Metal Fab AL29-4C User manual

CORR/GUARD

INSTALLATION INSTRUCTIONS

This symbol on the nameplate

means this product is listed by

Underwriters Laboratories Inc.

Tested to UL1738 / CAN / ULCS636-08

Listing No. MH26687

Testing No. 11EN

SMALL DIAMETER CORR/GUARD

& SLEEVED CORR/GUARD

PRESSURE RATED VENTING SYSTEM

AL29-4C®STAINLESS STEEL

CONDENSING APPLIANCES

CAT. II, III, IV APPLIANCES

FUME EXHAUST

3”(76mm) - 36”(914mm) DIAMETERS

C US

IMPORTANT: DO NOT INSTALL WITHOUT FIRST READING THESE INSTRUCTIONS

VERY CAREFULLY.

•EXAMINE ALL COMPONENTS FOR POSSIBLE SHIPPING DAMAGE

BEFORE INSTALLATION.

•PROPER JOINT ASSEMBLY IS ESSENTIAL FOR A SAFE INSTALLATION.

FOLLOW THESE INSTRUCTIONS EXACTLY AS WRITTEN. CHECK

SEVERENESS OF JOINTS UPON COMPLETION OF ASSEMBLY.

•THIS VENTING SYSTEM MUST BE FREE TO EXPAND AND CONTRACT.

SUPPORT SYSTEM IN ACCORDANCE WITH THESE INSTRUCTIONS.

CHECK FOR UNRESTRICTED MOVEMENT THROUGH WALLS, CEILINGS,

AND ROOF PENETRATIONS. DIFFERENT MANUFACTURERS HAVE

DIFFERENT JOINT SYSTEMS AND ADHESIVES. DO NOT MIX PIPE,

FITTINGS, OR JOINING METHODS FROM DIFFERENT MANUFACTURERS.

METAL-FAB, INC. P.O. BOX 1138, WICHITA, KS 67201-1138

2

GENERAL

CORR/GUARD VENTING SYSTEM INSTALLATION

INSTRUCTIONS

Corr/Guard is a special stainless steel venting system for gas-red

appliances listed as Cat. II, III & IV or in Canada, Type BH Gas Venting

Systems per ULC-636, with rated operating temperature of 550°F (287°

C). Corr/Guard is rated for positive pressure of 15” (381mm) w.c. for

3” (76mm) diameter through 36” (914mm) diameter. Metal-Fab, Inc.

recommends the system be inspected once a year by a qualied service

technician.

Venting system design may be limited by appliance performance.

Consult appliance installation instructions to determine proper sizing

and limitations such as maximum horizontal length and height,

maximum number of elbows or offsets, connecting two or more

appliances to a common venting system, and other limitations that

may affect design and installation. Permits may be required before

starting an installation. Installation is to be in accordance with local

building code requirements and National Codes: USA – NFPA 54

ANSI-Z223.1 or NFPA 211. In Canada – CAN/CGA-B149.1 or

CAN/CGA-B149.2 Propane Installation Code as applicable. It is

the responsibility of the installer to contact local building and re

ofcials concerning any installation restrictions and/or inspection

requirements that may apply.

Corr/Guard is to be installed in accordance with these installation

instructions and those of the appliance manufacturer. For conditions

and applicable restrictions not specically mentioned herein, contact

building or re ofcials having jurisdiction in your area. The following is a

guide to assist a professional installer:

• Proper operation of the venting system and appliance is dependant

on the use of all parts specied by Metal-Fab for use in the particular

installation. System performance may be affected if the proper

assembly of all required parts is not accomplished.

• Refer to appliance’s instructions to determine proper sizing and

connection of the venting system to the appliance.

• Corr/Guard Model CG, FCS, FCS-1 & FCS-2 double wall vent may

be used with Model CGSW & FCSSW single wall vent within the

same vent system.

• Tee sections should only be used in conjunction with a drain on

appliances tested for use with a drain, or if allowed by the appliance

manufacturer for multiple appliance connections.

• If required by the appliance manufacturer, a drain tting must be

located as close as possible to the appliance ue outlet. Unless a

drain tting is supplied with the appliance, install only a Corr/Guard

Drain Fitting.

• More than one Category II, III or IV appliance may not be connected

into the same vent system, unless the appliance manufacturer

specically approved such a system and the appliances are

designed for multiple venting. Cat. II, III or IV appliances MAY NOT

share any part of their vent system with a natural draft appliance.

• Check the joints and seams for gas tightness when using the

venting system with a Cat. III or Cat. IV appliance.

• Except for installation in one and two family dwellings, a venting

system that extends through any zone above that on which the

connected appliance is located shall be provided with an enclosure

having a re resistance rating equal to or greater than that of the

oor or roof assemblies through which it passes.

• Corr/Guard shall not be routed into, through, or within any other

vent, such as an existing masonry or factory-built chimney ue that

is connected to another appliance.

• WARNING! Do not place or install insulation in any required

clearance spaces surrounding the venting system.

• Enclosure of exterior mounted venting systems below the roof line

is recommended to limit condensation and protect from mechanical

damage.

When the Corr/Guard vent system is installed, check joints for tightness.

Repair any joint leaks by disassembling and resealing following the

guidelines in the Joint Assembly section of these instructions. Replace

any defective component.

(TABLE 1) CLEARANCE TO COMBUSTIBLES

Corr/Guard SINGLE WALL (CGSW & FCSSW)

Rated Operating Minimum Clearance Minimum Clearance

Temperatures Enclosed Unenclosed

Pipe Dia. Temp. Horiz. Vert. Horiz. Vert.

Single Wall

3”&4”

(76mm - 102mm)

(CGSW)

400°F

(204°C)

480°F

(249°C)

550°F

(288°C)

8”

(203mm)

8”

(203mm)

N/A

4”

(102mm)

4”

(102mm)

N/A

1”

(25mm)

2”

(51mm)

2”

(51mm)

1”

(25mm)

2”

(51mm)

2”

(51mm)

Single Wall

5”

(127mm)

(CGSW)

400°F

(204°C)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

N/A

6”

(152mm)

6”

(152mm)

N/A

1”

(25mm)

2”

(51mm)

2”

(51mm)

1”

(25mm)

2”

(51mm)

2”

(51mm)

Single Wall

6”-12”

(152mm - 305mm)

(FCSSW)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

N/A

N/A

2”

(51mm)

2”

(51mm)

2”

(51mm)

2”

(51mm)

Single Wall

14”-18”

(356mm - 457mm)

(FCSSW)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

N/A

N/A

3”

(76mm)

3”

(76mm)

3”

(76mm)

3”

(76mm)

Single Wall

20”-24”

(508mm - 610mm)

(FCSSW)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

N/A

N/A

4”

(102mm)

4”

(102mm)

4”

(102mm)

4”

(102mm)

Single Wall

26”-30”

(660mm - 762mm)

(FCSSW)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

N/A

N/A

5”

(127mm)

5”

(127mm)

5”

(127mm)

5”

(127mm)

Single Wall

32”-36”

(813mm - 914mm)

(FCSSW)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

N/A

N/A

6”

(152mm)

6”

(152mm)

6”

(152mm)

6”

(152mm)

(TABLE1) CLEARANCE TO COMBUSTIBLES

Corr/Guard DOUBLE WALL (CG, FCS, FCS-1 & FCS-2)

Rated Operating Minimum Clearance Minimum Clearance

Temperatures Enclosed Unenclosed

Pipe Dia. Temp. Horiz. Vert. Horiz. Vert.

