Metal-Fach T466 User manual

EN

METAL-FACH Sp. z o.o.

16-100 Sokółka, ul. Kresowa 62

Tel. no. +48 85 711 98 40

Fax: +48 85 711 90 65

BIG-BAG FERTILISER SUSPENDED LOADER

T466

Machine type: T466

Year of

manufacture: ................

Serial no. ......................

Edition no. 01

Year of issue: 2012

Original Instructions

Read the instructions

carefully before

operating the machine

2

WA R N I NG:

The manufacturer delivers the machine completely assembled and complete with the

operating instructions and the warranty card. When receiving the machine, the customer should

verify that the product and enclosed documents are complete, verify the technical condition and

check for any transport damage or missing parts.

Before starting operation of the machine, you absolutely must understand the safety

guidelines in the operating instructions. Also please ensure that all operators of the machine

read and understand these operating instructions before start.

Attention!

Complete understanding of the Operating Instructions and following the guidelines presented

herein guarantees easier work, reliability and safe work.

Detailed information concerning operation of this and other machines from Metal-Fach

Sp. z o.o., as well as service assistance and the spare parts catalogue are always available at our

sales representatives.

Always at your service, Metal-Fach Sp. z o.o.

Head ofce: tel. no. +48 85 711 98 40,

fax: +48 85 711 90 65,

biuro@metalfach.com.pl

Sales Department: tel. no. +48 85 711 98 44,

fax: +48 85 711 07 89,

handel@metalfach.com.pl

Service: tel. no. +48 85 711 07 80,

fax: +48 85 711 07 93,

serwis@metalfach.com.pl

Details of warranty and customer service are listed in the warranty card.

WE WISH YOU A SATISFACTORY EXPERIENCE WITH OUR PRODUCTS

THE MANUAL CONSTITUTES

A PART OF THE MACHINE'S EQUIPMENT

KEEP IT FOR ANY FUTURE USERS

3

Table of Contents

1. Preliminary information

.................................................................................................................. 7

1.1. machine identification

............................................................................................................. 7

1.2. General Guidelines for hydraulic system servicinG

..............................................................11

1.3. WarninG symbols

....................................................................................................................11

1.3.1. List of warning signs.................................................................................................. 12

1.3.2. Locations of signs on the machine............................................................................. 15

2. General information

...................................................................................................................... 15

2.1. intended use

........................................................................................................................... 15

2.2. technical and oPeratinG characteristics

............................................................................. 16

2.3. desiGn and oPeratinG PrinciPle of the biG baG fertiliser susPended loader

........................ 17

2.4. Work ranGe of the biG baG fertiliser susPended loader

...................................................... 19

3. oPeration

....................................................................................................................................... 23

3.1. couPlinG the arm With the tractor

....................................................................................... 23

3.2. installinG the Pto drive-shaft

............................................................................................. 24

3.3. charGinG the sPreader

........................................................................................................... 25

4. WorkinG With the loader

.............................................................................................................. 31

4.1. maintenance and servicinG

.................................................................................................... 32

4.2. safety of use durinG servicinG/maintenance

......................................................................... 32

4.3. daily service

.......................................................................................................................... 33

4.4. lubrication schedule

............................................................................................................. 34

4.5. tiGhteninG torques

................................................................................................................ 34

5. maintenance, care and storaGe

.................................................................................................. 35

5.1. safety

..................................................................................................................................... 35

5.2. transPort of the arm

............................................................................................................. 36

5.2.1. Outdoor transport...................................................................................................... 36

5.2.2. Indoor transport ........................................................................................................ 36

5.3. disassembly and handlinG of Worn out Parts

....................................................................... 36

6. descriPtion and assessment of residual risks

.............................................................................. 36

6.1. descriPtion of residual risks

................................................................................................. 36

6.2. residual risks assessment for oPeration and daily servicinG of the loader

....................... 37

7. Parts cataloGue

............................................................................................................................. 38

8. Warranty conditions and Warranty services

.............................................................................. 38

