Metallkraft GS 18 User manual

GS 18

Operating Instructions

GS 18

Tapping Power Tool

GS 18

2GS 18 | Version 1.05

Imprint

Product identification

Tapping Power Tool Article number

GS 18 3860018

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt/Bamberg

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metalkraft.de

Indications regarding the operating instructions

Original instructions

Edition: 15.05.2019

Version: 1.05

Language: English

Author: FL/ES

Indications regarding the copyright

Copyright © 2019 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the sole

property of the company Stürmer.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Content

1 Introduction .............................................................3

1.1 Copyright............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability ............................................ 3

2 Intended use ............................................................3

3 Safety........................................................................4

3.1 Symbol explanation ............................................ 4

3.2 Obligations of the operating company............... 4

3.3 Requirements to staff.......................................... 5

3.4 Personal protective equipment........................... 5

3.5 Safety identifications on the Tapping Power Tool....6

3.6 Safety devices .................................................... 6

3.7 Special safety rules for tapping power tool ........ 6

3.8 Residual risks ..................................................... 6

4 Technical Data.........................................................6

4.1 Table................................................................... 6

4.2 Type plate........................................................... 7

5 Transport, package and storage............................7

5.1 Delivery and transport ........................................ 7

5.2 Packaging........................................................... 7

5.3 Storage ............................................................... 7

6 Description of the device........................................8

6.1 Illustration ........................................................... 8

7 Operation .................................................................9

7.1 Preparation ......................................................... 9

7.2 Electrical connection .......................................... 9

7.3 Drilling............................................................... 10

7.4 Depth stop ........................................................ 11

7.5 Safety clutch..................................................... 11

8 Cleaning, maintenance and service/repair .........11

8.1 Cleaning ........................................................... 11

8.2 Maintenance..................................................... 12

8.3 Servicing.......................................................... 12

9 Disposal, Recycling of old equipment ................13

9.1 Decommission................................................. 13

9.2 Disposal of electrical equipment..................... 13

9.3 Disposal of lubricants...................................... 13

10 Spare parts...........................................................13

10.1 Ordering spare parts..................................... 13

11 Spare part drawing.............................................15

12 Electrical wiring diagram....................................16

13 EC Declaration of conformity.............................17

Introduction

GS 18 | Version 1.05 3

1Introduction

You have made a good choice by purchasing the

METALLKRAFT tapping power tool.

Read the operating manual thoroughly before commissioning

the machine.

It gives you information about the proper commission-

ing, intended use and safe and efficient operation and

maintenance of your tapping power tool.

The operating manual is part of the tapping power tool

machine package. Always keep this operating manual

in the location where your tapping power tool machine is

being operated. All local accident prevention regula-

tions and general safety instructions for the operating

range of your tapping power tool machine must also be

complied with.

Illustrations in this operating manual serve the general

understanding and may deviate from the actual design.

1.1 Copyright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the

tapping power tool. Any application beyond those de-

scribed is not permitted without the written approval of

Stürmer GmbH.

For the protection of our products, we shall register

trademark, patent and design rights, as this is possible

in individual cases. We strongly oppose any infringe-

ment of our intellectual property.

1.2 Customer service

Please contact your dealer if you have questions con-

cerning your tapping power tool or if you need techni-

cal advice. They will help you with specialist information

and expert advice.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair-service:

Fax: 0049 (0) 951 96555-111

E-Mail: service@stuermer-maschinen.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

We are always interested in valuable experience and

knowledge gained from using the application-which

then could be shared and be valuable to develop our

products even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards

and rules, the state-of-the-art technology and our long-

term knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- unauthorized modifications

- technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-

tions of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Intended use

The tap is used exclusively for producing right-hand

threads in continuous operation up to max. 14 mm (9/16

") diameter in steel and aluminum. Occasionally, threads

can be cut to 18mm. However, this is not possible in

continuous operation. Left-hand threads are not possi-

ble with this machine.

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or oth-

erwise is considered misuse.

WARNING!

Danger in case of misuse!

Misuse of the device can lead to dangerous situa-

tions.

- Only operate the machine in the power range spec-

ified in the technical data.

- Never bypass or override the safety devices.

- Only operate the machine in a technically perfect

condition.

4GS 18 | Version 1.05

Safety

Unauthorized modifications or changes to the tap can

invalidate the CE conformity of the tap and are prohib-

ited. The company Stürmer Maschinen GmbH assumes

no liability for design and technical changes to the tap.

The improper use of the tap and the disregard of the

safety regulations or the operating instructions exclude

liability of the manufacturer for resulting damage to per-

sons or objects and cause the warranty to expire!

