Metal-Fach KRUK U-710 User manual

1

METAL-FACH Sp. z o.o.

16-100 Sokółka, ul. Kresowa 62

Tel: (0-85) 711 98 40

Fax: (0-85) 711 90 65

OPERATING INSTRUCTIONS

"KRUK" CULTIVATOR

Type U-710, U710/1

Edition no. 05

Year of issue 2012

Original Operating Instructions

2

CE DECLARATION OF CONFORMITY

FOR THE MACHINE

Manufacturer:

METAL-FACH Sp. z o.o.

ul. Kresowa 62

16-100 SOKÓŁKA,

Machine:

"KRUK" Cultivator

type/model: U710..................................

serial number:........................................

year of manufacture: ............................

Function/ intended use: soil cultivation before sowing

We declare that the machine which this declaration concerns meets the

following requirements:

- Directive 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL dated

May 17th 2006 on machines and the Resolution of the Minister of Economy of October 21st 2008

concerning general requirements for machinery (Journal of Laws, issue 199 item 1228);

Compliance has been evaluated with the following harmonised standards:

PN-EN ISO 4254-1:2009 + AC:2010

PN-EN ISO 13857:2010

PN-EN ISO 12100:2011

- and the following standards: PN-ISO 3600:1998, PN-ISO 11684:1998; and the Resolution of the

Ministry of Infrastructure of 31.12.2002 on the technical requirements for vehicles and the scope of

their necessary equipment (Journal of Laws 2003, issue 32 item 262 as amended).

Safety Test Report No. MF/3/2010

Person authorised to prepare the technical documentation: Metal-Fach Technical Department

This Declaration of Conformity becomes void and null if the machine's design is

changed or modified in any manner without prior consent from the manufacturer.

Sokółka 13.10.2010r

President of the Management Board

Jacek Marek Kucharewicz

3

Nameplate

Please state the type and identification number of the machine in all communications,

questions and warranty issues.

The identification data of the machine can be found on the data plate located on the upper front

hitch of the three point hitch.

The manual is a part of the machine's base equipment.

Nameplate

4

Identification data

Machine type: cultivator

Commercial designation: KRUK

Type / Code: U-710- ............................................*

U-710/1- .........................................*

Serial no.: ....................................................................................

Machine manufacturer: "METAL-FACH" Sp. z o.o.

16-100 Sokółka

ul. Kresowa 62

Tel: (0-85) 711 98 40

Fax: (0-85) 711 90 65

Seller: ....................................................................................

Address: ....................................................................................

....................................................................................

Tel./Fax: ....................................................................................

....................................................................................

Date of delivery: ....................................................................................

Owner / User: Name: ....................................................................................

Address: ....................................................................................

....................................................................................

Tel./Fax: ....................................................................................

HINT: Note down the type and serial number of your machine. Please give this number every

time you contact your supplier.

*delete as appropriate

5

Table of contents:

page

CE DECLARATION OF CONFORMITY

NAMEPLATE

IDENTIFICATION DATA

1. INTRODUCTION..................................................................................................................................6

2. INTENDED USE....................................................................................................................................6

2.1 OPERATION ACCORDING TO THE INTENDED USE

3. USER SAFETY ......................................................................................................................................7

3.1 GENERAL SAFETY REGULATIONS

3.2 MAINTENANCE AND SERVICING

3.3 TRAVELLING ON PUBLIC ROADS

3.4 SAFETY SIGNS

4. DISMANTLING AND DISPOSAL....................................................................................................11

5. LIGHT SIGNALS (OPTIONAL).......................................................................................................11

6. MACHINE DESIGN............................................................................................................................12

6.1 TECHNICAL CHARACTERISTICS OF THE KRUK U-710 AND U-710/1 CULTIVATORS

7. DELIVERY AND LOADING ON MEANS OF TRANSPORT.......................................................13

8. OPERATION AND USE.....................................................................................................................13

