META 13 RS User manual

Short cuts for parts:

SPL - Left side section

SSL - left part for side wall

SPM - Middle section

SPR - Right side section

SSR - right part for side wall

TW - Partition

SWF - End wall with leg

SCHW - Privacy screen

TUL - Left door

TUR - Right door

13 RS

INSTALLATION INSTRUCTION

The following parts are required:

• Electric drill with

5 mm and 8 mm SDS

• Various HSS-drills

3,5 mm, 4,2 mm, 6,5 mm

• Cordless screwdriver with bits TX

15, 20, 25, 30 mm PH2 cross

• Various allen keys

• Water level at least 1 m or laser

• Small wooden wedges

• Various Philips-HP screwdrivers

• Several wooden blocks height 15 cm

• Several glass blocks 5 mm

• Hammer, rubber hammer

• Pop rivet gun

• Standard tools

• At least 2 scissor jacks

• Chop and fermentation saw with

blade for aluminum

• Hand-held circular saw if required

with blade for plastic and

non-ferrous metals

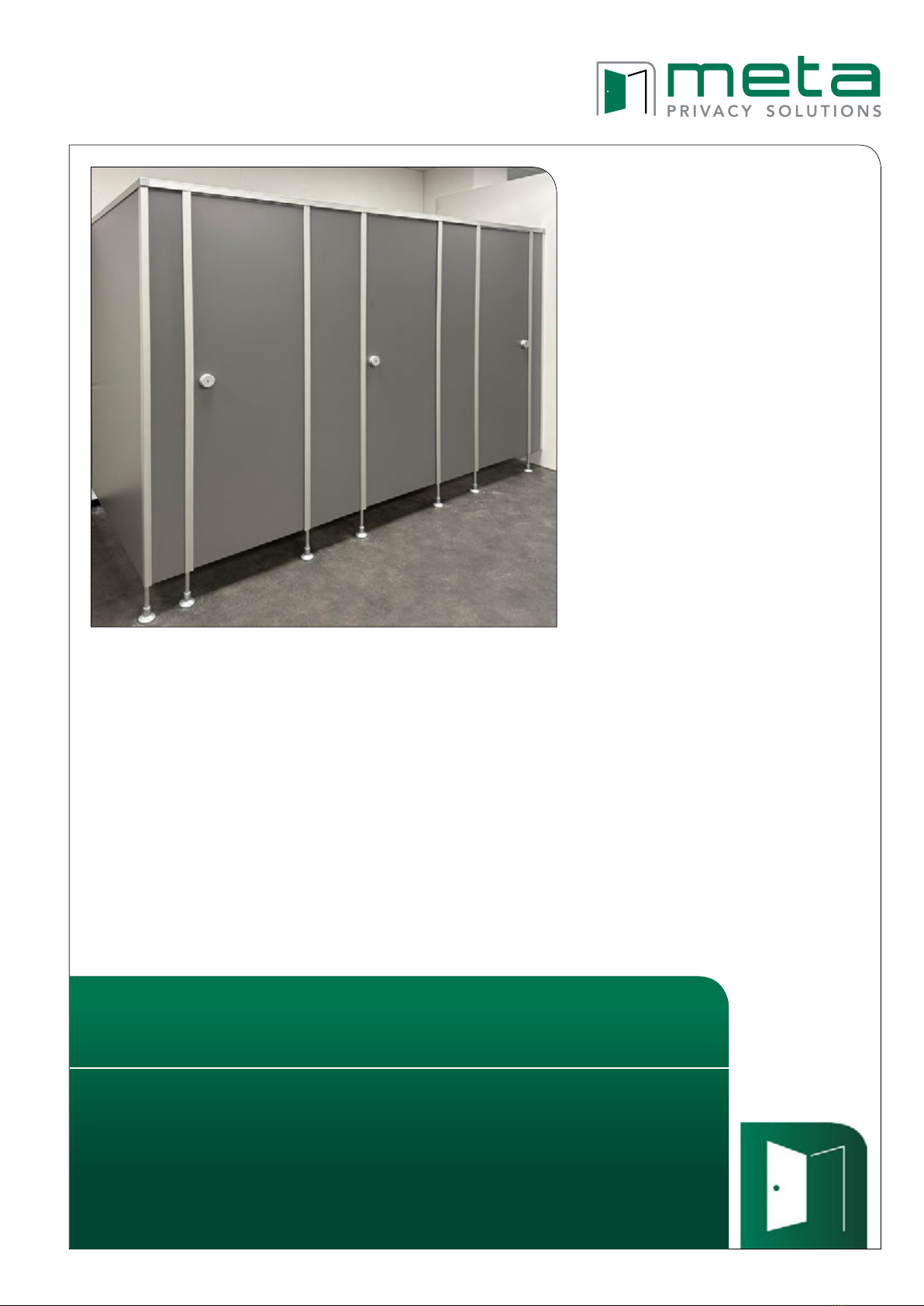

Marking of the wall connections (U proles)

The cabin axis dimensions (dimension 1) can be taken

from your drawing if neccessary. If no dimensions are

specied, the width of the system is divided into equal parts.

These axial dimensions are marked by a vertical line.

The U-prole is placed on a wooden block, which has the

height of the ground clearance.

