manual

Tektronix

Tektronix TDS 684A User manual

Tektronix

Tektronix 507 User manual

Tektronix

Tektronix TDS7000 Series Manual

Tektronix

Tektronix MDO3000 Series User manual

Tektronix

Tektronix 454A User manual

Tektronix

Tektronix 5441 User manual

Tektronix

Tektronix 2252 User manual