Metal Fab Temp/Guard User manual

2100°TEMP/GUARD CHIMNEY

SIZES 6” - 7” - 8” - 10” - 12”

TEMP/GUARD®

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

This symbol on the nameplate

means this product is listed by

Underwriters Laboratories Inc.

Listing No. MH 8251

Tested to 103 HT

A MAJOR CAUSE OF CHIMNEY RELATED FIRES IS FAILURE TO MAINTAIN

REQUIRED CLEARANCES (AIR SPACES) TO COMBUSTIBLE MATERIAL.*

MINIMUM CLEARANCE FOR 6” - 8” TEMP/GUARD IS ONE AND A HALF

(1-1/2) INCHES. MINIMUM CLEARANCE FOR 10” - 12” TEMP/GUARD IS

TWO (2) INCHES. IT IS OF UTMOST IMPORTANCE THAT THIS CHIMNEY

IS INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

WARNING: FOR SIZES 6”, 7” & 8” CHIMNEY, MINIMUM CLEARANCE TO COMBUSTIBLE

MATERIAL MUST BE TWO (2) INCHES UNLESS ALL CHIMNEY COMPONENTS ARE

LABELED TG MAX.

*Combustible material is dened as material made of, or surfaced with, wood, compressed paper, plant bers,

plastic, or other material that will ignite and burn, whether ame proofed or not, or whether plastered or unplastered.

The Metal-Fab Temp/Guard Chimney is intended for use on any residential and building heating appliance burning gas,

liquid or solid fuels such as replace stoves, furnaces, ranges, room heaters, or as dened in columns I and II, Table

2-2.1, NFPA 211. Contact Local Building or Fire Ofcials about restrictions and Installation Inspection in your area.

WARNING: Metal-Fab Temp/Guard Chimney is not designed for use on products that operate at continuous

temperatures in excess of 1,000°F.

WARNING: If decorative shrouds are being used with Temp/Guard Chimney, Reference the Temp/Guard Addendum L2372.

IMPORTANT: FOR OIL OR COAL BURNING APPLIANCES, OUTSIDE THE ENVELOPE OF THE BUILDING, USE ONLY PIPE WITH

STAINLESS STEEL CASING, ALSO USE FLASHING OR STORM COLLARS CONSTRUCTED OF STAINLESS STEEL OR ALUMINUM.

OPERATIONAL PRECAUTIONS

• Maintain 1-1/2” minimum clearance to combustibles for 6”- 8” diameters and 2” minimum clearance to combustibles

for 10”-12” diameters (Refer to WARNING above). Use only U.L. Listed products and INSTALL ONLY IN

ACCORDANCE WITH MANUFACTURER’S INSTRUCTIONS.

• Formation of Creosote and Soot and the need for removal.

When wood is burned slowly, it produces tar and other organic vapors, which combine with expelled moisture to

create creosote. The creosote vapors condense in the relatively cool chimney ue of the slow burning re. As a

result, creosote residue accumulates on the ue lining. When ignited, this creosote makes an extremely hot re.

The chimney should be inspected at least once every two (2) months during the heating season to determine if

a creosote or soot buildup has occurred. If creosote or soot has accumulated, it should be removed to reduce

the risk of chimney re.

• Do not use replace for food grill. Grease from foods can collect in chimney causing replace to become a potential re

hazard.

• On airtight stoves, open dampers and let equipment burn hot for 15 to 20 minutes. This should be done every time fuel is added.

This lessens the chance of creosote buildup.

• Some chemical chimney cleaners can be harmful to the chimney. These cause accelerated oxidation or corrosion.

If chemical cleaners are used, they must be non-corrosive in nature. If brush is used, it must be of proper size with

plastic bristles.

PAINT TOUCH-UP

• The at-black paint used on painted parts may be touched up,as required, with Stove Bright®Product No. 1990.