Now mark the drill holes. (see photo)

For the axial dimension of the wall connection “a”,

27 mm must be added to the partition depth.

Draw a vertical line with a spirit level and mark the holes.

TW and SW are different.

The dimension of the TW is decisive.

Draw a vertical line with the water level and mark the holes as before.

If the oor is uneven or has a slope,

the standard foot clearance at the lowest point must be 150 mm.

Fastening of U-proles

Drill the 8 mm holes and insert 8 x 51 mm wall plugs.

Fasten the U proles with washers and 5 x 50 mm

chipboard screws.

Leave the wooden blocks in place.

Inserting partitions and side walls

Place the walls in the U-proles (please do not screw them

together yet).

A scissor jack is required for the front part of the partition wall.

Align the walls horizontally.

SSL

Example Dimension 1, 2, 3 = axial dimension

TWSW TW

Maß 1

z.b 913mm

SSL SPM SPM SPR

TU TUR

Maß 2

z.b 1437mm

Maß 1

z.b 913mm

Maß 1

z.b 913mm

TUR a

Dimension 1

e.g. 913 mm

Dimension 1

e.g. 913 mm

Dimension 3

e.g. 906,5 mm

Dimension 2

e.g. 1437 mm

1

Marking doors, middle,

side and corner parts

First of all, the dimensions of the front parts

have to be marked on the oor.

Please note the following:

End part

For end parts, the clearance in the drawing

must be added to the width of the end wall connection.

(Example: end section 100 mm, mark 110 mm on

the oor.)

Doors

For doors, add 10 mm to their width.

(Example: Door 600 mm, mark out 610 mm on the oor.)

Middle section

For middle sections, the exact width must be marked.

Corner section

For corner sections the width dimension (see example)

minus 15 mm is marked. This corresponds to the axial

dimension of the end wall. Now the front axle dimensions

are marked.

(Important for the distribution of the middle sections)

side wall

end part left

(corner section) middle parts

end part right

(wall connection)

600

610

200 390 600

610

390 600

610

195

z.B z.B z.B z.Bz.B z.B z.B

For checking:

If the axial dimensions of the front are parallel to the axial

dimensions of the U-proles on the rear wall, the elevation

is OK.

