4 IMO-553 EN

3. INSTALLATION

3.1 General

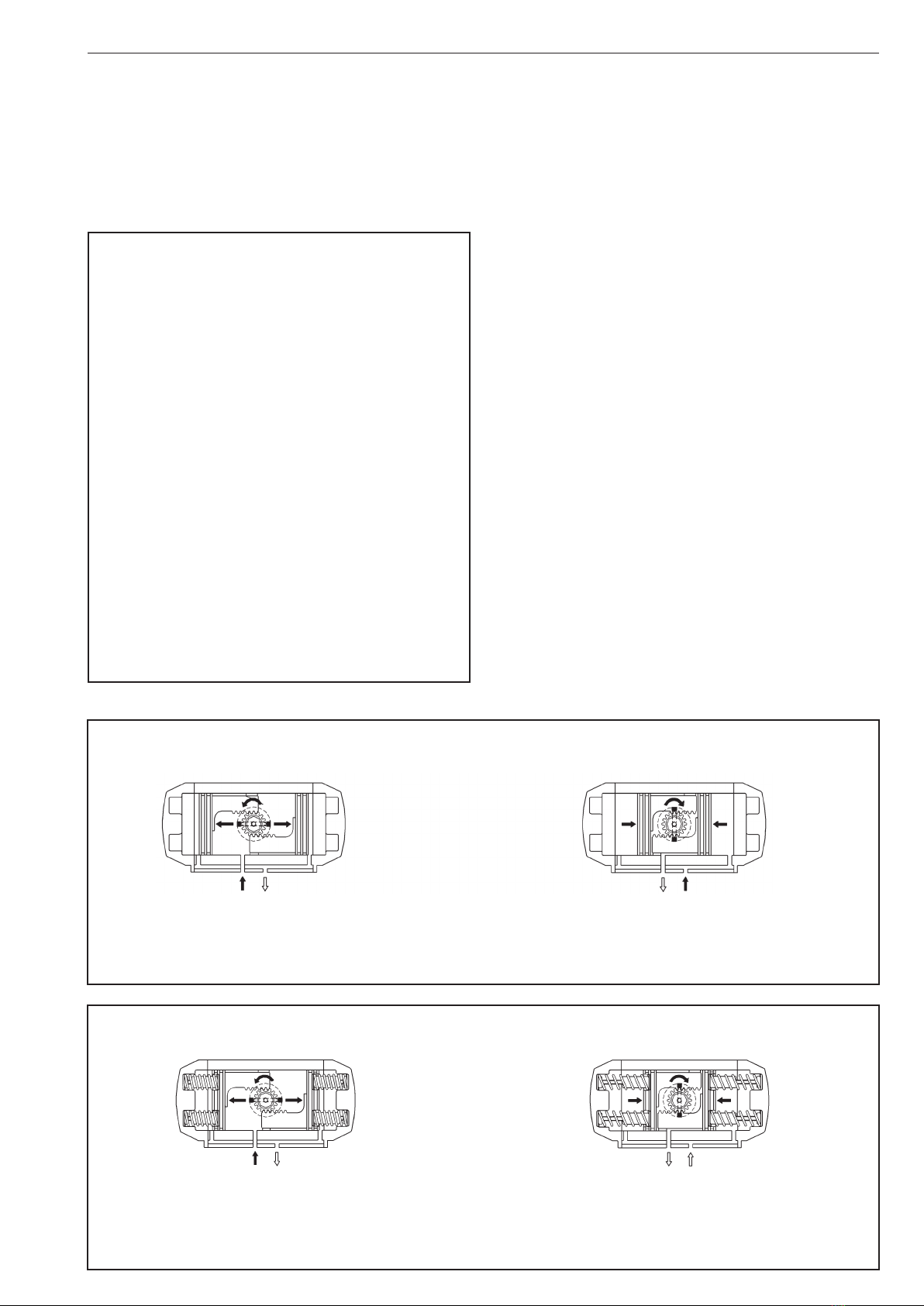

1. Check to see that the desired failure mode is correc

(Figures 1 & 2). In the spring-to-close mode, the actu-

ator will cycle clockwise to close upon loss of pressure.

If the spring-return actuator is not set up in the con-

guration desired, follow the disassembly procedure

section 4.2. Reverse the orientation of the pistons,

then reassemble following the assembly procedure,

section4.3.

2. Mount the actuator to the valve, following the direction

in the linkage AMI or valve IMO.

3. Connect a regulated air supply to the NPT tting in the

actuator housing. CAUTION: The maximum operat-

ing pressure is 116 psi (8 bar).

4. Adjust the stop screws following ASSEMBLY Section

4.3.5.

3.2 Operation

1. The actuator series, size, operating pressure, operating

temperature, output torque, spring directions, and

drive type is determined by the actuator designation.

2. The label lists the actuator series, size, operating pres-

sure, maximum pressure, and serial number.

3. Actuator designation example, VPVL300SR6BD is

a spring-return series, VPVL300 double-opposed piston

actuator that has 80-psi (5.5-bar) springs, a Teon®-

coated anodized housing (protection B), an end-of-

spring-stroke output torque of 44.9 FT•LBS (60.8 N•m).