Warranty card

..................................................................................................................................... 39

comPlaint call

..................................................................................................................................... 40

service loG

............................................................................................................................................ 41

external sPare Parts order

................................................................................................................... 42

4

CE DECLARATION OF CONFORMITY

FOR THE MACHINE

„METAL-FACH” Sp. z o.o.

ul. Kresowa 62

16-100 SOKÓŁKA

which acts as the manufacturer

declares under sole responsibility that the following machine:

this declaration concerns, meets the following requirements:

- Directive 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

dated 17 May 2006 on machines and the Resolution of the Minister of Economy

of 21 October 2008 concerning general requirements for machinery

(Journal of Laws, No. 199 item 1228);

The following harmonised standards were used for compliance evaluation:

PN-EN ISO 4254-1:2009 PN-EN 12525+A2:2010

PN-EN ISO 13857:2010 PN-EN ISO 12100:2012

PN-EN ISO 4413:2011

- and the following standards: PN-ISO 3600:1998, PN-ISO 11684:1998; and the Resolution of

the Ministry of Infrastructure of 31.12.2002 on the technical requirements for vehicles and

the scope of their necessary equipment (Journal of Laws 2003, issue 32 item 262 as amended).

Safety Test Report no. MF/6/2012

Unit responsible for engineering documentation: METAL-FACH Engineering Department

This Declaration of Conformity becomes void and null if the machine design is changed

or modied in any manner without prior consent from the manufacturer.

Sokółka, 06.12.2012 President of the Management Board

Jacek Marek Kucharewicz

BIG-BAG FERTILISER SUSPENDED LOADER

type/model T466.................................

year of manufacture: ........................................

serial number: ...................................................

function/purpose – loading of fertilisers in big-bags

5

Introduction

Dear Customers,

Thank you for your trust in us. You have chosen a product of highest quality that will help you

improve your work performance. The long-lasting experience of METAL-FACH guarantees

optimal efciency, quality and comfort of work.

Safety

Read the operating instructions before use and follow the safety rules!

All sections concerning safety in this manual are designated with the warning triangle

sign.

The warning and information symbols on the machine contain important guidelines to

ensure safe work. Follow the for your safety.

Should you have any doubts concerning safe use or require clarication, contact the

representative of METAL-FACH. Our employees are at your service.

This operating instructions manual contains important information about professional and

correct use of the machine, as well as its safe operation.

The machine shall be controlled from the tractor cabin only. The loader shall only be used for

the operations it has been designed for, i.e. handling and lifting of big-bags with fertilisers for

charging of fertilizer spreaders. Never exceed the permitted lifting capacity of 1000 kg. Despite

any experience in operation of this machine type, it is strongly recommended to read these

instructions to understand the product. The manual contains information that is critical to safety

and performance, as well as the validity of the manufacturer's warranty. Having received the

purchased product, verify that it was not damaged in delivery or transport. If any damage is

found or there are parts missing, immediately contact your dealer.

The user must read, understand and carefully follow the product's operating instructions.

The user is also required to keep the hitches and connections on the tractor in good technical

conditions, and to make sure that the driving vehicle has the required lifting capacity for the load

weight value of the complete machine equipment plus the big-bag lled with a fertiliser. Metal-

Fach reserves the right to introduce changes without notice to the operating and maintenance

instructions, and to update the contents without notice.

6

The dealer must have introduced you to operation, setting and maintenance of this machine

upon delivery.

This preliminary orientation usually covered only the basic information and it shall not

replace the thorough understanding of various tasks, functions and proper use.

An equally important factor for safe operation is ensuring the use of original and correct

spare parts for the bag lifting and unloading arm you operate.

7

1. Preliminary information

1.1. Machine identication

The machine is identied by the information on its nameplate. The nameplate contains the

basic information about the product, e.g. the machine's name, symbol, year of manufacture,

serial number, load capacity, weight and the CE mark to conrm compliance with the applicable

Community guidelines and engineering specications for the applicable product group.

The nameplate is on the loader support frame, i.e. on the left side of the main frame as

indicated below.