Double Wall

3”-5”

(76mm - 127mm)

(CG)

300°F

(149°C)

480°F

(249°C)

550°F

(288°C)

3”

(76mm)

6”

(152mm)

N/A

1”

(25mm)

1”

(25mm)

N/A

1”

(25mm)

1”

(25mm)

1”

(25mm)

1”

(25mm)

1”

(25mm)

1”

(25mm)

Double Wall 6”-12”

(152mm - 305mm)

(FCS/FCS-1/FCS-2)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

1”

(25mm)

1”

(25mm)

1”

(25mm)

1”

(25mm)

1”

(25mm)

1”

(25mm)

Double Wall 14”-18”

(356mm - 457mm)

(FCS/FCS-1/FCS-2)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

1”

(25mm)

1”

(25mm)

2”

(51mm)

2”

(51mm)

1”

(25mm)

1”

(51mm)

Double Wall 20”-24”

(508mm - 610mm)

(FCS/FCS-1/FCS-2)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

1”

(25mm)

1”

(25mm)

3”

(76mm)

3”

(76mm)

1”

(25mm)

1”

(76mm)

Double Wall 26”-30”

(660mm - 762mm)

(FCS/FCS-1/FCS-2)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

2”

(51mm)

2”

(51mm)

4”

(102mm)

4”

(102mm)

2”

(51mm)

2”

(51mm)

Double Wall 32”-36”

(813mm - 914mm)

(FCS/FCS-1/FCS-2)

480°F

(249°C)

550°F

(288°C)

N/A

N/A

2”

(51mm)

2”

(51mm)

5”

(127mm)

5”

(127mm)

2”

(51mm)

2”

(51mm)

The Corr/Guard ventilation system, manufactured by Metal-Fab, Inc.

is constructed to exacting standards. The proper operation of this vent

system is dependant on the use of correct components, proper sizing,

quality of installation, and guidelines and limitations expressed by the

appliance manufacturer.

3

USE AND INSTALLATION OF INDIVIDUAL PARTS:

These instructions comprise both general and specific requirements for

all parts in the product line. Before specifying a design or beginning an

installation, these instructions should be carefully reviewed.

PIPE WEIGHT

The average weight of the chimney, per foot of length, can be calculated

using the following formula.

FCSSW (6”-24”): 0.30 x diameter = lbs per foot

FCS (6”-24”): 0.70 x diameter = lbs per foot

FCS-1 (6”-24”): 0.85 x diameter = lbs per foot

FCS-2 (6”-24”): 0.95 x diameter = lbs per foot

FCSSW (26”-36”): 0.40 x diameter = lbs per foot

FCS (26”-36”): 0.80 x diameter = lbs per foot

FCS-1 (26”-36”): 0.95 x diameter = lbs per foot

FCS-2 (26”-36”): 1.05 x diameter = lbs per foot

Example: 8FCS-1: 0.85 x 8 = 6.80 lbs per foot

Vent design should make provisions for support adequate to ensure that

vent components are not overloaded.

PART NUMBERS

These instructions identify Model FCS, FCS-1 & FCS-2 parts by name

of part number in the text and illustrations. Actual parts also carry a flue

diameter prefix and a three digit “CTO” suffix which defines the materials

of construction, such as 8FCS24-CA1 for an 8-inch diameter double wall

pipe section 24 inches long with AL29-4C stainless steel inner flue wall,

aluminized steel outer casing wall and 1” insulation. (See TABLE 2 for

further explanations of CTO codes).

TABLE 2

1ST DIGIT 2ND DIGIT 3RD DIGIT

(INNER WALL) (OUTER WALL) (INSULATION)

C = AL29-4C A = ALUMINIZED STEEL 0 = AIR SPACE

4 = 304 S/S 1 = 1” INSULATION

6 = 316 S/S 2 = 2” INSULATION

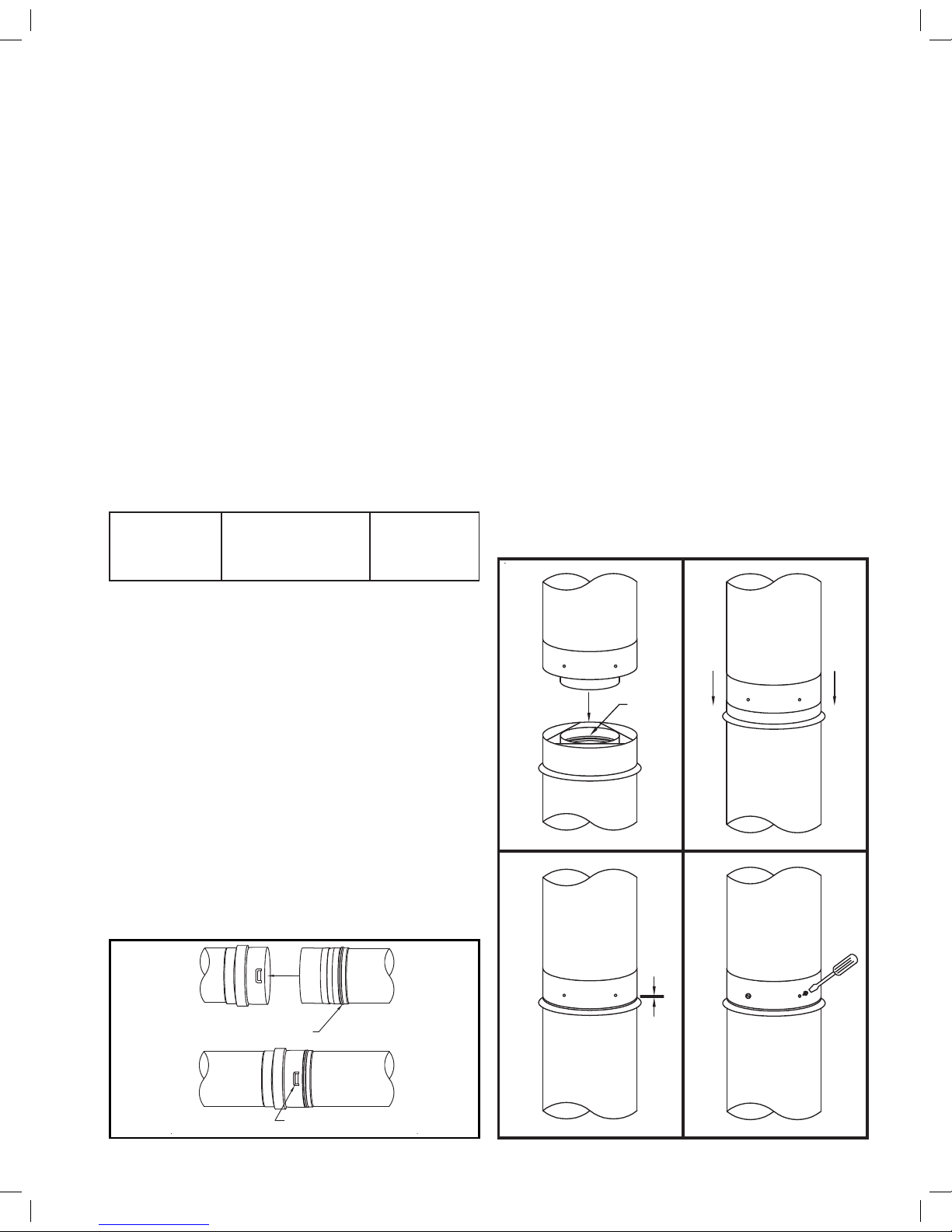

JOINT ASSEMBLY-SINGLE WALL

3”- 5” (76mm - 127mm) DIAMETER CGSW

Each Corr/Guard vent component contains a seal gasket on the

female end of the vent joint and locking tabs. Mechanical fastening

of the joint is automatic and requires no tools. Visually check the

gasket for proper location within the pipe bead during assembly or ue

gases could leak, resulting in carbon monoxide poisoning. Assembly

of joints is shown below:

NOTE: When assembling 3”-5” Diameter Corr/Guard vent, always install

the the female ue end elevated above the male ue end.The “UP” arrow

will point to the elevated female ue end. Change of directions are made

by using a male to male or female to female adapter depending on the

ow of the condensate.

1. Insert the male end of the vent pipe into the adjoining

female vent section until the bead of the male joint stops

at the edge of the female joint.

