CHESTER DB10VS User manual

DB10VS &

DB10VS LB

Manual

Chester UK Lt

d

Clwyd Close

Hawarden Industrial Par

k

Hawarden

Chester CH5

3PZ

Tel: 01244

531631

sales@chesterma

ch

i

n

etools.com

www.

ch

esterma

ch

i

n

etools.com

Safety Guidelines

Personnel working with any machine tools are required to follow the safety instructions stated below in order to

prevent any accident that may occur.

• This machine is designed and intended for use by properly trained and experienced personnel only. If you

are not familiar with the proper safe use of lathes, do not use this machine until properly trained.

• Keep guards in place. Safety guards must be kept in place and in working order.

• Remove adjusting keys and wrenches before turning the machine on. Check to see that any adjusting

wrenches are removed from the tool.

• Reduce the risk of unintentional starting. Make sure switch is in the OFF position before plugging in.

• Do not force tool. Always use a tool at the rate for which it was designed.

• Use the right tool. Do not force a tool or attachment to do a job for which it was not designed.

• Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow instructions

for lubrication and changing accessories.

• Always disconnect the machine from the power source before adjusting or servicing.

• Check for damaged parts. Check for alignment of moving parts, breakage of parts, mounting, and any

other condition that may affect the tools operation. A guard or any part that is damaged should be

repaired or replaced.

• Turn power off. Never leave a machine unattended. Do not leave a machine until it comes to a complete

stop.

• Keep work area clean, Cluttered areas and bench invite accidents.

• Do not use in a dangerous environment. Do not use in wet or damp locations, or expose to rain. Keep work

area well light.

• Keep children and visitors away. All visitors should be kept a safe distance from the work area.

• Make the workshop child proof. Use padlocks, master switches, and remove starter keys.

• Wear correct apparel. Loose clothing, gloves, neckties, rings, bracelets, or other jewellery may get

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain

long hair. Do not wear any type of glove.

• Always use safety glasses.

• Do not overreach. Keep proper footing and balance at all times.

• Do not place hands near the cutter whilst in operation.

• Do not perform set up work whilst machine is in operation.

• Read and understand all warning labels on the machine.

• This manual is intended to familiarize you with the technical aspects of this lathe. It is not intended to be

a training manual.

• Failure to comply with all of these warnings may result in serious injury.

Technical Specifications

DB10VS

DB10VS Long Bed

Swing over Bed

250mm

250mm

Swing over Cross Slide

145mm

145mm

Distance Between Centres

550mm

750mm

Centre Height

125mm

125mm

Width of Bed

135mm

135mm

Spindle Bore

26mm

26mm

Spindle Taper

MT4

MT4

No. of spindle speeds

Variable

Variable

Speed Range

50-2000rpm

50-2000rpm

Too l po s t Too l S i ze

12mm

12mm

Longitudinal Travel

520mm

650mm

Cross-slide Travel

115mm

115mm

Top -slide Travel

50mm

50mm

Chuck Diameter

125mm

125mm

Tai l st o ck Qu i ll Trave l

70mm

70mm

Tai l st o ck Ta p er

MT2

MT2

Motor Power

1200W (1.6hp)

1200W (1.6hp)

Net Weight

145kg

175kg

Dimensions

1150 x 560 x 570mm

1350 x 560 x 570mm

Toolbox Contents:

125mm 3 & 4 jaw chucks

Fixed & Travelling steadies

Lathe tool set

MT2 & MT4 Steel Centres

Machine set up

Start by removing the contents from the wooden crate. Check the accessories according to the packing list.

Unbolt the lathe from the shipping crate. Choose the location for your lathe; this should have good lighting and plenty

of room to service the lathe.

Using adequate lifting equipment, slowly raise the lathe out of the shipping crate. Make sure the lathe is balanced

before moving to the machine stand.

To a vo i d t wi s ti n g t he be d , t he lathe should be absolutely level. Bolt the lathe to the stand.

Clean all rust protected surfaces using a mild commercial solvent, kerosene or diesel fuel. Do not use paint

thinner, gasoline or lacquer thinner. These will damage painted surfaces. Cover all cleaned surfaces with a light

film of 20W machine oil.

Remove the end gear cover. Clean all components of the gear end assembly and coat all gears with a heavy,

non-slinging grease.