4. MAINTENANCE

4.1 General

Although Metso’s Jamesbury actuators are designed to work

under severe conditions, proper preventative maintenance

can signicantly help to prevent unplanned downtime and

in real terms reduce the total cost of ownership. Metso rec-

ommends inspecting actuators at least every ve (5) years.

The inspection and maintenance frequency depends on the

actual application and process condition.

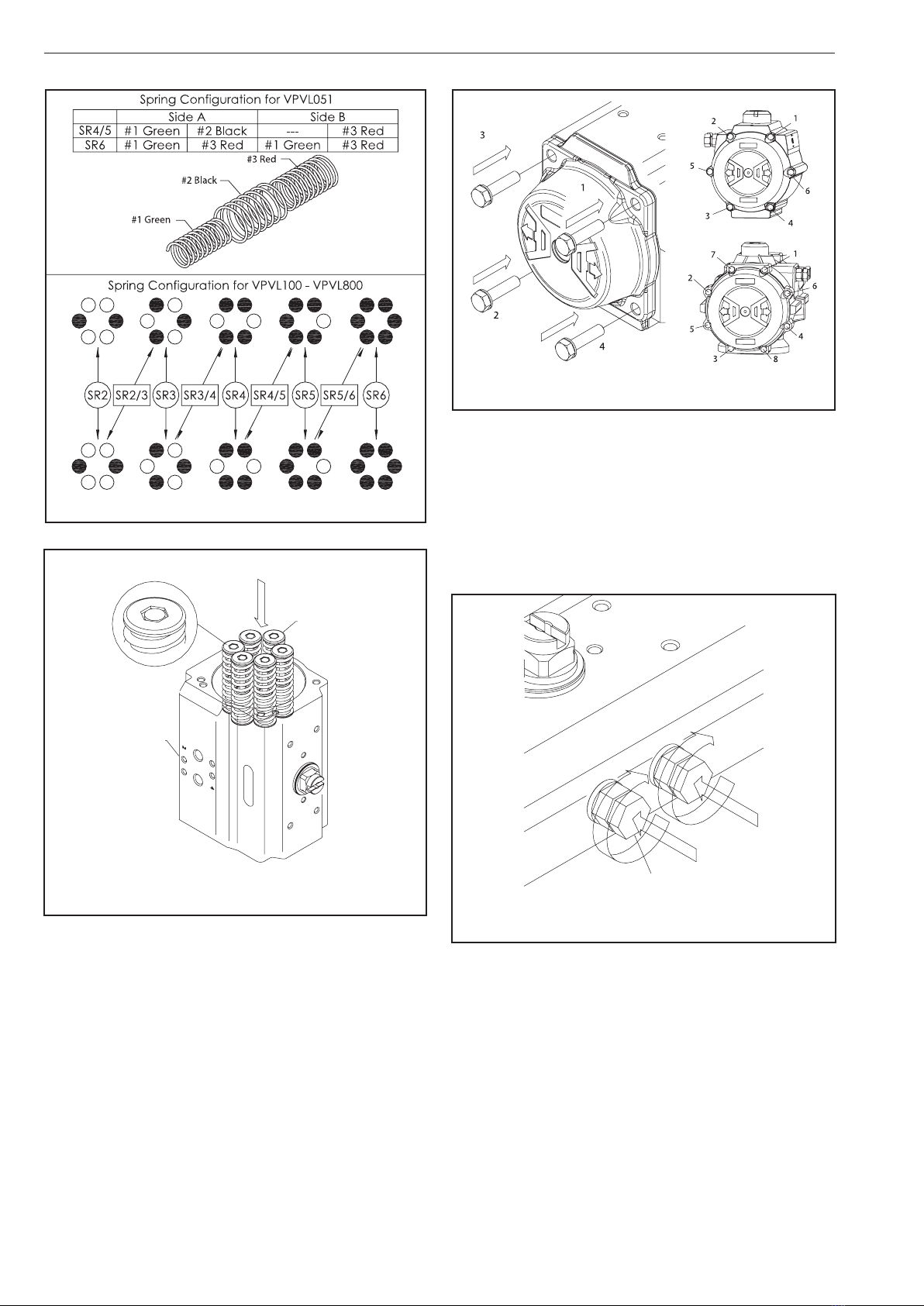

NOTE: All VPVL actuator fasteners are metric. Under normal

operating conditions the actuator requires only periodic

observation to ensure proper adjustment. Service kits are

available to replace seals and bearings (soft parts). These

parts are identied in (Figure 23) and listed in (Table 3).

(Table 1) below lists kit part numbers.

4.2 Disassembly

When disassembly of the actuator is required for mainte-

nance, remove the actuator from the valve. Ensure proper

lifting procedures are followed when moving or carrying

actuators. CAUTION: Do not use the M5 VDE/ VDI mount-

ing holes or the M6 hole in the pinion for lifting the

actuator.