2

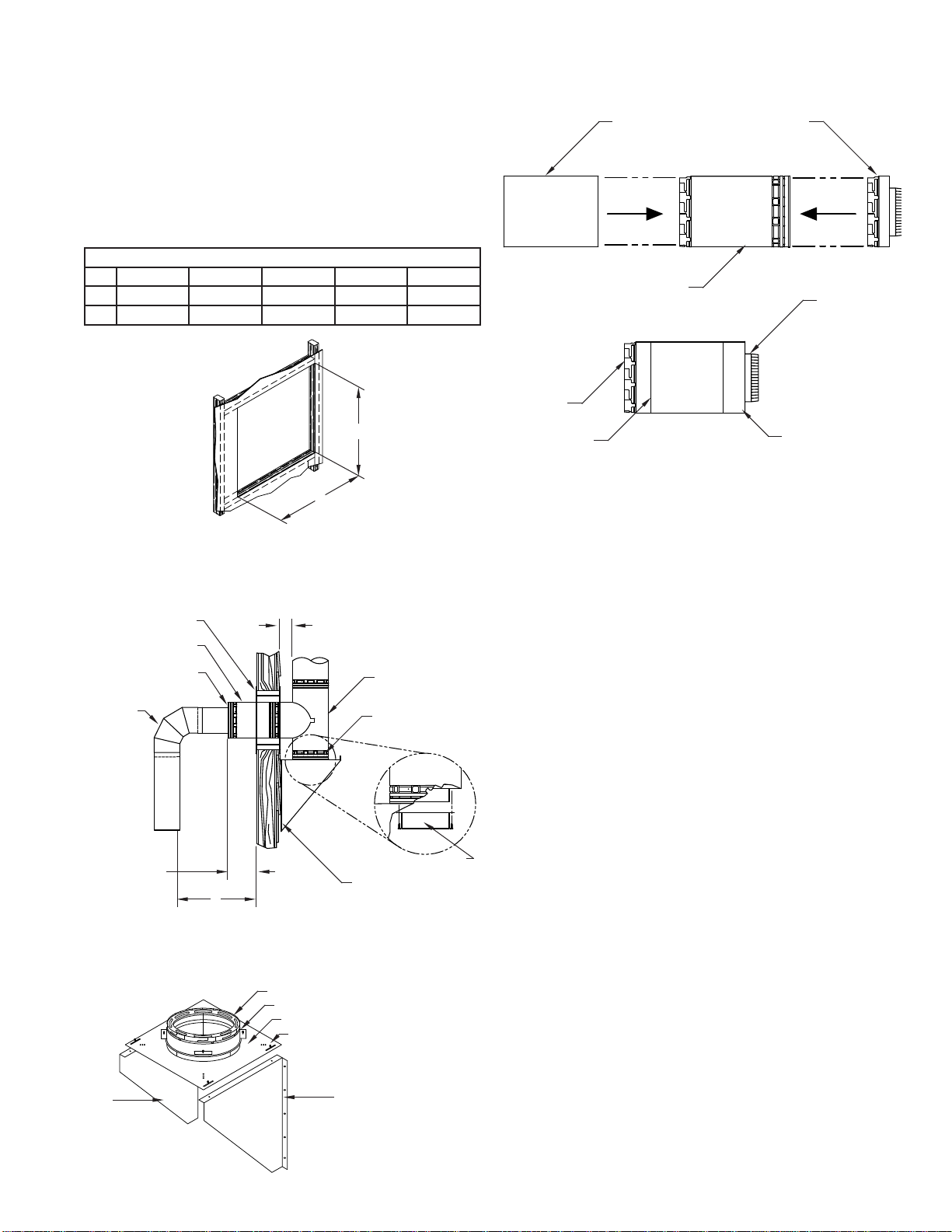

INSTALLATION THROUGH FLAT

CEILING(S)

1. From the appliance manufacturer’s instructions, determine

the correct ue diameter for the chimney, and proper

location of the chimney.

2. Using framing lumber equal to ceiling joist size, frame ceiling

opening as shown in FIG. 1 and TABLE 1.