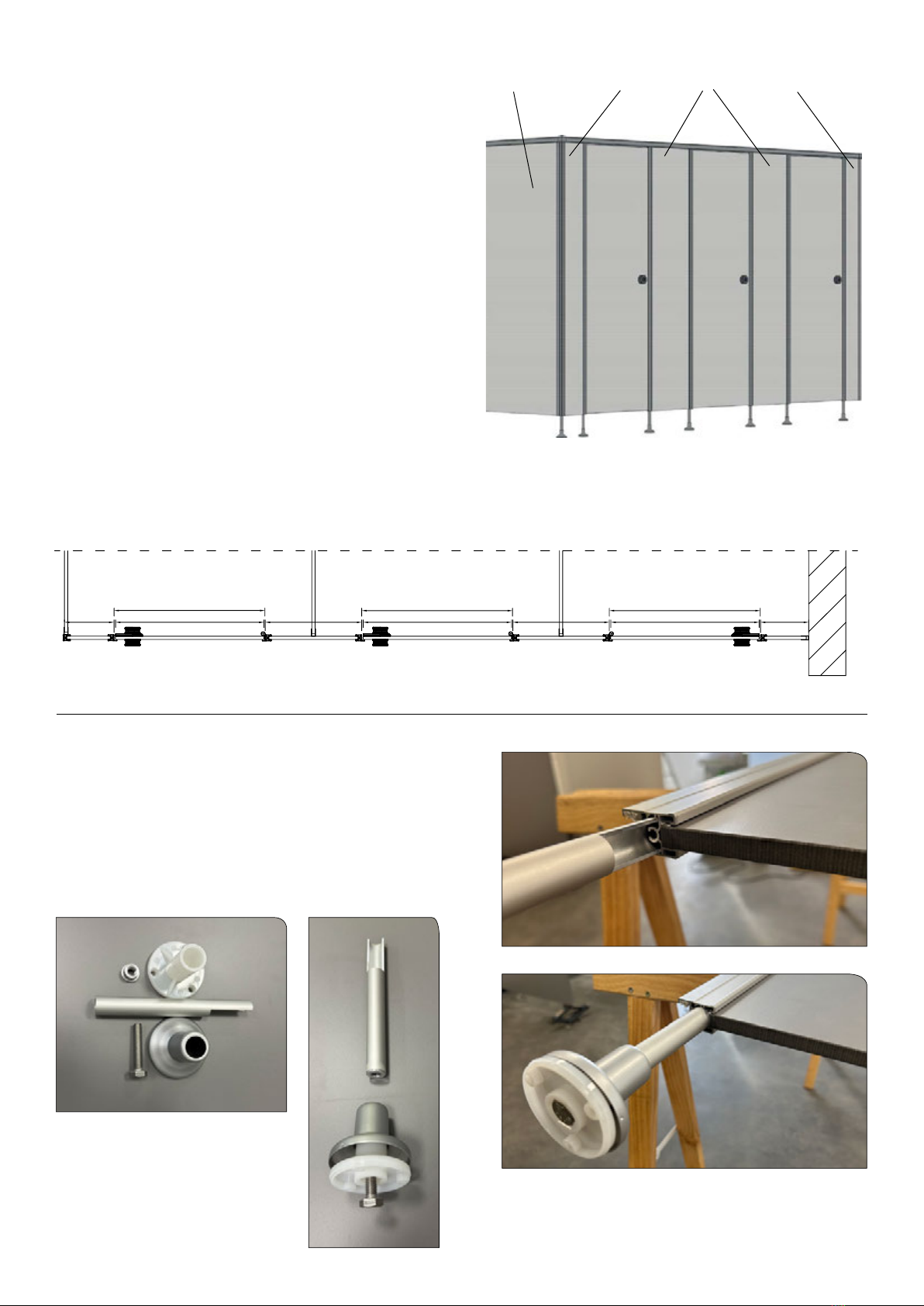

Installing the support feet and rosettes

Fit the support sleeve into the foot tube. Put on the rosette and

the base part and screw in the M10 x 50 screw from below.

Now hammer the foot with the recess into the prole.

2

Setting up the doors, middle-, end-

and corner parts

Place the side part on the marking and insert it into the

U-prole. (please do not screw yet)

For systems with a side wall

screw the U-prole with the recess onto the corner piece using

4,8 x 25 mm screws.

Place the U-prole U-13G (according to the dimensions in the

drawing) ush with the bottom and in the center of the middle

section, mark the drill holes, and fasten the U-prole with

4,8 x 11 mm screws (pre-drill 4,2 mm).

It is imperative that the exact drilling depth of 11 mm is

observed.

Slide the nished middle section onto the partition and fasten it

with 4 x 12 rivets.

Hang the doors, observing the exact door clearance of 5 mm on

the lock side.

The hinges are fastened to the doors with 6 stainless steel

screws 4,2 x 25 mm.

Lubricant should be applied to the screw tips beforehand.

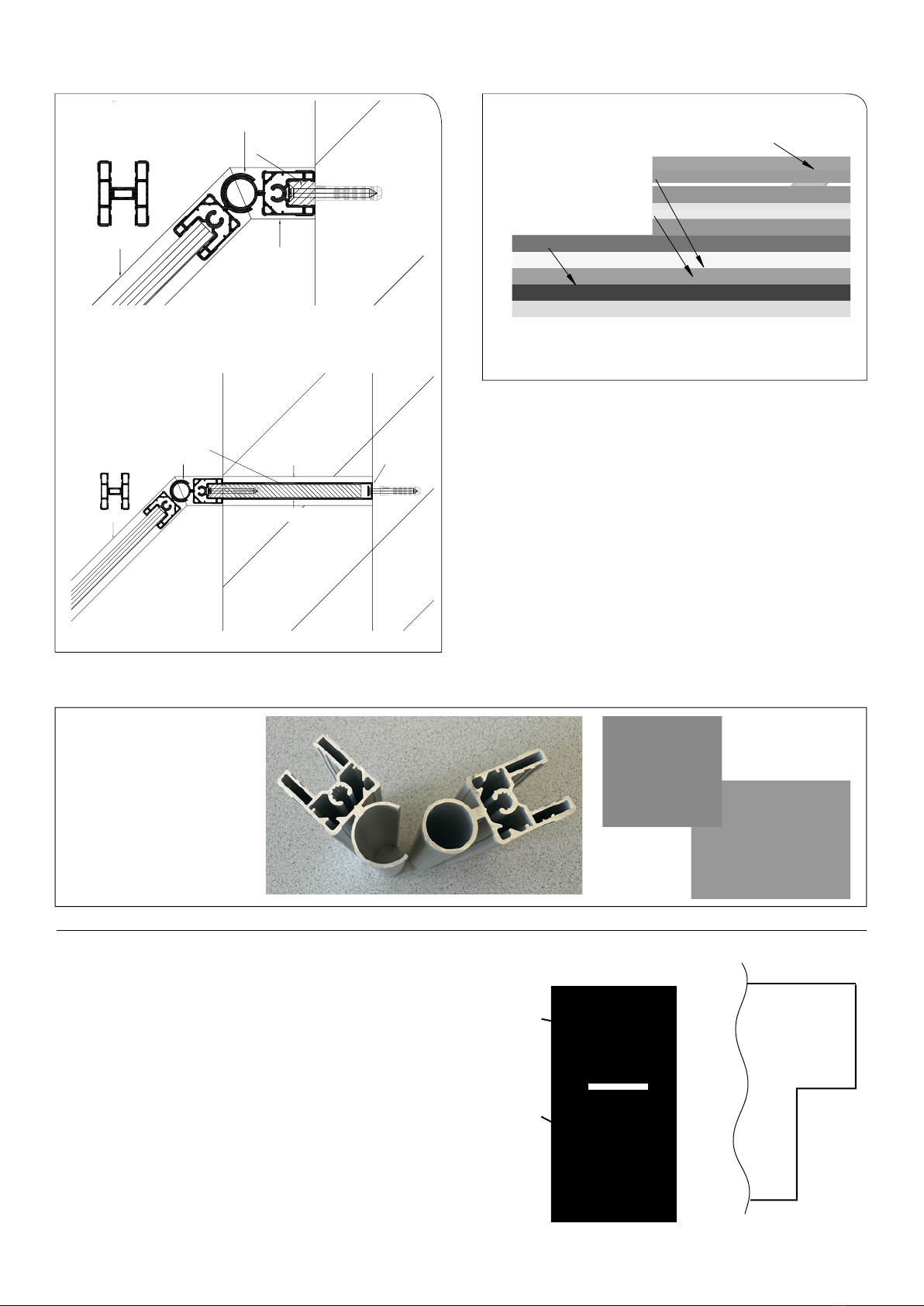

3

upper door clearance lower door clearance

using 5 mm glass blocks

Corner connector

Mounting the cover proles

To determine the exact length of the cover proles (AD13RFK),

place the corner connector on the corners of the front and side

walls. Mark the cover proles and cut to length accordingly.