NOTE: If the seal gasket pushes out of the groove during the

assembly process, apply a light lm of synthetic based lubricant to

the top surface of the gasket or spray a light lm of soapy water on

the top surface of the gasket. Visually check that the gasket has not

pushed out of the ue bead.

2. When properly inserted to the fullest extent, the integral locking tabs

will snap into place, securing the joint Before proceeding, verify

that all locking tabs are engaged for each joint assembly.

JOINT ASSEMBLY-DOUBLE WALL

3”- 5” (76mm - 127mm) DIAMETER CG

Connections between vent and ttings are male/female type. The inner

duct is sealed with an integral seal gasket and the joint is mechanically

secured via the overlapping outer wall of the double wall pipe.

NOTE: When assembling 3”-5” Diameter Corr/Guard vent, always install

the the female ue end elevated above the male ue end. The “UP”

arrow will point to the elevated female ue end. Change of directions are

made by using a male to male or female to female adapter depending on

the ow of the condensate.

Joints are assembled per the following steps:

1. Before assembly, observe that the seal gasket is located within the

female inner pipe joint. Locate next pipe or tting with male inner

pipe joint and insert to begin engagement of inner pipe joint.

NOTE: If the seal gasket pushes out of the groove during the

assembly process, apply a light lm of synthetic based lubricant to

the top surface of the gasket or spray a light lm of soapy water on

the top surface of the gasket. Visually check that the gasket has not

pushed out of the ue bead.

2. As the joint further engages, align the male and female ends of the

outer wall of each pipe so that they begin to engage as the pipes are

further pushed together.

3. Pipe joint is fully engaged when the female end of the outer pipe

comes in contact (or is at least within 3/16” 5mm) to the base of the

bead on the male end of the adjoining vent pipe.

4. When possible look within the pipe assembly to verify that no sign

of seal gasket is showing. Complete the joint assembly by

securing the joint using #8 x 1/2” sheet metal screws (3 per joint)

at each pre-punched hole on the female end of each joint.

WARNING: SHEET METAL SCREWS ARE FOR DOUBLE WALL

OUTER CASING ONLY. NEVER USE SCREWS, RIVETS OR OTHER

FASTENERS TO PENETRATE THE INNER FLUE WALL.

1

4

2

3

FIG. 2

SEAL

GASKET

3/16” GAP (MAX.)

INSERT MALE END UNTIL THE END OF THE

FEMALE PROFILE MAKES CONTACT WITH

THE MALE PROFILE BEAD.

FIG. 1 VERIFY THAT TABS “SNAP”

INTO LOCKING POSITION.

4

JOINT ASSEMBLY-LARGE DIAMETER

6”- 36” (152mm - 914mm) DIAMETER FCSSW, FCS, FCS-1 & FCS-2

Connection Tips For Sealant Applications (See FIG. 3):

The Corr/Guard (Model FCS and FCSSW) joint sealing system is

designed for quick and easy installation:

NOTE: When assembling 6”-36” diameter Corr/Guard vent, always

install the female ue end elevated above the male ue end. Change of

directions are made by using a male to male or female to female adapter

depending on the ow of the condensate.

1. Inspect anged surfaces just prior to installation, and if contaminated

with oil or dirt, clean with rubbing alcohol. Apply a continuous bead

of P070 or P077 sealant in the corner of the sleeve and ange.

2. Join the two anged ends of the pipe sections. compressing the

P070 or P077 sealant just applied.

3. Fill the channel of Flange Band with P070 or P077 Sealant.

4. Install the ange band around the anges and rmly tighten (Torque:

2 ft-lbs to 5 ft-lbs.). DO NOT over tighten for risk of damage

to joint. DO NOT locate the fasteners of the ange

band on the bottom side of vent for horizontal

installations.

IMPORTANT: Allow P070 or P077 Sealant to cure 24 hours

before operating appliances.

5. (FCS-1 & FCS-2 INSTALLATIONS ONLY) Pack the void between

inner and outer walls with insulation strips.

6. Secure the outer casing with the casing closure band. Apply clear

silicone sealant to closure band for exterior applications only.

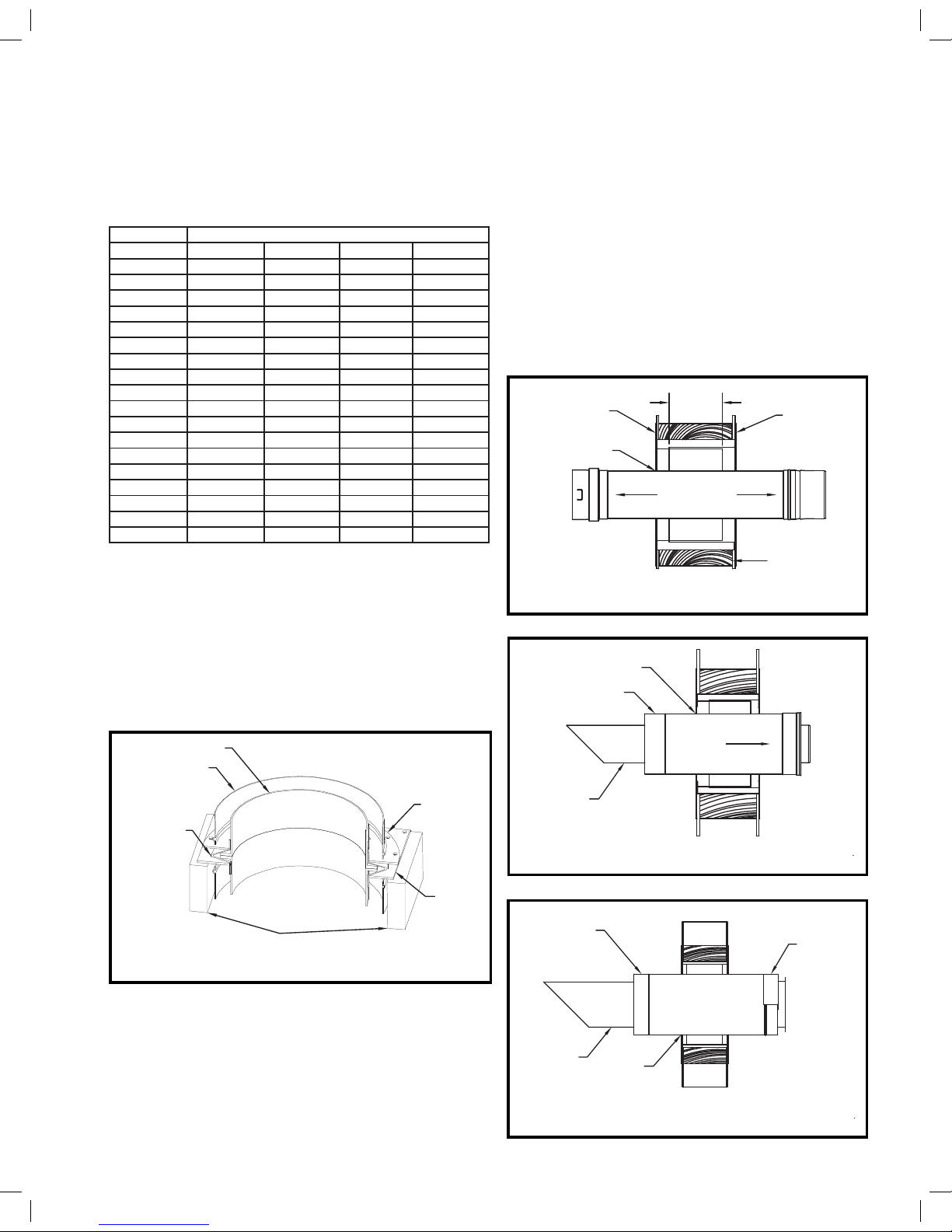

TABLE 3

SUPPORT PIPE DIA./MODEL DIST. BETWEEN

SUPPORTS

HORIZONTAL

RUNS

(INCLUDING

BETWEEN

ELBOWS)

3”-5” (76mm-125mm) CG & CGSW 7’ (2.13m)

6”-24” (152mm-610mm) FCS & FCSSW 7’ (2.13m)

6”-24” (152mm-610mm) FCS-1 6’ (1.83m)

6”-24” (152mm-610mm) FCS-2 5’ (1.52m)

26”-36” (660mm-914mm) FCS & FCSSW 10’-6” (3.20m)

26”-36” (660mm-914mm) FCS-1 10’ (3.05m)

26”-36” (660mm-914mm) FCS-2 9’ (2.70m)

VERTICAL SUPPORTS

• Unless installed in a re rated shaft, a re stop / vertical support is

required when penetrating oors and ceilings.