3 Safety

This section provides an overview of all important safety

packages for the protection of operating personnel as

well as for safe and fault-free operation. Other task-

based safety notes are included in the paragraphs of

the individual phases of life.

3.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are

high-lighted by symbols. The safety notes are intro-

duced by signal words which express the concern of

the risk.

Tips and recommendations

It is necessary to observe the safety notes written in

these operating instructions in order to reduce the risk of

personal injuries and damages to property.

3.2 Obligations of the operating company

Operator

Operators are defined as the persons who operate the

machine for commercial or profit-based purposes or

provide the machine to third parties for use or applica-

tion and bear the legal product responsibility in terms of

the protection of users, staff or third parties during oper-

ation.

Obligations of the operating company:

If the machine is used for commercial purposes, the op-

erating company must comply with the legal working

safety regulations. Therefore, the safety notes in this op-

erating manual, as well as the safety, accident preven-

tion and environment protection regulations applying for

the area of application of the machine must be met. The

following applies in particular:

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use the ma-

chine. She must implement these in form of oper-

ating manuals for the operation the machine.

- During the entire lifetime of the machine, the oper-

ating company must verify whether the operating

manuals prepared by her correspond to the cur-

rent status of the regulations, and must adapt

these if necessary.

- The operating company must unambiguously reg-

ulate and determine the responsibilities for instal-

lation, operation, troubleshooting, maintenance

and cleaning.

- The operating company must ensure that all per-

sons who work with the machine, have read and

understood this manual. Furthermore she must in-

struct the staff in regular intervals and inform them

about the hazards.

- The operator must provide the necessary protec-

tive equipment to the staff and order the use of the

necessary protective equipment in a binding way.

DANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

WARNING!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to death or severe injury if not avoided.

CAUTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to material or environmental damage if not

avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

Safety

GS 18 | Version 1.05 5

Furthermore the operating company is responsible to

keep the machine always in a technically flawless state.

Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices

checked regularly for their good working order

and their integrity.

3.3 Requirements to staff

Qualifications

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator:

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behavior. Any tasks which need to be per-

formed beyond the operation in the standard mode

must only be performed by the operator if it is indicated

in these instructions and if the operating company ex-

pressively commissioned the operator.

Electrically qualified person:

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a po-

sition to carry out work on the electrical systems and to

independently recognize and avoid possible dangers.

Qualified personnel:

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognize and avoid any possible dangers them-

selves.

Manufacturer:

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

3.4 Personal protective equipment

Personal protective equipment is intended to protect the

health and safety of persons at work. Staff must wear the

personal protective equipment indicated in individual

sections of these operating instructions when carrying

out the different tasks on the machine.

The personal protective equipment is described in the

following section:

WARNING!

Danger in case of insufficient qualification

of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the vacuum cleaner and expose

themselves and others to the danger of severe or

lethal injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the

working area.

Ear protection

The Hearing protection protects ears from hearing

damage caused by noise.

Head protection

The industrial helmet protects the head against fall-

ing objects and knocking against fixed objects.

Face protection

The face shield protects the face from flying parts.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed,

falling parts and slipping over on slippery ground.

6GS 18 | Version 1.05

Technical Data

3.5 Safety identifications on the Tapping

Power Tool

The following safety identifications have been attached

to the tapping power tool (Fig. 1) which must be ob-

served:

Fig. 1: Safety identifications - 1 Mandatory signs: Read the operating

manual, Pull out the mains plug, wear eye protection, Wear ear

protection

The safety markings and instructions attached to the

tapping power tool must not be removed. Damaged or

missing safety markings can lead to malfunctions, per-

sonal injury and material damage. They have to be re-

placed immediately.

If the safety markings are not immediately recognizable

and comprehensible, the tapping power tool must be

taken out of operation until new safety markings have

been affixed.

3.6 Safety devices

3.7 Special safety rules for tapping power tool

- Do not connect other machines to the same mains

supply. This can cause voltage fluctuations.

- Do not use the machine overhead. It is highly rec-

ommended to use them at 45 ° to the horizontal.

Avoid larger angles. Working overhead is ex-

tremely dangerous and should be avoided.

- Do not work with blunt or damaged tools. This can

lead to overuse of the motor.

- Protect the engine. Make sure that no coolant, wa-

ter or other substances enter the motor.

- Metal shavings are usually very sharp-edged and

hot. Never touch them with your bare hands. Re-

move these with a magnetic chip collector or a

chip hook. Remove metal chips only when the ma-

chine is switched off.