(Only if SW)

To attach the cover prole (AD13RFK), the holes in the prole

must be drilled in the area of the front so that they t into the

holes in the side, corner and SW proles. To do this, mark the

center of the screw channel on the longitudinal proles, place

the cover prole and transfer the marking.

4

5

Now drill the holes in the center of the front and side

cover proles in the area of the markings using a

6,5 mm diameter drill bit.

In the area of the wall connections, push the cover cap onto the cover prole and position the

proles on the system using the corner connector.

Then fasten the front cover prole from above with

6 x 80 mm screws

Use 4,8 x 28 pan-head screws to fasten

the cover prole above the side wall.

Finally, screw the cover caps with

4,8 x 16 screws from above.

6

Alignment of the system

Check that the door is properly aligned with the prole

and the distance to the upper prole. By raising or

lowering the partition and side walls, the door stop

can be changed.

If necessary, a correction can also be made using the

adjustable support feet.

Screwing and riveting the assembled system

The foot rosettes are usually glued. If screwing to the oor is

desired, push the cover cap (a) upwards and drill diagonally into

the oor through 2 holes of the base plate (b) using a 5 mm drill

bit.

Then insert dowels 5 x 31 mm and fasten with stainless steel

screws 4,8 x 32 mm.Press cover cap (a) onto base plate (b).

a

b

The wall proles must have the same height as the partitions.

The U-proles must butt against each other in the area of the

cover tubes. This may have to be corrected with a block and

hammer. Now rivet the walls and side mirrors with 4 x 12 rivets.

4 per side per prole.

7

Inclined wall connection Angling

If there is facing masonry in the area of the wall connections,

a recess is required. In this case, the procedure remains as

described in “Marking the wall connections”,

but in this case U-proles and at material must be cut.

Recess

Example: system with clearance

U-prole

Flat material

U-prole

A

B

13RF-Eckkabine neu ab 2023 mit schrägem Wandanschluss und Abwinklung

DETAIL A

MAßSTAB 1 : 2

SSR

ABW13RF-B

ABW13RF-A

SW

DETAIL B

MAßSTAB 1 : 2

Füllstück

ABW13RF-B

ABW13RF-A

SW

Wand

AD13RFK läuft über schräge hinweg

A A

B B

C C

D D

E E

F F

G G

H H

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

13RF-neu ab 2023-Eckkabine mit schrägem

Wandanschluss und Abwinklung

D.

Becker

GEWICHT:

A2

BLATT 1 VON 1

MASSSTAB:1:50

ZEICHNUNGSNR.

BENENNUNG:

ÄNDERUNG

ZEICHNUNG NICHT SKALIEREN

WERKSTOFF:

DATUM

SIGNATUR

NAME

ENTGRATEN

UND SCHARFE

KANTEN

BRECHEN

OBERFLÄCHENGÜTE:

WENN NICHT ANDERS DEFINIERT:

BEMASSUNGEN SIND IN MILLIMETER

OBERFLÄCHENBESCHAFFENHEIT:

TOLERANZEN:

LINEAR:

WINKEL:

QUALITÄT

PRODUKTION

GENEHMIGT

GEPRÜFT

GEZEICHNET

A = open

angling prole

B = closed

angling prole

Angle up to 90 to 162

degrees possible.

A B

Schräger Wandanschluß !

ABW13RF-A + ABW13RF-B

AD13RFK

AD13RFK

Füllstück

Schräger Wandanschluß mit Aussparung!

Hier wird eine Blende eingesetzt!

AD13RFK

Beidseitig Flachmaterial

UP13G

ABW13RF-A + ABW13RF-B

AD13RFK

Filler

Inclined wall connection with recess.

An orice plate is inserted here!