• Vertical supports are to be used after each transition to vertical. Refer

to TABLE 4 for support methods and heights.

TABLE 4

SUPPORT METHODS PIPE DIAMETER / MODEL MAXIMUM HEIGHT

PLATE SUPPORTS

3”-5” (76mm-125mm) CG/CGSW 30’ ( 9.1m)

6”-12” (152mm-305mm) FCS 50’ (15.2m)

6”-12” (152mm-305mm) FCS-1 41’ (12.5m)

6”-12” (152mm-305mm) FCS-2 37’ (11.3m)

6”-12” (152mm-305mm) FCSSW 100’ (30.5m)

14”-24” (356mm-610mm) FCS 30’ ( 9.1m)

14”-24” (356mm-610mm) FCS-1 25’ ( 7.6m)

14”-24” (356mm-610mm) FCSSW 75’ (22.9m)

26”-36” (660mm-914mm) FCS/FCSSW 100’ (30.5m)

26”-36” (660mm-914mm) FCS-1 85’ (25.9m)

26”-36” (660mm-914mm) FCS-2 75’ (22.9m)

WALL BAND

6”-16” (152mm-406mm) FCS 8’ (15.2m) INTERIOR

6”-16” (152mm-406mm) FCS-1 7’ ( 2.1m) INTERIOR

6”-14” (152mm-406mm) FCS-2 6’ ( 1.8m) INTERIOR

6”-12” (152mm-305mm) FCSSW 8’ (15.2m) INTERIOR

ROOF SUPPORTS

(PLATE SUPPORT

AT ROOF FOR

FREE STANDING)

3” - 5” (76mm-125mm) CG/CGSW 5’ ( 1.5m)

6”-24” (152mm-610mm) FCS/FCSSW 5’ ( 1.5m)

6”-24” (152mm-610mm) FCS-1/FCS-2 5’ ( 1.5m)

26”-36” (660mm-914mm) FCS/FCSSW 10’ ( 3.0m)

26”-36” (660mm-914mm) FCS-1/FCS-2 10’ ( 3.0m)

WALL SUPPORTS

(GUIDE EVERY

10’ (3.0M)

FOR EXTERIOR)

3” - 5” (76mm-125mm) CG/CGSW 6’ ( 1.8m) EXTERIOR

3” - 5” (76mm-125mm) CG/CGSW 30’ ( 9.1m) INTERIOR

6”-24” (152mm-610mm) FCS/FCSSW 8’ ( 2.4m) EXTERIOR

6”-24” (152mm-610mm) FCS-1 8’ ( 2.4m) EXTERIOR

6”-22” (152mm-610mm) FCS-2 8’ ( 2.4m) EXTERIOR

6”-24” (152mm-610mm) FCS/FCSSW 30’ ( 9.1m) INTERIOR

6”-24” (152mm-610mm) FCS-1 25’ ( 7.6m) INTERIOR

6”-22” (152mm-610mm) FCS-2 22’ ( 6.7m) INTERIOR

26”-36” (660mm-914mm) FCS/FCSSW 40’ (12.2m) INTERIOR

26”-36” (660mm-914mm) FCS-1 34’ (10.4m) INTERIOR

26”-36” (660mm-914mm) FCS-2 30’ ( 9.1m) INTERIOR

STACK SUPPORTS

6”-24” (152mm-610mm) FCS 30’ ( 9.1m)

6”-24” (152mm-610mm) FCS-1 25’ ( 7.6m)

6”-24” (152mm-610mm) FCS-2 22’ ( 6.7m)

6”-12” (152mm-305mm) FCSSW 30’ ( 9.1m)

14”-24” (356mm-610mm) FCSSW 20’ ( 6.1m)

26”-36” (660mm-914mm) FCS/FCSSW 100’ (30.5m)

26”-36” (660mm-914mm) FCS-1/FCS-2 100’ (30.5m)

NOTE: Wall Hanger 3”-5” CG/CGSW alignment only, not a vertical support.

INSTALLATION

HORIZONTAL SUPPORTS

Use non-combustible hanger straps of Half Angle Rings (HAR). See

TABLE 3 to support the vent system from ceiling joints or other solid

structures (see FIG. 4)

WARNING: DO NOT PUNCTURE VENT SYSTEM.

• Vent must not sag or dip, providing areas for condensate to collect.

FIG. 3

1 2 3

4 5 6

SEE TABLE 3 TERMINATION

HANGER

STRAP OR H.A.R.

WALL

PENETRATION

ROUTE TO DRAIN.

DISPOSE OF CONDENSATE

ACCORDING TO LOCAL CODE.

ELBOW

APPLIANCE ADAPTER

H.A.R = HALF

ANGLE

RING

APPLIANCE

FIG. 4

SIDE WALL TERMINATION

INSTALLATION

HORIZONTAL DRAIN TEE

OR DRAIN FITTING

5

PLATE SUPPORT ASSEMBLY

The Plate Support Assembly is designed to provide support to vertical and

horizontal sections. The Plate Support must be attached to the building structure

or support with rigid structural members. Proper clearance to combustible

construction must be maintained.

For maximum support, attach the entire perimeter of the Plate Support Assembly

to the structural framing. (See FIG. 5). Structural members are supplied by the

installer. The Flange Band is placed between the Support Plate and the Clamp

Rings and aligned with notches for the Flange Band Clamps. Align holes of

the support plate and Clamp Rings and assemble together using the hardware

provided.

Vertical vent systems can be suspended pre-assembled and lowered into

a shaft. Refer to TABLE 5 for maximum height that can be suspended from

overhead. Do not pre-assemble in the horizontal position and raise to the

vertical position for installation.

WARNING: ALL JOINTS MUST BE PROPERLY ASSEMBLED

AND ALLOWED TO CURE BEFORE LIFTING FOR

INSTALLATION.