8.1 PREPARATION OF THE MACHINE

8.2 COUPLING THE MACHINE TO THE TRACTOR

8.3 MACHINE ADJUSTMENT

8.3.1 ADJUSTMENT OF THE HARROW DISKS' WORKING DEPTH

8.3.2 WORKING DEPTH AND TINE ANGLE ADJUSTMENT

8.4 OPERATION OF THE MACHINE

8.5 LUBRICATION AND STORAGE

9. RESIDUAL RISKS..............................................................................................................................15

9.1 DESCRIPTION OF RESIDUAL RISKS

9.2 EVALUATION OF THE RESIDUAL RISK

10. WARRANTY CONDITIONS AND WARRANTY SERVICES......................................................16

WARRANTY CARD

COMPLAINT CALL

SERVICE LOG

11. STABILITY OF THE UNIT CONSISTING OF THE TRACTOR AND CULTIVATOR...........17

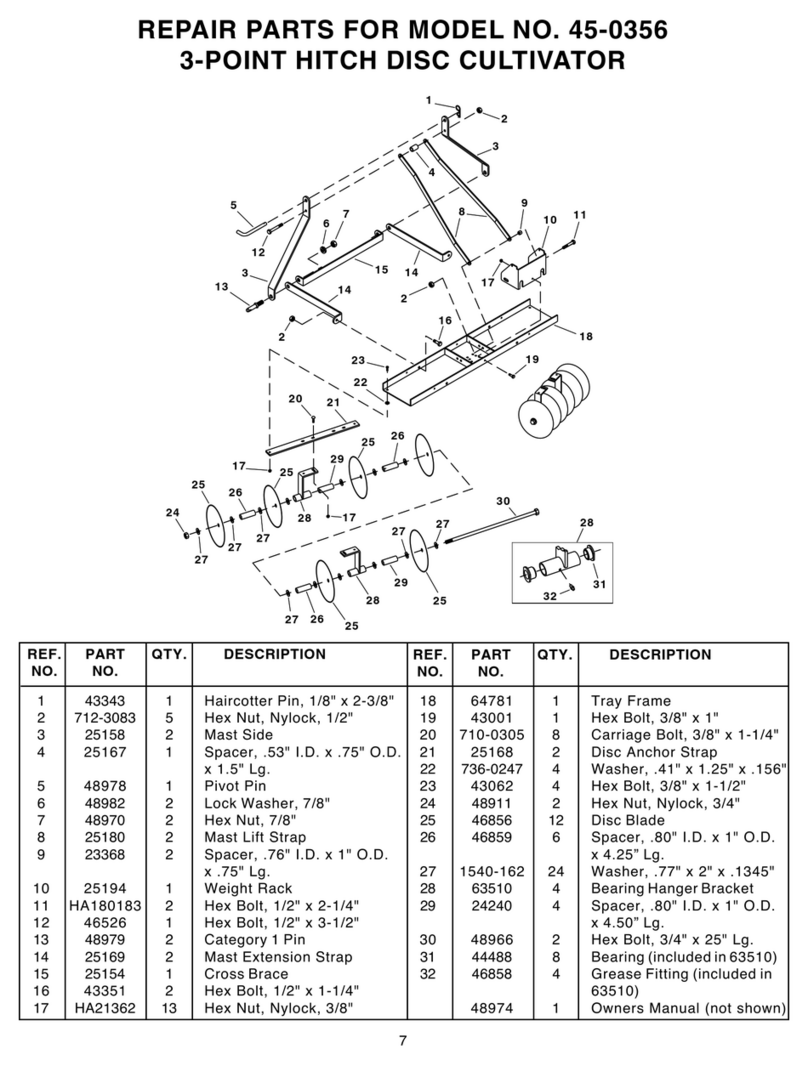

12. PARTS CATALOGUE........................................................................................................................21

12.1 USING THE PARTS CATALOGUE

12.2 ORDERING PARTS

6

1. INTRODUCTION

The following instruction manual describes the use and operation of the U-710, U-710/1

machine. If particular problems arise during the operation of the machine which were not discussed

in detail in the operating instructions the customer may request supplementary information from the

manufacturer or the supplier. The crucial obligations of the manufacturer are stated in the warranty

document which specifies the complete and current regulations for warranty services.