General Description of the Lathe

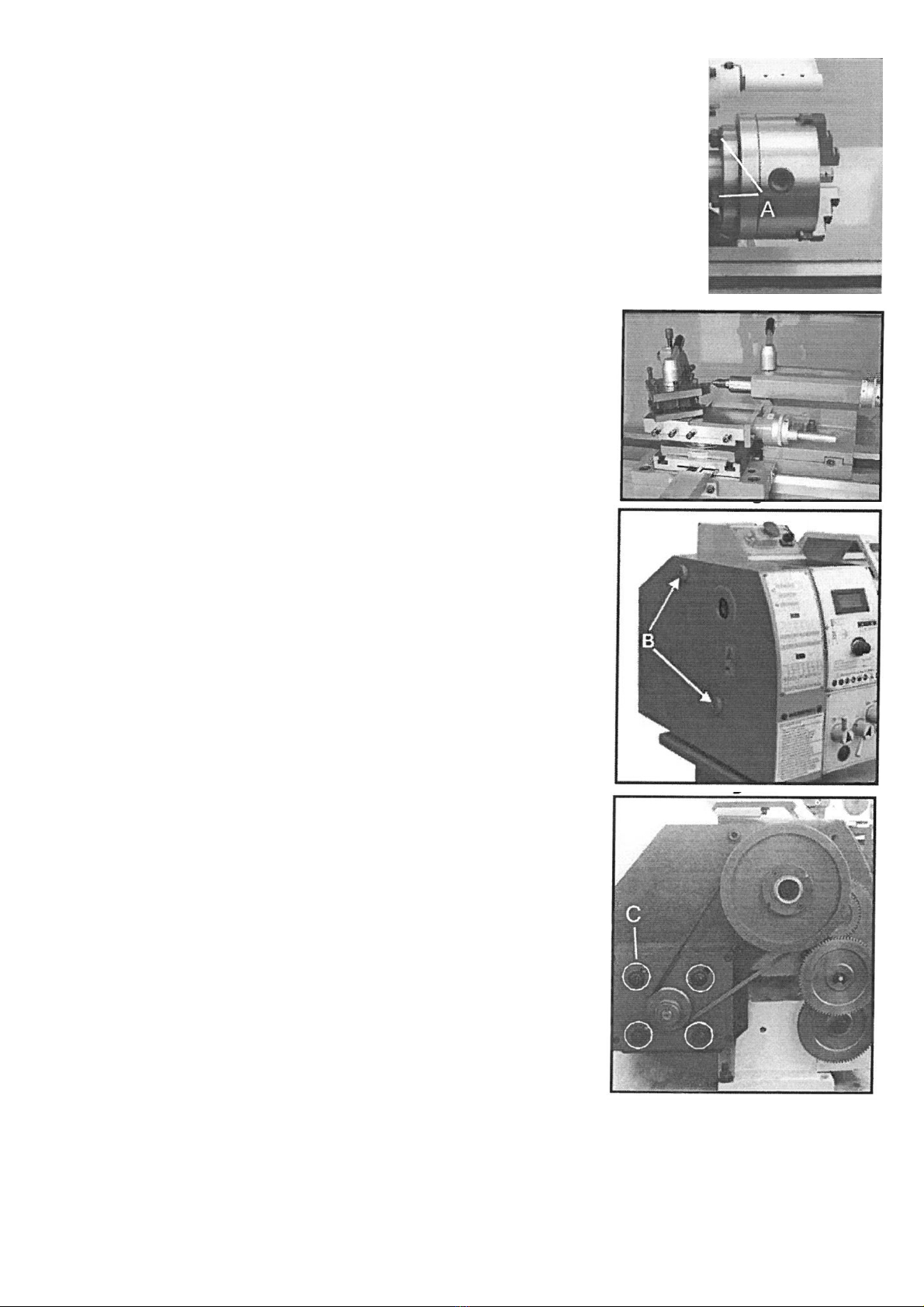

Lathe Bed

The lathe bed is made of high-grade iron. By combining high cheeks with

strong cross ribs, a bed of low vibration and rigidity is produced. It integrates

the headstock and drive unit, for attaching the carriage and leadscrew. The two

precision-ground V - sideways, re-enforced by heat hardening and grinding,

are the accurate guide for the carriage and tailstock. The main motor is

mounted to the rear of the left side of the bed.

Headstock

The headstock is cast from high grade, low vibration cast iron. It is bolted to the

bed with four screws. The headstock houses the main spindle with two precision

taper roller bearings and the drive unit.

The main spindle transmits the torque during the turning process. It also holds

the workpieces and clamping devices. (e.g. 3-jaw chuck).

Gear Box

The gear box is made from high quality cast iron and is mounted on the left

side of the machine bed. It used to select the feeds for straight turning as well

as for thread cutting. In order to achieve certain thread pitches, it is necessary

to replace the change gears.

The torque of the work spindle is transmitted to the feed gear and thus to the

leadscrew.

Carriage

The carriage is made from high quality cast iron. The slide parts are smoothly

ground. They fit the on the bed without play. The lower sliding parts can be

easily and simply adjusted. The cross slide is mounted on the carriage and

moves on a dove tailed slide. Play in the cross slide may be adjusted with the

gibs.

Move the cross slide with its conveniently positioned handwheel. There is a

graduated collar on the handwheel.

The top slide, mounted on the cross slide, can be rotated 360°. The top slide and the cross slide travel in dove

tailed slides and have gibs, adjustable nuts, and graduated collars.

A four way tool post is fitted on the top slide and allows four tools to be clamped. Loosen the center clamp handle

to rotate any of the four tools into position.

Apron

The apron is mounted on the bed. It houses the half nut with an

engaging lever for activating the automatic feed. The half nut gibs can

be adjusted from the outside.

A rack, mounted on the bed, and a pinion operated by handwheel on

the carriage allow for quick travel of the apron.

Leadscrew

The leadscrew is mounted on the front of the machine bed. It is

connected to the gear box at the left for automatic feed and is

supported by bearing on both ends. The two groove nuts (A, Fig. 10)

on the right end are designed to take up play on the leadscrew.