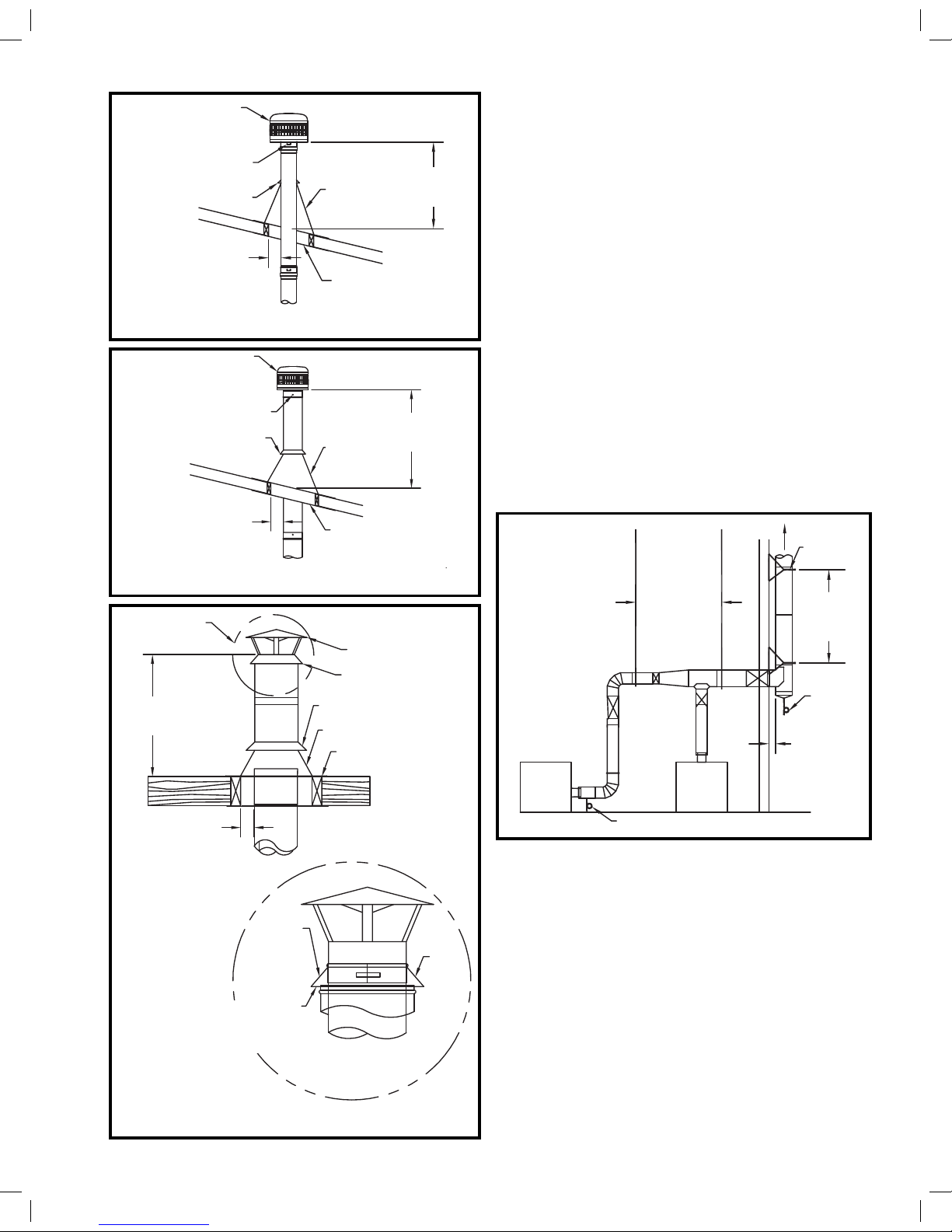

WALL PENETRATION

1. Prior to installation, determine proper location of wall thimble so that

a minimum slope of 1/4” (6mm) per foot is maintained in the

horizontal section of vent to ensure proper ow of condensation.

2. Prepare the wall by cutting a square opening per TABLE 6. (Opening

size adequate to insert Wall Thimble components)

3. Install the Wall Thimble by inserting the larger of the two parts

on the appliance (interior) side.

4. Next, apply a bead of sealant around the edges of the

exterior (smaller of the two parts) Wall Thimble component. Then

install this part of the Wall Thimble by inserting the smaller collar into

the other component from the previous step.

NOTE: The two horizontal cylinders of the Thimble must engage a

minimum of two inches.

5. Fasten both sides of the Wall Thimble using screws or nails.

6. Once the Thimble is installed, Corr/Guard vent pipe can be inserted

into the Thimble. For 3” - 5” diameter Corr/Guard insert the male

end rst. (See FIG. 6, 7 & 8).

7. Assemble Corr/Guard vent from the Wall Thimble section back to the

appliance.

8. Install a horizontal termination to complete the assembly.

9. Once assembly is completed, apply a bead of high-temp sealant

around the pipe and the exterior plate of the Thimble to protect

against weather.

TABLE 5

Height

Diameter FCSSW FCS FCS-1 FCS-2

6”(152mm) 229’(70m) 75’(23m) 62’(19m) 55’(17m)

7”(178mm) 215’(66m) 70’(21m) 58’(18m) 52’(16m)

8”(203mm) 200’(61m) 70’(21m) 58’(18m) 52’(16m)

9”(229mm) 190’(58m) 60’(18m) 49’(15m) 44’(13m)

10”(254mm) 175’(53m) 60’(18m) 49’(15m) 44’(13m)

12”(305mm) 145’(44m) 50’(15m) 41’(15m) 37’(11m)

14”(356mm) 120’(37m) 50’(15m) 41’(15m) 37’(11m)

16”(406mm) 120’(37m) 50’(15m) 41’(15m) 37’(11m)

18”(105mm) 105’(32m) 45’(14m) 37’(11m) 33’(10m)

20”(508mm) 105’(32m) 45’(14m) 37’(11m) 33’(10m)

22”(559mm) 95’(29m) 40’(12m) 33’(10m) 30’( 9m)

24”(610mm) 90’(27m) 40’(12m) 33’(10m) 30’( 9m)

26”(660mm) 90’(27m) 50’(15m) 40’(12m) 40’(12m)

28”(711mm) 90’(27m) 40’(12m) 40’(12m) 30’( 9m)

30”(762mm) 80’(24m) 40’(12m) 40’(12m) 30’( 9m)

32”(813mm) 80’(24m) 40’(12m) 30’( 9m) 30’( 9m)

34”(864mm) 70’(21m) 40’(12m) 30’( 9m) 30’( 9m)

36”(914mm) 70’(21m) 30’( 9m) 30’( 9m) 30’( 9m)

FIG. 5

FLUE

CASING

FLANGE BAND

CLAMP RING

PLATE

STRUCTURAL BRACING

(BY OTHERS)

FIG. 6

2” MIN.

OVERLAP

OUTSIDE BUILDING

SURFACE

SEALANT

INSIDE BUILDING

SURFACE

WOOD STUD

TO TERMINATION TO APPLIANCE

WALL THIMBLE INSTALLATION

3”- 5” (76mm-127mm) CGSW

FIG. 7

WALL THIMBLE INSTALLATION

3”- 5” (76mm-127mm) CG

SEALANT

CASING END CLOSURE

TERMINATION

TO APPLIANCE

FIG. 8

WALL THIMBLE INSTALLATION

6”- 36” (152mm-914mm) FCSSW, FCS, FCS-1 & FCS-2

CASING END

CLOSURE

TERMINATION

SEALANT

RADIATION

SHIELD

(SINGLE WALL)

