Metallkraft TBS 1501-15 User manual

TBS 1501-15

Instruction Manual

TBS 1501-15

TBS-SERIES

Manual sheet metal shear

TBS 2001-12

2 TBS-Series | Version 1.03

Imprint

Product identification

Manual sheet metal shears Item number

TBS 1501-15 3746015

TBS 2001-12 3746020

Manufacturer

Stuermer Mas hinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Information on the operating instructions

Original instru tions

Edition: 20.11.2019

Version: 1.03

Language: English

Author: SN/FL

Copyright information

Copyright © 2019 Stuermer Mas hinen GmbH, Hall-

stadt, Germany.

The ontents of this manual are the sole property of Stu-

ermer Mas hinen GmbH.

Unauthorized opying and distribution of this do ument,

as well as the use and ommuni ation of its ontent are

stri tly prohibited unless expressly permitted. Infringe-

ments require ompensation.

Te hni al hanges and errors reserved.

Contents

1 Introduction ............................................. 3

1.1 Copyright ............................................................ 3

1.2 Customer Servi e ............................................... 3

1.3 Limitation of Liability ........................................... 3

2 Safety ....................................................... 3

2.1 Symbol Explanation............................................ 3

2.2 Responsibility of the operator ............................. 4

2.3 Qualifi ation of personnel ................................... 4

2.4 Personal prote tive equipment ........................... 5

2.5 Safety markings on the ma hine ........................ 5

3 Intended Use............................................ 5

3.1 Predi table misuse ............................................. 6

3.2 Residual risks ..................................................... 6

4 echnical Data......................................... 6

