2

The liner should terminate with the lowest discharge opening no closer

to the roof than the minimum height shown in the table below. These

minimum heights may be used provided the vent is not less than 8 ft.

(2.4 m) from any vertical wall.

Roof Pitch Minimum Height

Flat to 6/12 1.0 foot (305mm)

6/12 to 7/12 1.25 feet (380mm)

Over 7/12 to 8/12 1.5 feet (451mm)

Over 8/12 to 9/12 2.0 feet (610mm)

Over 9/12 to 10/12 2.5 feet (762mm)

Over 10/12 to 11/12 3.25 feet (991mm)

Over 11/12 to 12/12 4.0 feet (1218mm)

Over 12/12 to 14/12 5.0 feet (1524mm)

Over 14/12 to 16/12 6.0 feet (1829mm)

Over 16/12 to 18/12 7.0 feet (2134mm)

Over 18/12 to 20/12 7.5 feet (2286mm)

Over 20/12 to 21/12 8.0 feet (2438mm)

GENERAL:

MLK and MLKE gas vent lining systems are listed by UL & ULC for

installation at zero clearance to the inside masonry surface and with

zero clearance from the outside surface of the masonry chimney and

surrounding combustible material.

Do not place insulation or other materials in required clearance spaces

surrounding the liner unless otherwise specied.

Use only parts referenced in the these instructions when installing a MLK

or MLKE liner system. Never substitute liner material.

Rain caps and ashing must be used to prevent moisture from entering

the liner and entering the space between liner and chimney. Bird screens

on rain caps may be necessary and/or required in some areas but could

be susceptible to blockage through freezing moisture. Consult authority

having jurisdiction before using bird screen.