Flat material on both sides

8

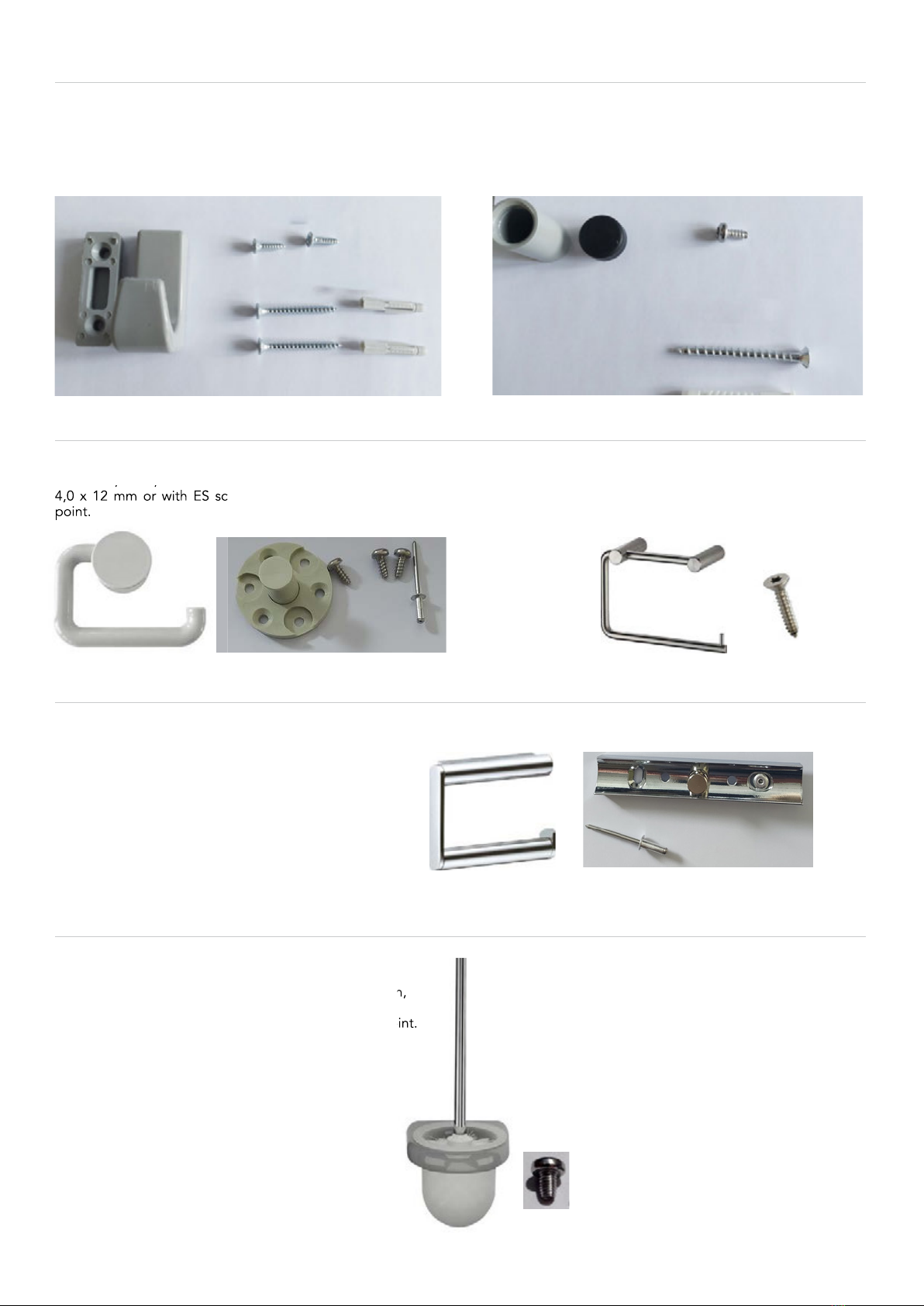

Mounting hook nylon

The hooks are marked and then fastened with 5 mm dowels

and screws 4 x 40. Use screws 3,9 x 13 when fastening to door

or TW. Pre-drill 3,5 mm with stop, max. 11 mm deep.

Then push on the rosette.

Mounting buffer nylon

Mark the buffers at the height of the door handles. Fasten

the bottom parts using an 8 mm dowel and screws 5 x 50

with washer. When fastening to the TW, use screws

4,8 x 11. For this purpose, predrill 4,2 mm with stop,

max. 11 mm deep. Then press on the buffer.

Mounting toilet roll holder

ECO nylon

Pre-drill 4,2 mm, max 11 mm deep. Fastening with rivets

4,0 x 12 mm or with ES screw 4,8 x 11 mm TX25 without

point.

KEUCO

Pre-drill 4,2 mm, max 11 mm deep.

The fastening is done with aluminum blind rivets

4,0 x 12 mm.

Nylon

When fastening to partition or side wall pre-drill 4,2 mm,

max 11 mm deep.

Fastening with ES screws 4,8 x 11 mm TX25 without point.

For masonry wall use screws and dowels.

(are included with the brush).

Pre-drill 4,2 mm, max 11 mm deep. Fastening with rivets

4,0 x 12 mm or with ES screw 4,8 x 11 mm TX25 without

point.

Stainless steel

Pre-drill 4,2 mm, max 11 mm deep.

Fixing with ES screw 4,8 x 22 mm TX25.

When fastening to partition or side wall pre-drill 4,2 mm,

Fastening with ES screws 4,8 x 11 mm TX25 without point.