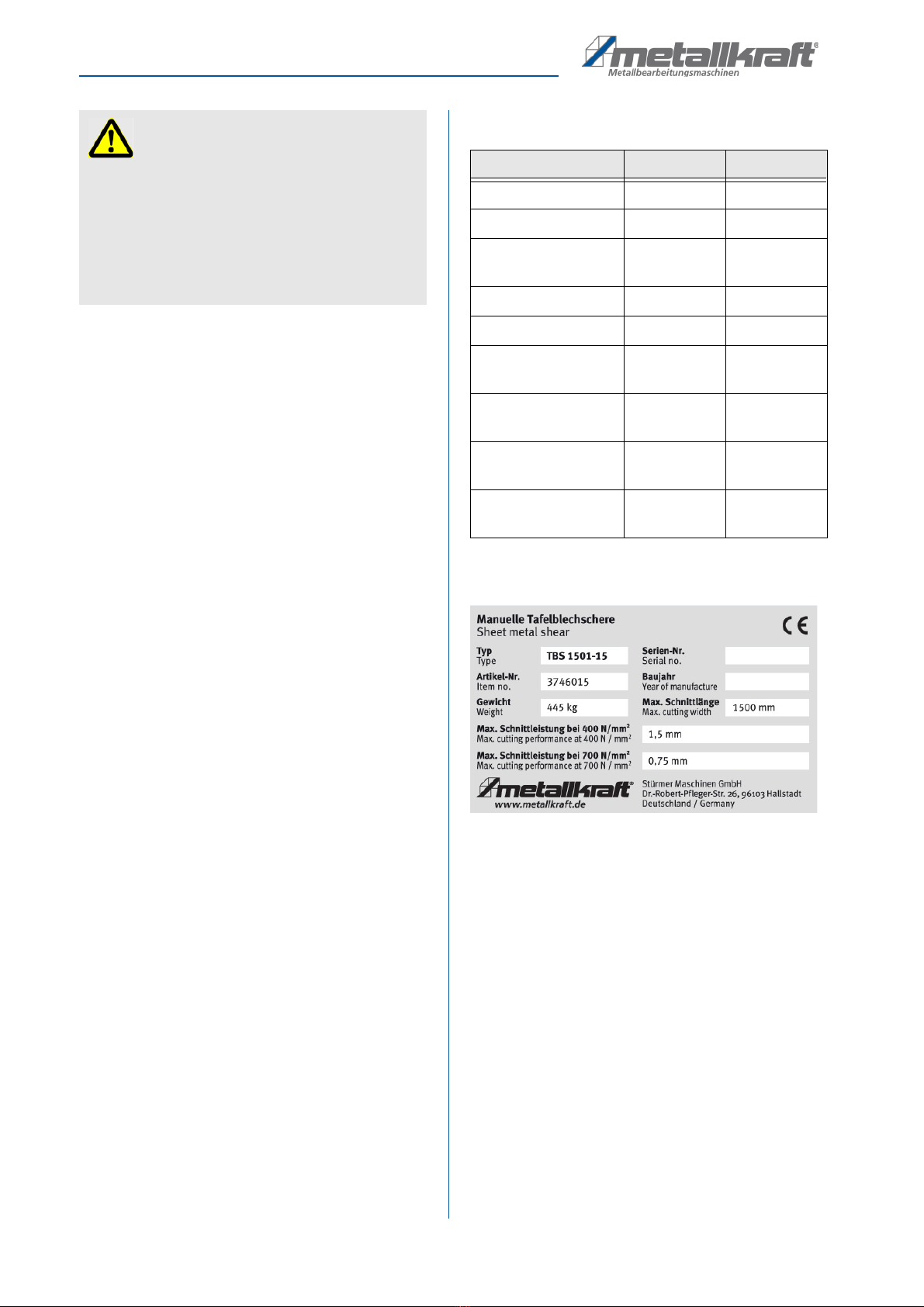

4.1 Type plate ........................................................... 6

5 ransport, Packaging, Storage .............. 6

5.1 Delivery and Transport ....................................... 6

5.2 Pa kaging........................................................... 7

5.3 Storage ............................................................... 7

6 Description .............................................. 7

6.1 S ope of delivery ................................................ 7

6.2 A essories - not in luded.................................. 8

7 Assembly and adjustments.................... 8

7.1 Set up ................................................................. 8

7.2 Settings............................................................... 8

8 Operation ............................................... 10

9 Care and Maintenance .......................... 10

9.1 Care by leaning............................................... 10

9.2 Lubri ation s hedule......................................... 10

10 roubleshooting.................................. 11

11

Disposal, recycling of old equipment

... 11

11.1 De ommission ................................................ 11

11.2 Disposal of lubri ants...................................... 11

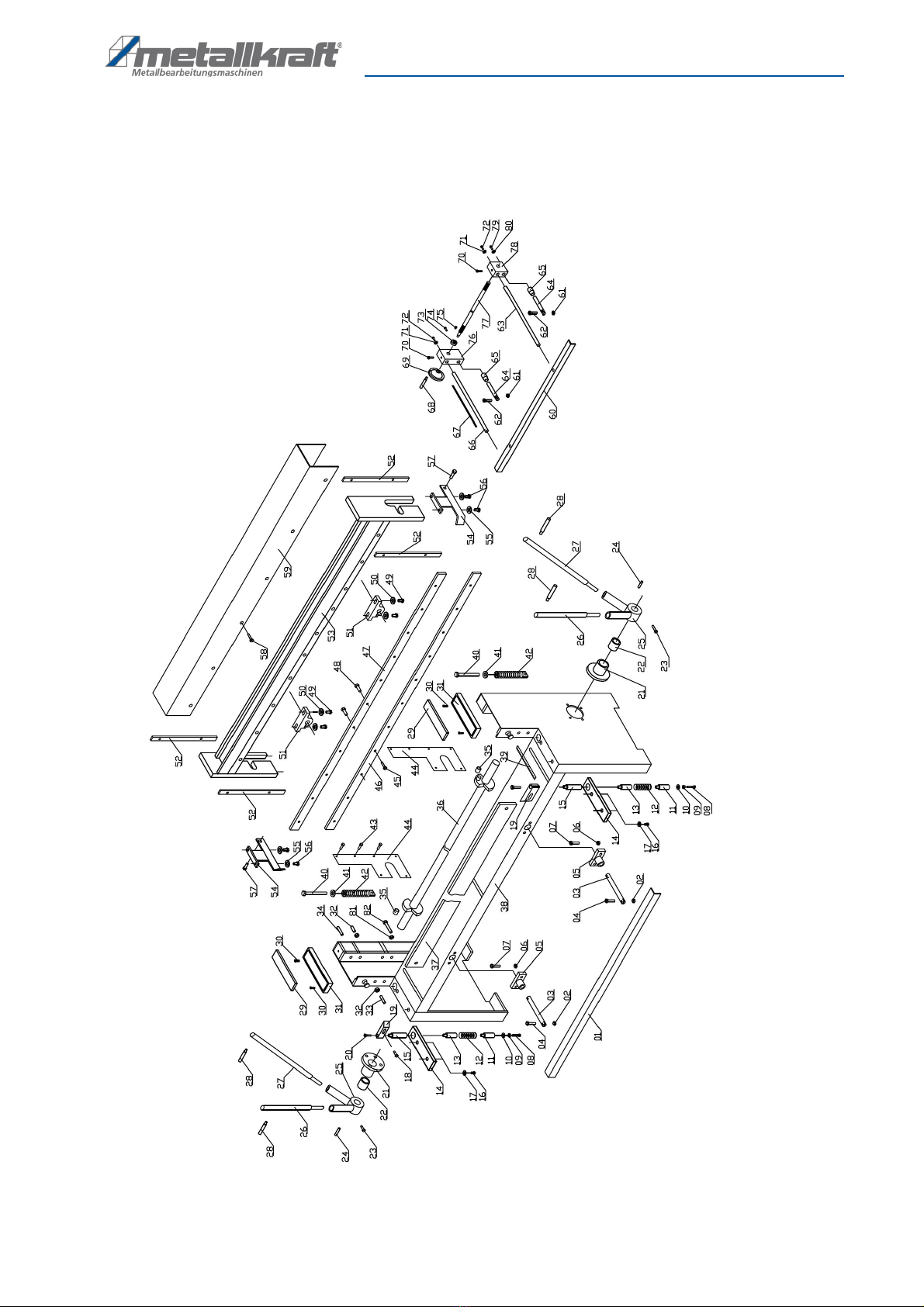

12 Spare parts .......................................... 12

12.1 Ordering spare parts....................................... 12

12.2 Spare parts drawing........................................ 13

13 Declaration........................................... 14

14 Notes .................................................... 15

Introduction

TBS-Series | Version 1.03 3

1 Introduction

You have made a good hoi e by pur hasing the Manual

sheet metal shears made by METALLKRAFT.

horoughly read the operating instructions before

commissioning the machine.