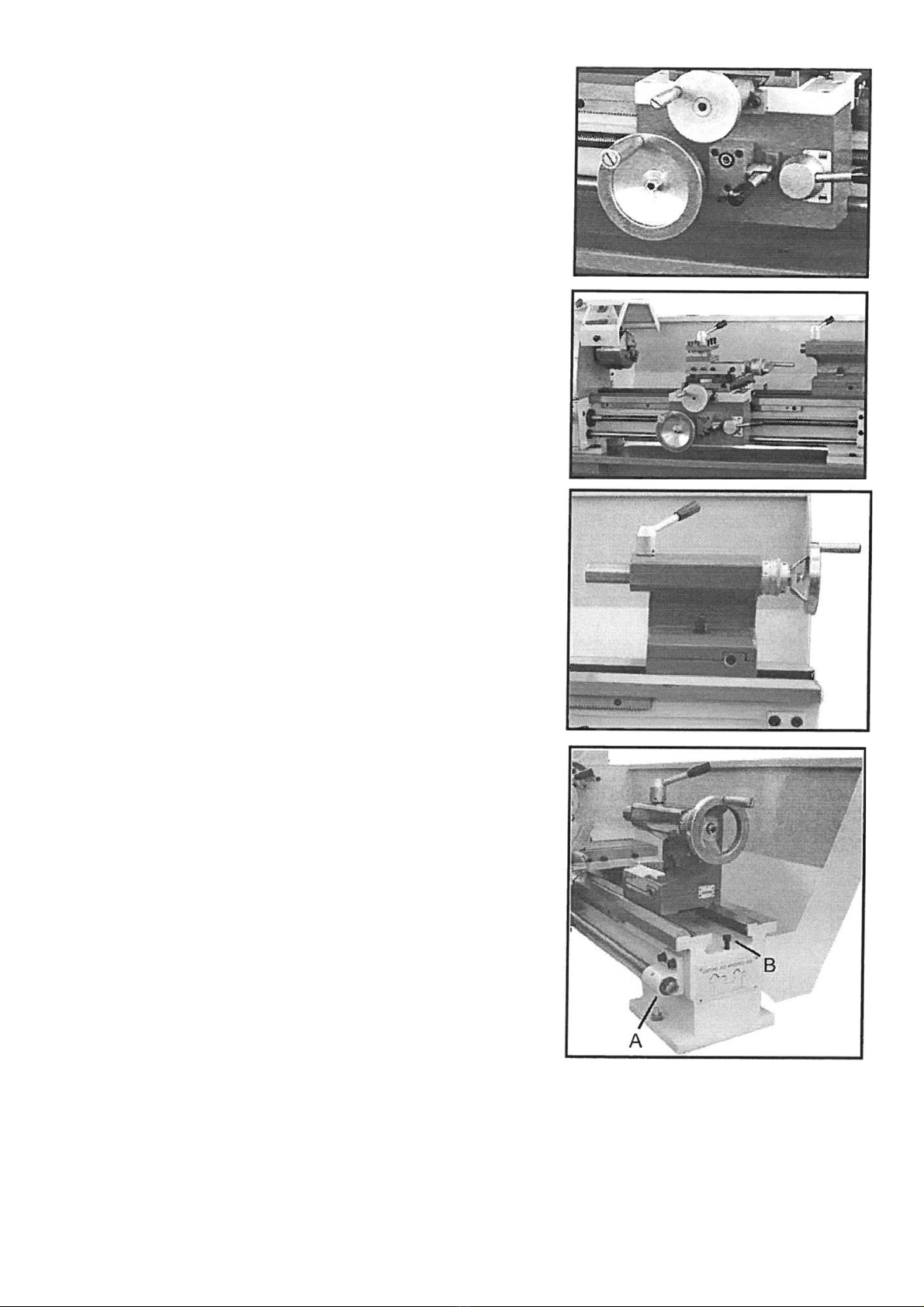

Tailstock

The tailstock slides on a V way and can be clamped at any location.

The tailstock has a heavy-duty spindle with a Morse taper No. 2

socket and a graduated scale. The spindle can be clamped at any

location with a clamping lever. The spindle is moved with a

handwheel at the end of the tailstock.

Note:

Fit the securing screw (B) at the end of the lathe bed in order to

prevent the tailstock from falling off.

Lathe controls

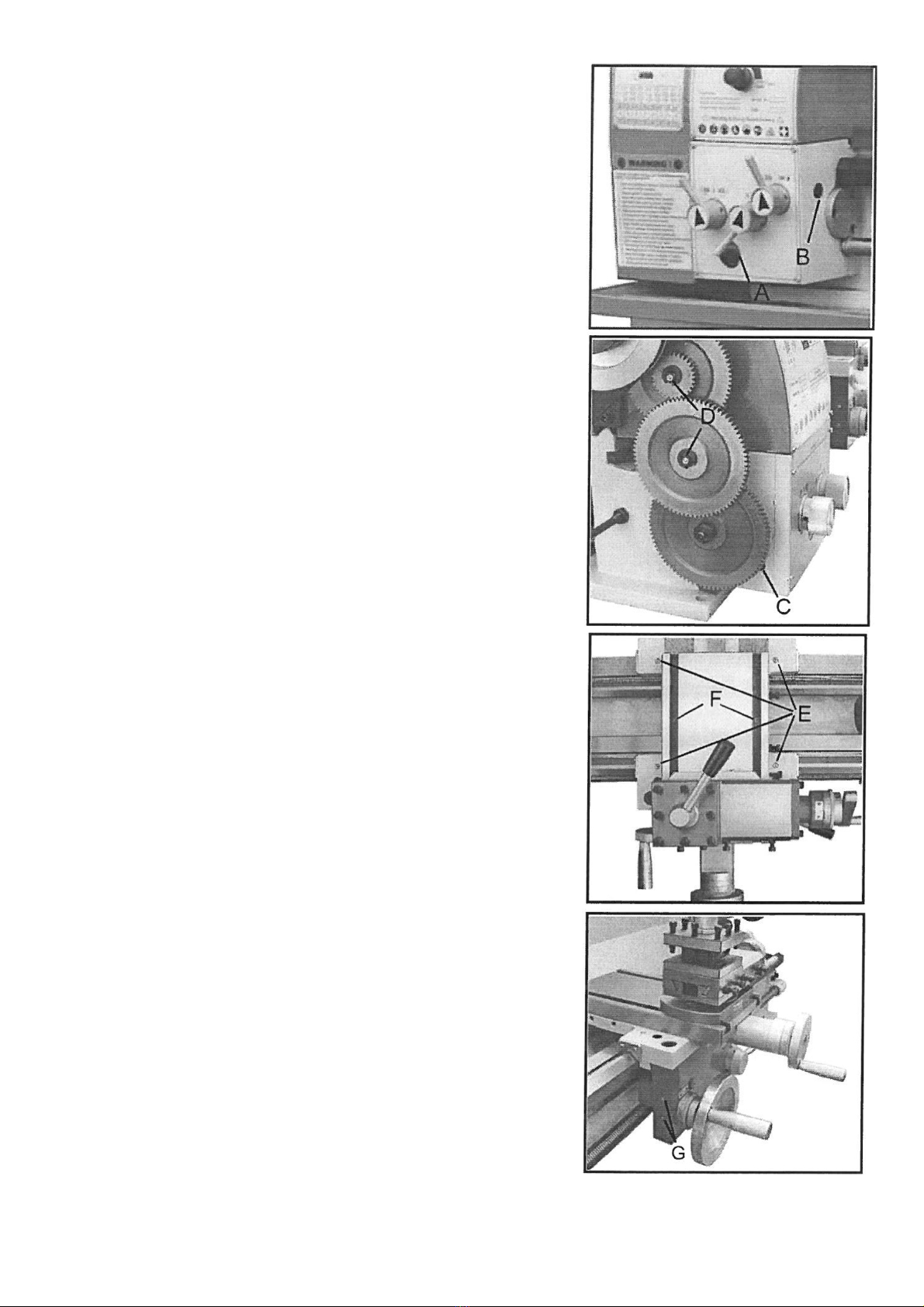

Change-over switch

After the machine is switched on, turn the switch to "F" position for counter-

clockwise spindle rotation (forward). Turn the switch to "R" position for

clockwise spindle rotation (reverse). "O" position is OFF and the spindle

remains idle.

