Metallkraft SSG 16 User manual

SSG 16

Instruction Manual

SSG 16

Compressing and stretching

machine

SSG 16

2 SSG 16 | Version 2.01

Imprint

Product identification

Compressing and stretching machine Item number

SSG 16 3776103

Manufacturer

Stürmer aschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt/Bamberg

Fax: 0049 (0) 951 96555 - 55

Internet: www.metalkraft.de

Information on the operating instructions

Original operating instructions

Edition: 04.03.2019

Version: 2.01

Language: English

Author: S

Indications regarding the copyright

Copyright © 2019 Stürmer aschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions is the sole

property of the company Stürmer aschinen GmbH.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Contents

1 Introduction ............................................. 3

1.1 Copyright ............................................................ 3

1.2 Costumer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................... 3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company ................ 4

2.3 Requirements to staff.......................................... 4

2.4 Personal protective equipment ........................... 5

3 Intended Use............................................ 5

3.1 Residual risks ..................................................... 6

Technical Data......................................... 6

4.1 Table................................................................... 6

5 Transport, package and storage............ 6

5.1 Delivery and Transport ....................................... 6

5.2 Packaging........................................................... 6

5.3 Storage ............................................................... 6

6 Description of the device ....................... 6

6.1 Illustrations.......................................................... 6

6.2 Scope of delivery ................................................ 6

6.3 Accessories ........................................................ 6

7 Assembly ................................................. 7

8 Operation ................................................. 9

8.1 Operation and adjustment .................................. 9

9

Cleaning, maintenance and service/repair

.. 10

9.1 Cleaning............................................................ 10

9.2 Repair ............................................................... 10

10

Disposal, recycling of old equipment

.... 10

10.1 Decommission ................................................ 10

11 Spare parts .......................................... 11

11.1 Ordering spare parts....................................... 11

12 Spare parts drawing............................ 12

13 Notes .................................................... 13

Introduction

SSG 16 | Version 2.01 3

1 Introduction

With the purchase of the device of ETALLKRAFT you

have made a good choice.

Thoroughly read the operating instructions before

commissioning the machine.

It informs you about the proper commissioning, the in-

tended use as well as the safe and efficient operation

and maintenance of your device.

The operating instructions are part of the device. It must

always be stored at the place of use of the device. In ad-

dition, the local accident prevention regulations and ge-

neral safety regulations apply to the area of application

of the device.

The illustrations in these operating instructions serve the

general comprehension and may deviate from the ac-

tual type.

1.1 Copyright

The contents of these instructions are copyright. Their

application is admissible in the frame the device utilisa-

tion. An application beyond the described application is

not allowed without written approval of the manufac-tu-

rer. For the protection of our products, we shall regis-ter

trademark, patent and design rights, as this is possi-ble

in individual cases. We strongly oppose any infringement

of our intellectual property.

1.2 Costumer service

Please contact your dealer if you have any questions

about your machine or technical information. There you

will be happy to help with expert advice and information.

Germany:

Stürmer aschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair-Service:

Fax: 0049 (0) 951 96555-111

E- ail: service@stuermer-maschinen.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E- ail: ersatzteile@stuermer-maschinen.de

We are always interested in valuable experience and

knowledge gained from using the application-which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised taking the applicable standards and

rules, the state-of-the-art and our long-term knowledge

and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use,

- Use of untrained staff,

- Unauthorised modifications,

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery conditi-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This paragraph will give you an overview of all important

safety packages for the protection of persons as well as

for the safe and undisturbed operation. Other taskba-sed

safety notes are included in the individual chapters.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are intro-duced by

signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-

cate an imminently dangerous situation which may

lead to death or severe injuries if they are not avoi-

ded.

WARNING!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to death or severe injuries if they are not avoided.

4 SSG 16 | Version 2.01

Safety

Tips and recommendations

It is necessary to observe the safety notes quoted in

these operating instructions in order to reduce the risks

for personal injuries and damages to property.

2.2 Obligations of the operating company

The operating company is the person who operates the

machine for business or commercial reasons by herself,

or leaves it to a third party for use or application, and who

bears the legal product responsibility for the protection of

the user, the staff or for third parties.