It informs you about the proper ommissioning, the in-

tended use as well as the safe and effi ient operation

and maintenan e of your ma hine.

The operating instru tions are part of the ma hine. Al-

ways keep it at the pla e of use of the ma hine. Further-

more, the lo al a ident prevention regulations and the

general safety notes are appli able for the field of appli-

ation of the ma hine.

The illustrations in these operating instru tions serve the

general omprehension and may deviate from the a -

tual type.

1.1 Copyright

The ontents of these instru tions are opyright. Their

appli ation is admissible in the frame of the ma hine uti-

lisation. An appli ation beyond the des ribed appli ation

is not allowed without written approval of the manufa tu-

rer. For the prote tion of our produ ts, we shall register

trademark, patent and design rights, as this is possible in

individual ases. We strongly oppose any infringement

of our intelle tual property.

1.2 Customer Service

Please onta t your dealer if you have any questions

about your Manual sheet metal shears or for te hni al in-

formation. There you will be happy to help with expert

advi e and information.

Germany:

Stürmer Mas hinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair-Service:

Fax: 0049 (0) 951 96555-111

E-Mail: servi e@stuermer-mas hinen.de

Internet: www.metallkraft.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-mas hinen.de

We are always interested in valuable experien e and

knowledge gained from using the appli ation, whi h-then

ould be shared and be valuable to develop our produ ts

even further.

1.3 Limitation of Liability

All information and notes in these operating instru tions

were summarised taking the appli able standards and

rules, the state-of-the-art and our long-term knowledge

and experien es into onsideration.

In the following ases the manufa turer is not liable for

damages:

- Non-observan e of the operating instru tions,

- Inappropriate use,

- Use of untrained staff,

- Unauthorised modifi ations,

- Te hni al hanges,

- Use of not allowed spare parts.

The a tual s ope of delivery may deviate from the ex-

planations and presentations des ribed here in ase of

spe ial models, when using additional ordering options

or due to latest te hni al modifi ations.

The obligations agreed in the delivery ontra t, the gen-

eral terms and onditions as well as the delivery ondi-ti-

ons of the manufa turer and the legal regulations at the

time of the on lusion of the ontra t are appli able.

2 Safety

This paragraph will give you an overview of all important

safety pa kages for the prote tion of the people using it

well as for a safe and undisturbed operation. Other task-

based safety notes are in luded in the individual hap-

ters.

2.1 Symbol Explanation

Safety Instructions

The safety notes in these operating instru tions are high-

lighted by symbols. The safety notes are introdu ed by

signal words whi h express the on ern of the risk.

DANGER!

This ombination of symbol and signal words indi-

ates an imminently dangerous situation whi h may

lead to death or severe injuries if they are not avoided.

WARNING!

This ombination of symbol and signal words indi-

ates a possibly dangerous situation whi h may lead

to minor or light injuries if they are not avoided.

4 TBS-Series | Version 1.03

Safety

ips and recommendations

It is ne essary to observe the safety notes quoted in

these operating instru tions in order to redu e the risks

for personal injuries and damages to property.

2.2 Responsibility of the operator

The operator is the person who operates the ma hine for

ommer ial or e onomi purposes himself or leaves it to

a third party for use or appli ation and bears the legal

produ t responsibility for the prote tion of the user, the

personnel or third parties during operation.

Operator obligations:

If the ma hine is used in the ommer ial se tor, the ope-

rator of the ma hine is subje t to the legal obligations for

o upational safety. Therefore, the safety instru tions in

this operating manual as well as the safety, a ident pre-

vention and environmental prote tion regulations valid

for the area of appli ation of the ma hine must be obser-

ved. The following applies in parti ular:

- The operator must inform himself about the appli-

able o upational health and safety regulations

and, in a risk assessment, determine additional ha-

zards that result from the spe ial working onditi-

ons at the pla e of use of the ma hine. He must im-

plement these in the form of operating instru tions

for the operation of the ma hine.

- The operator must he k during the entire period

of use of the ma hine whether the operating in-

stru tions he has prepared omply with the urrent

state of the regulations and adjust them if ne es-

sary.

- The operator must learly regulate and determine

the responsibilities for installation, operation,

troubleshooting, maintenan e and leaning.

- The operator must ensure that all persons handling

the ma hine have read and understood this ma-

nual. In addition, he must train the staff at regular

intervals and inform them about the dangers.

- The operator must provide the personnel with the

ne essary prote tive equipment and bind the wea-

ring of ne essary prote tive equipment.

Furthermore, the operator is responsible for ensuring

that the ma hine is always in perfe t te hni al ondition.

Therefore, the following applies:

- The operator must ensure that the maintenan e in-

tervals des ribed in this manual are observed.

- The operator must have all safety equipment regu-

larly he ked for fun tionality and ompleteness.

2.3 Qualification of personnel

The different tasks des ribed in this manual represent

different requirements to the qualifi ation of the persons

entrusted with these tasks.

Only persons reliable working pro edures an be ex-

pe ted from, are allowed to perform all works. Persons

the responsiveness of whi h is affe ted by e. g. drugs,

al ohol or medi ation, are not allowed to work with the

ma hine.