Mounting toilet brush unit

short screws for 13 mm sheets

long screws for masonry

short screws for 13 mm sheets

long screws for masonry with dowel

dowel 8 x 48 Torx

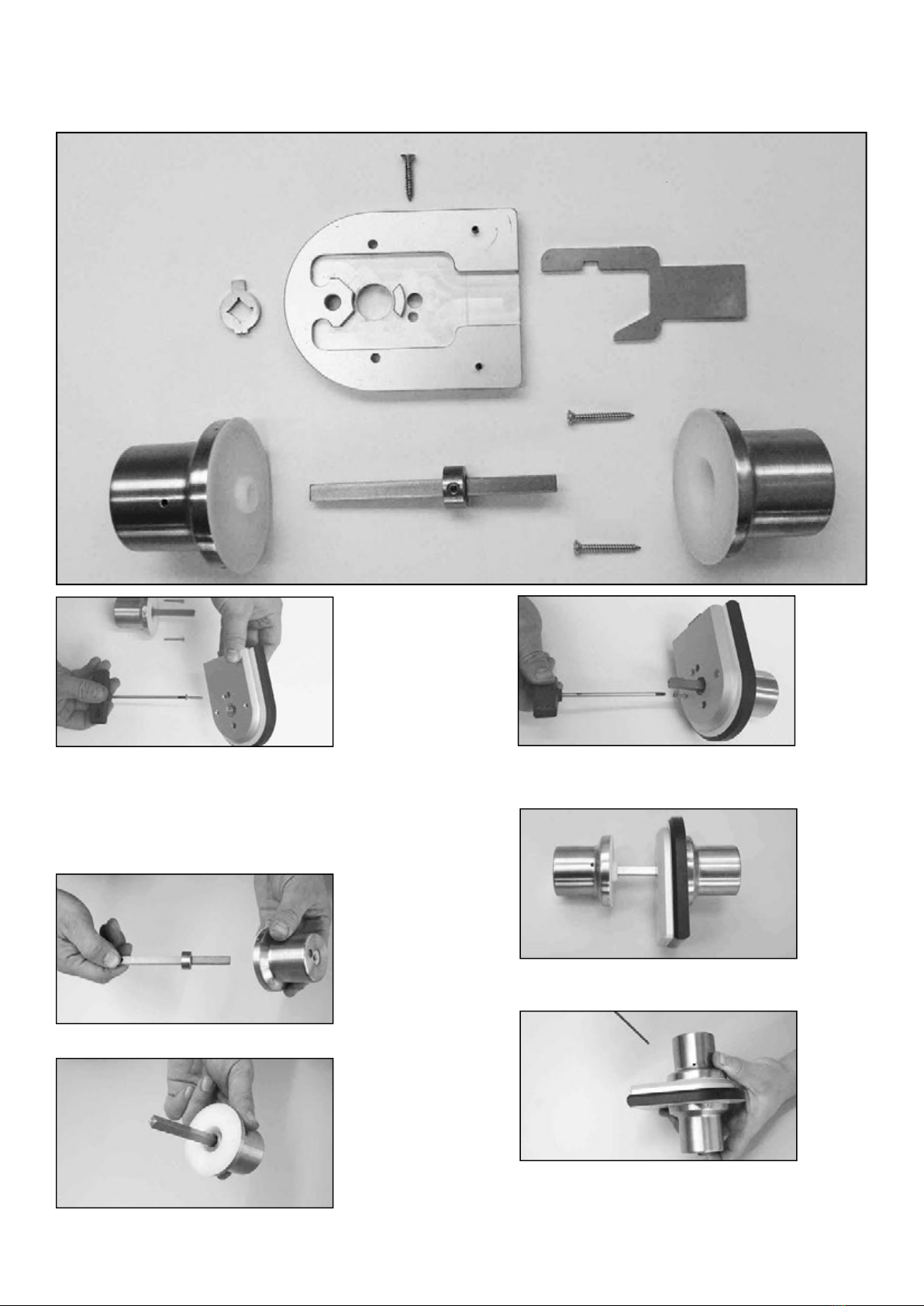

Installation Lock RS1

Always place the lock case on the side after which the door is opened.

First the 2 coiled spring pins (3 x 10 mm, without illustration) must be inserted into the housing (1) with pliers.

(squeeze if necessary)

The base plates of the red/white locking device (2, 3) and the 2 screws 3,5 x 35 (12) must be ready to hand

before attaching the lock case.

Insert the cam (6) with the long tab upwards into the lock case (1) and add the slider (5). Insert this sub-unit with

the dowel pins through the door bore, possibly press together with pliers.

Insert the base plate (3) on the side on which the red/white disc appears later.

Place the base plate (2) on the other side of the door and screw both parts together.

The square (9) is now inserted into the locking knob (7).

This unit is now inserted with the square through the cam

in the lock case and pressed rmly.

Put the red/white indicator (8) with the external emergency release

to the outside on the square pin (9) and then x it by pressing on

the rosette.

The button parts (11) are fastened with the screws (12).

Finally move the cover caps (10) onto the buttons and

check the lock for function.

the following tools are required: Phillips-HP screwdriver

Torx driver 15

small hammer

fully assembled lock

for doors that open

outwards

Installation lock RS2, RS3 the following tools are required: Phillips-HP screwdriver

Torx key 15

small hammer

Allen key 2,5 mm

(1)

(2)

(3)

(5)

(8)

(7)

(6)

(4)

First, the 2 dowel pins (3 x 10 mm, without

illustration) must be inserted into the housing (1).

(possibly press together with pliers)

The housing with inserted slider (2) and cams (3) is

now attached with the 3.9 x 22 screw (4)

(Torx 15) on the side after which the door is opened.

