CATSKILL 1448 User manual

Other CATSKILL Indoor Furnishing manuals

CATSKILL

CATSKILL 51533 User manual

CATSKILL

CATSKILL 1468 User manual

CATSKILL

CATSKILL 1622 User manual

CATSKILL

CATSKILL 51527 User manual

CATSKILL

CATSKILL 7237 User manual

CATSKILL

CATSKILL 54230 User manual

CATSKILL

CATSKILL 15216 User manual

CATSKILL

CATSKILL 1447-1446 User manual

CATSKILL

CATSKILL 51575 User manual

CATSKILL

CATSKILL 51538 User manual

CATSKILL

CATSKILL 1471 User manual

CATSKILL

CATSKILL 64024 User manual

CATSKILL

CATSKILL 53220 User manual

CATSKILL

CATSKILL 7227 User manual

CATSKILL

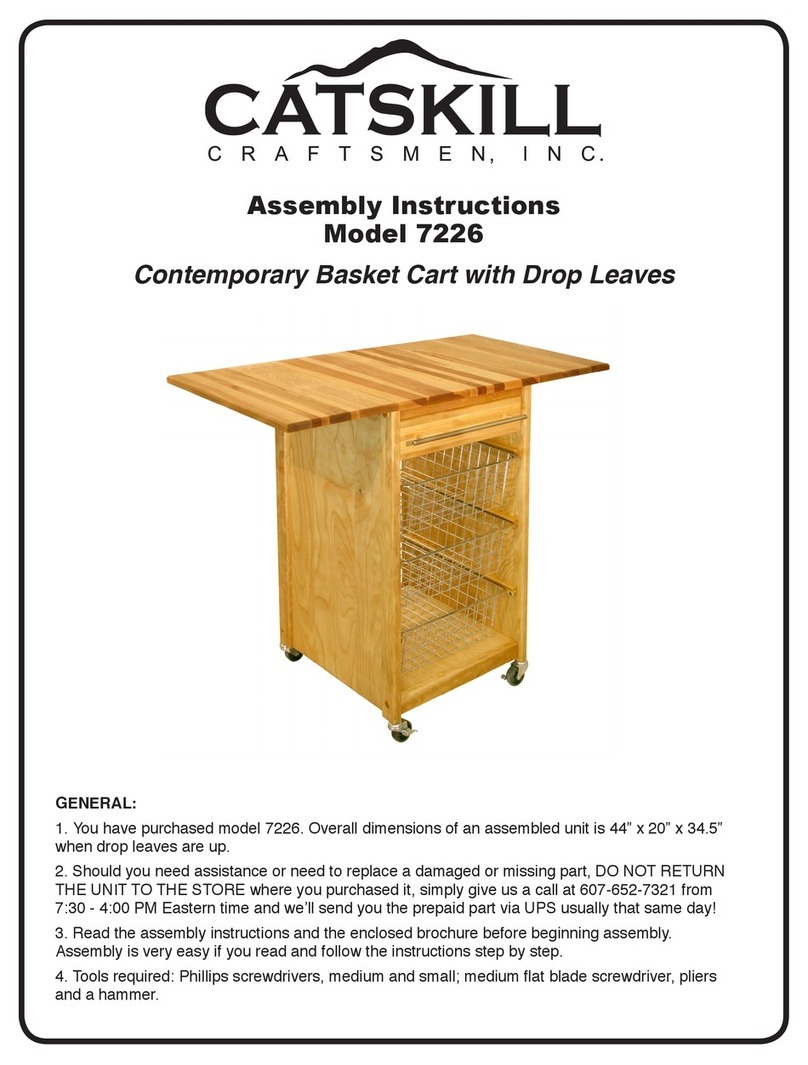

CATSKILL 7226 User manual

CATSKILL

CATSKILL Cuisine Island 1536 User manual

CATSKILL

CATSKILL 1429 User manual

CATSKILL

CATSKILL 2005 User manual

CATSKILL

CATSKILL 1426 User manual

CATSKILL

CATSKILL 15445 User manual

Popular Indoor Furnishing manuals by other brands

Coaster

Coaster 4799N Assembly instructions

Stor-It-All

Stor-It-All WS39MP Assembly/installation instructions

Lexicon

Lexicon 194840161868 Assembly instruction

Next

Next AMELIA NEW 462947 Assembly instructions

impekk

impekk Manual II Assembly And Instructions

Elements

Elements Ember Nightstand CEB700NSE Assembly instructions