The qualifi ations of the personnel for the different tasks

are mentioned below:

CAU ION!

This ombination of symbol and signal word indi ates

a potentially hazardous situation whi h, if not avoi-

ded, ould result in minor injury.

A EN ION!

This ombination of symbol and signal word indi ates

a potentially hazardous situation whi h, if not avoi-

ded, ould result in property damage and environ-

mental damage.

NO E!

This ombination of symbol and signal words indi-

ates a possibly dangerous situation whi h may lead

to property and environmental damages if they are

not avoided.

ips and recommendations

This symbol highlights useful tips and re ommenda-

tions as well as information for an effi ient and trou-

ble-free operation.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insuffi iently qualified persons annot estimate the

risks while using the ma hine and expose them-sel-

ves and others to the danger of severe injuries.

- Have all works only performed by qualified per-

sons.

- Keep insuffi iently qualified persons and hildren

out of the working area.

Intended Use

TBS-Series | Version 1.03 5

Operator:

The operator is instru ted by the operating ompany

about the assigned tasks and possible risks in ase of

improper behaviour. Any tasks whi h need to be perfor-

med beyond the operation in the standard mode must

only be performed by the operator if it is indi ated in

these instru tions and if the operating ompany expres-

sively ommissioned the operator.

Electrician:

Due to their professional training, knowledge and experi-

en e as well as knowledge of the relevant standards and

regulations, the ele tri ian is in a position to arry out

work on ele tri al installations and to re ognize and

avoid possible dangers independently.

Specialist staff:

Due to their professional training, knowledge and experi-

en e as well as their knowledge of relevant regulations

the spe ialist staff is able to perform the assigned tasks

and to re ognise and avoid any possible dangers them-

selves.

Manufacturer:

Certain works may only be performed by spe ialist per-

sonnel of the manufa turer. Other personnel is not au-

thorized to perform these works. Please onta t our u-

stomer servi e for the exe ution of all arising work.

2.4 Personal protective equipment

The personal prote tive equipment serves to prote t per-

sons against impairments of safety and health while wor-

king. The staff has to wear personal prote tive equip-

ment while performing different works on and with the

applian e whi h are indi ated in the individual paragra-

phs of these instru tions.

The personal prote tive equipment is explained in the

following paragraph:

2.5 Safety markings on the machine

There are various warning signs and safety markings on

the sheet metal shears (Fig. 1), whi h must be observed

and followed.

Fig. 1: Safety signs

The safety markings atta hed to the sheet metal shears

must not be removed. Damaged or missing safety mar-

kings an lead to malfun tions, personal injury and pro-

perty damage. They are to be repla ed immediately. If

the safety markings are not immediately re ognizable

and omprehensible, the sheet metal shears should be

taken out of servi e until new safety markings have been

made.

3 Intended Use

The sheet metal shears are used ex lusively for utting

mild steel, aluminum, opper, zin and plasti s. It may

only be operated by instru ted persons familiar with the

devi e. Proper use also in ludes omplian e with all in-

formation in this manual. Any use beyond the intended

use or otherwise is onsidered misuse.

Head protection

The industrial helmet prote ts the head from falling

obje ts and bumping against fixed obje ts.

Ear protection

Hearing prote tion prote ts ears from hearing

damage aused by noise.

Eye protection

The goggles prote t the eyes from flying parts and

liquid splashes.

Protective gloves

The prote tive gloves serve to prote t the hands

against sharp omponents as well as against fri -

tion, abrasions or deep injuries.

Safety boots

The safety boots prote t the feet against rushes, fal-

ling parts and slipping over on slippery underground.

Protective clothes

The prote tive lothes are tight lothes of little ten-

sile strength.

1

3

2

4

6 TBS-Series | Version 1.03

echnical Data

Unauthorized modifi ations or hanges to the sheet me-

tal s issors an invalidate the CE onformity of the sheet

metal s issors and are prohibited. The ompany Stürmer

Mas hinen GmbH assumes no liability for design and

te hni al hanges to the sheet metal s issors.

The improper use of the sheet metal shears as well as

the disregard of the safety regulations or the operating

instru tions ex lude a liability of the manufa turer for re-

sulting damage to persons or obje ts and ause the war-

ranty to lapse!

3.1 Predictable misuse

When using the sheet metal shears, no reasonably fore-

seeable misuse is possible if the intended use is obser-

ved, whi h ould lead to dangerous situations involving

personal injury.

3.2 Residual risks

Even if all safety regulations are adhered to, a residual

risk des ribed below remains with the operation of the

sheet metal shears. All persons working with the sheet

metal s issors must be aware of these residual risks and

follow the instru tions that prevent these residual risks

leading to a idents or damage.

- There is a risk of injury to the upper limbs (e.g., hands,

fingers).

- Danger from falling workpie es.

- During set-up and set-up work, it may be ne essary to

dismantle on-site prote tive equipment. This reates

various residual risks and potential dangers that every

operator must be aware of.

4 Technical Data

4.1 Type plate

Fig. 2: Type plate

5 Transport, Packaging, Storage

5.1 Delivery and Transport

Delivery

After delivery, inspe t the sheet metal shears for visible

transport damage. If the sheet metal shears show da-

mage, they must be reported immediately to the trans-

port ompany or the dealer.

WARNING!

Danger in case of misuse!