META-FACH Sp. z o.o. reserves the right to introduce changes without prior notice and

without assuming any obligations resulting from those changes.

The design of the machine allows for safe operation on condition that it is are used

according to the operating instructions. Therefore before starting the machine we request that the

users read the following manual and familiarise themselves with the safe operation conditions.

All operator of this machine must familiarise themselves with the contents of the operating

instructions before commencing works.

This is to make sure the user knows how to operate the machine properly and safely.

This also conditions that your warranty rights are maintained.

The manual is part of the machine's equipment.

2. INTENDED USE

The compact KRUK disc harrow is a universal tool for the cultivation of the top layer of soil

to the depth of 5 cm to 15 cm. It is designed for use after harvest and before sowing following

ploughing or in soil cultivation without ploughing, when the vegetation remains are not covered but

mixed with the top soil layer (i.e. mulched). It may be used on all types of soils including those with

stones thanks to the use of elastic suspension of the harrow discs. The harrow allows for opening

and mixing of the soil and in connection with the packer also for packing and compressing of soil.

Due to the resistance to clogging the harrow is well suited for the cultivation of tall stubbles which

remain after the harvest of crops and corn and for cultivation of aftercrops intended to be used as

fertiliser.

2.1 OPERATION ACCORDING TO THE INTENDED USE

The machine may be started, operated and repaired only be persons who are familiarised

with its operation and the operation of the tractor as well as with the rules of safe use of the

machine.

The manufacturer does not assume responsibility for any changes made by the user without

permission. During the service life of the machine only original parts manufactured by

METAL-FACH may be used.

REMEMBER - The machine is designed to be used only in agricultural applications. Any use

of this machine other than specified in section 2 is considered improper use. Improper use

also includes using the machine in work conditions other than those specified by the

manufacturer, improper repair and maintenance.

The manufacturer does not assume any responsibility for any damage resulting from

improper use of the machine.

7

3. USER SAFETY

REMEMBER - Before starting the maintenance or use of the machine the user should

familiarise himself with these operating instructions and know the design of individual

assemblies and their functions, scopes and means of adjustment paying particular attention to

the information regarding safe operation.

It is too late to learn that during work.

3.1 GENERAL SAFETY REGULATIONS

The safety regulations given below apply to the machine. Regardless of those regulations the

user must also follow the general safety and accident prevention regulations and the traffic code.

The machine (cultivator + tractor) should be operated maintaining all rules of safe operation,

in particular:

every time before start-up check the machine and the tractor - whether they are in condition

which guarantees safety during movement and operation;

to maintain steerability the machine may only be coupled to a tractor with a full set of

weights on the front axle. When the machine is coupled the load on the tractor's front axle

must be at least 20% of the tractor's own weight;

the user must make sure to follow the maximum allowable axle loads and transport

dimensions;

when coupling the machine to the tractor, raising and lowering the machine using the

tractor's hydraulic system, unfolding the machine to its transport or working position and on

headlands the operator must ensure that there are no bystanders nearby, especially children;

when the engine is running no person is allowed between the tractor and the machine;

noise - the equivalent sound pressure emission corrected by A characteristics (LpA) does not

exceed 70 dB;

when connecting the hydraulic lines to the tractor's hydraulic system the operator must make

sure that the system is not under pressure. The operator must check the positions of the

tractor hydraulic system control levers;

it is only allowed to operate the hydraulic elements when no person is nearby;

the hoses and pipes in the hydraulic lines must be checked on a regular basis and replaced

with new ones it they are damaged;

all hydraulic lines must be replaced every 6 years;

raising, lowering, folding and unfolding and movements of the machine should be done

slowly without jerking movements;

it is forbidden to reverse the tractor and make turns when the machine is lowered to its

working position;

when making turns bear in mind that there are protruding elements in the machine, the use