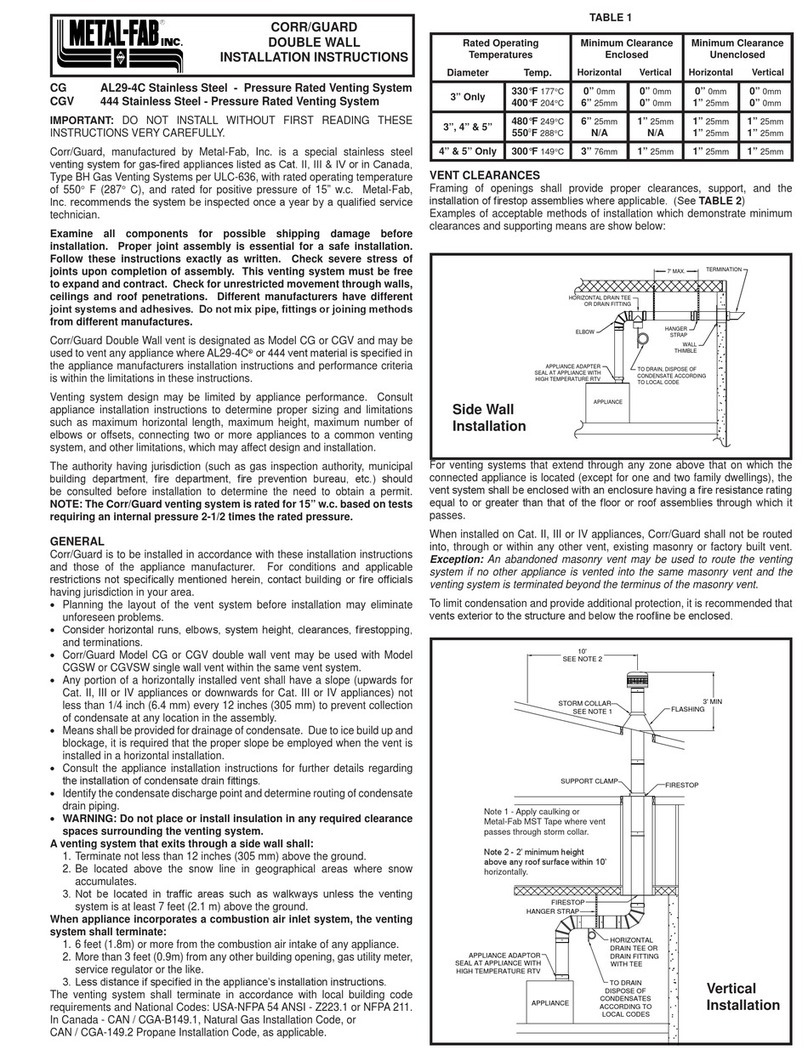

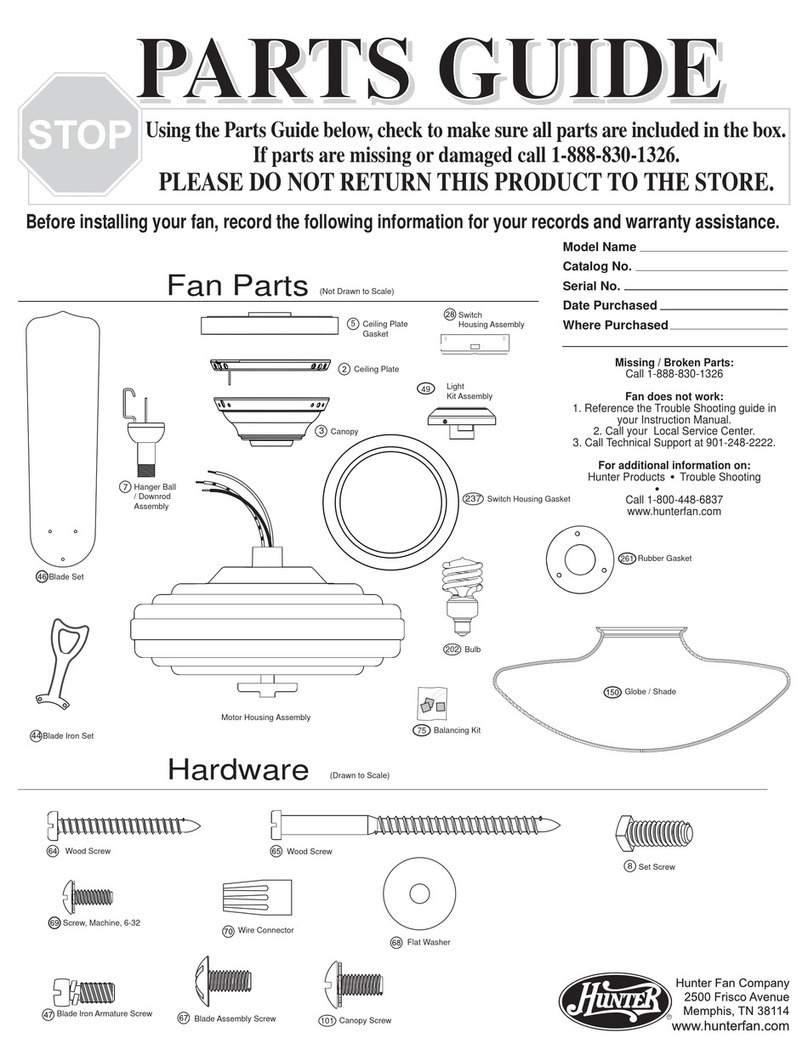

TABLE 1

CHIMNEY FLUE DIAMETER

6” 7” 8” 10” 12”

A 12-7/16” 13-7/16” 14-7/16” 17” 19”

B 12-7/16” 13-7/16” 14-7/16” 17” 19”

NOTE: If possible, it is recommended that the chimney be

located in such a manner as to not cut the ceiling joist. For

the 8TG chimney, design and testing allows the clearance to

combustibles to be 1½ inches through the ceiling joist (using

the 8TGCSP) and through the roof joists. The chimney can be

centered between joists on 16 inch centers in these areas.

3. As shown in FIG. 2, insert the Ceiling Support (TGCSP)

from below until the anged edges are rmly against the

ceiling drywall. Secure into framing with eight (8) 8-penny

nails inserted through the sides of the ceiling support. If

the TGCSP was installed during construction and drywall

now covers the anged edges, install Metal-Fab’s ceiling

support trim kit (TGCST), as shown in FIG. 3.

4. Single wall or double wall connector pipe may now be

installed between the appliance and the ceiling support.

(See FIG 2.)

If the area above the ceiling is an attic, go to step 7.

5. Proceed to the next ceiling. If Metal-Fab Elbows are to

be used because the chimney is to be offset, refer to

“Installation of Elbows” section. Directly above the

Center of the ue in the ceiling support, mark the ceiling. A

plumb bob is normally used to nd the center. Cut an

opening in the ceiling using FIG. 1 and Table 1.

6. Install Temp Guard chimney sections starting at the TGCSP.

Secure the sections by pushing together and twisting until

stop-locked (See FIG. 3a). Additional chimney sections

may be added to maximum height of 60 feet. At

each additional ceiling, a restop (TGFSA) is required.

Insert the TGFSA into the joist area prepared in step 5.

Continue this process for each oor level until the area

above the attic.

NOTE: When the chimney extends between oors, which

can be occupied, the chimney must be enclosed to

prevent contact. As previously noted, 1-1/2” clearance

to combustibles for 6”- 8” diameters and 2” clearance to

combustibles for 10” to 12” diameters is to be maintained,

except within the joist area controlled by the TGCSP.

7. The rst chimney section through the joist area into attic is

to be approximately two (2) feet. If the pipe sections in the

attic are not enclosed, an insulation shield (TGIS) must be

installed. Lower insulation shield (TGIS) over TG pipe until

the ange is resting on the joist. Secure the TGIS in place

by nailing the ange to the joist. See FIG. 4. If the section

within the attic area is to be chase enclosed, the TGIS is

not required.

8. Continue the chimney to the roof. See “Flashing Installation”

and “Termination” sections.

L944 FIG03A

B

A

FIG. 1

Framing lumber of

equal size to the joist should be used.