Fig. 1 Location of the nameplate

8

Identication data:

Machine type: big-bag fertiliser suspended loader

Type / Code: T466 /

Serial no.:

Manufacturer: METAL-FACH Sp. z o.o.

16-100 Sokółka

ul. Kresowa 62

Tel. no. +48 85 711 98 40

Fax: +48 85 711 90 65

Sold by:

Address:

Tel. / Fa x:

Date of delivery:

Owner / User:

Name:

Address:

Tel. / Fa x:

9

Environment, health, and safety

The big-bag fertiliser suspended loader can only be operated and serviced by persons who

have read and understood these operating instructions and the following general rules for safe

work.

1. Never commission and test run the machine in closed shelters due to the hazard of exhaust

gas inhalation.

2. Before starting this machine, understand all systems, controls and their functions! It is too

late to learn that during normal operation!

3. Operation and servicing of the arm can only be assigned to persons who is applicably

qualied to become authorised for operation of farming machines.

4. Before use of the big-bag fertiliser suspended arm, inspect its technical condition, and the

fastening of individual mechanisms, especially of the hydraulic system parts and working

units.

5. Do not operate the machine when it is completely functioning.

6. Re-tighten all loose components and immediately replace all damaged components.

7. If repairs are necessary, use original spare parts only and have a properly qualied person

do the repairs.

8. Do not replace the hook with any other part that has not been factory installed.

9. All safety guards shall be installed and undamaged.

10. Wear protective clothing at work.

11. The driving tractor of the big-bag fertiliser suspended loader shall be equipped with a

driver's cabin.

12. Start the machine when it is in the operating position only and after verifying that no persons

and animals are within 50 m of radius.

13. Prior to starting the machine, ensure that all adjustment elements work correctly.

14. Children must not approach the machine when it is in motion.

15. If any failure occurs, immediately stop the tractor's hydraulic system.

16. The big-bag fertiliser suspended loader shall only be coupled with tractors rated at the

power output listed in the technical characteristics in these operating instructions. In order

to maintain the required stability of the tractor, the vehicle must be equipped with front

weight to keep the tractor front axle load at a minimum 20% of the tractor alone, including

the loader, spreader and bag weight.

17. During transport driving, the machine must remain lifted on the hydraulic lift of the tractor

at a height that leaves at least 300 mm of clearance under the loader frame. Secure the three-

point hitch with chain to prevent the machine from dropping. The lower links of the tractor

shall be rigid (the loader-spreader system must not swing sideways).

18. Transport the lifting arm on public roads only when coupled with a fertiliser spreader.

19. Before transport check:

�that the feed lines are properly connected;

�the hydraulic and braking systems for visible faults;

�that the parking brake has been fully released;

�operation of the braking system;

�fastening of the support on the loader.

20. If the hydraulic system drive is engaged with the PTO drive, remove the drive shaft for

transport driving of the loader-spreader system charged with a fertiliser.

10

21. Always mind the steerability and braking performance of the tractor! The machine installed

on or coupled to the tractor, as well as the front and rear weights affect traction, steerability

and braking performance of the tractor.

22. Check the braking performance before driving!

23. When cornering with the machine suspended or hitched, mind the reach of the machine and

its inertia!

24. Always adapt your driving speed to the trafc!

25. Before driving downhill, always shift into a lower gear!

26. Exceeding the permitted load capacity may result in an accident.

27. During all adjustments and servicing, lower the machine into its rest position, stop the

tractor engine, ensure that all rotating parts have stopped and decouple the drive shaft.

28. All components loosened for inspection, repairs or replacement must be permanently

reafxed.

29. In case of cut, wash the wound and sterilise with hydrogen peroxide. Contamination of the

wound may result in hazards to health and life!

30. Do not carry persons, animals or objects that are irrelevant to operation on the machine.

31. The PTO drive shaft guard must be always installed and secured with chains from turning.

Replace all damaged guards immediately.

32. Exercise extreme caution when travelling on public roads and follow the valid trafc code.

Install a triangle warning sign when in transit.