6

HORIZONTAL TERMINATIONS

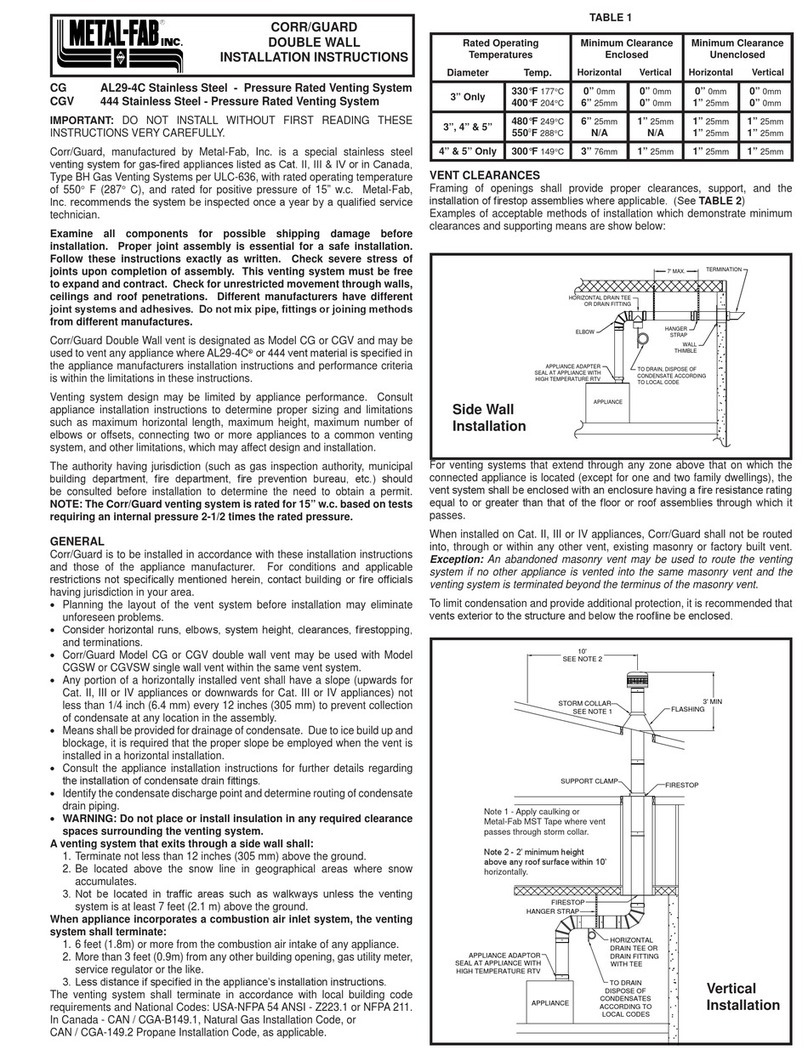

A venting system that exits through a side wall shall:

• Terminate not less than 12 inches (305 mm) above the ground.

• Be located above the snow line in geographical areas where snow

accumulates.

• Not be located in trafc areas such as walkways unless the venting

system is at least 7 feet (2.1 m) above the ground (See FIG. 9).

When an appliance incorporates a combustion air inlet system, the

venting system shall terminate:

• 6 feet (1.8m) or more from the combustion air intake of any

appliance.

• More than 3 feet (0.9m) from any other building opening, gas utility

meter, service regulator or the like.

• Less distance is permitted if specied in the appliance’s installation

instructions.

TABLE 6

PIPE DIAMETER FRAMING DIMENSIONS (MINIMUM)

3”-5” (76mm-127mm)

CGSW (SINGLE WALL)

(PIPE DIA.+5”) x (PIPE DIA.+5”)

(PIPE DIA.+127mm) x (PIPE DIA.+127mm)

3”-5” (76mm-127mm)

CG (DOUBLE WALL)

(PIPE DIA. + 5”) X (PIPE DIA. + 5”)

(PIPE DIA.+127mm) x (PIPE DIA.+127mm)

6”-24” (152mm-610mm)

FCSSW (SINGLE WALL)

(PIPE DIA. + 6”) X (PIPE DIA. + 6”)

(PIPE DIA.+152mm) x (PIPE DIA.+152mm)

6”-24” (152mm-610mm)

FCS & FCS-1 (DOUBLE WALL)

(PIPE DIA. + 6”) X (PIPE DIA. + 6”)

(PIPE DIA.+152mm) x (PIPE DIA.+152mm)

6”-24” (152mm-610mm)

FCS-2 (DOUBLE WALL)

(PIPE DIA. + 8”) X (PIPE DIA. + 8”)

(PIPE DIA.+203mm) x (PIPE DIA.+203mm)

26”-36” (660mm-914mm)

FCSSW (SINGLE WALL)

(PIPE DIA. + 8”) X (PIPE DIA. + 8”)

(PIPE DIA.+203mm) x (PIPE DIA.+203mm)

26”-36” (660mm-914mm)

FCS & FCS-1 (DOUBLE WALL)

(PIPE DIA. + 8”) X (PIPE DIA. + 8”)

(PIPE DIA.+203mm) x (PIPE DIA.+203mm)

26”-36” (660mm-914mm)

FCS-2 (DOUBLE WALL)

(PIPE DIA. + 10”) X (PIPE DIA. + 10”)

(PIPE DIA.+254mm) x (PIPE DIA.+254mm)

VERTICAL TERMINATIONS

• Enclose residential exterior vent systems below the roof line or use

double wall Corr/Guard (CG/FCS/FCS-1/FCS-2) to limit condensation

due to cool down of ue gases.

• The total equivalent length from the appliance outlet to the termination

shall not exceed maximum length specied by the appliance

manufacturer’s installation instructions.

• Vertical terminations must terminate no less than 2’ (0.61m) above the roof

or any wall or vertical structure closer than 8’ (2.4m). A vent cap or other

equivalent termination is required to keep rain or debris out of the vent.

AC

D

AE

B

CA = 12 IN. MIN.

B = 3 FT. MIN.

C = 4 FT. MIN.

D = 7 FT. MIN.

E = LESS THAN 10 FT.

FIG. 9

1. Starting at the appliance outlet, attach the rst section or appliance

adaptor. (See FIG. 10 & 11 for typical installation.)

2. Continue assembly of pipe until nearing a ceiling

penetration. Locate and cut hole in oor and ceilings

that will be penetrated. Hole size must maintain minimum listed clearances

per TABLE 1.

3. Install a restop

support when

penetrating the

ceiling to support the

vertical run of the

vent system.

4. When installing

a restop in the

attic, the restop

or support plate is

located on top of

the joist to prevent

insulation from

falling into the joist.

5. Continue with the

vent penetrating

the roof. At the roof,

the opening must

maintain a minimum

of clearance to

combustibles as

specied in these

instructions and on

the labeled vent

product.

6. Above the roof, a

ashing and storm

collar are required.

Use high temperature

sealant to seal the

storm collar to the

vent so that rain will

not penetrate the roof

opening (See FIG.

12, 13 & 14).

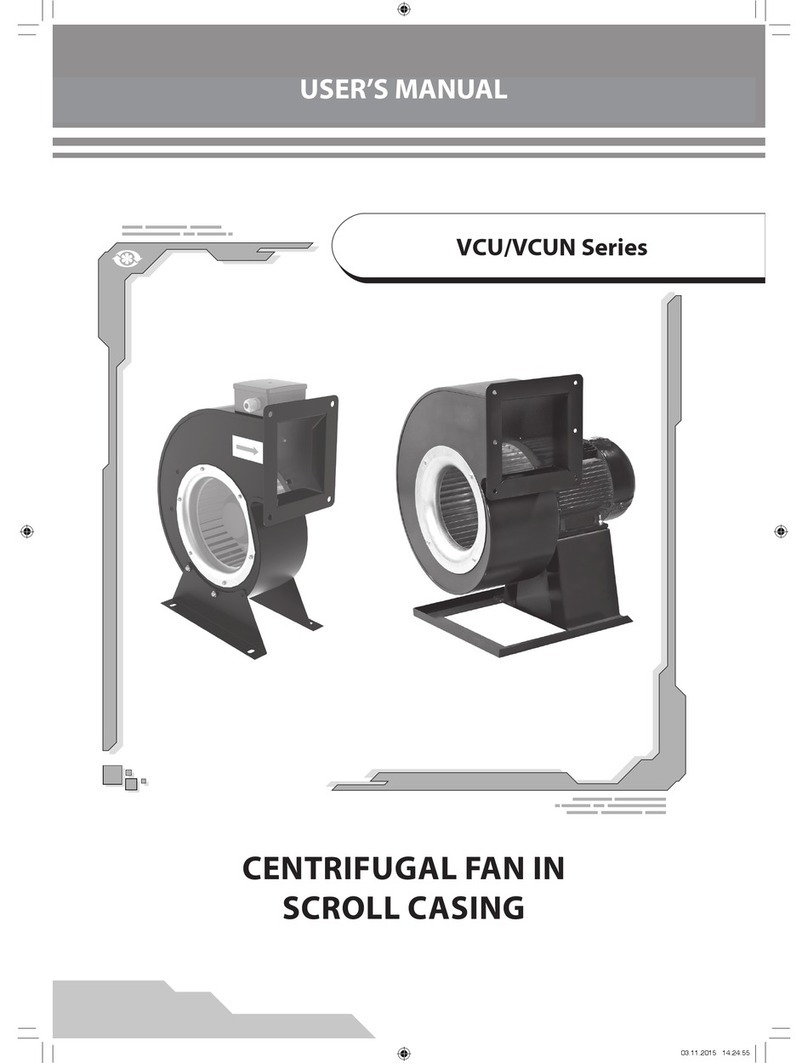

FIG. 10

RAINCAP

STORM COLLAR FLASHING

SUPPORT CLAMP

FIRESTOP

SEE TABLE 3

FIRESTOP

HANGER

STRAP

APPLIANCE

ADAPTER

APPLIANCE

HORIZONTAL

DRAIN TEE OR

DRAIN FITTING

WITH TEE.