of tractor's independent brakes must be avoided;

the user must check the tyre pressure in the tractor and in the machine;

during transport no person should be allowed to stand on the machine nor any load may be

placed on it;

due to the machine height in the folded position, exercise extreme caution near overhead

power lines;

any repairs, lubrication or cleaning of the working elements required during work may only

be performed with the engine turned off and the machine lowered;

only uncouple the machine when its discs rest on stable firm ground, the hook support is

unfolded and the engine is turned off;

the machine may only be stored in its unfolded position, resting on all working components;

when not in use the machine should be stored in places where it cannot be accessed by

unauthorised persons and animals;

8

3.2 MAINTENANCE AND SERVICING

The technical maintenance may be performed when the machine is lowered to the ground. If

the machine is coupled with a tractor it must be turned off and the brakes must be engaged.

Only use tools and instruments that are in good condition and original materials and spare

parts. Use standard pins and safety devices to lock the machine's bolts in place. It is forbidden to

use make-shift safety devices such as bolts, rods, wires etc. which may be the cause of damage to

the tractor or the machine during operation and may reduce safety.

3.3 TRAVELLING ON PUBLIC ROADS

According to the road travel safety rules /Regulation by the Minister of Infrastructure of

31.12.2002 Journal of Laws no. 32 of 2002, item 262/

A unit consisting of a tractor with a coupled farming machine must meet the

same requirements as an individual tractor.

WARNING - The machine (part of the unit consisting of the tractor and machine) is a part

protruding outside the outline of the vehicle and obstructing the tractor's rear lights and as

such it poses a threat to other vehicles travelling on the road.

REMEMBER - It is forbidden to travel on the roads with the unit (tractor + machine) without

appropriate marking.

While travelling on public roads with a unit consisting of the tractor and the machine

all rules of the Traffic Code specific to vehicles of this type apply, in particular:

the side sections of the machine must be folded to the transport position and secured with

bolts against unfolding during transport (see. fig. 1).

during transport on the road the cultivators coupled to a tractor require:

–marking with warning plates with red and white stripes,

–lights:

–elements protruding to the side of the tractor (front marker lights - white),

–repeated rear lights of the tractor (combined lights + reflective lights),

–marking with a triangle plate indicating a slow moving vehicle,

do not exceed the maximum allowable transport speed, which is:

–on paved roads –up to 20 km/h,

–on dirt roads or cobblestone –6 - 10 km/h

–on uneven roads –5 km/h maximum

The speed must be adapted to road conditions and the condition of the road surface.

special care must be taken while passing or overtaking other vehicles and on corners. The

maximum permissible width of the machine which is allowed on a public road is 3.0 m.

9

Fig. 1 Transport position of the machine –1 –coupling rod

3.4 SAFETY SIGNS

Table 1

Item

Safety Symbol

Meaning of the symbol (sign) or

text

Location on the machine

1

2

3

4

1

1 pc.

Dimensions 100x50

Colour: yellow background, black

figures

Read the operating instructions.

On the front left section of the frame.

2

1 pc.

Dimensions 100x50

Colour: yellow background, black

figures

Turn off the engine and remove

the ignition key before servicing

or repairs.

On the front left section of the frame.

3

1 pc.

Dimensions 100x50

Colour: yellow background, black

figures

Keep a safe distance from the

machine.

Danger of being crushed by the

machine.

On the front left section of the frame.

10

Item

Safety Symbol

Meaning of the symbol (sign) or

text

Location on the machine

1

2

3

4

4

2 pcs.

Dimensions 100x50

Colour: yellow background, black

figures

Do not reach into the crushing

area if the machine may move.

On the side wall of the machine frame in

the side section folding areas on the left

and right sides.

5

2 pcs.

Dimensions 100x50

Colour: yellow background, black

figures

Danger of being crushed by the

side sections of the machine.

On the wall of the machine frame at the

folding rotation axis of the side sections

on the left and right sides.

6

2 pcs.

Dimensions 100x50

Colour: yellow background, black

figures

Keep a safe distance from the

machine.