Misuse of the sheet metal s issors an lead to dan-

gerous situations.

- Only operate the sheet metal shears in the perfor-

man e range spe ified in the te hni al data.

- Never bypass or override the safety devi es.

- Only operate the sheet metal shears in a te hni ally

perfe t ondition.

Model BS 1501-15 BS 2001-12

Length [mm] 1950 2450

Width [mm] 1100 1100

Height

[mm]

1050 1050

Weight [kg] 455 511

Table height (mm) 684 684

Max. working width

max [mm]

1500 2000

Sheet thi kness (400

N/mm²) max.

1,5 1,25

Sheet thi kness (700

N/mm²) max.

0,75 0,62

Rear stop adjustment

range up to [mm]

0-300 0-300

Description

TBS-Series | Version 1.03 7

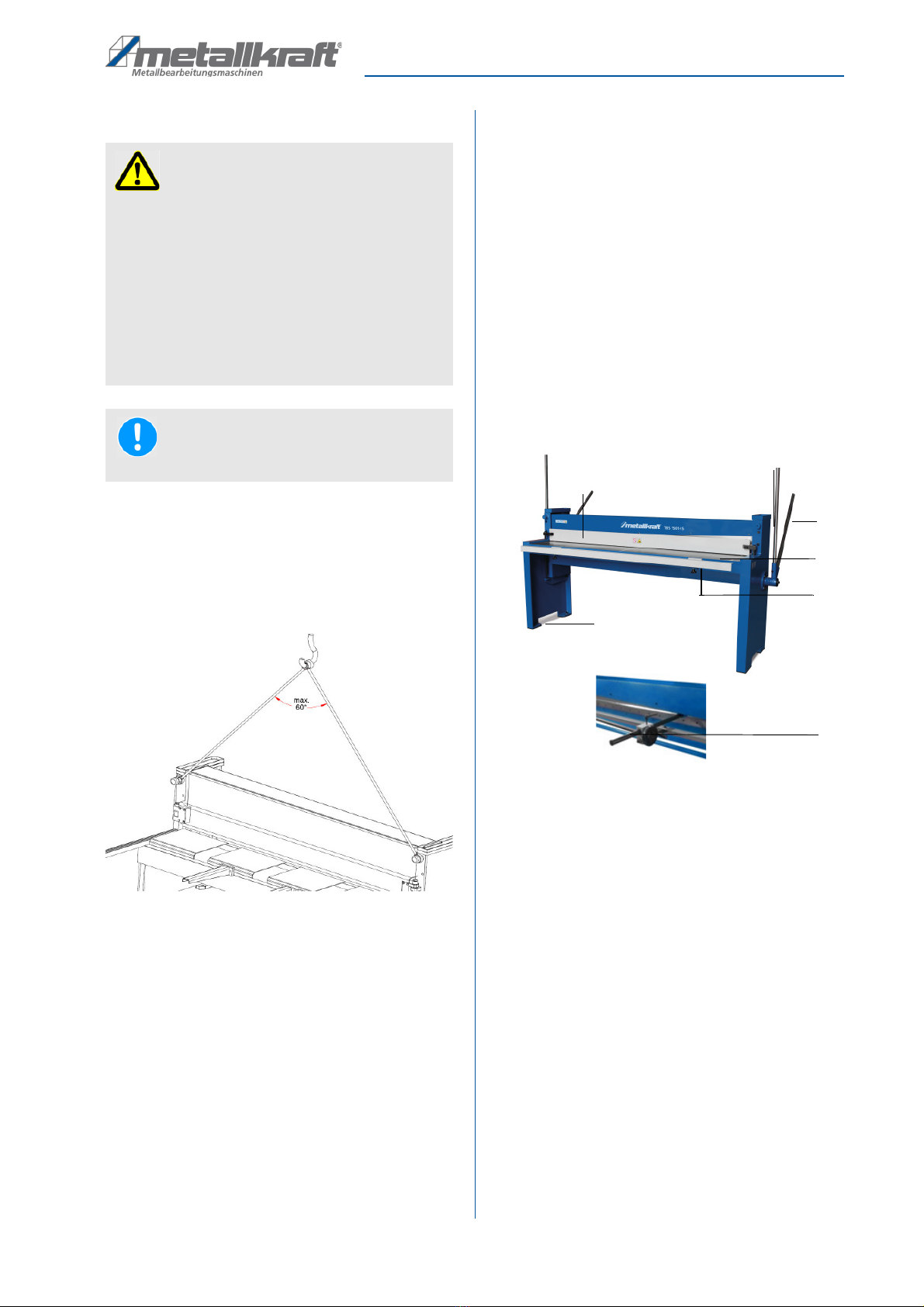

ransport

ransport with a forklift / pallet truck:

The unit is delivered on a pallet so that it an be trans-

ported with a forklift or pallet tru k.

ransport by crane:

Fig. 3: Stop of ropes for transport by rane

Transport only with steel ables and hooks designed to

weigh at least 1 tonne. The atta hment points for the

transport must be used on the sheet metal shears (Fig.

3).

5.2 Packaging

All used pa kaging materials and pa kaging aids of the

applian e are re y lable and generally need to be trans-

ported to the material re y ling.

Crush the pa kaging material made of ardboard and

supply it to the waste paper olle tion.