L944 FIG02

PROPER CLEARANCE TO

COMBUSTIBLES WITHIN JOIST

AREA CONTROLLED BY TGCSP

CHIMNEY PIPE

(CAT. NO. TG)

CEILING DRYWALL

FLANGED EDGE

SINGLE OR

DOUBLE WALL

CONNECTOR PIPE

ATTACH TO

TGCSP WITH

SCREWS

CEILING

SUPPORT

(CAT. NO. TGCSP)

FIG. 2

L944 FIG03

CEILING

DRYWALL

FLANGE

COVERED

BY DRYWALL

CEILING

SUPPORT TRIM

(CAT. NO. TGCST)

FIG. 3

TWIST LOCK JOINT

FIG. 3a

L944 FIG04

FIG. 4

INSULATION SHIELD

(CAT. NO. TGIS)

NAIL

FIRESTOP

(CAT. NO. TGFSA)

3

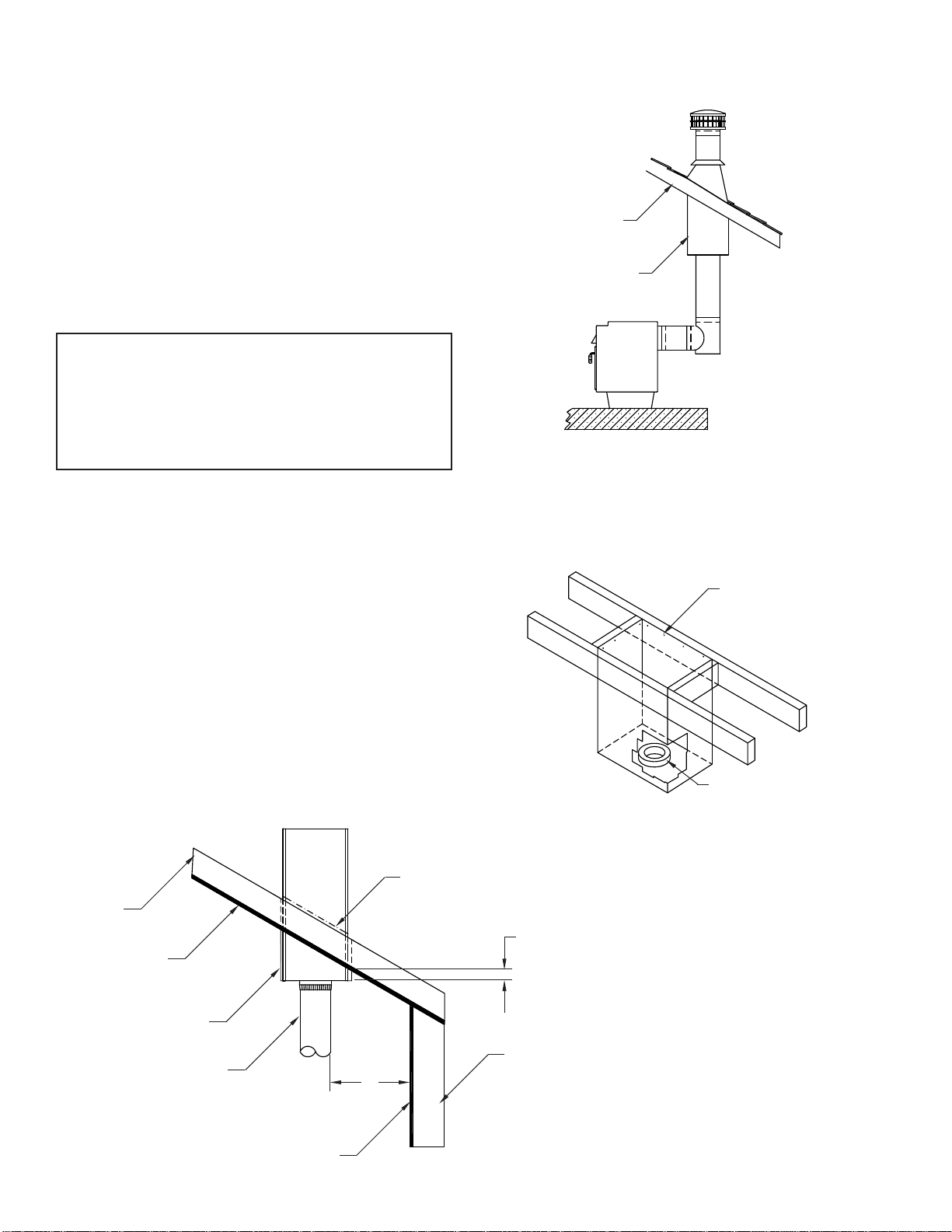

INSTALLATION THROUGH SIDE WALL

1. Locate the area where the chimney section is to penetrate

the vertical wall. Cut and frame an opening so that

the ue is centered between the vertical wall studs on 6”,

7” and 8” systems. Note that 10”, and 12” systems may

require relocation of wall studs to maintain 2” clearance

to combustibles. Consult local authorities if structural

modications are required. Frame opening per FIG. 5 and

Table 2.

TABLE 2

CHIMNEY FLUE DIAMETER

6” 7” 8” 10” 12”

A 12-7/16” 13-7/16” 14-7/16” 17” 19”

B 13” 14” 15” 17” 19”

2. A wall restop (TGWFSP) must be installed in framed

opening from the outside. Push remaining half through

opening from inside until plate is ush. Use four (4) #10 x

2 ½” wood screws to attach to opening. (See FIG. 6).

3. Remove wall support adaptor from TGWS box and attach

adaptor to bottom of tee by inserting into bottom of tee and

rotating to lock.