Emergency On/Off switch

The machine is switched on and off with the ON/OFF button. Depress to

stop all machine functions. To restart , lift the cover and press ON button.

Variable speed control switch

Turn the switch clockwise to increase the spindle speed. Turn the switch counter-clockwise to decrease the spindle

speed. The possible speed range is dependent from the position of the drive belt.

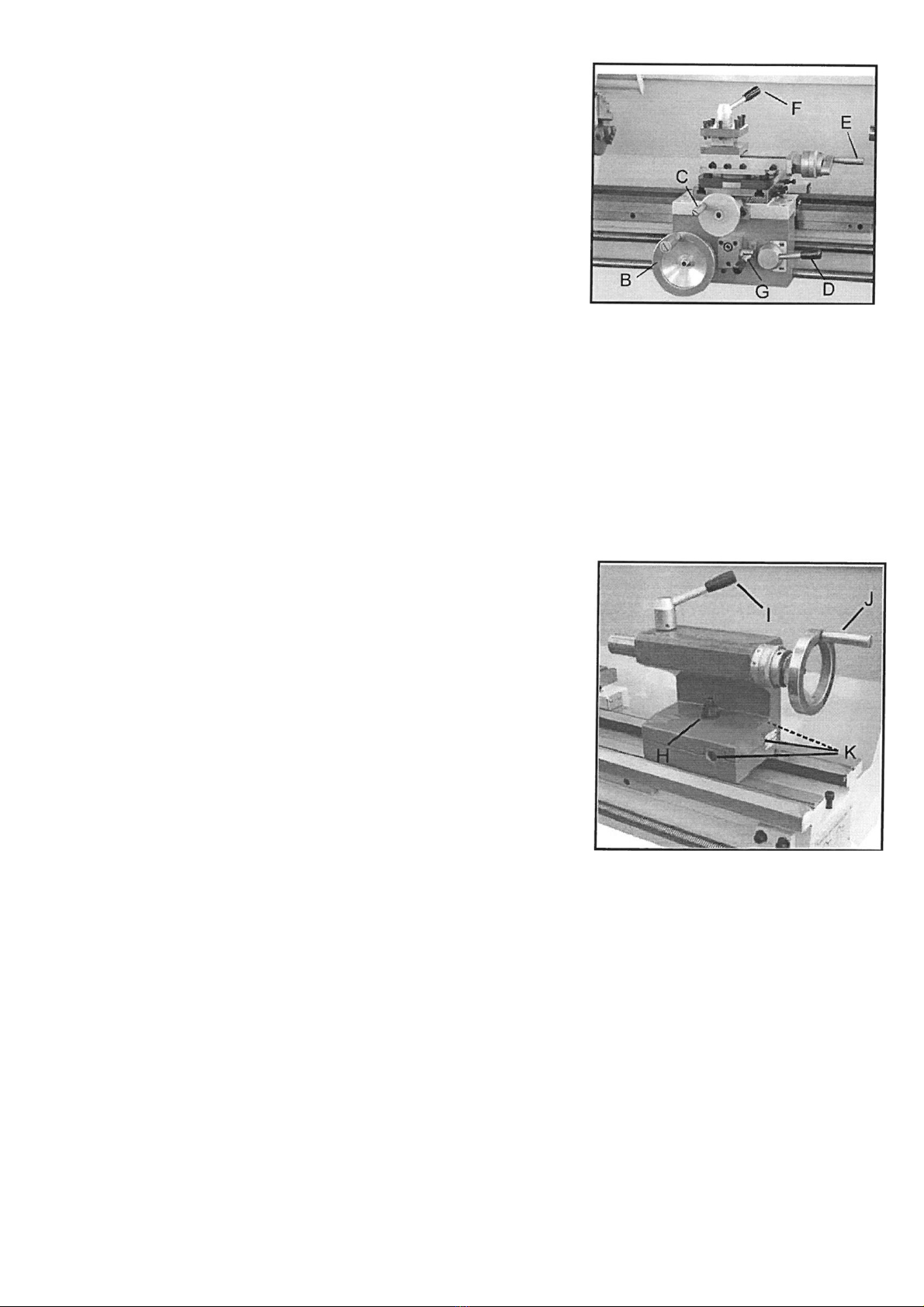

Feed direction selector (D)

Select carriage travel direction when the chuck is rotating in the forward

direction or counter-clockwise as viewed from the front of the chuck.

Feed rate selector (E)

Set the desired feed or thread rates.

Feed/Thread selector (F)

Select the handle for shift left to thread. Select the handle for shift right

to feed.

Compound rest lock (G)

Turn two hex nuts (G) clockwise to lock and counter-clockwise to

unlock.

Compound slide lock (H)

Turn hex socket cap screws clockwise, and tighten to lock. Turn

counter-clockwise to loosen.

Cross slide lock (I)

Turn hex socket cap screw clockwise and tighten to lock. Turn counter-

clockwise and loosen to unlock.

Carriage lock (A)

Turn hex socket cap screw (A, Fig.14) clockwise and tighten to lock. Turn

counter-clockwise and loosen to unlock.

Caution: carriage lock screw must be unlocked before engaging automatic

feeds or damage to lathe may occur.