33. Fill the tank of the spreader coupled with the loader only with the PTO shaft decoupled and

the dosing openings closed.

34. Do not enter between the tractor and the loader when the tractor engine is running.

35. Do not leave the loaded loader lifted unattended.

36. Do not use the loader to haul, push or strike any objects.

37. Exercise extreme caution when unloading or loading near power lines. Keep a safe distance

from live power cables.

38. Do not assign any person to operate the loader before making sure that they have understood

the rules of operation and safety regulations.

39. Do not transport any persons or cargo with the loader.

40. When driving the tractor coupled with the loader and the fertiliser spreader, retract the

loader arm and set it horizontally. Install red-and-white warning plates with lamp clusters

on both sides of the spreader. Install the slow-moving vehicle sign in the bracket on the back

of the spreader. Install a red-and-white warning side with a red parking light at the back of

the loader arm.

41. Check the fastening of the support on the loader before driving.

11

1.2. General guidelines for hydraulic system servicing

1. When coupling the hydraulic hose with the tractor's hydraulic system, make sure that the

hydraulic systems of the tractor and of the machine have been depressurised.

2. Periodically inspect all hydraulic lines and replace with new ones when damaged or expired.

Replaced hydraulic lines must meet the applicable technical requirements.

3. Before servicing the hydraulic system, lower the machine, turn off the tractor engine and

remove the ignition key.

Warning!

Travelling on public roads without the identication required by the

trafc code is forbidden.

4. The operating life of hydraulic lines shall not exceed 5 years (including storage for up to

two years). The hydraulic lines age and weather, which is natural. Hence the operating and

storage life is limited.

5. Never attempt to seal leaking hydraulic lines with your hands or ngers. The liquid (hydraulic

oil) which escapes under high pressure may puncture skin, penetrate the body and cause

severe injury. If injured by hydraulic oil, immediately seek medical attention. Danger of

infection.

1.3. Warning symbols

The big-bag fertiliser suspended loader features adhesive labels with warning

and information symbols for the user and also indicating that the operating

instructions must be read for operation, maintenance and transport.

Keep the symbols clean. If damaged or lost, apply a new sticker of the same

type.

New labels are available for purchase from the manufacturer.

The warning signs must always be legible. If signs are illegible or

destroyed, new ones are available for purchase from METAL-

FACH dealers as spare parts.

12

1.3.1. List of warning signs

Warning sign

PO17

Danger of cutting or severing of ngers or hands by

moving operating parts!

These hazards may be the cause of most frequent injuries,

including amputation of ngers and hands.

Never reach into the hazardous areas when the tractor

engine is running and the power transmission shaft/

hydraulic system is coupled/connected.

Only touch the moving operating parts when they have

completely stopped.

PO13

Danger of crushing ngers or hands by exposed

moving machine parts!

This hazard may be the cause of most frequent injuries,

including amputation of ngers and hands.

Never reach into the hazardous areas when the tractor

engine is running and the power transmission shaft/

hydraulic system is coupled/ connected.

PO28

Danger of crushing the whole body under suspended

loads/machine parts!

This hazard may result in extremely severe or fatal body

injuries.

Do not stay under suspended loads/machine parts.

Maintain safe distance from the suspended load/machine

part.

Mind that all persons must be at a safe distance from the

suspended load/machine part.

Remove all persons from the hazardous area of the

suspended load/machine part.

PO1

Read and follow the safety guidelines in these operating

instructions before starting the machine!

13

PO18

Danger from escaping high-pressure hydraulic oil –

may pierce the skin and penetrate the body (danger

of infection)!

This hazard may result in severe damage with long-term

consequences.

Read and follow the applicable guidelines in the

operating instruction before repairing the hydraulic

system.

PO2

Hazards to service personnel from accidental

start/movement of the machine during assembly,

adjustment, troubleshooting, cleaning or repairs of

the machine.

The potential hazards may result in extremely severe or

fatal injuries.

- Secure the tractor and the machine before any actions

that may result in accidental start and movement of

the machine.