3.8 Residual risks

Even if all safety regulations are followed and the ma-

chine is used correctly, there are still residual risks listed

below:

- By Touching rotating parts or tools.

- Injuries from flying around workpieces or work-

piece parts.

- Fire hazard with insufficient ventilation of the en-

gine.

- Danger from electricity, noise and dust.

- Danger caused by breakage of the tool.

4 Technical Data

4.1 Table

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

WARNING!

Danger to life due to non-functioning safety

devices!!

In case of safety equipment is not in working order

or suspended there is danger of heavy injuries and

Danger to death.

- Before starting work, check that all safety equip-

ment is in place and correctly installed.

- Never override or bypass safety devices.

- Ensure that all safety devices are always accessi-

ble.

ATTENTION!

Never use the machine with incorrect current or volt-

age. Check the connection details on the type plate

of the machine to see whether they match those of

your power source.

Model GS 18

Motor power input 450 W

Motor power output 210 W

Power connection 230 V/50 Hz

Speed forward 280 U/min-1

Speed backward 680 U/min-1

Thread size in steel 14 mm*

Thread size in Aluminum 16 mm*

On-load speed during cutting pro-

cess

170 U/min-1

Slip clutch (Stall torque) 31,4-34,3 Nm

Transport, package and storage

GS 18 | Version 1.05 7

* in continuous operation (For occasional thread cutting

it is possible to do cuts to 18 mm)

4.2 Type plate

The nameplate with the following data for identification as

well as the CE marking are attached to the tap (fig. 2).

Fig. 2: Type plate and CE-marking of the tap GS 18

5 Transport, package and storage

5.1 Delivery and transport

The thread cutter must be checked after delivery for vis-

ible transport damage and for completeness. If the tap

has damage or parts are missing, immediately report

this to the carrier or dealer.

5.2 Packaging

All used packaging materials and packaging aids are

recyclable and should be taken to a materials recycling

depot to be disposed of.

The delivery packaging is made of cardboard, so

please dispose carefully by having it chopped up and

given to the recycling collection.

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (PS). Deliver these substances to a

collection point for recyclable materials or to the waste

disposal company which looks after your region.

5.3 Storage

Store the tapping power tool thoroughly cleaned in a

dry, clean and frost-free environment.

It must not be shut down with chemicals in a room.

If the machine must be stored in a damp room, all elec-

trical components in the control cabinet must be pro-

tected by moisture-absorbing agents.

If the machine is stored for a long time, all bare metal

parts must be greased against rusting.

Overvoltage protection available

Dimensions (LxBxH) [mm] 498 x 125 x 453

Weight (without side handle) 3,15 kg

Model GS 18

8GS 18 | Version 1.05

Description of the device

6 Description of the device

6.1 Illustration

Illustrations in this operating manual serve the general under-standing and may deviate from the ac-

tual design.

Fig. 3: Description Tapping Power Tool GS 18

1 Locking screw

2 Turning head

3 Locking screw

4 Depth stop

5 Housing

6 Motor

7 Handle

8 ON-Schwitch

9 Side handle

10 Safety friction clutch

11 Universal holder

12 Tap (not in the scope of delivery)

Scope of delivery:

- Universal holder M6 – M18 with friction clutch

- Additional handle

- 4 mm hexagon key

- Depth stop

- Transport case

Operation

GS 18 | Version 1.05 9

7 Operation

7.1 Preparation

Step 1: Place the machine on a level surface to clamp

the desired Tapping Power Tool into the clamp-

ing device.

Step 2: Open the clamp device far enough to involve the

whole shaft of the tap.