Obligations of the operating company:

If the machine is used for commercial purposes, the op-

erating company must comply with the legal working saf-

ety regulations. Therefore, the safety notes in this op-

erating manual, as well as the safety, accident preven-

tion and environment protection regulations applying for

the area of application of the machine must be met. The

following applies in particular:

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use the ma-

chine. She must implement these in form of oper-

ating manuals for the operation the machine.

- During the entire lifetime of the machine, the oper-

ating company must verify whether the operating

manuals prepared by her correspond to the cur-

rent status of the regulations, and must adapt

these if necessary.

- The operating company must unambiguously reg-

ulate and determine the responsibilities for instal-

lation, operation, troubleshooting, maintenance

and cleaning.

- The operating company must ensure that all per-

sons who work with the machine, have read and

understood this manual. Furthermore she must in-

struct the staff in regular intervals and inform them

about the hazards.

- The operator must provide the necessary protec-

tive equipment to the staff and order the use of the

necessary protective equipment in a binding way..

Furthermore the operating company is responsible to

keep the machine always in a technically flawless state.

Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices checked

regularly for their good working order and their in-

tegrity.

2.3 Requirements to staff

Qualifications

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

CAUTION!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to minor or light injuries if they are not avoided.

NOTE!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the machine and expose themsel-

ves and others to the danger of severe or let-hal inju-

ries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the wor-

king area.

Intended Use

SSG 16 | Version 2.01 5

Operator

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behavior. Any tasks which need to be per-for-

med beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company expres-

sively commissioned the operator.

Electrically qualified person:

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a po-

sition to carry out work on the electrical systems and to

independently recognize and avoid possible dangers.

Qualified personnel:

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognize and avoid any possible dangers them-

selves.

Manufacturer:

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while wor-

king. The staff member has to wear personal protec-tive

equipment while performing different tasks on and with

the machine which are indicated in the individual para-

graphs of these instructions. The personal protective

equipment is explained in the following paragraph:

3 Intended Use

The Compressing and stretching machine is used for

universal use in the workshop and construction site area

for upsetting and stretching sheet metal. The version

SSG 16 can handle a maximum plate thickness of 1.5

mm.

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or

otherwise is considered misuse.

Unauthorized modifications or alterations to the device

can invalidate the CE conformity of the device and are

prohibited. The company Stürmer aschinen GmbH as-

sumes no liability for design and technical changes to the

device.

The improper use of the device as well as the disregard

of the safety regulations or the operating instructions

exclude a liability of the manufacturer for resulting da-

mage to persons or objects and cause the warranty to

expire!

Ear and head protection

The ear protection protects against hearing damage

caused by noise. The industrial helmet protects the

head against falling objects and bumping against

fixed objects.

Face protection

The face shield protects the face from flying parts.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fal-

ling parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

WARNING!

Danger in case of misuse!

isuse of the device can lead to dangerous situati-

ons.

- Only operate the device in the power range speci-

fied in the technical data.

- Never bypass or override the safety devices.

- Only operate the compression and stretching de-

vice in a technically perfect condition

- An optimal processing of the sheet can only be

done by clamping the respective jaws

6 SSG 16 | Version 2.01

Technical Data

3.1 Residual risks

Even if all safety regulations are observed and the ma-

chine is used correctly, there are still residual risks listed

below:

- Pinching of body parts.

- Injuries from flying workpieces or workpiece parts.

- Danger of breakage of the tool.

4 Technical Data

4.1 Table

5 Transport, package and storage

5.1 Delivery and Transport

Check the machine on delivery for any visible transpor-

tation damage. If you notice any damage to the device

please report this immediately to the carrier or dealer.

5.2 Packaging

All packaging materials and packing aids used for the hy-

draulic workshop press are suitable for recycling and

must always be disposed of using material-based recy-

cling systems.

Packaging materials made of cardboard must be shred-

ded and disposed of as part of waste paper recycling.

The foils are made of polyethylene (PE), padding is

made of polystyrene (PS). Dispose of these at a recy-

cling center or hand them over to the relevant waste dis-

posal company.

5.3 Storage

Store the device in a dry, clean, dust-free and frost-free

environment. It must not be placed in a room with highly

oxidising chemicals.

Also, all bare metal parts must be greased against corro-

sion.