The films are made of polyethylene (PE) and the uphol-

stery parts are made of polystyrene (PS). These materi-

als have to be delivered to a re y ling station of the re-

sponsible dumping ompany.

5.3 Storage

Thoroughly lean the sheet metal shears in a dry, lean

and frost-free environment.

6 Description

Illustrations in this operating manual serve the gene-

ral understanding and may deviate from the actual

design.

Fig. 4: Des ription TBS 1501-15

1 Transport lifting point

2 Hand lever

3 Work table

4 Material support, extendable

5 Adjustable ba kgauge

6 Hole for an horing

7 Hold downs

6.1 Scope of delivery

- Rear stop

- Two ontrol handles

- Instru tion manual

WARNING!

Risk of death!

If the weight of the ma hine and the permissible lif-

ting apa ity of the lifting gear are not observed

during transport or lifting, the ma hine may tip over

or fall.

- During transport and lifting work, pay attention to

the weight of the ma hine. The means of transport

and lifting equipment must be able to take up the

load.

- The transport may only be arried out by spe ia-

lists.

NO E!

Prote t the sheet metal shears from moisture.

1

2

6

4

7

3

5

8 TBS-Series | Version 1.03

Assembly and adjustments

6.2 Accessories - not included

TBS 1501-15:

- Repla ement knife set TBS 1501-15

- Spe ial knife set for utting stain-less steel TBS

1501-15

TBS 2001-12:

- Repla ement knife set TBS 2001-12

- Spe ial knife set for utting stain-less steel TBS

2001-12

7 Assembly and adjustments

7.1 Set up

In order to a hieve good fun tionality and long life of the

sheet metal shears, the site should meet the following

riteria:

- The substrate must be level, firm and vibration-

free.

- The installation or working room must be dry and

well ventilated.

- Do not operate ma hines that ause dust and

hips nearby.

- There must be suffi ient spa e for the operating

personnel, for material transport as well as for ad-

justment and maintenan e work.

- The site must have good lighting.

The sheet metal shears are already preassembled in the

delivery state with the ex eption of some add-on parts.

Step 1: Insert the hand lever (2, Fig. 4) into the holder

and s rew tight. The shorter hand levers must

be mounted on the operator side.

Step 2: Insert the ra ks of the ba kgauge (Fig. 5) into the

re esses on the rossbeam on the ba k, tigh-

ten and align with the zero point.

Fig. 5: Assembly of the ba kgauge

7.2 Settings

Cutting gap

Step 1: Uns rew the tool holders and the overs of the

knife guides.

Step 2: Loosen the nuts (32, Fig. 12) and s rews (33) on

the front and lower the upper knife on the right

side to a position 5 - 6 mm lower than the left

side.

Step 3: Tighten the s rews (33) on the rear one after the

other until the utting gap between the upper

blade and the lower blade is set to the desired

value.

Use protective gloves!

Use protective boots!

Wear protective clothes!

A EN ION!

Risk of crushing!

In orre t work on the motorized sheet metal s issors

is a risk of injury to the upper limbs.

NO E!

After setting up, remove the prote tive agent from the

bare metal parts, whi h have been applied to prote t

against rusting..

- Use usual solvents.

- No water, no nitroli solvents or similar use!

Assembly and adjustments

TBS-Series | Version 1.03 9

Fig. 6: Adjust utting gap, nuts for position of the upper knife on the

front

Fig. 7: Adjust utting gap, s rews for position of the upper knife on the

ba k

Step 4: Tighten the nuts (32) on the ba k. Then tighten

the nuts (32) and the s rews (33) on the front.

Step 5: Perform a test ut to see if the kerf is well set for

high quality uts.

Step 6: S rew on the tool trays and the overs of the

knife guides.

Lower stop for upper knife

Step 1: Use the hand lever to lower the upper knife until

the left end of the upper knife overlaps the lo-

wer knife by approx. 2-3 mm.

Step 2: Loosen the nuts (81) and bring the stop into on-

ta t with the am (36). Then tighten the nuts

(81).

Fig. 8: Lower stop for upper knife

Adjust the hold down

In order to ensure a uniform fixation of the workpie e du-

ring utting, the hold-down an be adjusted.

Step 1: Loosen the nuts (9) on the underside of the ma-

hine and adjust the position of the blank hol-

der with the adjusting s rews (8). Then tighten

the nuts (9).

Step 2: Che k whether there is a uniform fixation of the

workpie e. If ne essary, readjust the position

of the hold-down.

Fig. 9: Workpie e hold-down (left), adjusting s rew (right)

Behind-stop

In order to be able to pro ess several workpie es with

the same dimensions, the stop on the ba k of the devi e

an be set to the desired dimension.

Fig. 10: Adjust rear stop: Clamping s rew, handwheel and s ale

Step 1: Loosen the lamping s rews on both sides of the

stopper.

Step 2: Move the stop to the desired position with the

handwheel. The position value an be read on

the s ale.

Step 3: Tighten the lamping s rews on both sides of the

stopper.

10 TBS-Series | Version 1.03

Operation

8 Operation

Step 1: Pla e the sheet to be ut on the ma hine table,

bring the s ale into the orre t position and ad-

just the material stops to the desired size.

Step 2: Press the sheet against the material stops and fix

it with the hold-down by moving the hand lever

downwards a little.