When disassembling VPVL actuators, use caution and be

certain that the actuator is free from accessories and the air

supply is disconnected. When the actuator is a springreturn

unit, make sure that the actuator is in the failed position

before disassembling.

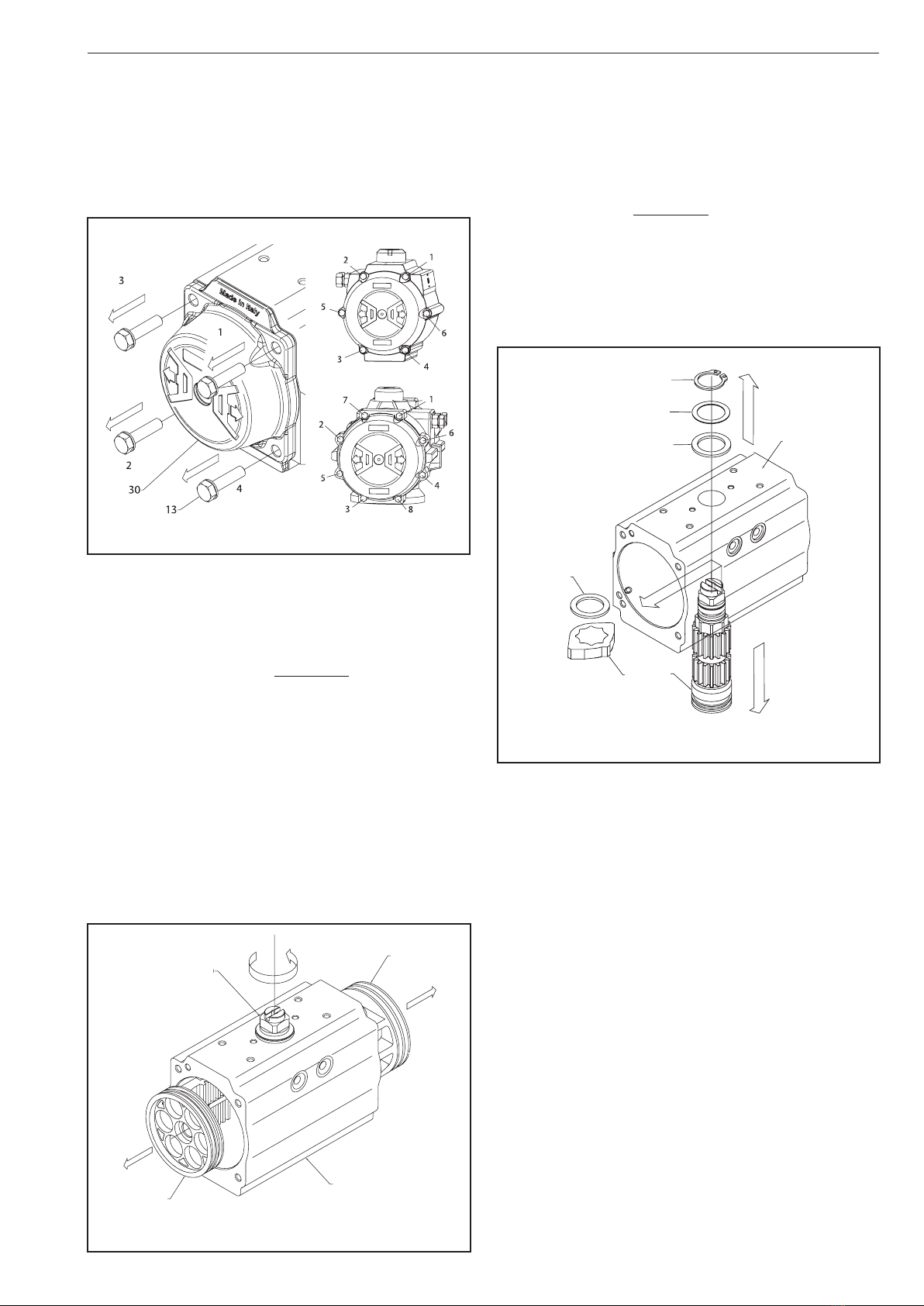

1. Removal of Position Indicator (19,20), (Figure 3):

A. Remove cap screw if tted (39).

TABLE 1

Complete Service Kit

Actuator Standard High Temp.

VPVL-01/011 RKP-152 RKP-232

VPVL-050/051 RKP-262 RKP-233

VPVL-100 RKP-263 RKP-234

VPVL-200 RKP-264 RKP-235

VPVL-250 RKP-265 RKP-236

VPVL-300 RKP-266 RKP-237

VPVL-350 RKP-267 RKP-238

VPVL-400 RKP-268 RKP-239

VPVL-450 RKP-269 RKP-240

VPVL-500 RKP-270 RKP-241

VPVL-550 RKP-271 RKP-242

VPVL-600 RKP-272 RKP-243

VPVL-650 RKP-273 RKP-244

VPVL-700 RKP-274 RKP-245

VPVL-800 RKP-275 RKP-246

39

19

Figure 3

02, 04, 03,and 11

Figure 4