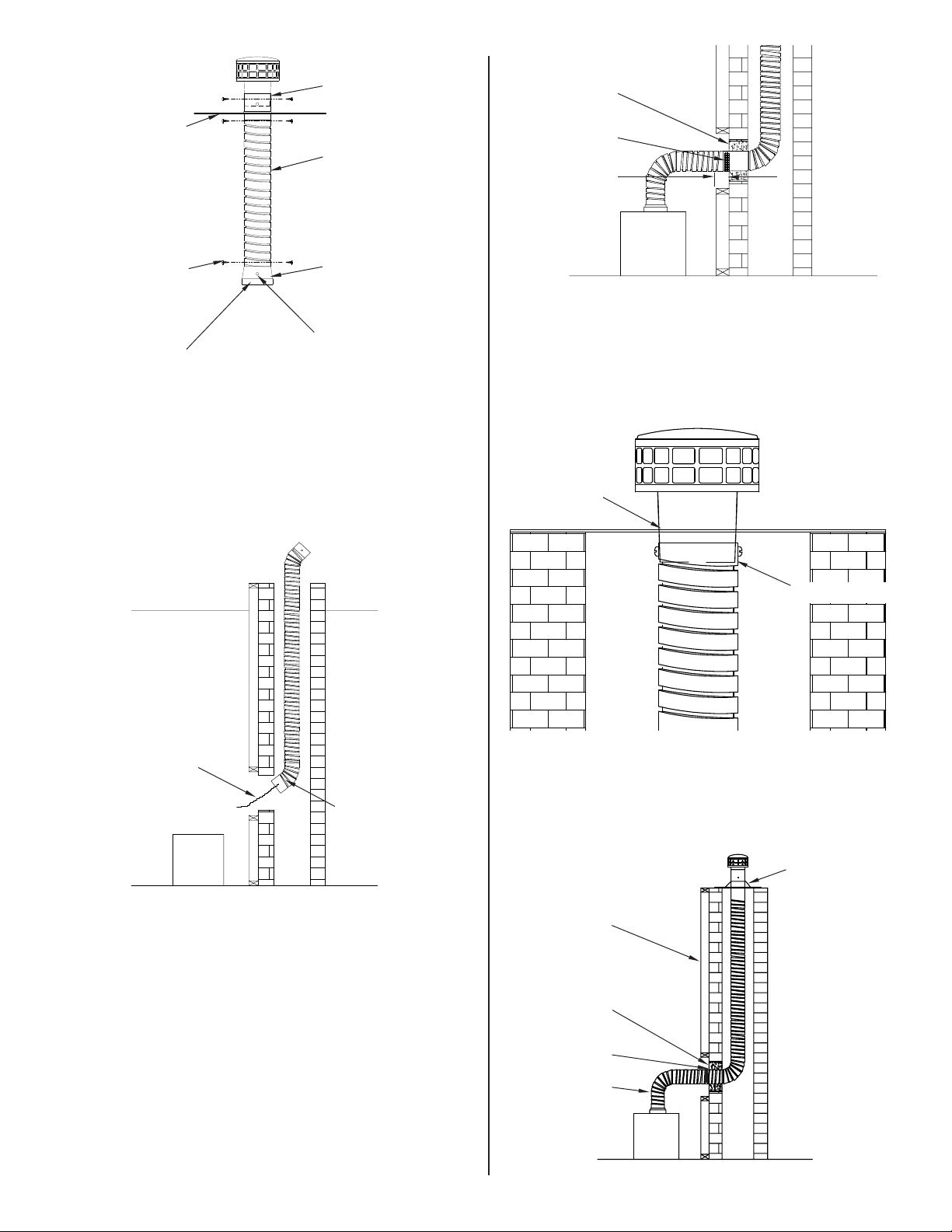

Metal-Fab MLK liners may be extended from the outlet (top), to the cap

using Type-B gas vent. MLK and MLKE liners may be extended from

the inlet (bottom) to the appliance using exible MLCK connectors (See

FIG. 6 & 8).

Metal-Fab MLK and MLKE liners may be connected continuously from

the appliance to the termination cap, provided that the liner is always

in an unenclosed space or is within a masonry chimney, factory built

chimney, or Type-B gas vent.