Longitudinal traverse (B)

Rotate hand wheel clockwise to move the apron assembly toward the

tailstock (right). Rotate the hand wheel counter-clockwise to move the

apron assembly toward the headstock (left).

Cross traverse handwheel (C)

Clockwise rotation moves the cross slide toward the rear of the machine.

Half nut engage lever (D)

Move the lever down to engage. Move the lever up to disengage.

Compound rest traverse lever (E)

Rotate clockwise or counter-clockwise to move or position.

Tool post clamping lever (F)

Rotate counter-clockwise to loosen and clockwise to tighten. Rotate the tool post when the lever is unlocked.

Feed axis selector (G)

Push lever to the left and down to engage cross feed Pull lever to the right and up to engage longitudinal

feed.

Tailstock clamping scr ew (H)

Turn hex nut clockwise to lock and counter-clockwise to unlock.

Tailstock quill clamping lever (I)

Rotate the lever clockwise to lock the spindle and counter-clockwise to

unlock.

Tailstock quill traverse handwheel (J)

Rotate clockwise to advance the quill. Rotate counter- clockwise to retract

the quill.

Tailstock off-set adjustment (K)

Three sets screws located on the tailstock base are used to off-set the

tailstock for cutting tapers. Loosen lock screw on tailstock end. Loosen one side set screw while tightening the

other until the amount of off-set is indicated on scale. Tighten lock screw.

Operation

Replacement of chuck

The head spindle holding fixture is cylindrical. Loose three set screws and nuts (A, Fig.17,

only two are shown) on the lathe chuck flange to remove the chuck. Position the new chuck

and fix it using the same set screws and nuts.

Tool set up

Clamp the turning tool into the toolholder.

The tool must be clamped firmly. When turning, the tool has a tendency to

bend under the cutting force generated during the chip formation. For best

results, tool overhang should be kept to a minimum of 3/8" or less.

The cutting angle is correct when the cutting edge is in line with the center

axis of the work piece. The correct height of the tool can be achieved by

comparing the tool point with the point of the center mounted in the tailstock.

If necessary, use steel spacer shims under the tool to get the required height.

Change H/L speed

1. Unscrew the two fastening screws (B) and remove the protective cover.

2. To se l ec t io n A or B acc o rd i ng to your requirement, A is low speed, B is

high speed.

Caution: we recommend selecting low speed position to work, it is

could provide a stronger torque for working!

Belt adjustment

Loosen the four nuts and screws (C, Fig. 20) to remove the plate of

mounting motor and position!

Manual turning

Apron travel, cross travel, and top slide handwheel can be

operated for longitudinal or cross feeding.

Longitudinal turning with auto-feed

1.

Set the selector knob (A) to select the feed direction and

feed speed.

2. Use the table (B) on the lathe for selecting the feed speed or

the thread pitch. Adjust the change gear if the required feed or

thread pitch cannot be obtained with the installed gear set.

Change gears replacement

1.

Disconnect the machine from the power source.

2.

Unscrew the two fastening screws and remove the protective cover.

3.

Loosen the locking screw (C) on the quadrant.

4.

Swing the quadrant (D) to the right.

5.

Unscrew the bolt (E) from the leadscrew or the square bolts (F)

from the quadrant bolts in order to remove the change gears from

the front.

6.

Install the gear couples according to the thread and feed table and

screw the gearwheels onto the quadrant again.

7.

Swing the quadrant to the left until the gearwheels have engaged

again.

8.

Readjust gear backlash by inserting a normal sheet of paper as an

adjusting or distance aid between the gearwheels.

9.

Immobilize the quadrant with the locking screw.

10.

Install the protective cover of the headstock and reconnect the

machine to the power supply.

Threading and feeding table

Straight turning

In the straight turning operation, the tool feeds parallel to the axis

of rotation of the workpiece. The feed can be either manual by

turning the handwheel on the lathe saddle or the top slide, or by

activating the automatic feed. The crossfeed for the depth of cut is

achieved using the cross slide.

Facing and recesses

In the facing operation, the tool feeds perpendicular to the axis of

rotation of the workpiece. The feed is made manually with the cross

slide handwheel. The crossfeed for cut depth is made with the top

slide or lathe saddle.

Turning between centres

For turning between centers, it is necessary to remove the chuck

from the spindle. Fit the MT3 center into the spindle nose and the

MT2 center into the tailstock. Mount the workpiece fitted with the

driver dog between the centers. The driver is driven by a catch or

face plate.

Note: Always use a small amount of grease on the tailstock center

to prevent center tip form overheating.

Taper turning using tailstock off-set

Work to a side angle of 5 can be turned by off-setting the tailstock.

The angle depends on the length of the workpiece.

To off-set the tailstock, loosen locking screw (A). Unscrew the set

screw (B) on right end of the tailstock. Loosen the front adjusting

screw (C) and take up the same amount by tightening the rear

adjusting screw (D) until the desired taper has been reached.

The desired cross-adjustment can be read off the scale. (E). First

retighten the set screw (B) and then the two (front and rear) adjusting

screw to lock the tailstock in position. Retighten the locking screw (A)

of the tailstock. The workpiece must be held between to centers and

driven by a face plate and driver dog.

After taper turning , the tailstock should be returned to its original

position according to the zero position on the scale of tailstock. (E)

Taper turning by setting the top slide

By angling the top slide, tapers may be turned manually with the top slide.

Rotate the top slide to the required angle. A graduated scale permits

accurate adjustment of the top slide. The crossfeed is performed with the

cross slide. This method can only be used for short tapers.

Thread cutting

Set the machine up to the desired thread pitch (according to the threading

chart). Start the machine and engage the half nut. When the tool reaches

the part, it will cut the initial threading pass. When the tool reaches the

end of the cut, stop the machine by turning the motor off and at the same

time back the tool out of the part so that it clears the thread. Do not

disengage the half nut lever. Reverse the motor direction to allow the

cutting tool to traverse back to the starting point. Repeat these steps until

you have obtained the desired results.

Notes:

Example: Male Thread

•

The workpiece diameter must have been turned to the

diameter of the desired thread.