- Follow the chapters of these operating instructions

that apply to the intended task.

PO38

Danger of touching power cables when lifting fertiliser

bags!

These hazards may result in extremely severe or fatal

body injuries.

Exercise extreme caution when working near power lines

to avoid touching them with the arm.

PO4

Danger of crushing and impact between the tractor

tail and the machine during coupling and decoupling!

These hazards may result in extremely severe or fatal

body injuries.

- Do not start the tractor's TPH hydraulic system when

any person remains between the tractor and the

machine.

- Actuate the TPH hydraulic system controls:

• only from the suitable station at the tractor.

• never start the TPH when there is someone in

the hazardous area between the tractor and the

machine.

14

PI3

Lifting points for machine loading.

PO39

Danger of overloading (destruction) of the machine

and/or turning over of the tractor when loading bags

exceeding 1000 kg of weight!

These hazards may result in extremely severe or fatal

body injuries.

Do not exceed 1000 kg of weight when lifting fertiliser

bags.

PI2

Grease lubrication points.

PO22

Install a support before entering the hazardous area.

PIX Information label –

WARNING! Do not lift or transport any persons

PIXX Information label – Lifting capacity: 1000 kg

15

1.3.2. Locations of signs on the machine

Fig. 2 Locations of warning and information signs on the machine

2. General information

2.1. Intended use

The fertiliser bag loader is intended for handling and lifting of big bags lled with fertilisers

for charging of the load body of fertiliser spreaders.

The loader is designed for coupling with Class 2 one-man tractors equipped with the driver's

cabin, a fully operational three point hitch and a power take-off shaft. Special adapters are

available from the manufacturers for Class 3 tractors. Fertilisers for long-distance sowing shall

be delivered to the eld by other means of transport.

16

Any other use of this machine is forbidden and an unintended

use. The user shall be solely liable for all damage resulting from

unintended use and METAL-FACH shall not be held responsible.

Do not transport any persons or cargo with the loader

2.2. Technical and operating characteristics

Item

no. Parameters Units Va lue

1Overall width mm 1160

2 Overall length mm 2126

3Length w/extended arm mm 2926

4Overall height of the machine resting on the ground mm 2220

5Overall height of the machine resting on the ground and with the

arm lifted and extended

mm 4639

6Overall height of the machine resting on the ground and with the

arm lifted and retracted

mm 3889

7Max load capacity kg 1000

8Weight kg 350

9Minimum operating pressure MPa 16

10 Minimum ow rate l/min 25

11 Maximum operating pressure MPa 20

12 Maximum ow rate l/min 45

13 Driving tractor power output (minimum) HP 90

14 TPH system category -2

15 Transport speed (maximum) km/h 15

16 Noise – the equivalent sound pressure emission corrected by A characteristics (LpA)

does not exceed 70 dB.