4. Insert the side tap of the tee into the opening in the wall

restop.

5. Assemble right and left gusset to support plate using

hardware provided.

6. Attach wall support plate to wall support adaptor using 4

clamps provided. Do not tighten. (See FIG. 6a).

7. Align wall support with wall and secure to wall studs using

5/16” x 2” lag screws (not provided). DO NOT SECURE TO

SIDING. For masonry walls, use 5/16” x 2” masonry lag

bolts.

8. Install tee cap to bottom of wall support adaptor with a

minimum of two (2) #10 x ½” sheet metal screws.

9. Position tee and adapter on wall support to maintain

2” clearance to combustibles. TIGHTEN CLAMPS.

10. Slip a trim sleeve joint cover (TGTS) over the male end of

TG pipe that is to reach through the wall restop to the tee.

Attach single wall adapter (TGPSWA) to the female end of

TG pipe and slip TGTS ush to the end of TGPSWA. (See

FIG. 7a and 7b.)

11. Slide Metal-Fab chimney pipe into top of tee. Align male

and female ends. Push down on pipe sections and turn

clockwise to lock. Additional chimney sections are added

and locked to a MAXIMUM OF 60 FEET. As sections are

added, it will be necessary to secure them to the outside

wall with bands (TGWB) at eight-foot intervals and 2” from

combustibles. Wall bands (TGWB) are secured to the

chimney by placing band around the chimney and tightening

clamping bolt. The assembly is anchored to the wall studs

(not the siding) with 5/8” x 2” lag bolts. To complete the

chimney installation, see “Flashing Installation” and

“Termination” sections.

A

B

FIG. 5

L944 FIG06A

LEFT

GUSSET RIGHT GUSSET

(ATTACH GUSSETS TO

WALLSTUDS USING 5/16”

X 2” LONG LAG SCREWS)

WALL SUPPORTADAPTOR ASSEMBLY (1 EA.)

CLAMPS (4 EA.)

SUPPORT PLATE (1 EA.)

10-32 HEX NUTS & MACHINE SCREWS

SUPPLIED WITH TGWS (8 EA.)

TGTS TGSWA

TG PIPE TGSWA

ALIGN FLUSH WITH

EDGE OF TGSWA

TG PIPE

TGTS

FIG. 7b

FIG. 7a

AIR CLEARANCE 2”

TO COMBUSTIBLES

CHIMNEY TEE

(CAT. NO. TGT)

WALL SUPPORT

ADAPTOR

WALL SUPPORT

(CAT. NO. TGWS)

TEE CAP SUPPLIED

WITH TGT

WALL FIRESTOP

(CAT. NO. TGWFSP)

CHIMNEY PIPE

(CAT. NO. TG)

SINGLE WALL

ADAPTOR

(CAT. NO. TGSWA)

SINGLE OR

DOUBLE

WALL BLACK

STOVE PIPE

6 INCH MIN.

THRU WALLS L

L=18” FOR SINGLE WALL BLACK STOVE PIPE

L=6” FOR DOUBLE WALL BLACK STOVE PIPE

FIG. 6

FIG. 6a

4

HIGH PITCH OR

CHALET CEILING

ROOF SUPPORT

(CAT. NO. TGRS)

(4) NAILS PER SIDE

TEMP GUARD

ADAPTOR INCLUDED

FIG. 8

FIG. 9

INSTALLATION THROUGH HIGH

PITCH OR CHALET CEILING USING

TGRS

1. From the appliance manufacturer’s instructions, determine

the correct ue diameter for the chimney and proper location

of the chimney.

2. Using framing lumber equal to ceiling joist size, frame

opening as shown in FIG. 9. Framing that is perpendicular

to the roof joists must also be vertically mounted so that

support can be installed vertically.

Opening dimensions will vary based on roof pitch (slope).

Framed openings should be approximately ¼” larger than

support. The TGRS dimensions are:

LENGTH WIDTH HEIGHT

6”TGRS 12-7/16” X12-7/16” 29”

7”TGRS 13-7/16” X13-7/16” 29”

8”TGRS 14-7/16” X14-7/16” 29”

10”TGRS 16-7/16” X16-7/16” 29”

12”TGRS 18-7/16” X18-7/16” 29”

3. Insert TGRS into framed opening so that the TGRS

extends a MINIMUM of three (3) inches below the nished

ceiling on the lower side of the installation.

4. With TGRS properly located, mark roof slope on the roof

support (See FIG. 10.), Remove from opening and trim off

excess metal.

5. Reinsert TGRS and secure in position using a minimum 1”

roong nail, four (4) each per side.

6. The TGRS contains an integral starter collar for TG chimney.

Attach rst section of pipe to TGRS.

7. Continue pipe through the roof. See “Flashing Installation”

and “Termination” sections.

FIG. 10

JOIST

SHEET ROCK

ROOF SUPPORT

CONNECTOR PIPE

MARK SLOPE AND TRIM OFF THIS PORTION

WALL STUDS

SHEET ROCK

3” MINIMUM LENGTH

18” FROM SINGLEWALL BLACK STOVE PIPE

6” FROM DOUBLEWALL BLACK STOVE PIPE

AA=CLEARANCE TO COMBUSTIBLES OF:

5

LOCK

WASHER

INSTALLATION THROUGH HIGH

PITCH OR CHALET CEILING USING

TGAS

1. From the appliance manufacturer’s instructions, determine

the correct ue diameter for the chimney and proper location

of the chimney.