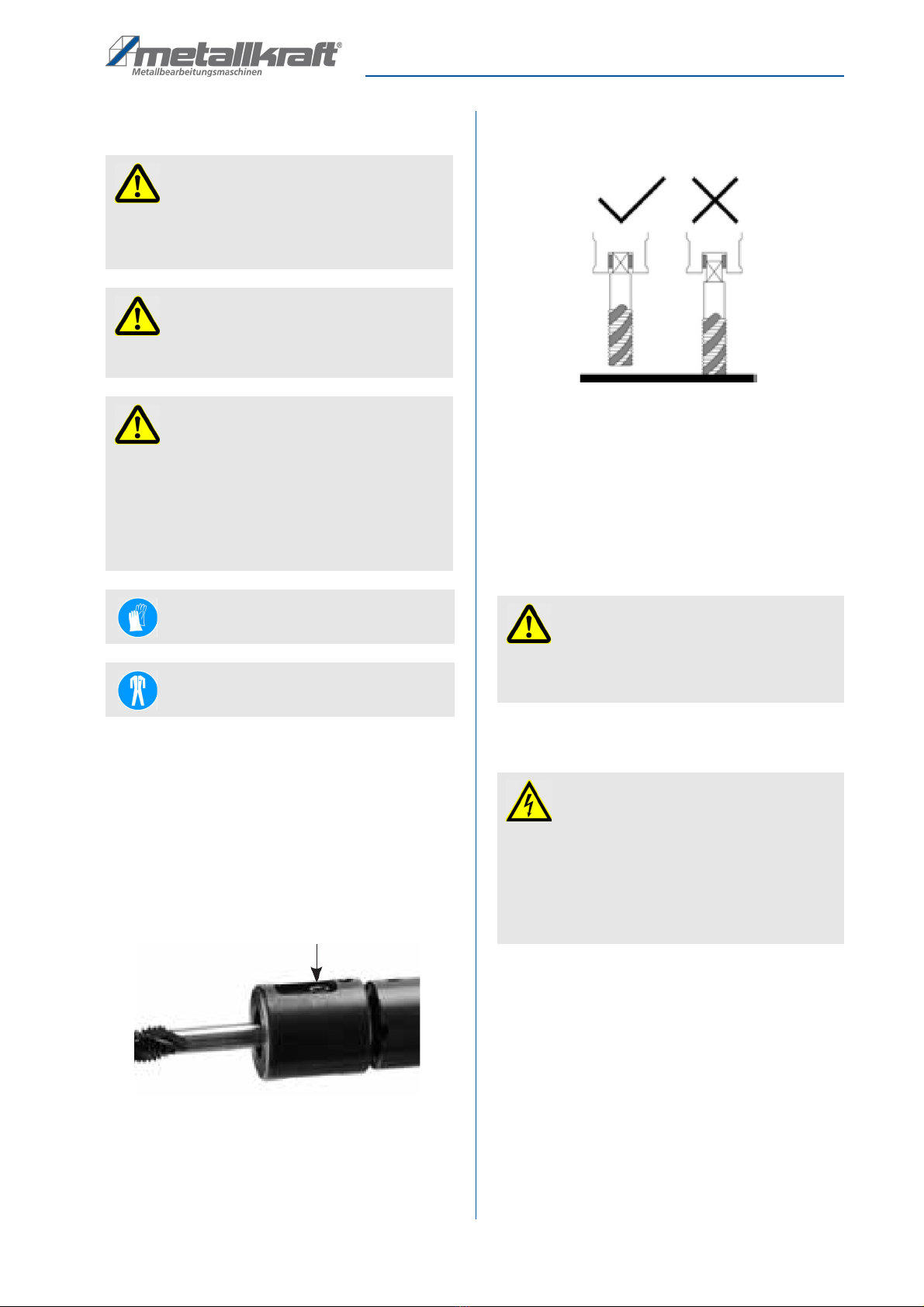

Fig. 4: Holder for taps

Step 3: Insert the tap as far as possible into the clamp-

ing device.

Fig. 5: Inserting the tap

Step 4: Close the clamping device, making sure that the

shaft surfaces do not cant when closing and that

the shaft is inserted into the clamping device as

far as possible.

Step 5: Attach the side handle to your machine to guide

the machine safely with both hands during the

cutting process.

7.2 Electrical connection

When connecting the tap, make sure that:

- the power connection has the same characteris-

tics (voltage, mains frequency, phase angle) as

the motor.

- the mains voltage of 400 V is used.

Connect the Tapping Power Tool to the mains in the fol-

lowing steps:

Step 1: Check that the motor switch is off.

Step 2: Plug in the mains plug into the 230V socket after

clamping the tool.

ATTENTION!

- Make sure that the workpiece is not under pressure

before each cutting operation.

- Check that the workpiece is securely fastened.

ATTENTION!

Before connecting the machine to the mains, check

that the motor switch is off.

ATTENTION!

Never use the machine with larger taps than the

maximum permissible diameter. In relation to steel

14 mm and aluminum 16 mm in continuous opera-

tion. In occasional operation, the tap can be oper-

ated up to a diameter of 18mm. Readjust the slip

clutch if too much slippage occurs. For this please

contact the customer service under 1.2.

Wear protective gloves!

Wear protective clothing!

Locking screw for taps

ATTENTION!

Make sure that the shaft faces of the tap are inserted

as far as possible into the chuck and that the shaft

faces do not cant when the chuck is closed.

DANGER!

Danger to life due to electric current!

There is an immediate danger of electrocution on

contact with live components.

- The tapping power tool may only be connected by

electricians.

- Work on the electrical system should only be car-

ried out by qualified electricians.