Step 3: Move the hand lever ompletely down to make

the ut.

9 Care and Maintenance

9.1 Care by cleaning

Clean the sheet metal shears regularly with a soft, damp

loth. Treat bare metalli work surfa es with anti-rust

spray. Never use solvents to lean plasti parts or pain-

ted surfa es. A surfa e release and onsequential da-

mage may o ur.

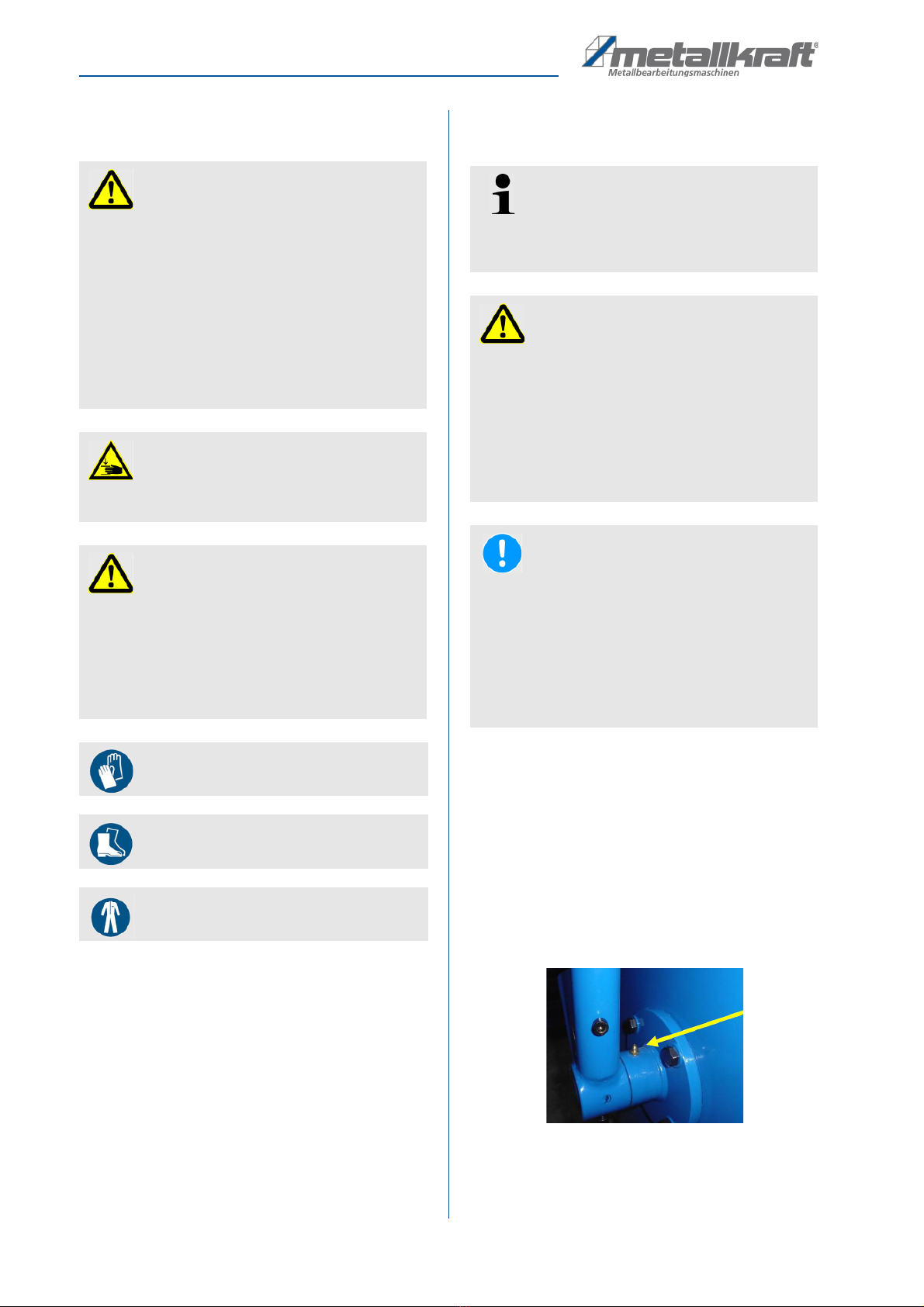

9.2 Lubrication schedule

Fig. 11: Grease nipple for hand lever

All moving parts of the metal shears must be lubri ated

regularly.

WARNING!

Danger due to insufficient qualification of

persons!

Insuffi iently qualified persons an not assess the

risks involved in handling sheet metal shears and

expose themselves and others to the risk of serious

or fatal injuries.

- All work should only be arried out by qualified per-

sons.

- Keep inadequately qualified persons out of the work

area.

A EN ION!

Risk of crushing!

In orre t work on the sheet metal s issors is a risk of

injury to the upper limbs.

DANGER!

The following rules must be followed.

- Never work on the sheet metal s issors under the

influen e of al ohol, drugs or medi ation and / or in

ase of fatigue or on entration-impairing illnesses.

- The sheet metal shears may only be operated by a

trained person.

Use protective gloves!

Use protective boots!

Wear protective clothes!

ips and recommendations

To ensure that the sheet metal shears are always in

good operating ondition, regular are and main-

tenan e work must be arried out.