2. Using framing lumber equal to ceiling joist size, frame

opening providing a minimum 1-1/2” clearance for 6”-8”

diameters and 2” clearance for 10” - 12” diameters from

the chimney to combustibles. Opening dimensions will vary

based on roof pitch (slope).

3. Assemble TGAS as shown in FIG 12. Tighten nuts nger

tight only.

4. Locate the TGAS over the framed opening in the roof. Nail

the brackets to the framing using a minimum of two (2) #8

nails per bracket.

5. Slip a trim sleeve joint cover (TGTS) over the end of the TG

pipe that is to go through the support and protrude into the

house. Attach a single adaptor (TGPSWA) to the female

end of the TG pipe and slip TGTS ush to the end of the

TGPSWA.

6. From below, slide TG chimney pipe section through the

opening and through the support band. Drill 1/8” holes into

the exterior casing of the TG pipe at each pilot hole in the

support band. DO NOT PENETRATE FLUE. Secure the

support band to the chimney using sheet metal screws

provided with the TGAS assembly.

7. Adjust the pipe section so that it stands vertically through

the roof. TIGHTEN all nuts to secure the pipe in the

vertical position.

8. The interior opening in the ceiling may be trimmed with a

TGPCP. Select the appropriately shaped trim plate for your

ceiling pitch (slope). Slide the trim plate over the opening

and secure to the ceiling. Determine ceiling pitch as shown

in FIG. 13.

9. WARNING: Use only Single Wall or Double Wall Black

Stove Pipe connector below the ceiling line as shown in

FIG. 11. Use of additional TG pipe as a connector is

prohibited.

L944 FIG12

L944 FIG13

STORM COLLAR

FLASHING

ADJUSTABLE

SUPPORT

(CAT. NO. TGAS)

TRIM SLEEVE

(CAT. NO. TGTS)

A

REF. TO FIG. 10

PITCHED CEILING

PLATE

(CAT. NO. TGPCP)

FIG. 11

PILOT HOLES

NUT

FLAT WASHER

SUPPORT BRACKET

SUPPORT BAND

FIG. 12

VERTICAL DISTANCE

12”

CEILING

Pitch is the vertical distance, 12 “ from ceiling.

Example: In a 6/12 pitch, the vertical

distance is six (6) inches. FIG. 13

SINGLE WALL

ADAPTER

(CAT. NO. TGPSWA)

6” MIN.

6

MASONARY FIREPLACE CHIMNEY,

AND CHIMNEY EXTENSION

An anchor plate (TGAP) is used to attach Metal-Fab Temp/

Guard Chimney to a masonry replace or chimney. Maximum

support height of 60 ft.

1. Where the transition is to be made, apply a bed of mortar

approximately 3/4 inches deep and approximately one

(1) inch larger than the anchor plate. (See TG Chimney

Catalog for anchor plate dimensions).

2. Insert four (4) 1/4-20 x 2” anchor bolts, head down into the

mortar bed. J-style anchor bolts are preferred. An alternate

method would be to allow the mortar bed to cure. Then, drill

four (4) holes, matching the holes in the anchor plate and

insert four (4) each 1/4-20 metal anchors. The anchor plate

would then be attached by four (4) each 1/4-20 bolts.

3. Before the mortar sets, place the anchor plate over the bolts

and press down into the mortar. Loosely secure using a

washer and nut on each bolt.

4. Use a level to check the installation, assuring that the TG

chimney connection (TGAP) is level.

5. When the mortar has set up, tighten the nuts onto the bolts.

Proceed to stack Metal-Fab chimney pipe (TG) on the

anchor plate.

6. See “Flashing Instructions” and “Termination” sections.

NOTE: Existing masonry ues may be extended with TG pipe

by using an anchor plate, following steps 1 through 7 above,

provided that:

a) The existing masonry chimney is structurally sound,

and;

b) The ue extension is properly sized so that the

appliance attached to the ue drafts properly.

NOTE: The TG ue size for a height less than 15 feet should be

at least 1/8 the area of the replace opening. The TG ue size

for a height over 15 feet should be at least 1/10 the area of the

replace opening. (For sizing of TG ue, See Metal-Fab literature

L1372.)

EXAMPLE: A replace opening of 22” x 34” has an area of

(748 in2) with a chimney height less than 15 feet, the effective

area is 1/8 x (748 in2) = 93.5 in2. Closest ue diameter size = 10”.

With a chimney height over 15 Feet, the effective area is 1/10 x

(748 in2)=74.8 in2. closest ue diameter size = 10”.

ANCHOR

EMBEDDED

IN MORTAR

L944 FIG15A

NOTE:

ANCHOR PLATE MOUNTED

AT MASONRY FIREPLACE

FLUE OPENING AREA

WITH, BOLT, NUTS, AND

WASHERS

ANCHOR PLATE

(CAT. NO. TGAP)