Insert the square pin (6) into the red/white-knob (7)

For doors that open inwards, insert this unit from the

outside through the door and the cam.

Screw it together with 2 Torx-screws 3,9 x 32 (5).

Observe the position of the red/white-indicator!

From the opposite side, slide the knob (8) onto

the square.

With a 2,5 mm allen key, the rotary knob,

is screwed with the red-white-side under

pressure on the square.

Attention! Don`t treat stainless-steel with

acidic cleaner!

Installation lock RS4 the following tools are required: Torx key 15 und 20

Allen key 2,5 mm

Remove foil from lock case (Attention: loose parts)

Put the lock case with 3 mm dowel pins on the door

and fasten it with screw 3,8 x 21. The slider must be in

the lock case. It has to be preparated for DIN R, as shown.

For DIN L the slide and the cam must be ipped.

Insert the square with the red/white indicator

into the display unit. „White“ must be displayed in the

viewing window.

Now insert the knob through the lock case.

The attened side of the square must face down.

The basic part is now attached from the other

side and is screwed with the 2 screws

M5 x 45 (Torx 20), through the lock case, to the

red/white indicator knob.

Put on the turning part. The movement can be

adjusted by pressing the knob and holding the

square on the other side.

Finally fasten the knob with a 2,5 mm Allen key.

Ground part (POM)

(3033)

Indicator part

(3031)

Turned part

(2925) Square with red/white

(3066) und (3142)

Fixing screws

M5 x 45 ES SK DIN 965 (2920)

Lock case xing screw

3,9 x 22 ES SK Tx 15

DIN 7982 (3146)

Lock case

(2148)

Cam

(2103)

Slide

(2127)

12

Keep the door closed.

Remove the cover cap and unloose the setscrew

with a 2,5 mm Allen key.

Tense the springe hinge with a 6 mm Allen key.

If the spring pin is tightened in the door closing

direction, the door closes automatically.

If the door schould open automatically

spring bar must be tightened in the other direction.

Prestress a maximum of 2 grid points.

No more than 120°.

(Risk of spring overload)

Now tighten the setscrew again and t the cover cap.