6 Description of the device

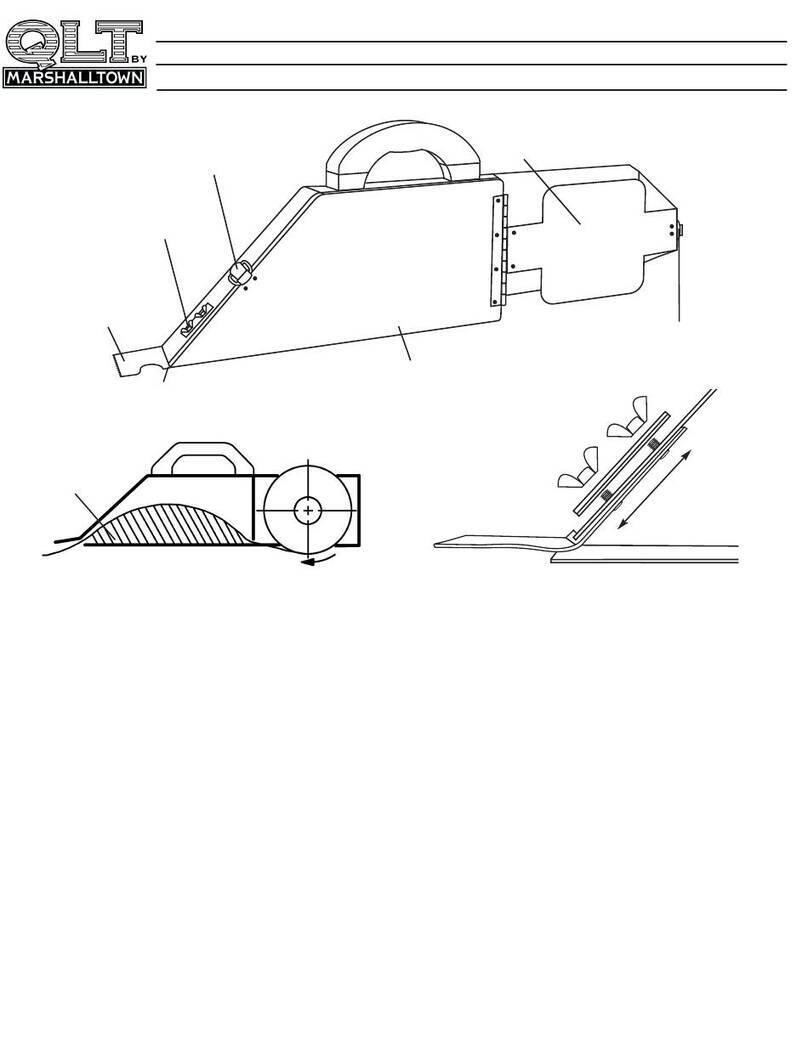

6.1 Illustrations

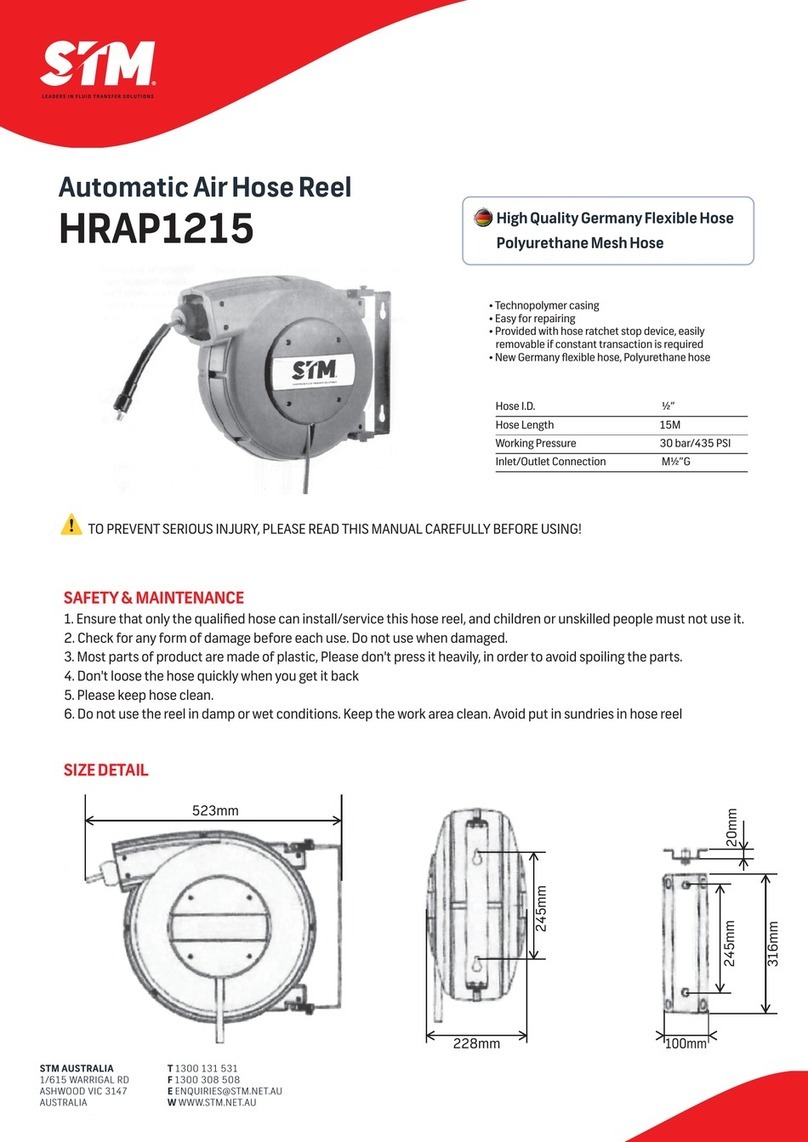

Fig. 1: Description of the device

1 - Cover for shrub and stretch jaw

2 - Upsetting and stretching jaws

3 - ain unit or pedestal

4 - Foot pedal

6.2 Scope of delivery

- Basic machine

- Stretching jaws

- Compression jaws

6.3 Accessories

- Compression jaw SET for SSG 16 for metal

Item number: 3776106

- Stretching jaw SET for SSG 16 for metal

Item number: 3776107

- Compression jaw SET for SSG 16 for aluminium

Item number: 3776108

- Stretching jaw SET for SSG 16 for aluminium

Item number: 3776109

Type SSG 16

ax. sheet thickness 1,5 mm

Throat 153 mm

Length 1175 mm

Width / Depth 410 mm

Height 920 mm

Weight 36 kg

Assembly

SSG 16 | Version 2.01 7

7 Assembly

Set up the device where you want to work with it. Alter-

natively, you can mount the device on a pedestal, ma-

king sure the pedestal will withstand the device when

working.

Fig. 2: ounting in the ground

To improve the stability of the device, the device can be

pegged in the ground.

Fig. 3: Drilling

ount the foot pedal to the rear axle using the 10

screws.

Fig. 4: ount the foot pedal

Put some fat on the axle.

Fig. 5: Greasing the axle

ount the axle to the end of the foot pedal.