•

The workpiece requires a chamfer at the beginning of the

thread and an undercut at the thread runout.

•

The speed must be as low as possible.

•

The change gears must have been installed according to the required pitch.

•

The thread cutting tool must be exactly the sample shape as the thread, must be absolutely rectangular and

clamped so that it coincides exactly with the turning center.

•

The thread is produced in various cutting steps so that the cutting tool has to be turned out of the thread

completely (with the cross slide) at the end of each cutting step.

•

The tool is withdrawn with the leadscrew nut engaged by inverting the change-over switch.

•

Stop the machine and feed the thread cutting tool in low cut depths using the cross slide.

•

Before each passage, place the top slide approximately 0.2 to 0.3mm to the left and right alternately in order to

cut the thread free. This way, the thread cutting tools cuts only on one thread flank with each passage. Keep

cutting the thread free until you have almost reached the full depth of thread.

Lathe accessories

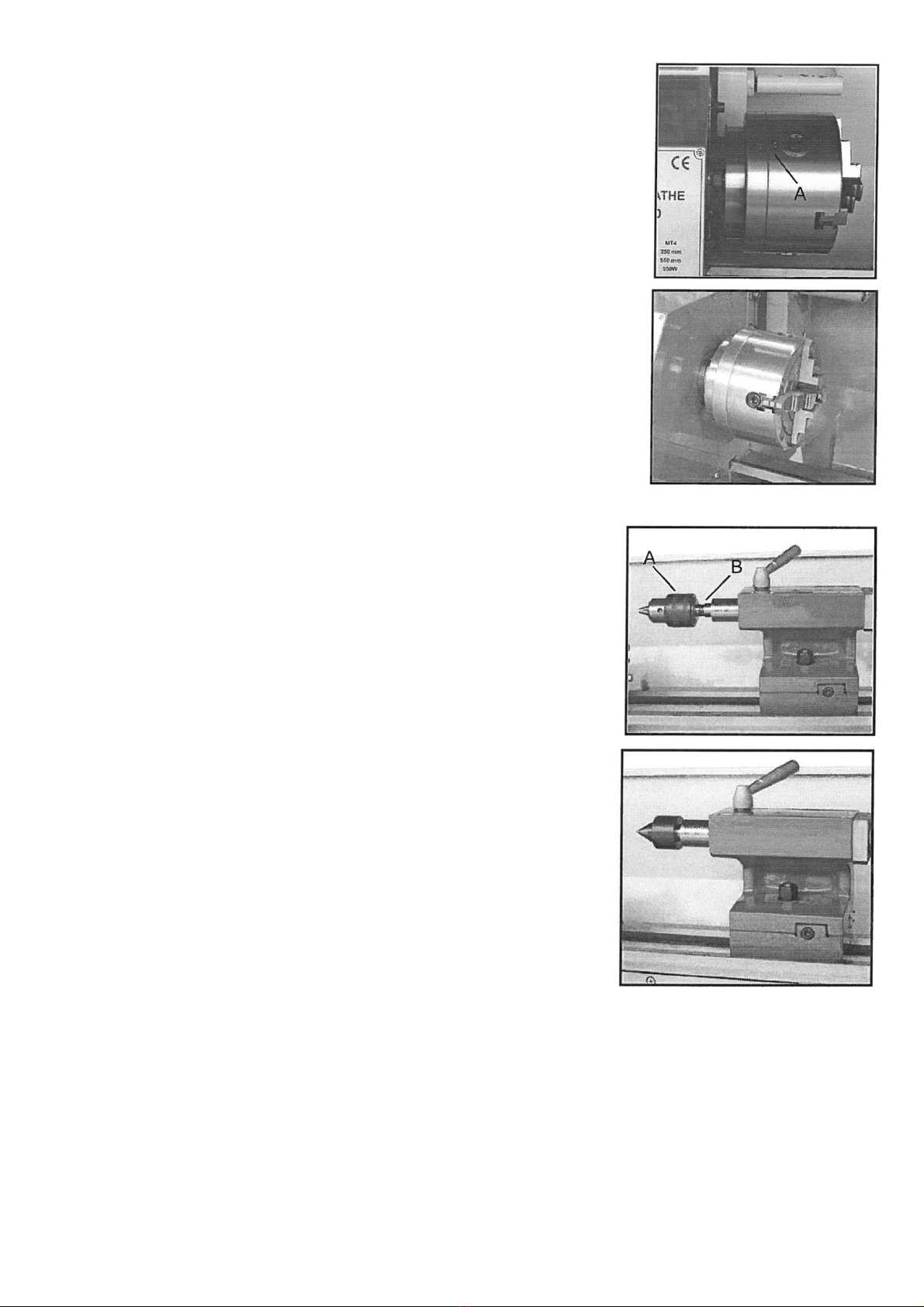

3 jaw universal lathe chuck

Using this universal chuck, round, triangular, square, hexagonal octagonal, and

twelve-cornered stock may be clamped.

Note: new lathes have very tight fitting jaws. This is necessary to ensure accurate

clamping and long service life. With repeated opening and closing, the jaw adjust

automatically and their operation becomes progressively smoother.

Note:

For the original 3-jaw chuck that mounted on the lathe, the factory has mounted

the chuck in the best way to guarantee the holding accuracy with two "0" mark

(A) showed on the chuck and chuck flange.

There are two types of jaws: Internal and external jaws. Please note that the

number of jaws fit with the number inside the chuck's groove. Do not mix them

together. When you are going to mount them, please mount them in ascending

order 1-2-3, when you are going to take them out, be sure to take them out in

descending order 3-2-1, one by one. After you finished this procedure, rotate the

jaws to the smallest diameter and check that the three jaws are well fitted.

Four jaw independent lathe chuck

This special chuck has four independently adjustable chuck jaws. These

permit the holding of asymmetrical pieces and enable the accurate set-up

of cylindrical pieces.