17

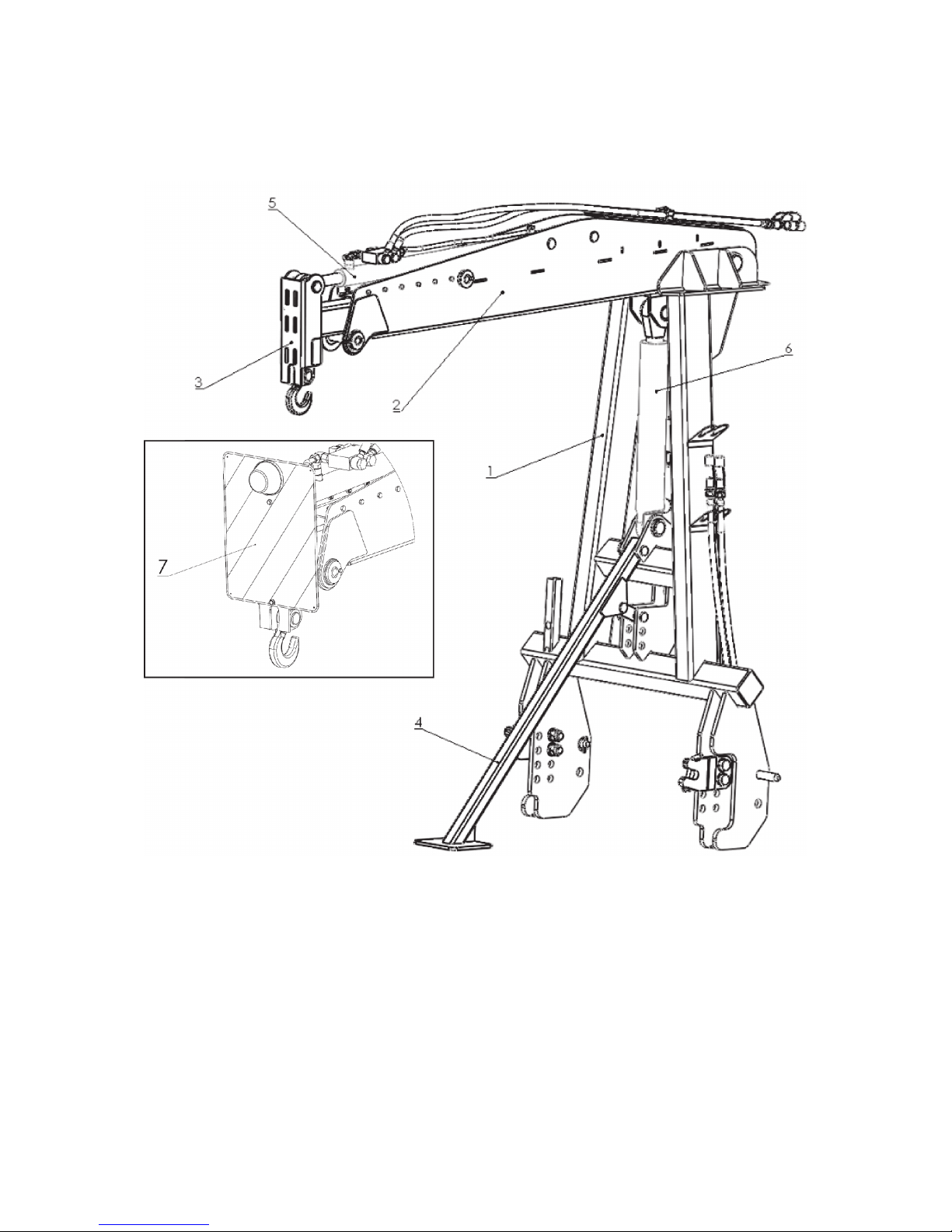

2.3. Design and operating principle of the big bag fertiliser suspended loader

The general design of the big-bag fertiliser suspended loader is shown in g. 6.

Fig. 3 Design of the arm.

1 - support frame; 2 - upper arm; 3 - extended arm; 4 - support assembly; 5 - extension

actuator; 6 - lifting actuator; 7 - warning plate with lamp.

(1) is a support frame designed as an open welded structure made of sections and high-grade

steel sheets. The upper part of the frame features the mounting opening for the upper arm. The

middle part has eyes for the upper arm lifting actuator. The frame can be attached to a three

point hitch on a tractor and on its other end, it allows coupling with a spreader. The compatible

18

spreaders are N061 standard versions from Metal-Fach; other spreaders can be coupled via

adapters.

The upper arm (2) is made as an open welded structure and serves as the guide for extending

and retracting of the extended arm. It has welded bushes at the other end for articulated coupling

with the support frame. The lower part features the mounting opening for the lifting actuator.

The upper part has eyes for the lifting actuator.

The extended arm (3) is a welded structure that increases the working range of the upper

arm. At its end, the arm has a hook with the adequate strength class for hooking of big bags.

The support assembly (4) is a welded structure used for secure resting of the arm on a hardened

ground after decoupling from the tractor. Children must not approach the machine, especially

when it is in the position explained above. The actuators (5) and (6) are used, respectively, to

extend the upper arm and to lift it in the horizontal plane.