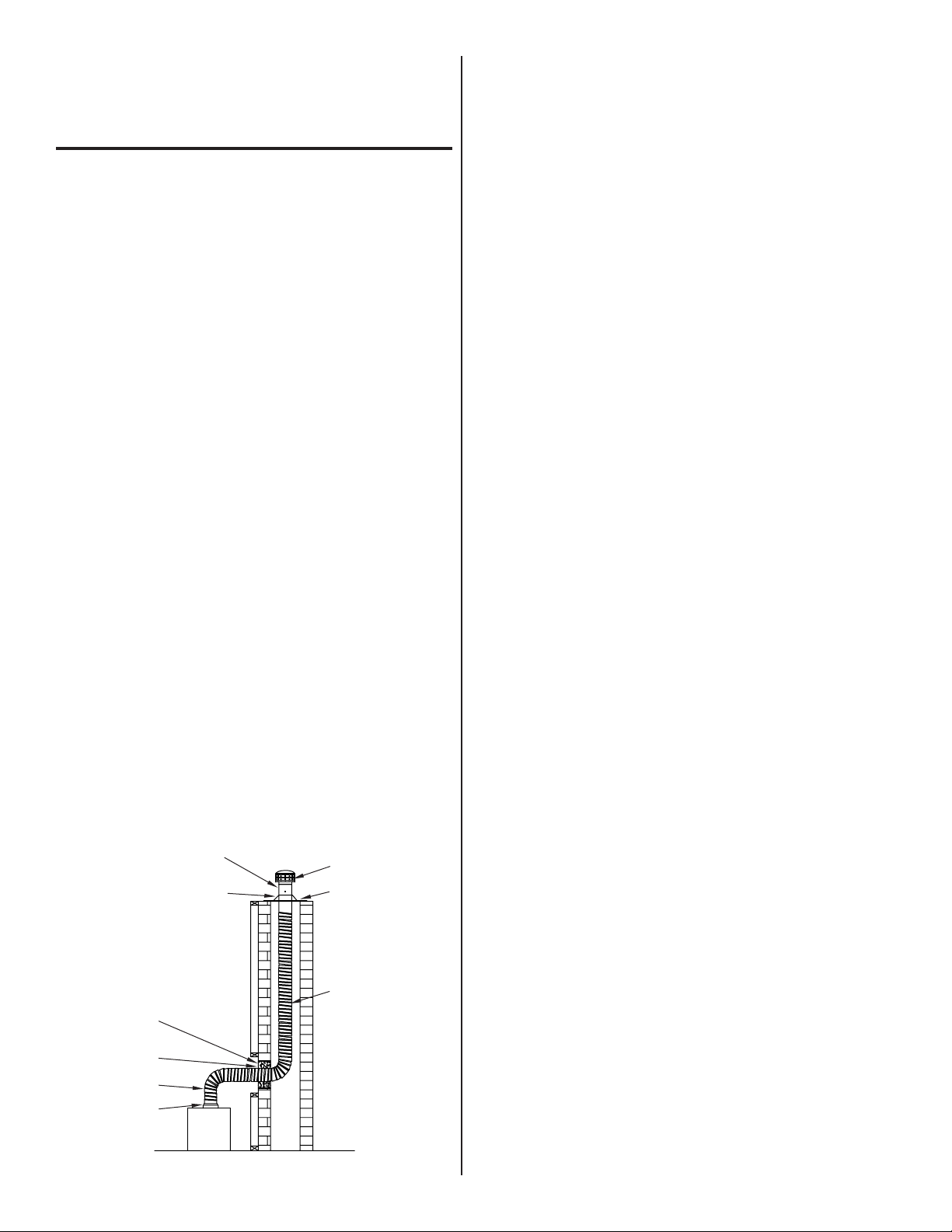

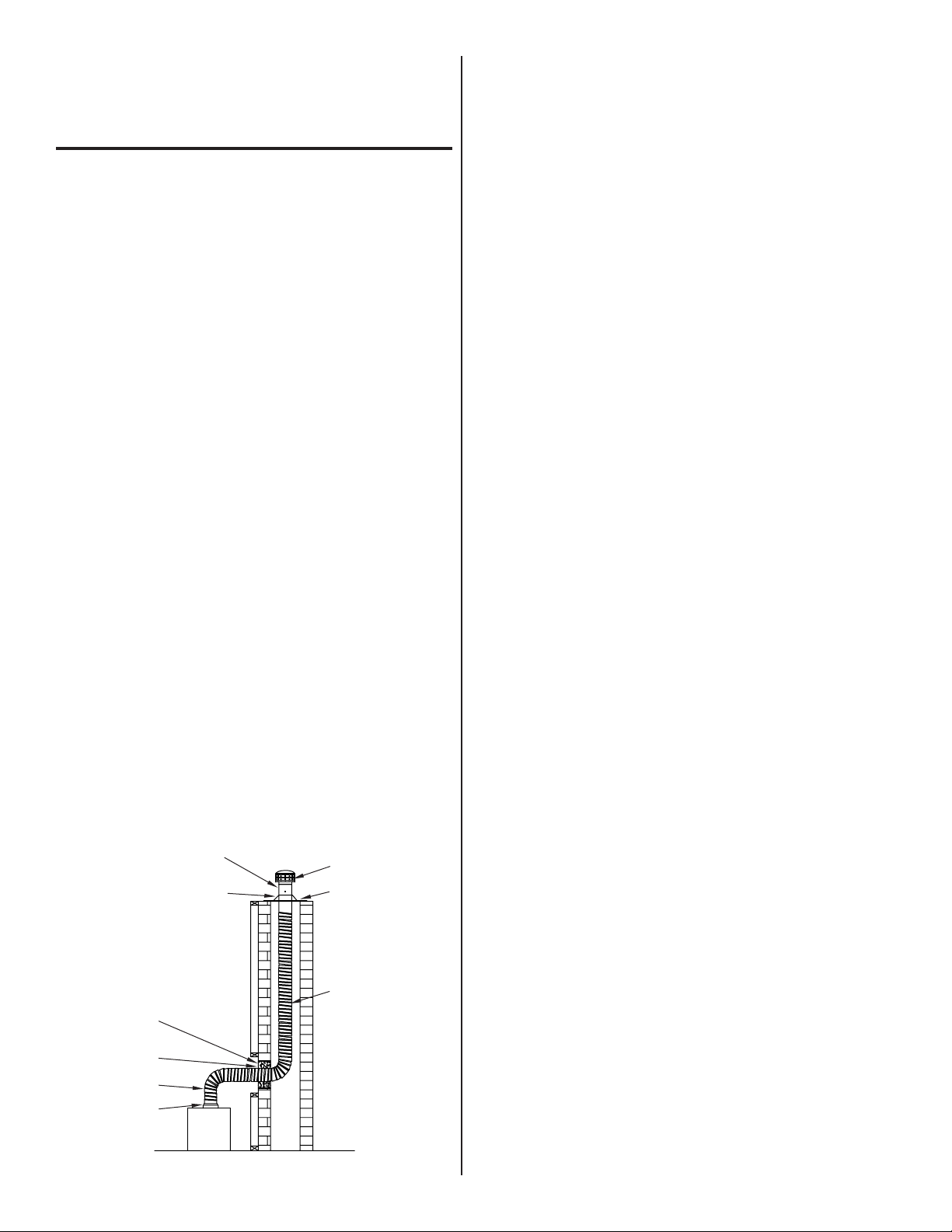

CONNECTOR

(MLK ONLY)

STORM COLLAR

(MLK ONLY)

CAP

FLASHING

FLEXIBLE LINER

NON-COMBUSTIBLE

FILLER MATERIAL

MORTAR GUARD

FLEXIBLE LINER

APPLIANCE OUTLET

(CONNECTOR

COLLAR NOT

PROVIDED)

APPLIANCE

FIG. 1

These liner systems are NOT listed as Type-B gas vent and are

not intended to pass through any wall, ceiling, attic, crawl space or

other combustible area. A liner that is used as a connector in open

and unenclosed space must be installed with minimum clearance to

combustibles, in accordance with NFPA 211. The appliance to which the

exible liner is connected shall be listed gas-red appliance equipped

with a draft hood or other appliance listed for use with Type-B Vent.

To size the liner system, follow the Category 1 venting table now

contained in the National Fuel Gas Code NFPA 54/ANSI Z223.1 in the

USA or CAN CSA-B149.1 in Canada. Be certain to follow the capacity

reduction directions for the corrugated metallic chimney liner systems.

While installing exible liner, consideration should be given to the

following: 1) make no unnecessary bends 2) make no bends greater

than 90° 3) make bends as smooth as possible, with no dips or sags and

4) install with at least a 1/4” per foot rise.

Before installing liner authorities having jurisdiction (such as Gas

Inspection Authority, Municipal Building Department, Fire Department,

Fire Prevention Bureau, etc.) should be consulted to determine the need

to obtain a permit.

The installer must post the completed date of installation notice at the

point where the connection is made to the appliance. This notice shall

include date of installation, the manufacturer’s name, the model number

and class of lining system, and a reminder to homeowners to check the

rain cap for icing during low ambient temperatures.

INSTALLATION:

1. MLK/MLKE: Determine the length of the liner needed by dropping a

pre-measured length of rope or other measuring device down the

chimney. If the liner is to mate directly to an appliance, measure all

the way to the appliance. Otherwise, measure to a point that is just

outside of the chimney that is being re-lined.

2. MLK/MLKE: If installing the liner into a masonry chimney, determine

the location of the point where the ex system will penetrate the

masonry sidewall. This opening must be located above the appliance

outlet. It is recommended that you install an inspection/cleanout

door on the opposite side of the chimney, if conditions permit.