BED

OF MORTAR

FIG. 14

FIG. 15

7

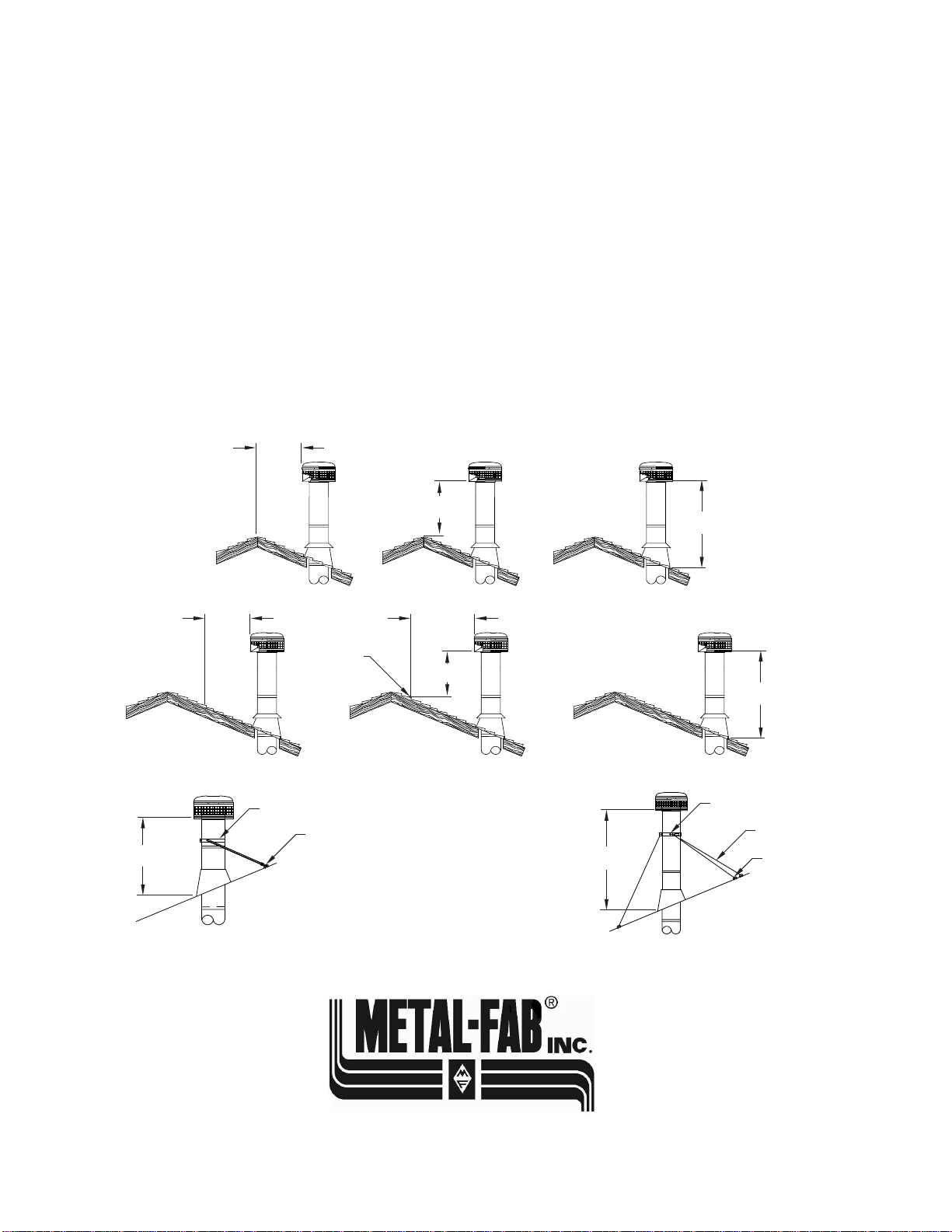

ELBOW INSTALLATION

1. Metal-Fab provides a 15°(TGA15) and 30°(TGA30) Elbow

to allow chimneys to avoid framing member or roof peaks.

A maximum of 30° from the vertical is allowed, and a total

of four elbows (two pair) for each chimney installation.

Maintain 1-1/2” clearance to combustibles for 6” - 8”

diameters and 2” clearance to combustibles for 10” - 12”

diameters.

2. Attach the elbow to the chimney pipe or other support part

and twist to lock. Using the offset chart, add chimney

sections between elbows. A support band (TGSB) is

required at the upper elbow of the pair to support the load,

as shown in FIG. 16. Attach the upper elbow to bring

chimney back to vertical.

Offset combinations: see Table 3 and illustration, FIG. 17.

TABLE 3

6”,7”,8”,10”, AND 12” DIAMETER OFFSET TABLE

A15° Angle 30° Angle

Length No. Pcs. B C B C

0 0 18-7/16” 2-1/4” 20-3/16” 5”

6” 1 22-13/16” 3-3/8” 24-1/16” 7-1/4”

12” 1 28-5/8” 4-15/16” 29-1/4” 10-1/4”

18” 1 34-3/8” 6-1/2” 34-7/16” 13-1/4”

24” 1 40-3/16” 8-1/16” 39-5/8” 16-1/4”

30” 2 44-1/2” 9-1/4” 43-1/2” 18-1/2”

36” 1 51-3/4” 11-3/16” 50-1/16” 22-1/4”

42 2 56-1/8” 12-3/8” 53-15/16” 24-1/2”

48”* 1 63-3/8” 14-1/4” 60-7/16” 28-1/4”

54”* 2 67-3/4” 15-7/16” 64-3/8” 30-1/2”

60”* 2 73-1/2” 17” 69-1/2” 33-1/2”

66”* 2 79-11/16” 18-1/2” 74-3/4” 36-1/2”

72”* 2 85-1/2” 20-1/16” 79-15/16” 39-1/2”

78”* 3 89-7/16” 21-1/4” 83-13/16” 41-3/4”

84”* 2 96-11/16” 23-3/16” 90-5/16” 45-1/2”