TO DRAIN

DISPOSE OF

CONDENSATE

ACCORDING TO

LOCAL CODES.

FIG. 11

MORE THAN 10’ (3m)

10’ (3m)

2’ MIN. HEIGHT

ABOVE ANY

ROOF SURFACE

WITHIN 10 FT. (3m)

HORIZONTAL

CHIMNEY

3’ (.9m) MIN. FLASHING

MAINTAIN CLEARANCE TO

COMBUTIBLE THROUGH

JOIST AREA SEE TABLE 1

PLATE SUPPORT-

SEE TABLE 3 FOR

MAXIMUM DISTANCE

BETWEEN SUPPORTS

FIRESTOP - LOCATE OVER

JOIST TO MAINTAIN CORRECT

CLEARANCE FROM VENT

CASING TO COMBUSTIBLE

MATERIAL.

DRAFT HOOD CONNECTOR

(IF REQUIRED) SEE

APPLIANCE INSTRUCTIONS

APPLIANCE

7

EXTERIOR INSTALLATION

Enclose exterior vent systems below the roof line or use

double wall Corr/Guard (CG/FCS/FCS-1/FCS-2) to limit condensation due

to cool down of ue gases.

1. There may be installations where Corr/Guard vent shall run vertically

- exterior to the building and a wall band support is needed. A wall

support (WS) is used to secure the vent system to a wall while

maintaining the minimum clearance to combustible construction

(See FIG. 15).

2. Wall supports must be securely fastened to a solid member of the

building using appropriate fasteners for various building materials

such as wood, steel siding or masonry.

3. Exterior mounted wall supports are to be vertically spaced per

TABLE 4 on PAGE 4.

4. Wall supports are designed to be fastened to the vent by means of

clamping externally to the vent for 3”-24” diameters. No screws are

to puncture the vent wall.

5. When system is installed outdoors, the upper side (upper half of

horizontal position) of the closure band bead should be sealed with

clear silicone sealant to make the casing water tight.

WARNING: DO NOT RIVET OR SCREW SUPPORTS TO THE VENT

OR OTHERWISE PUNCTURE THE VENT WALL.

WARNING: DO NOT PLACE ANY TYPE OF INSULATION IN ANY

REQUIRED CLEARANCE SPACES SURROUNDING THE

VENT SYSTEM.

GUY RING (FCSGR)

Chimneys that exceed 5’ above the roof, or are installed in severe

weather regions, may require a guy ring (FCSGR) to enable the chimney

to resist wind loads. The guy ring is connected to the building or other

structure by means of cables or braces.

RAINCAP

LOCKING TAB

STORM COLLAR PITCHED

FLASHING

SEE TABLE 4 FOR

MAX. HEIGHT

UNLESS SUPPORTED

BY GUY WIRES

PLATE SUPPORT

USED ABOVE OR

BELOW ROOF JOIST

SEE TABLE 1

FOR CLEARANCES

FIG. 12

ROOF INSTALLATION

3”- 5” CGSW

ROOF INSTALLATION

3”- 5” CG

RAINCAP

STORM COLLAR

PITCHED

FLASHING

ATTACHED BY USING

#8 X 1/2” SCREWS

SEE TABLE 1

FOR CLEARANCES PLATE SUPPORT

USED ABOVE OR

BELOW ROOF JOIST

FIG. 13

FIG. 14

ROOF INSTALLATION

6”- 36” FCSSW, FCS, FCS-1 & FCS-2

SEE CAP DETAIL

CAP

CLOSURE RING

STORM COLLAR

FLASHING

PLATE SUPPORT USED ABOVE

OR BELOW ROOF JOIST

FOR CLEARANCE TO

COMBUSTIBLES

SEE TABLE 1

CLOSURE

RING

JOINT

CLAMP

ALLOW AIR SPACE

BETWEEN END

OF CASING AND

CLOSURE RING

AS SHOWN

CAP DETAIL

FIG. 15

BOILER 1 BOILER 2

SEE TABLE 3

FOR DISTANCE

BETWEEN SUPPORTS

TO TERMINATION

WALL

SUPPORT

SEE TABLE 4

FOR DISTANCE

BETWEEN

SUPPORTS

SEE TABLE 1 FOR

CLEARANCES

TO DRAIN

TO DRAIN

SEE TABLE 4 FOR

MAX. HEIGHT

UNLESS SUPPORTED

BY GUY WIRES

SEE TABLE 4 FOR

MAX. HEIGHT

UNLESS SUPPORTED

BY GUY WIRES

8

MAINTENANCE INSTRUCTIONS

As with all vents, the Corr/Guard vent system should be inspected at

least annually for the presence of deposits or debris and any

accumulation should be removed. The vent system should

also be inspected at regular periods for signs of leakage of

condensate or combustion products at any joints.

If the vent system incorporates a drain hose from either an inline fitting

or from a drain tee, the hose must be inspected periodically to ensure

that water is in the trap loop. If a proper trap loop is not

maintained, exhaust from the connected appliances may accumulate

in the building area.

Where the duct is installed outside the building, the aluminized

steel outer casing must be primed and painted. The painted

surface should be maintained regularly to prevent possible

deterioration of the casing surface. The use of stainless steel outer

casing negates the need for painting.

IMPORTANT: The listing for this product is void if components

other than those supplied as Listed Components by Metal-Fab,

Inc. are used. All warranties, stated or implied, are void if this

product and the appliances to which it is connected are not

installed in accordance with their respective instructions and

local code requirements.

VARIABLE LENGTH

For installations that require non-standard vent lengths, Corr/Guard

Variable Length vent sections may be used. The vent section consists of

an inner conduit that slip fits into the outer conduit, a compression band,

or integral clamp and an outer casing (for double wall only).

3”- 5” (76mm-127mm) CG & CGSW

To install the VL vent section, first install the inner pipe section by

connecting the male section to the adjoining double or single wall

vent pipe. Insert male section until the bead of the joint stops at the

edge of the female end of the vent section.

Next, expand the length of the inner pipe to the necessary length and

tighten the integral clamping band using a hex drive or screw driver.

The VL’s are adjustable from 7 1/2” to 22” (191mm to 559mm).

Continue with the next section of vent, making sure to fully join the

inner pipe of the vent from the female end of the VL vent.

When installing double wall, finish the VL vent assembly by installing

the outer casing wall around the VL inner pipe section. Secure

the casing by installing #8x1/2” sheet metal screws at prepunched

holes (See FIG. 17).

P.O. Box 1138 • WICHITA, KANSAS 67201

(316)943-2351 • Fax (316)943-2717

©2018 Metal-Fab, Inc. Form No. L2591 02/18

9753

6”- 36” (152mm-914mm) FCSSW, FCS, FCS-1 & FCS-2

To install the Variable Length, first apply a heavy bead of P070 or

P077 sealant into the outer vent bead. Slide the inner vent into the

outer vent. Locate the Variable Length into position and adjust to the

proper length. Follow joint assembly details on PAGE 4. Apply a bead

of P070 or P077 sealant at the joint of inner and outer vent and attach

the compression band. The VL-22 is available for diameters 6”-36”

(152mm-914mm). The VL-22 is adjustable from 9”-22” (228mm-559mm)

for 6”-24” (152mm-610mm) diameters and 7”-22” (178mm-559mm)

for 26”-36” (660mm-914mm) diameters. The VL-10 is available for

diameters 26”-36” (660mm-914mm). The VL-10 is adjustable from

7”-10” (178mm-254mm). If the inner vent sleeve is too long to fit into

adjacent vent component, trim back to fit. When installing double wall

vent system, cut the outer jacket to fit between the mating vent and install

using sheet metal screws (provided). (See FIG 18).