19

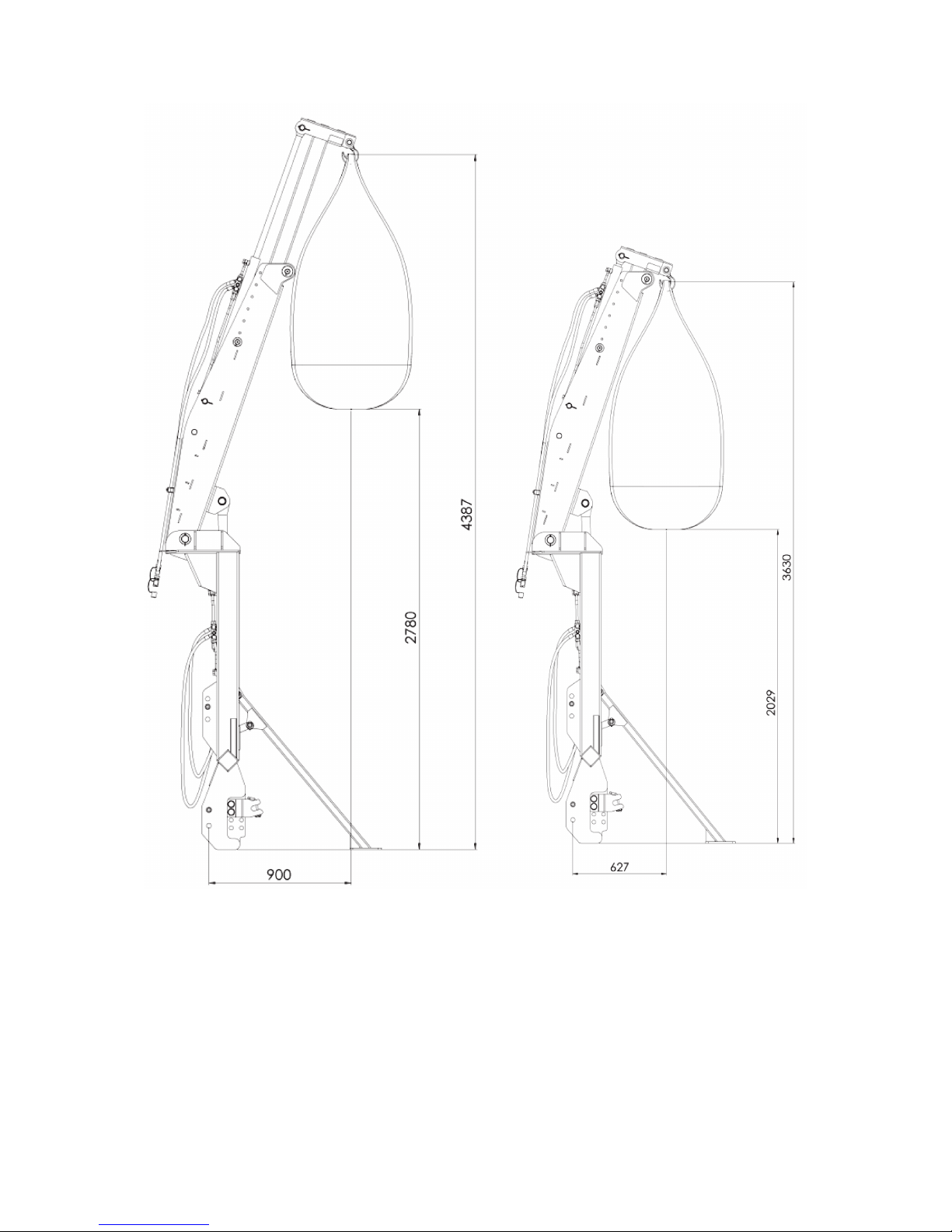

2.4. Work range of the big bag fertiliser suspended loader

Fig. 4 Big-bag fertiliser suspended loader – overall dimensions

20

Fig. 5 Top position of the loader arm

Table of contents

Other Metal-Fach Tractor Accessories manuals