Fig. 6: ount the axle

Insert the foot pedal into the rack.

Fig. 7: ount the foot pedal

ove the foot pedal in the main unit while inserting the

screw into the corresponding opening.

Fig. 8: Inserting the screw

Hold the two 10 screws for the axle and insert the

threaded connection into the opening.

Fig. 9: Inserting the threaded connection

8 SSG 16 | Version 2.01

Assembly

Install the two screws and tighten securely.

Fig. 10: Inserting the screws

ount the spring first on the main unit, then on the foot

pedal.

Fig. 11: Assembly of the spring

Lubricate the foot pedal connection and the axle with

grease.

Fig. 12: Lubricating the foot pedal connection

Insert the axle into the hole at the end of the foot pedal.

Fig. 13: Insertion of the axle

Now screw the connection into the thread with about 15

turns.

Fig. 14: Screw in the connection

The length of the connection must be adjusted so that

the height of the side of the foot pedal is 190.5 mm +/-

12.7 mm.

Fig. 15: Setting the connection

ount the two 8 screws for the axle and tighten them.

Fig. 16: Tighten the axle

First insert the corresponding screws for the assembly of

the jaws.

Fig. 17: Assembly of the jaws

Operation

SSG 16 | Version 2.01 9

Insert the jaws into the device and connect them with the

corresponding screws.