CONDENSATE REMOVAL

All sections of a ventilation system shall have a minimum upward slope

of 1/4”:12” for CAT II, CAT III and CAT IV appliances or downward slope

for CAT III & CAT IV appliances. Condensate Drains must be provided at

any low point within the venting system.

If an appliance does not supply a condensate drain and one is required

per the appliance manufacturer’s instructions or local codes, install a drain

fitting in the horizontal conduit, as close as possible to the appliance vent

collar.

WARNING: NEVER INSTALL A DRAIN IN A SYSTEM WITH AN

APPLIANCE NOT INVESTIGATED FOR USE WITH A

CONDENSATE DRAIN.

Sleeved Corr/Guard drain fittings contain a drain tube that should be

located at the bottom of the vent or fitting when installed properly.

A drain hose must be attached to the tube and a trap loop must be

formed into the drain hose. The trap loop should be at least four times

the appliance’s rated stack pressure in inches of water column or

sized for 15” (381mm) w.c. max. vent pressure, which ever is less

(See FIG. 16).

FIG. 16

TUBING

TRAP LOOP

(4X STACK PRESSURE)

FIG. 17

INTEGRAL

CLAMP

INNER VENT

CASING JACKET

OUTER VENT

FIG. 18

INNER VENT

OUTER VENT

BEAD

OUTER JACKET

FOR CG ONLY

SLEEVE (EXTEND

INTO ADJACENT

COMPONENT)

AIRFLOW

Table of contents

Other Metal Fab Fan manuals

Popular Fan manuals by other brands

Vents

Vents VCU series user manual

CTC Union

CTC Union CLATRONIC VL 2838 Instruction manual & guarantee

Broan

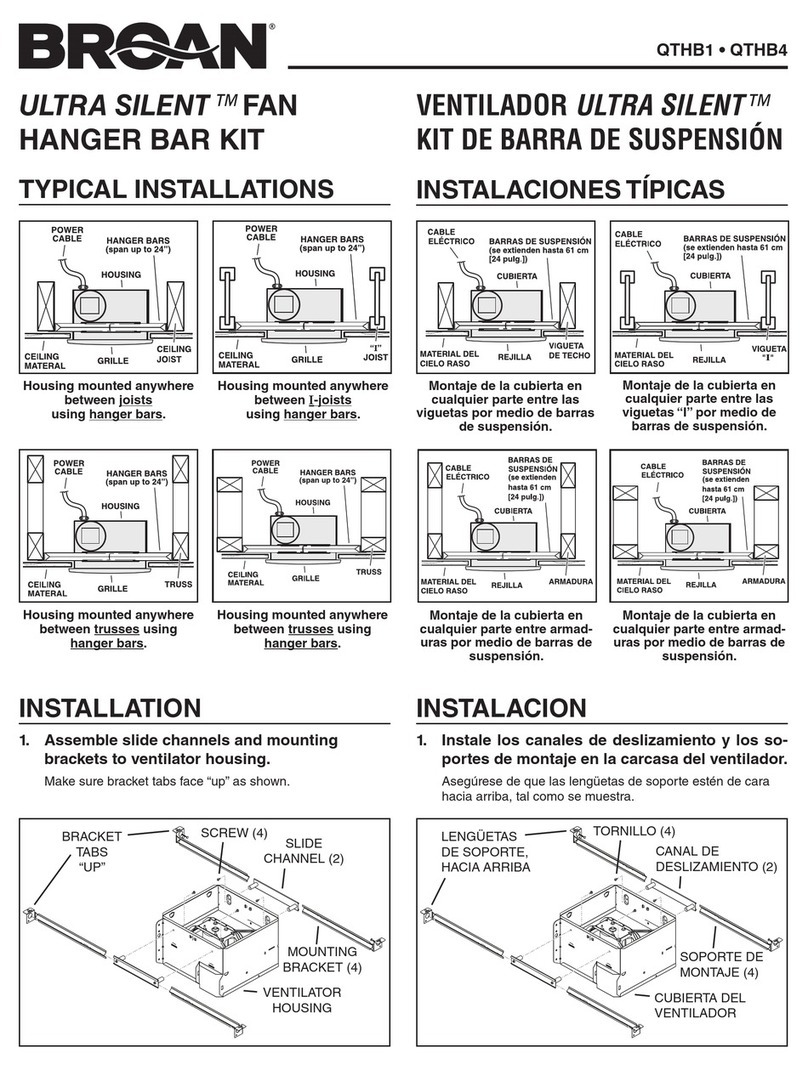

Broan ULTRA SILENT QTHB1 Installations

Airflow

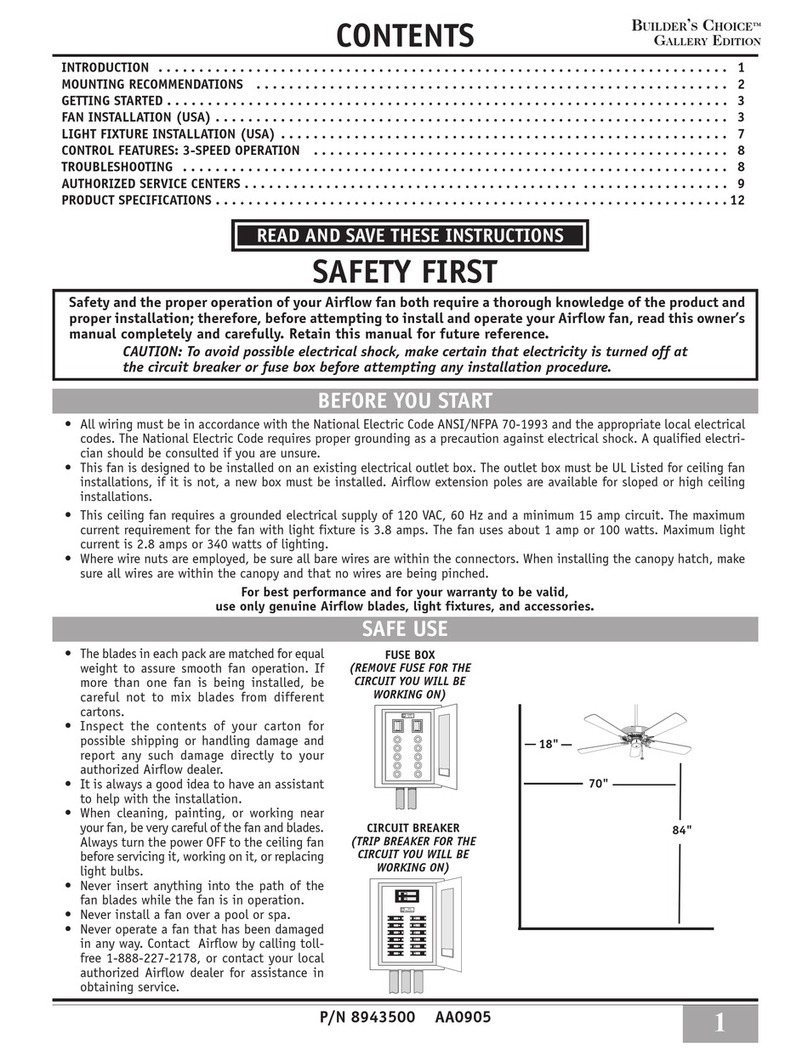

Airflow Ceiling fans owner's manual

The Modern Fan Company

The Modern Fan Company Altus ALT-42 Installation instructions and owner's manual

Swann

Swann Retro SFA12610 manual