Drill Chuck (Optional)

Use the drill chuck to hold centering drills and twist drills in the tailstock. (A)

Morse Taper Arbor (Optional)

An arbor is necessary for mounting the drill chuck in the tailstock. It has a

No. 2 Morse taper. (8)

Live Center (Optional)

The live center is mounted in ball bearings. Its use is highly recommended

for turning at speeds in excess of 600 RPM.

Steady rest

The steady rest serves as a support for shafts on the free tailstock end. For

many operations the tailstock cannot be used as it obstructs the turning tool

or drilling tool, and therefore, must be removed from the machine.

The steady rest, which function as an end support, ensures chatter-free

operation. The steady rest is mounted on the bedways and is secured from

below with a locking plate. The sliding fingers require continuous lubrication

at the contact points to prevent premature wear.

Setting the steady rest

•

Loosen three hex nuts (A)

•

Loosen knurled screw and open the sliding fingers (C) until the steady

rest can be moved with its finger around the workpiece. Secure the

steady rest in position.

•

Tighten knurled screws so that fingers are snug but not tight against

the workpiece. Tighten three nuts (A). Lubricate the sliding points with

machine oil.

•

When after prolonged operation, the jaw starts to wear, the tips of the

fingers may be filed or remilled.

Follow rest

The follow rest is mounted on the saddle and follow the movement of the

turning tool. Only two sliding fingers are required. The place of the third

finger is taken by the turning tool. The follow rest is used for turning

operations on long, slender workpieces. It prevents flexing of the workpiece

under pressure from the turning tool.

Set the fingers snug to the workpiece but not overly tight. Lubricate the

fingers during operation to prevent premature wear.

Adjustment

After a period of time, wear in some of the moving components may need to

be adjusted.

Main spindle bearings

The main spindle bearings are adjusted at the factory. If end play becomes

evident after considerable use, the bearings may be adjusted.

Loosen two hex socket cap screws (A) in the slotted nut (B) on the back of

the spindle. Tighten slotted nut until all end play is taken up. The spindle

should still revolve freely. Tighten two hex socket cap screws (A).

Caution: excessive tightening or preloading will damage the bearings.

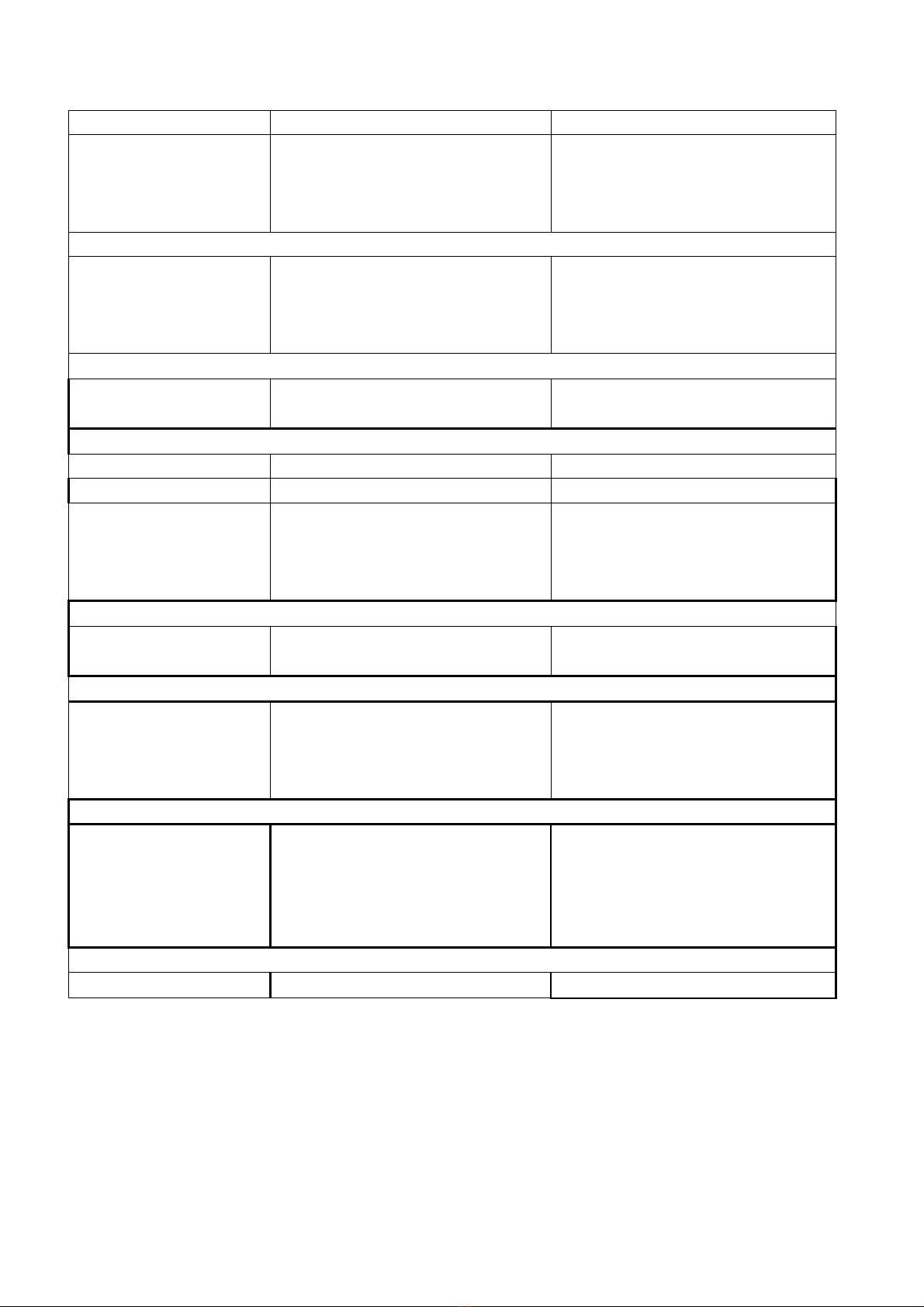

Adjustment of cross slide

The cross slide is fitted with a gib strip (C) and can be adjusted with

screws (D) fitted with lock nuts. (E) Loosen the lock nuts and tighten the

set screws until slide moves freely without play. Tighten lock nuts to

retain adjustment.