10 GS 18 | Version 1.05

Operation

7.3 Drilling

Step 1: Place the tap on the workpiece and position the

machine so that the tap is accurately centered

on the center of the core hole.

Step 2: Press the machine onto the workpiece to set the

rotation direction for screwing in.

Step 3: Start the machine by pressing and holding the

ON switch.

Fig. 6: ON- / OFF-Switch

Step 4: Make sure that the tap is exactly in line with the

core hole, during the entire cutting process.

Step 5: When the desired depth of cut has been

reached, release the On button. The machine

halts.

Step 6: Pull the machine backwards to set the direction

of rotation to bore and restart the machine by

pressing and holding the on switch until the tap

is removed from the core hole.

ATTENTION!

Never use a tool with larger dimensions than

approved by the manufacturer.

ATTENTION!

- Make sure that the workpiece is not under pressure

before each cutting operation.

- Check that the machine has been aligned exactly

to the core hole.

- Only cut with sharp tools!

- Remove chips regularly to avoid large amounts of

chips. This could damage the tool.

- The tool and the cutting residue are very hot at the

end of the cutting process. Do not touch, risk of

burns!

- When cutting, always apply cutting oil to the tool by

hand!

Wear eye protection!

Wear ear protection!

Wear protective clothing!

CAUTION!

Risk of crushing!

Improper work with the tap can result in injury to the

upper limbs.

ATTENTION!

This machine is designed exclusively for cutting

right-hand threads. Left-hand threads are not possi-

ble with this machine!

Downforce:

Clockwise

ON- / OFF-Switch

Cleaning, maintenance and service/repair

GS 18 | Version 1.05 11

Step 7: Pull out mains plug and remove chips with a tool.

7.4 Depth stop

The depth stop is useful if you have to work a blind hole

or a through hole with an obstacle behind the hole. Of

course, the depth stop can be used for each threaded

hole. You can move the depth stop forwards or back-

wards or remove it when you do not need it.

Step 1: Loosen the locking screw of the depth stop and

set it so that it is flush with the end of the tap.

This will be their zero position.

Step 2: Subtract the desired depth of cut from this posi-

tion and additional 4 mm (due to internal me-

chanics). Set this from the zero position.

Step 3: Close the locking screw.

7.5 Safety clutch

The slip clutch is designed in such a way that when the

maximum torque is reached, the clutch slips over. This

is to protect against tearing of the tap and protect the

motor.

The slip clutch is pre-set at the factory and can be read-

justed if it changes in maximum torque. For this please

contact our customer service (see 1.2).

8 Cleaning, maintenance and service/

repair

8.1 Cleaning

NOTE!

Use the supplied depth stop to keep control over the

depth of cut.

Upforce:

Counterclockwise

Tips and recommendations

To ensure that the tapping power tool is always in

good operating condition, regular care and mainte-

nance work must be carried out.

WARNING!

Danger due to insufficient qualification of

persons!!

Insufficiently qualified personnel can not assess the

risks involved in maintenance work on the machine

and expose themselves and others to the risk of seri-

ous injury.

- All maintenance work should only be carried out by

qualified persons.

DANGER!

Danger to life due to electrical shock!

There is a danger to life when in contact with live

components.

- Always unplug the appliance before cleaning and

maintenance.

- Connections and repairs of the electrical equip-

ment may only be carried out by a qualified electri-

cian.

NOTE!

After servicing, maintenance and repair work, check

that all panels and guards are properly installed on

the machine again and that there is no more tools

inside or in the working area of the tapping power

tool.

Damaged safety devices and parts must be

repaired or replaced by the customer service.

NOTE!

Oil, grease and cleaning agents are hazardous to

the environment and must not be dumped into

wastewater or normal household waste. Dispose of

these funds in an environmentally friendly way. The

cloths soaked in oil, grease or detergent are easily

flammable. Collect the cleaning rags or cleaning

wool in a suitable, closed container and dispose of

them in a manner suitable for environmentally-

friendly disposal - do not dispose of with household

waste!

12 GS 18 | Version 1.05

Cleaning, maintenance and service/repair

Clean the machine after each use.

Do not remove metal or scrap with bare hands, but use

safety gloves to prevent cuts.

Clean all painted surfaces with a soft, damp cloth.

Never use solvents to clean plastic parts or painted sur-

faces. A surface release and consequential damage

may occur.

Keep the ventilation slots of the engine free from cont-

amination to ensure sufficient cooling.

8.2 Maintenance

Every 50 hours of operation, clean the engine with com-

pressed air during operation without load. Attention!

Wear eye protection.