WARNING!

Danger due to insufficient qualification of

persons!

Insuffi iently qualified persons an not assess the

risks involved in handling sheet metal shears and

expose themselves and others to the risk of serious

or fatal injuries.

- All work should only be arried out by qualified per-

sons.

NO E!

After servi ing, maintenan e and repair, he k that all

panels and guards are orre tly installed on the ma-

hine and that there are no tools inside or in the wor-

king area of the sheet metal shears.

Damaged prote tive devi es and parts of the devi e

must be repaired or repla ed as agreed by a re ogni-

zed spe ialist workshop.

roubleshooting

TBS-Series | Version 1.03 11

10 Troubleshooting

11 Disposal, recycling of old equipment

In the interests of the environment, are must be taken to

ensure that all omponents of the ma hine are disposed

of in the proper and approved way.

11.1 Decommission

Disused equipment must be taken out of servi e immedi-

ately in order to avoid later misuse and endangering the

environment or people.

- Dispose of all environmentally hazardous fluids from

the old devi e.

- If ne essary, disassemble the ma hine into manage-

able and usable omponents and omponents.

- Supply the ma hine omponents and operating materi-

als to the appropriate disposal hannels.

11.2 Disposal of lubricants

Remove the leaking, used or ex ess grease at the lubri-

ated lubri ation points.

The disposal instru tions for the lubri ants used are pro-

vided by the lubri ant manufa turer. If ne essary, ask for

the produ tspe ifi data sheets.

Maintenance inter-

val

Maintenance tasks

Before the operation Oil knife and lubri ate hand

lever bearing (grease nip-

ple)

Before the operation Lubri ate gears

Weekly Oil down me hanism

Weekly Lubri ate e entri bearing

Monthly Lubri ate plain bearing of

the ba k gauge

Fault Remedy

Burr at the utting

edge

1. Cutting gap too large, ad-

just utting gap.

2. Blunt knives, hange

knives

Cut off sheet metal

does not have the set

dimension.

Adjust the stop.

12 TBS-Series | Version 1.03

Spare parts

12 Spare parts

12.1 Ordering spare parts

The spare parts an be obtained from the dealer or di-

re tly from the manufa turer. The onta t details are in

hapter 1.2 Customer Servi e.

Spe ify the following key data for inquiries or when orde-

ring spare parts:

- Type of devi e

- Arti le number

- Part number

- Quantity

- Year of manufa turing

- Required mode of dispat h (mail, freight, sea, air,

express)

- Address of dispat h

Spare parts orders without above given information an

not be onsidered. If the shipping method is missing,

shipping will be at the dis retion of the supplier.

Information on the devi e type, arti le number and year

of manufa ture an be found on the type plate, whi h is

atta hed to the devi e.

Example

The upper knife for the Manual sheet metal shear

TBS 1501-15 must be ordered. The upper knife has the

number 47 in the spare parts drawing 1.

By ordering spare parts, send a opy of the spare parts

drawing (1) with the marked part (upper knife) and mar-

ked positon number (47) to the dealer or spare parts de-

partment and provide the following information:

- Type of devi e: Manual sheet metal shears

BS 1501-15

- Item number: 3746015

- Drawing number: 1

- Position number: 47

Item number of your device:

Manual sheet metal shears TBS 1501-15: 3746015

Manual sheet metal shears TBS 2001-12: 3746020

DANGER!

Danger of injury by the use of

wrong spare parts!

Dangers may result for the user and damages as well

as malfun tions may be aused by using wrong or

damaged spare parts.

- Only use original spare parts of the manufa turer or

spare parts admitted by the manufa turer.

- Always onta t the manufa turer in ase of un erta-

inties.

ips and recommendations

Using non-approved spare parts voids the manu-

fa turer's warranty.

Spare parts

TBS-Series | Version 1.03 13

12.2 Spare parts drawing

The following drawing should help in ase of servi e to identify ne essary spare parts. To order, send a opy of the parts

drawing with the parts marked to your authorized dealer.

Fig. 12: Spare parts drawing TBS 1501-15 and TBS 2001-12

14 TBS-Series | Version 1.03

Declaration

Manufacturer / distributor: Stürmer Mas hinen GmbH

Dr.-Robert-Pfleger-Straße 26

D-96103 Hallstadt

hereby de lares, that the following produ t

Product Group: Metallkraft® Metal working ma hines

Machine type: Manual sheet metal shears

Designation of the machine *: TBS 1501-15 Item number *: 3746015

TBS 2001-12 3746020

Serial number*: ____________________

Year of manufacture*: 20____

* please fill in a ording to the information on the type plate

Due to its design and onstru tion as well as in the version that we have pla ed on the market, it omplies with the rele-

vant basi health and safety requirements.

A de laration of onformity a ording to Ma hinery Dire tive 2006/42 / EC Annex 1 does not require this ma hine. In the

event of a modifi ation of the ma hine not agreed with us, this de laration shall lose its validity.

Responsible for documentation: Kilian Stürmer, Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, 28.08.2017

______________________

Kilian Stürmer

Manager

13 Declaration

Notes

TBS-Series | Version 1.03 15

14 Notes

www.metallkraft.de

This manual suits for next models

3

Table of contents

Other Metallkraft Power Tools manuals