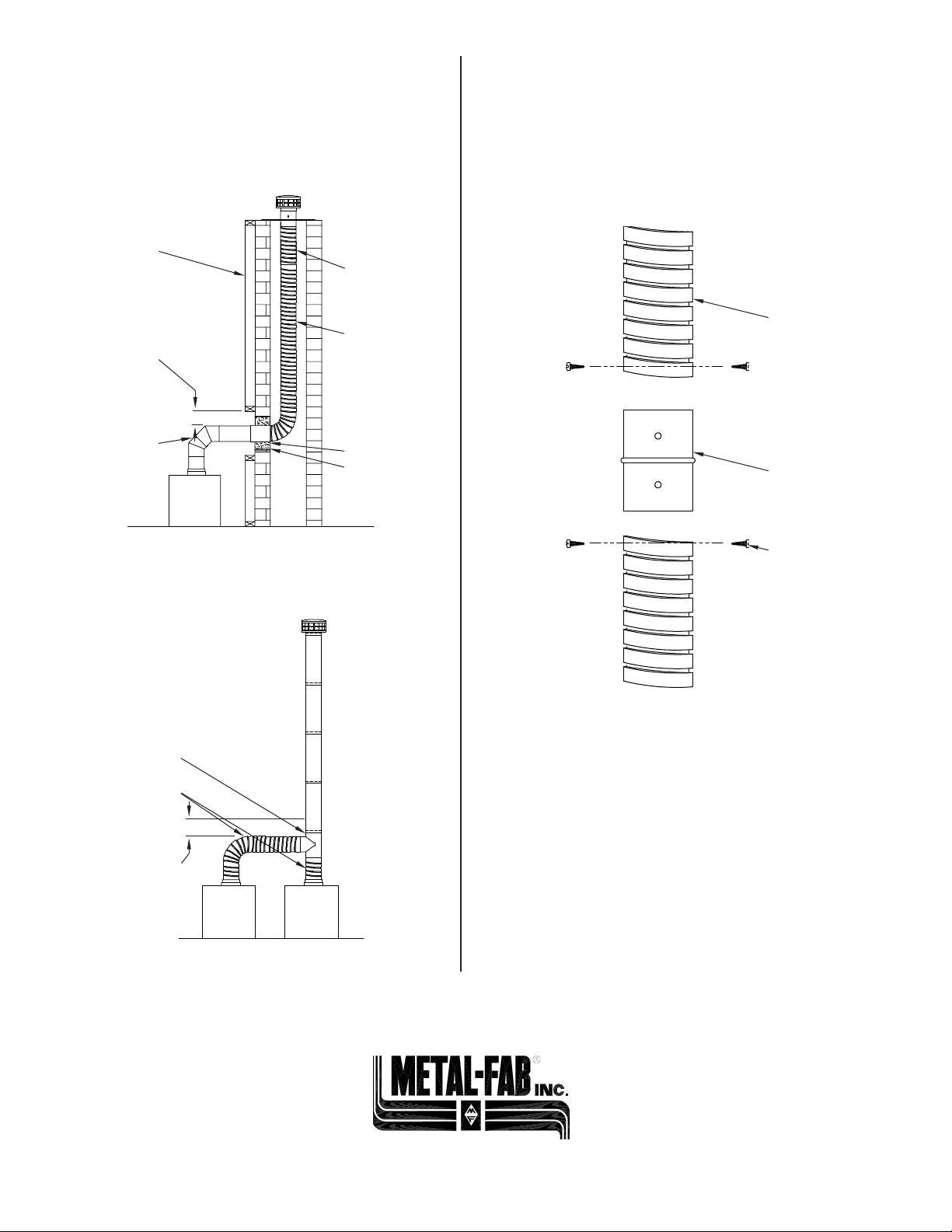

3. MLK/MLKE: To congure the liner to it’s proper length, remove the

liner from the carton. One person (wearing gloves) is to securely

grasp one end of the liner while the second person (also wearing

gloves) pulls and stretches the liner from the other end. Both persons

should be on level ground when stretching the liner. Pull and stretch

to the required length, being careful not to over-stretch the liner.

NOTE: For shipping purposes, the exible liner has been

compressed to approximately 1/3 it’s usual length. A

25-foot (7.62 m) length will be approximately 8 feet

(2.44 m) in the carton. For taller chimneys two lengths of

liner can be joined together (See Flex Extension on

Page 4).

4. MLKE Only: While still on level ground, press a termination into the

ashing until the tapered termination collar makes contact with

ashing. Attach one end of the exible liner to the portion of the

termination protruding below the ashing (use 3 ea. screws

provided). Attach sleeve/connector to the inlet (bottom) end

of the exible liner (use 3 ea. screws provided). Temporarily

attach a bolt through the holes that are provided in the sleeve

connector to serve as a pull bar. You are now ready to lower the ex

into the chimney from the top down (See FIG. 2).

5. MLK Only: This liner has a B-Vent style connector

pre-attached to the outlet (top) end of the ex and a stainless

steel slip connector pre-attached to the inlet (bottom) end.

You are now ready to lower the ex into the chimney from

the top down.