Adjustment of top slide

The top slide is fitted with a gib strip (F) and can be adjusted with screws

(G) fitted with lock nuts. (H) Loosen the lock nuts and tighten the set

screws until slide moves freely without play. Tighten lock nuts to retain

adjustment.

Adjustment of half nut guide

Loosen the nut (I) on the right side bottom of the apron and adjust the

control screws (J) until both half nuts move freely without play. Tighten

the nut.

Lubrication

Caution

Lathe must be serviced at all lubrication points and all reservoirs filled to

operating level before the lathe is placed into service.

Failure to comply may cause serious damage.

Note:

Lubricate all slideways lightly before every use. Lubricate the change

gears and the leadscrew slightly with a lithium-based grease.

Gearbox

Oil must be up to indicator mark in oil sight glass (A). Top off with

Mobilgear 627 or equivalent. Fill by pulling plug (B). To drain, remove

drain plug on the right side of headstock (C). Drain oil completely and

refill after the first three months of operation. Then, change oil in the

headstock annually.

Change gear

Lubricate two oil ports (D) on the gear shafts with 20W machine oil once

daily.

Carriage

Lubricate Four oil ports (E) with 20W machine oil once daily.

Cross slide

Lubricate two oil ports (F) with 20W machine oil once daily.

Apron

Lubricate two oil ports (G) with 20W machine oil once daily.

Leadscrew

Lubricate the oil port (A) with 20W machine oil once daily.

Tailstock

Lubricate two oil ports (B) with 20W machine oil once daily.

Electrical connections

Warning!

Connection of the lathe and all other electrical work should be carried out by a qualified electrician.

Failure to comply may cause serious injury and damage to the machine.

The DB10VS is rated at 750W, 220V only. Confirm power available at the lathes location is the same raiting as

the lathe. Using the wiring diagram below for connecting the lathe to the mains supply.

Make sure the lathe is properly grounded.

Maintenance

Maintain the lathe during operation to guarantee accuracy and service life of the machine tool.

In order to retain the machine's precision and functionality, it is essential to treat it with care, keep it clean and grease

and lubricate it regularly. Only through good care, you can be sure that the working quality of the machine will remain

constant.

Note:

Disconnect

the machine plug from the mains supply whenever you carry out cleaning, maintenance, or

repair work!

Oil, grease and cleaning agents are pollutants and must not be disposed of through the drains or in normal refuse.

Dispose of those agents in accordance with current legal requirements on the environment.

Cleaning rags impregnated with oil, grease and cleaning agents are easily inflammable. Collect cleaning rags or

cleaning wool in a suitable closed vessel and dispose of them in an environmentally sound way - do not put them

with normal refuse.

Lubricate all slideways lightly before each use. The change gears and the leadscrew must also be lightly lubricated with

lithium base grease.

During operation any chips that fall onto the sliding surface should be cleaned and inspected to prevent chips falling

into the position between the machine tool saddle and lathe bed guide way. Asphalt felt should be cleaned at certain

time.

Note:

Do not remove the chips with your bare hands. There is a risk of cuts due to sharp-edged chips. Never use

flammable solvents or cleaning agents or agents that generate noxious fumes.

Protect electrical components such as motors, switches, switch boxes, etc., against humidity when

cleaning.

After operation every day, eliminate all the chips, clean all parts of the machine tool and apply machine tool oil to prevent

rusting.

To maintain the machines accuracy, take care of the center, the surface of the machine tool for the chuck and the

guide way and avoid mechanical damage and the wear due to improper guide.

If any damage is found, any maintenance should be done immediately.

Note:

Repair work may only be carried out by qualified personnel with the corresponding mechanical

and electrical knowledge.

Troubleshooting

Problem

Possible Reason

Elimination

Surface of workpiece too

rough

Tool blunt

Tool springs

Feed too high

Radius at the tool tip too small

Resharpen tool

Clamp tool with less overhang

Reduce feed

Increase radius

Workpiece becomes coned

Centers are not aligned (tailstock has

offset)

Top slide not aligned well (cutting with

the top slide)

Adjust tailstock to the center

Align top slide well

Lathe is chattering

Feed too high

Slack in main bearing

Reduce feed

Adjust the main bearing

Center runs hot

Workpiece has expanded

Loosen tailstock center

Tool has a short edge

life

Cutting speed too high

Crossfeed too high

Insufficient cooling

Reduce cutting speed

Lower crossfeed(finishing allowance

should not exceed 0.5mm)

More coolant

Flank wear too high

Clearance angle too small

Tool tip not adjusted to center high

Increase clearance angle

Correct height adjustment of the tool

Cutting edge breaks off

Wedge angle too small (heat build-up)

Grinding crack due to wrong cooling

Excessive slack in the spindle bearing

Arrangement (vibrations)

Increase wedge angle

Cool uniformly

Adjust the slack in the spindle bearing

arrangement

Cut thread is wrong

Tool is clamped incorrectly or has

been started grinding the wrong way

Wrong pitch

Wrong diameter

Adjust too to the center

Grind angle correctly

Adjust the right pitch

Turn the workpiece to the correct

diameter

Spindle does not activate

Emergency stop switch activated

Unlock emergency stop switch

This manual suits for next models

1

Table of contents

Other CHESTER Lathe manuals

CHESTER

CHESTER Crusader User manual

CHESTER

CHESTER DB8VS User manual

CHESTER

CHESTER CONQUEST SUPER User manual

CHESTER

CHESTER DB11VS User manual

CHESTER

CHESTER DB8VS User manual

CHESTER

CHESTER CONQUEST SUPER LATHE User manual

CHESTER

CHESTER Craftsman User manual

CHESTER

CHESTER Crusader Deluxe Lathe User manual

CHESTER

CHESTER Centurion Series User manual

CHESTER

CHESTER 920 User manual