Danger of crushing of toes or

feet.

- Force applied from the top.

On the side wall of the machine frame in

the side section folding areas on the left

and right sides.

7

Dimensions 50x50

Colour: white background, black

figures

Pictogram indicating attachment

points for loading the machine on

means of transport.

On both sides of the main frame near the

attachment point of the upper hitch of

the 3-point hitch and near the carriage

attachment plate.

11

4. DISMANTLING AND DISPOSAL

The cultivator is made of materials which do not pose a threat to the environment. After its

service life expires, i.e. when further operation is no longer justified, the machine must be

dismantled.

Due to the heavy weight of the parts it is required to use lifting devices such as a gantry

crane or a forklift during the dismantling process.

The metal parts must be transferred to a scrap metal collection point and the rubber elements

must be taken to a collection point for waste of this type. Used oil from the hydraulic system should

be collected in sealed containers and transferred to a point which collects such waste.

5. LIGHT SIGNALS (OPTIONAL)

Before entering public roads a warning plate with red and white stripes, signal lights and a

bracket for a plate indicating slow moving vehicles must be installed (the means for installation as

specified in fig. 2 and 3). The power supply shall be connected with the tractor's electric system,

and a triangle plate must be installed in the bracket. A warning plate with lights is an optional part

of the machine and is supplied on request.

Fig. 2 Installation of warning signals on the machine with a truck.

Fig. 3 Installation of lights on the machine without a truck.

12

6. MACHINE DESIGN

The KRUK –4.5 m or 6 m semi-suspended type cultivator consists of the following

assemblies and subassemblies:

•the 3-point hitch to which two side frames are attached; disc blades are attached to the

side frames;

•the draw-bar with the hitch axis;

•packer mounting brackets with hydraulic adjustment of depth of operation which

allow for compacting of the opened soil to obtain the optimum soil structure for

sowing;

•the undercarriage frame;

•the truck;

•thebeams with spring tines with operating depth and inclination angle adjustment;

•the double acting hydraulic cylinders with lines.

Fig. 4 KRUK Cultivator

1- 3-point hitch, 2- machine arms, 3- disc blades, 4- undercarriage frame 5- packer, 6- truck,

complete, 7- hitch, complete

6.1 TECHNICAL CHARACTERISTICS OF THE KRUK U-710 AND U-710/1

CULTIVATORS

Item

Parameters

Unit

Type

KRUK U-710/1

KRUK U-710

1

Cultivator type

-

suspended / semi-suspended

2

Service width

m

4,5

6

3

No. of discs

pcs

32

44

4

Packer type

- pipe (Ø600)

- Packer (Ø500)

5

Disc diameter

mm

Ø560

6

No. of scrapers

pcs

34

48

7

Depth adjustment range

cm

od 5 cm do 15 cm

8

Disc pitch

mm

250

9

Working speed

km/h

8-13

10

Efficiency

ha/h

4,0-6,5

5,0-8,0

13

11

Power demand

HP

kW

180-200

132-147

200-240

147-176

12

Operation

person

s

operator

13

Dimensions

Length/Width/Height

mm

3220/4820/1650

3220/6450/1650

14

Weight /with packer/

kg

3450

4250

15

Hitch category

-

3

7. DELIVERY AND LOADING ON MEANS OF TRANSPORT

The machine is supplied to the user partially disassembled. How much the machine is

disassembled depends on the used mean of transport. While loading and unloading the machine,

parts of the frame indicated as lifting points with appropriate pictograms should be used for lifting

the machine see section 3.4.

8. OPERATION AND USE

8.1 PREPARATION OF THE MACHINE

While preparing the machine to work it is required to check its technical condition, most

importantly the condition of the working elements.

In addition it is required to:

•check the condition of the bolted joints,

•check the folding and unfolding of the machine,

•check the condition of the hydraulic lines and actuators - whether there are any leaks,

•check whether the discs and packer rotate freely by rotating them by hand,

•lubricate the elements of the machine in accordance with the guidelines specified

in section 8.5.