Always keep the spindle shaft free of dirt and swarf. Lu-

bricate the spindle shaft regularly.

Changing the carbon brushes:

The carbon brushes are normal wear parts and must be

replaced as soon as they are worn.

Fig. 7: Carbon brushes

Fig. 8: Change carbon brush

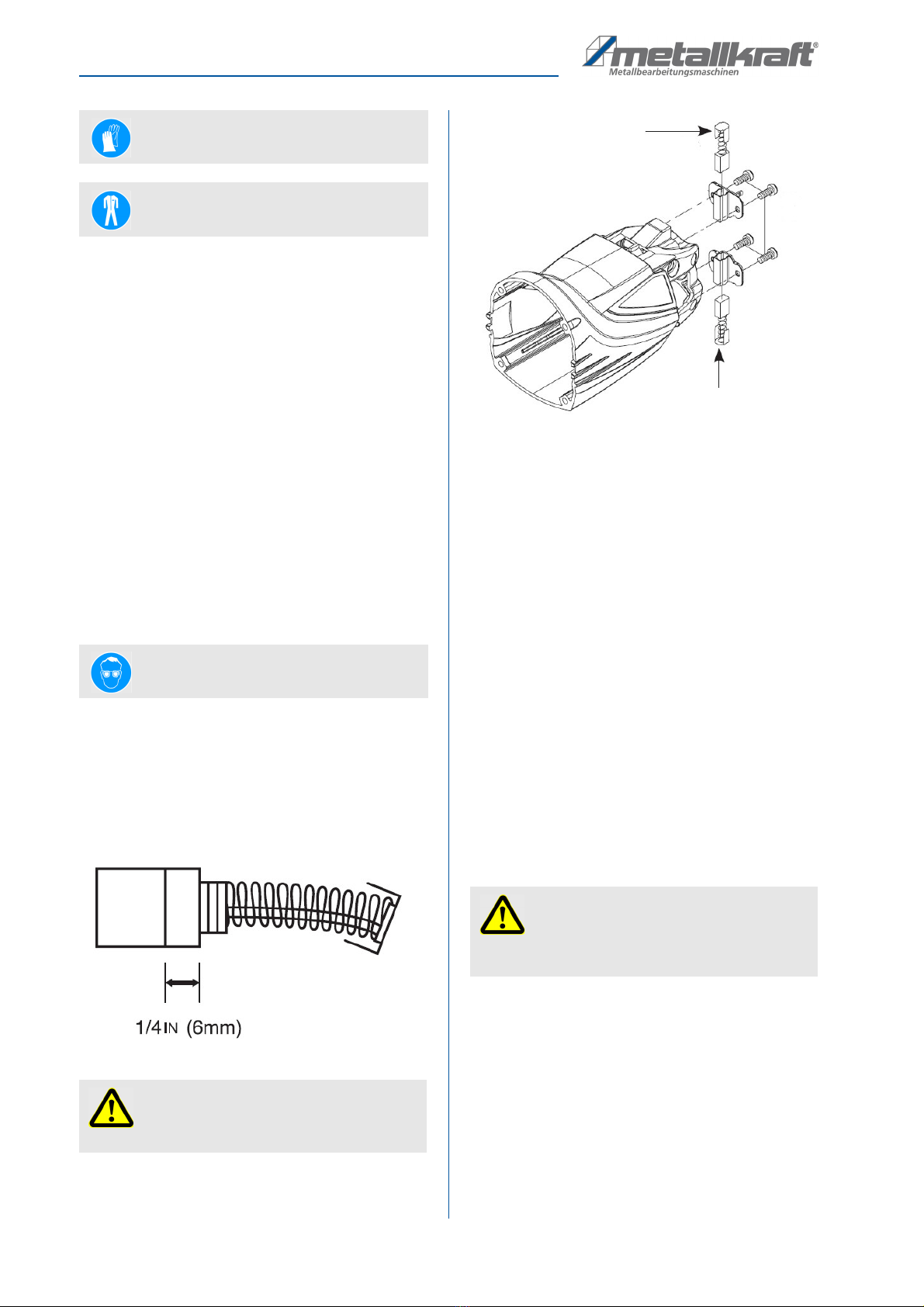

Step 1: Unscrew the four engine cover screws and re-

move the engine cover.

Step 2: Use needle-nose pliers to push the spring aside.

Step 3: Unscrew the connection cable of the carbon

brush and remove the carbon brush.

Step 4: Insert the new carbon brush into the holder and

assemble in reverse order.

Step 5: Follow these steps on both sides.

Step 6: Screw on the engine cover.