90”* 3 102-3/8” 24-3/8” 94-3/16” 47-1/2”

96”* 2 108-1/4” 26-5/16” 100-11/16” 51-1/2”

*48” length not available for 10” and 12” diameters

L944 FIG17

C

B

A

FIG. 17

1-1/2” FOR 6”-8” DIAMETERS

2” FOR 10”-12” DIAMETERS

DIM. WILL VARY WITH ROOF PITCH

(Must maintain 1-1/2” for 6”-8” diameters,

2” for 10”-12” diameters to combustibles)

1-1/2” FOR 6”-8” DIAMETERS

2” FOR 10”-12” DIAMETERS

FIG. 18

FLASHING INSTALLATION

1. Continue the TG chimney to the roof. Cut the roof opening,

centered over the chimney. A 1-1/2 inch for 6” - 8”

diameters and 2 inch for 10” - 12” diameters, airspace around

the chimney is required as it penetrates the roof. The size of

hole in the roof will vary depending on the roof pitch. See

note for Table 1 regarding special 8TG clearances.

2. Install the next TG chimney section through the roof. See

FIG. 18. For 12” chimney only, install a

radiation shield (TGRSH) over the chimney section so that

the shield straps can be temporarily bent over the roof to

hold in place. After installing the ashing, these straps will be

attached to the ashing as shown in FIG. 19.

NOTE: If your roof is already shingled, be sure to slide the upper

edge under the shingles to prevent leakage.

3. Install a bead of caulk around the pipe at the top edge of

the ashing. Wrap the storm collar around the pipe and

imbed the edge in the caulk to prevent leakage around the

pipe.

4. Continue to install pipe sections until proper termination

height is reached. See termination section.

NAILNAIL

L944 FIG18

FIG. 16

SUPPORT BAND

(CAT. NO. TGSB)

4’ MAX.

4’ MAX.

FIRESTOP

(CAT. NO. TGFSA)

L944 FIG20

FIG. 19

CONTEMPORARY CAP

(CAT. NO. TGC)

CAULK

STORM COLLAR

BEND RADIATION SHIELD

STRAPS OVER FLASHING

EDGE MIN. 2”

(FOR 12” DIA. ONLY)

FLASHING

(CAT. NO. TGF)

DO NOT OBSTRUCT

OPENING BETWEEN

STORM COLLAR AND

FLASHING

RADIATION SHIELD

P.O. Box 1138 • WICHITA, KANSAS 67201

(316) 943-2351 • FAX (316) 943-2717

8852

TERMINATION

Major building codes specify a minimum chimney height above

the roof top. These specications are summarized in what is

known as the “Ten Foot Rule”. This rule states:

If the horizontal distance from the side of the chimney to the peak

of the roof is 10 feet or less, the top of the chimney must be at

least 2 feet above the peak of the roof, but never less than 3 feet

in overall height above the highest point where it passes through

the roof (FIG. 20).

If the horizontal distance from the side of the chimney to the peak

of the roof is more than 10 feet, a chimney height reference point

is established on the surface of the roof a distance of 10 feet

from the side of the chimney in a horizontal plane. The top of the

chimney must be at least 2 feet above this reference point, but

never less than 3 feet in height above the highest point where it

passes through the roof (FIG. 21)

These chimney heights are necessary in the interest of safety and

do not ensure smoke free operation. Trees, buildings, adjoining

roof lines, adverse wind conditions, etc., may create need for a

taller chimney should smoking occur.

Additional support is required above the roof if the chimney

height exceeds four (4) feet.

Select the proper support for your application, using either a

roof brace (FIG. 22) or a support band with guy wires (FIG. 23)

L944 FIG22

L944 FIG23

FIG. 20

IF 10

FEET OR

LESS

L944 FIG21

THEN BUT

MUST BE AT

LEAST 2 FEET NEVER LESS

THAN 3 FEET

FIG. 21

IF 10

FEET OR

MORE

MUST BE AT

LEAST 2 FEET NEVER LESS

THAN 3 FEET

10 FEET

FIG. 22

FOR HEIGHTS

FROM 4’ TO 8’

REFERENCE

POINT

ROOF

TGRB ROOF BRACE

LAG BOLTS

FIG. 23

ROOF

TGSB SUPPORT BAND

LAG BOLT

GUY WIRES

(1/4” MINIMUM CABLE

DIAMETER)

FOR HEIGHTS EXCEEDING

8’ UP TO 20’

THEN BUT

8

1. Form the attachment band around the chimney, and clamp

in place at the desired height using bolt and nut provided.

2. Loosely attach the support legs to the bolts on the

attachment band using hardware provided.

3. Position the support legs as shown in FIG. 22. The length

of the support legs can be adjusted by loosening the bolt on

the leg clamp.

4. Secure legs to roof using screws provided. Seal screw holes

to prevent roof leaks.

5. Tighten all hardware.

TG ROOF BRACE INSTALLATION

Other manuals for Temp/Guard

1

This manual suits for next models

4

Table of contents

Other Metal Fab Fan manuals

Popular Fan manuals by other brands

Minka-Aire

Minka-Aire F601 Acero instruction manual

Hunter

Hunter Grand Cayman Owner's guide and installation manual

Hunter

Hunter Tribeca 82021 Parts guide

OBH Nordica

OBH Nordica 1385 Instructions of use

Envirovent

Envirovent SLIMLINE 300 Installation guide for engineer / installer

Tesco

Tesco DF98 user guide