The machine's hydraulic system is filled with Renolin VG46 hydraulic fluid manufactured

by FUCHS. It is allowed to mix it with the hydraulic liquid with the oil from the tractor's hydraulic

system.

8.2 COUPLING THE MACHINE TO THE TRACTOR

To safely and securely couple the machine to the tractor it should be placed on a firm and

level ground.

To couple the machine to the tractor it is required to perform the following actions:

•reverse the tractor to a distance which allows to couple the machine with the tractor's lower

hitch,

•attach the upper rod of the 3 point hitch to the machine and remove any play (suspended

version),

•attach the hitch chain (truck version) at the upper rod mounting place on the tractor,

•attach the hydraulic lines of the machine to the tractor's external hydraulic system,

•raise the machine, in truck version fold the hitch support,

•check the leaktightness of the machine's hydraulic system, the hydraulic lines may not be

bent or damaged,

14

8.3 MACHINE ADJUSTMENT

8.3.1 ADJUSTMENT OF THE HARROW DISKS' WORKING DEPTH

The working depth of the harrow disks may be adjusted using the tractor's three point hitch

or the mechanical or hydraulic shaft adjustment mechanism.

In case of the mechanical adjustment the depth is adjusted by changing the length of the

turnbuckles.

In case of hydraulic depth control the adjustments are made using the hydraulic control

levers inside the tractor's cabin by changing the number of pressure plates of the actuators placed on

the piston rod (fig. 5 - item A).

8.3.2 WORKING DEPTH AND TINE ANGLE ADJUSTMENT

The adjustment of the tine working depth is performed using pins placed in appropriate

openings in the plough frog secured with a cotter pin (fig 5. - item B).

The angle may be adjusted using the lower scraper attachment pins (fig. 5 - item C).

Fig. 5. Machine operation adjustment.

WARNING - Remember to always check the positioning of unused pressure plates of the

hydraulic actuator to avoid damaging the hydraulic adjustment system.

8.4 OPERATION OF THE MACHINE

Before commencing fieldwork using the machine it is required to:

•remove the warning markings,

•disconnect the coupling rod 1 (fig. 1), then unfold the machine to its working position,

•lower the tractor's lift and set it to floating mode, set the machines working depth,

•lift the undercarriage to the maximum so that the wheels are lifted off the ground.

If during operation the machine becomes clogged with vegetation remains it must be cleared

by raising the machine for a moment using the tractor's hydraulic system.

Hydraulic adjustment

Mechanical adjustment

15

The machine should be adjusted during the first pass. If the machine is properly levelled the

frame is parallel to the field's surface.

WARNING - Avoid jerky movements while using the machine.

- Make turns gently with the machine raised in the transport position.

- Do not reverse or turn the tractor around with the machine in the working

position as it may cause damage to the machine.

8.5 LUBRICATION AND STORAGE

The durability and efficiency of the machine depends to a large degree on systematic

lubrication. Use mineral oils for lubricating the machine. Before adding grease clear the lubrication

points. The lubrication should be performed according to fig. 5.

Use the ŁT-4S-3 once per season.

The hubs of the harrow disks must be lubricated twice per year:

+ before the spring season,

+ before the autumn season.

Fig. 6. 1- joint bushing, 2- hitch spindle bolts, 3- undercarriage spindle bolts, 4,6- hydraulic

cylinders (cylinder eye), 5- bearing set of the disc blades, 7- undercarriage

joint, 8- packer bearing set, 9- arm pins.

Before a long period of storage the machine should be cleaned and all malfunctions should be

repaired. Protect the machine against weather conditions. The machine should be stored in the

unfolded position on a level, hard surface.