If the machine comes to an unexpected stop, check the

carbon brushes. Due to the automatic stop, the carbon

brushes are not sanded down to the end. This serves to

protect the engine.

8.3 Servicing

As a result of wear, it may happen that maintenance

work must be carried out on the machine.

Wearing Protective gloves!

Wearing Protective clothing!

Wearing Eye protection!

ATTENTION!

Always replace the carbon brushes in pairs.

ATTENTION!

Repairs or maintenance work may only be carried

out by qualified and trained specialist personnel.

Carbon brush

Carbon brush

Disposal, Recycling of old equipment

GS 18 | Version 1.05 13

9 Disposal, Recycling of old equip-

ment

In your own interests and in the interests of the environ-

ment, please ensure that all components of the machine

are disposed of in the proper and approved way.

9.1 Decommission

Disused devices must be taken out of service immedi-

ately in order to avoid later misuse and endangering the

environment or people.

- Remove all environmentally hazardous operating fluids

from the old device.

- Disconnect the power cord.

- If necessary, dismantle the machine into manageable

and usable assemblies and components.

- Guide the machine components and operating materi-

als to the appropriate disposal routes.

9.2 Disposal of electrical equipment

Please note that electrical appliances contain a variety

of recyclable materials as well as environmentally harm-

ful components.

Make sure that these components are disposed of sep-

arately and properly. In case of doubt, please contact

your municipal waste disposal.

If necessary, the help of a specialized waste manage-

ment company can be used for the treatment.

9.3 Disposal of lubricants

Please pay attention to an environmentally friendly dis-

posal of the used coolants and lubricants. Observe the

disposal instructions of your municipal disposal compa-

nies. The disposal instructions for the lubricants used

are provided by the lubricant manufacturer. If neces-

sary, ask for the productspecific data sheets.

10 Spare parts

10.1 Ordering spare parts

The spare parts can be obtained from the dealer or di-

rectly from the manufacturer. The contact details are in

chapter 1.2 Customer Service.

When ordering spare parts, please use the spare parts

document accompanying the machine.

- Type of device

- Serial number

- Quantity

- Designation

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Spare part orders which do not include the above indi-

cations may not be taken into consideration. If the indi-

cations regarding the mode of dispatch are missing, the

product is dispatched at the discretion of the supplier.

Information on the device type, article number and year

of manufacture can be found on the type plate, which is

attached to the device.

ATTENTION!

For maintenance work, please contact your nearest

metalworking dealer. Please write down the follo-

wing information from the machine or the operating

instructions beforehand so that you can be helped in

the best possible way with your problem:

- Model of the machine,

- Serial number of the machine,

- Hydraulic data

- Exact error description

DANGER!

Risk of injury due to incorrect spare

parts!

The use of incorrect or faulty replacement parts can

be dangerous to the operator and cause damage

and malfunction.

- Only original spare parts from the manufacturer or

replacement parts approved by the manufacturer

must be used.

- In case of doubt, always contact the manufacturer.

Tips and recommendations

Using non-approved spare parts voids the manu-

facturer's warranty.

14 GS 18 | Version 1.05

Spare parts

Example

The motor housing of the thread cutter GS 18 must be

ordered. The motor housing has the position number 14

in the spare part drawing.

- Type of device: Tapping Power Tool GS 18

- Item number: 3860018

- Position number: 14

The order number is: 0-3860018-14

The order No. consists of the item No (3860018), the po-

sition No. (14) and one digit in front of the item No. (0).

- Place the digit 0 in front of the item No.

- Also place the digit 0 in front of the position No 1

through 9.

The order number is: 3860018.

Spare part drawing

GS 18 | Version 1.05 15

11 Spare part drawing

In case of service, the following drawing shall help to identify the necessary spare parts. If necessary, send a copy of

the parts drawing with the marked components to your authorized dealer.