How to tense spring hinges

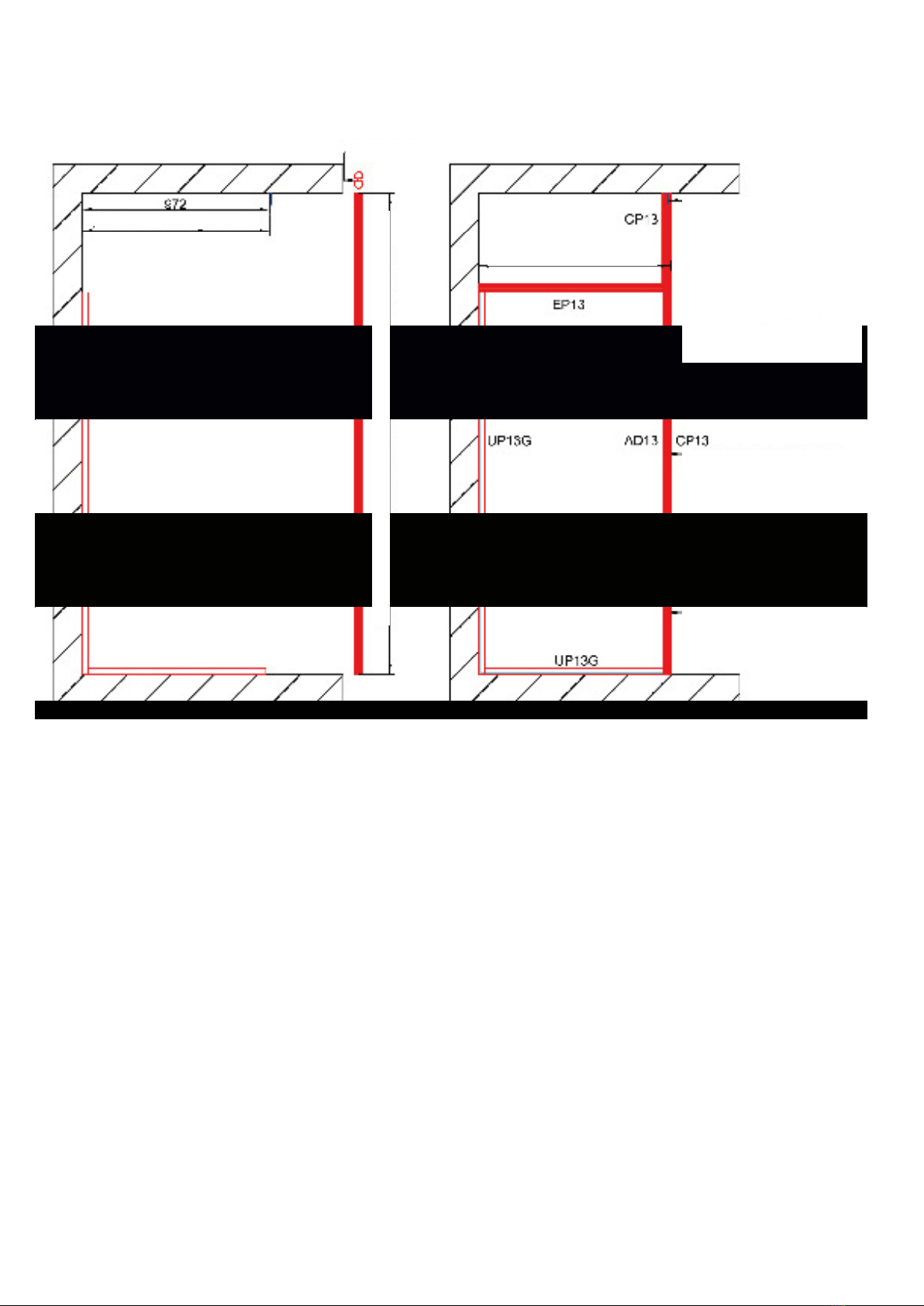

Urinal screens

Aluminium support angle

Type 13 RS without clearance

UP13G

For the oor connection, the UP13G proles

must be cut to the width of the front

elements on site.

They are then screwed to the oor.

Stainless steel

support angle

The mounting materials are included in the scope of delivery in each case.

Example: Floor- and ceiling support with clearance!

Measurements Installed system

Installation procedure

Draw a vertical line with the spirit level at the position where the wall is to be mounted

and mark the holes for the UP13G.

Also mark the two angles at oor and ceiling. Same axial dimension as the UP13G.

Formula: outer dimension -28 mm.

Now drill 8 mm holes and insert dowels 8 x 51 mm.

Fit the UP13G to the specied size using washers and 5 x 50 mm Spax screws.

Mount the two brackets with 5 x 50 mm Spax screws.

Cut the AD13 to length on both heads.

Formula: clear height -2 mm.

The reccesses of AD 13 must face the xed wall.

Place the 13 mm sheet in the U-prole. Place the front part on a wooden block and in the scale.

Now the wall is xed with 4 rivets. Pre-drill 4,0 mm for this.

The AD13 is now screwed to the top and bottom angles with 4,8 x 16 mm screws. Furthermore, the AD13 must be

connected to the 13 mm sheet. Pre-drill 4,2 mm into the plate and screw together with 4,8 x 32 mm screws.

Attention! Drill straight into the plate to avoid tearing!

Now the EP13 is cut to size and glued with silicone (on site). Formula: Outer dimension -45 mm.

Finally, the CP13 are cut to length and inserted.

Recess

Axis measure for angle

Cut the stiffening prole on both sides equally to the length

Fixing AD13 to angle

with 4,8 x 16 mm screws

Fixing AD13 to sheet

with 4,8 x 32 mm screws

Fixing AD13 to sheet

with 4,8 x 32 mm screws

Fixing AD13 to sheet

with 4,8 x 32 mm screws

Fixing AD13 to angle

with 4,8 x 16 mm screws

External dimension 1000 mm

Cut the lower UP13G to length. Formula: Outer dimension -75 mm.

Draw a vertical line with the spirit level at the position where the wall is to be mounted

and mark the holes for the UP13G.

Also mark the angle at the ceiling. Same axis measure as at the UP13G.

Formula: external dimension -28 mm.

Now drill 8 mm holes and insert dowels 8 x 51 mm.

Fit the UP13G to the specied size using washers and 5 x 50 mm Spax screws.

Mount the two brackets with 5 x 50 mm Spax screws.

Cut the AD13 to length on both heads.

Formula: clear height -2 mm.

The reccesses of AD 13 must face the xed wall.

Place the 13 mm sheet in the U-prole. Place the front part on a wooden block and in the scale.

Now the wall is xed with 4 rivets. Pre-drill 4,0 mm for this.

The AD13 is now screwed to the top and bottom angles with 4,8 x 16 mm screws. Furthermore, the AD13 must be

connected to the 13 mm sheet. Pre-drill 4,2 mm into the plate and screw together with 4,8 x 32 mm screws.

Attention! Drill straight into the plate to avoid tearing!

Now the EP13 is cut to size and glued with silicone (on site). Formula: Outer dimension -45 mm.

Finally, the CP13 are cut to length and inserted.

Example: Floor- and ceiling support without clearance!

Measurements Installed system

Recess

Axis measure for angle

Cut the stiffening prole on both sides equally to the length

Fixing AD13 to angle

with 4,8 x 16 mm screws

Fixing AD13 to sheet

with 4,8 x 32 mm screws

Fixing AD13 to sheet

with 4,8 x 32 mm screws

Fixing AD13 to sheet

with 4,8 x 32 mm screws

External dimension 1000 mm

meta Trennwandanlagen • Metastraße 2 • D-56579 Rengsdorf • Tel. +49 26 34 / 66-0 • Fax +49 26 34 / 66 450 • E-mail: [email protected] • Internet: www.meta.de 10/23

Table of contents

Other META Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

SleepSafe Beds

SleepSafe Beds SleepSafe Product Assembly Guide

Safavieh Furniture

Safavieh Furniture Bennet MCR4737 quick start guide

ggm moebel INTERNATIONAL

ggm moebel INTERNATIONAL Coco Manual instruction

Rauch

Rauch M2659 Assembly instructions

RH Baby&child

RH Baby&child WOOD SHADOW-BOX Assembly instructions

Songmics

Songmics LCD871 instructions