9. RESIDUAL RISKS

9.1 DESCRIPTION OF RESIDUAL RISKS

The residual risk results mostly from improper behaviour of the operator caused by lack of

knowledge or attention. The highest residual risk occurs in the following situations:

•the machine is operated by minors or persons who are unfamiliar with the operating

instructions,

•the machine is operated by persons under the influence of alcohol or other intoxicants,

•the machine is used for purposes other than specified in the operating instructions,

16

•a person is present between the tractor and the machine with the tractor's engine running,

•bystanders, especially children are present near the working machine,

•the machine is cleaned while working,

•manipulation of the moving elements while the machine is working,

•checking of the machine's technical condition.

While presenting the residual risk the machine is treated as designed according to the state

of knowledge in the year of its manufacture and maintaining the basic OH&S rules.

9.2 EVALUATION OF THE RESIDUAL RISK

If the following guidelines are adhered to the occurrence of residual risk may be minimised:

•always follow the safety regulations described in the operating instructions,

•read and fully understand the operating instructions,

•keep your hands out of hazardous spaces;

•it is forbidden to operate the machine in the presence of bystanders and in particular

children,

•maintenance and repair of the machine may only be performed by trained personnel,

•the machine may only be operated by persons who were trained in its operation and have

familiarised themselves with the operating instructions,

•the machine is protected against access by children,

•the machine is operated by persons in good physical condition who are not under the

influence of any intoxicants.

WARNING!

The residual risks are present when the listed rules and indications are not followed.

10. WARRANTY CONDITIONS AND WARRANTY SERVICES

The detailed information on the warranty for agricultural equipment is listed in the Civil

Code, Part III, Warranties, art. 577-581. This information should be available at every farming

equipment dealership and service workshop.

The organisations responsible for the execution of warranty services (reseller/dealer) should

be entered in the warranty card during the sale of the machine.

17

11. STABILITY OF THE UNIT CONSISTING OF THE TRACTOR AND

CULTIVATOR

The tractor should have appropriate ballast at its

front end to provide proper steering and braking

performance. When the machine is coupled the load

on the tractor's front axle must be at least 20% of the

tractor's own weight (Fig. 7).

Remember that the road and the coupled machine

influence the driving characteristics. The driving

style should be adjusted to terrain conditions and

type of soil.

While negotiating corners with the coupled or

suspended machine it is important to bear in mind

the reach and weight of the machine.

Fig. 7. Minimum load on the tractor's front axle.

18

16-100 SOKÓŁKA, POLAND UL. KRESOWA 62

WARRANTY CARD

FOR THE "KRUK" CULTIVATOR

U-710, U-710/1

The warranty service is provided on behalf of the manufacturer by:

................................................................................................................................................................

filled out by the seller

Date of manufacture ....................................... Serial no. ..........................................

Date of sale ........................................ Dealer's signature ..........................................

Customer name ....................................................................................................................................

Address (Postal code / Post office)......................................................................................................

Street / Number....................................................Telephone..............................................................

META-FACH Sp. z o.o. reserves the right to introduce changes to the machine's design without

prior notice and without assuming any obligations resulting from those changes. Unauthorised

modifications of the machine shall result in the warranty becoming null and void. During the

service life of the machine only original parts manufactured by METAL-FACH may be used.

19

COMPLAINT CALL NO.

DATE

Customer data:

Customer's name and surname / Company name...............................................................................................

City:.................................................................................... (Postal code / Post office) .......................................

Street ................................................Telephone.........................................Fax..................................................

Machine name and code

....................................................................... Z/T-.................................

Date of

purchase

Serial number

Year of

manufacture

1. When and under what circumstances was the machine's failure discovered?

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

2. Comprehensive fault description

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

3. Customer's proposed mode of complaint call processing

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

.................................................................................

(legible signature of the customer who filed the complaint)

NOTE: If the complaint is found to be unjustified, all complaint processing costs will

be charged to the complaint applicant.

Customer complaint placed by phone

date..........................................................................

Dealer's stamp

............................................................

Legible signature of the Dealership Representative

20

SERVICE LOG

Item

Date of call

Date of

completion

Description of completed service

actions and replaced parts

Name and stamp of the

mechanic or service

station

This manual suits for next models

1

Table of contents

Other Metal-Fach Tiller manuals