Fig. 9: Spare part drawing GS 18

16 GS 18 | Version 1.05

Electrical wiring diagram

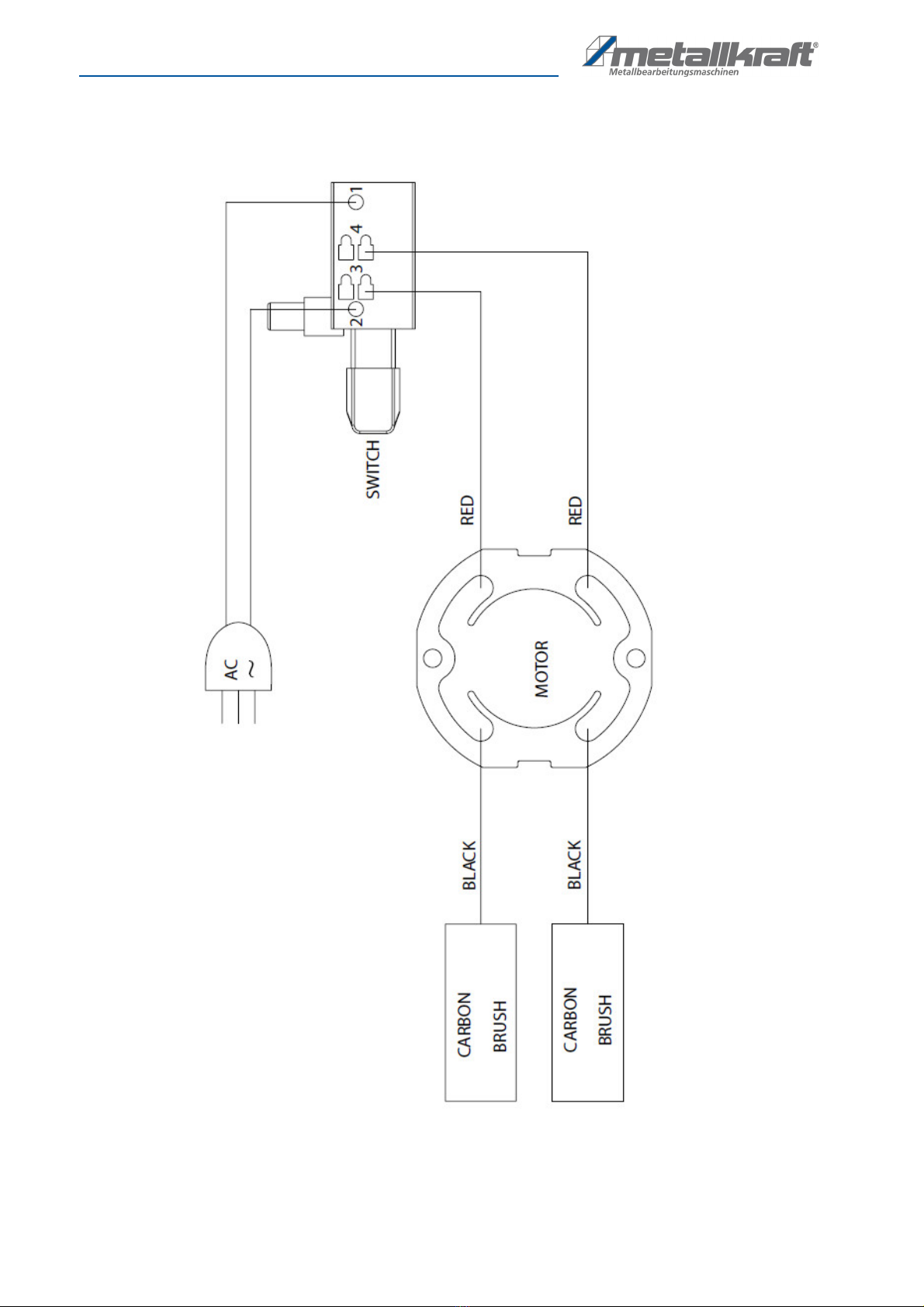

12 Electrical wiring diagram

Fig. 10: Electrical wiring diagram GS 18

EC Declaration of conformity

GS 18 | Version 1.05 17

According to machine directive 2006/42/EC Annex II 1.A

Manufacturer/retailer: Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Starße 26

D-96103 Hallstadt

herewith declares that the following product

Product group: Metallkraft®Metallbearbeitungsmaschinen

Machine type: Tapping Power Tool

Designation of machine: GS 18

Item number: 3860018

Serial number: ____________________

Year of manufacture: 20____

corresponds, on the basis of its design and construction, as well as the version that we have put into circulation, with the

relevant fundamental health and safety requirements of (subsequent) EC guidelines.

Relevant EU directives 2014/30/EU EMC-Directive

2011/65/EU RoHS-Directive

The following harmonized standards were applied:

DIN ES ISO 12100:2010 Safety of machinery - General principles for design -

Risk assessment and risk reduction

DIN EN 60204-1:2007-06 Safety of machinery - Electrical equipment of machines -

Part 1: General requirements

DIN EN 61029-1:2009+A11:2010 Safety of transportable motor-operated electric tools

Part 1: General requirements

Responsible for documentation: Kilian Stürmer, Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, 20/07/2016

______________________

Kilian Stürmer

Manager

13 EC Declaration of conformity

www.metallkraft.de

This manual suits for next models

1

Table of contents

Other Metallkraft Power Tools manuals