Fig. 18: Inserting the cheeks

It is very important to always use the ups and jaws to-

gether. It is also very important to mount these as shown

in the picture. The jaws of the appliance should be oiled

weekly or according to use.

Fig. 19: Jaw

If the upsetting and stretching device is not in use, al-

ways install the locking pin to avoid injury.

Fig. 20: ount the locking pin

Place the unused jaws in the appropriate box. Attach the

wrench to the stand for mounting on the tripod.

Fig. 21: Storage of the cheeks

8 Operation

8.1 Operation and adjustment

Please make sure that the jaws are properly attached to

the body of the device and the body part is fixedly moun-

ted on the associated stand. The opening and closing of

the tool teeth is only possible by pressing the foot pedal

(see exploded view). Place the sheet to be processed in

the middle of the jaws and press the foot pedal.

Note: The work carried out should be within the max. Ca-

pacity.

DANGER!

Never press the upsetting and stretching jaws without

workpiece or Sheet metal together. This avoids da-

mage to the jaws

DANGER!

- Always assemble upsetting and stretching jaws cor-

rectly on the body of the device.

Wear Protective gloves

Wear Protective clothes!

DANGER!

CRUSHING! When upsetting and stretching is

always to make sure that your own security is given.

There are crushing hazards on upper limbs.

10 SSG 16 | Version 2.01

Cleaning, maintenance and service/repair

9 Cleaning, maintenance and service/

repair

9.1 Cleaning

Clean the machine after each use.

Do not remove metal or scrap with bare hands, but use

safety gloves to prevent cuts.

Clean all painted surfaces with a soft, damp cloth.

Never use solvents to clean plastic parts or painted sur-

faces. A surface release and consequential damage may

occur.

9.2 Repair

As a result of wear and tear, it may happen that main-

tenance work must be carried out on the machine..

10 Disposal, recycling of old equipment

In your own interest and to protect the environment make

sure that all machine components are exclusively dispo-sed

of in as intended and permitted.

10.1 Decommission

Disused devices must be taken out of service immedi-ately

in order to avoid later misuse and endangering the en-

vironment or people.

- Remove all environmentally hazardous processing ma-

terials from the used machine.

- if necessary, disassemble the machine into assem-

blies and components that are easy to handle and suit-

able for recycling.

- The machine components and processing materials

must be disposed of us-ing the intended disposal me-

thods.

Tips and recommendations

To ensure that the machine is always in good opera-

ting condition, regular care and maintenance work

must be carried out.

WARNING!

Danger due to insufficient qualifica-

tion of persons!

Insufficiently qualified persons can not assess the

risks associated with repair work on the upsetting

and stretching equipment and expose themselves

and others to the risk of serious injury.

- All maintenance work should only be carried out by

qualified persons.

NOTE!

After care, maintenance and repair work, check that

all panels and guards are correctly mounted on the

upsetting and stretching equipment and that no tools

are left inside or in the working area of the upsetting

and stretching equipment.

Damaged protective devices and parts of the device

must be repaired or replaced as agreed by a recogni-

zed specialist workshop.

NOTE!

Oil, grease and cleaning agents are hazardous to the

environment and must not be disposed of in waste-

water or normal household waste. Dispose of these

funds in an environmentally friendly way. The

cleaning cloths soaked in oil, grease or detergent are

easily combustible. Collect the cleaning rags or

cleaning wool in a suitable, closed container and dis-

pose of them in a manner suitable for environmen-

tally-friendly disposal - do not dispose of with house-

hold waste!

Wear safety gloves!

Wear Protective clothes!

DANGER!

Repairs or maintenance may only be carried out by

qualified and trained specialist personnel.

DANGER!

For maintenance work, please contact your nearest

metalworking dealer. Please write down the follo-

wing information from the machine or the operating

instructions in advance to help you with your pro-

blem in the best possible way:

- odel of the machine,

- Serial number of the machine,

- Exact error description

Spare parts

SSG 16 | Version 2.01 11

11 Spare parts

11.1 Ordering spare parts

The spare parts can be obtained from the dealer or di-

rectly from the manufacturer. The contact details are in

chapter 1.2 Customer Service.

Specify the following key data for inquiries or when orde-

ring spare parts:

- Device type

- Article number

- Position number

- Year of manufacture

- Quantity

- Desired shipping type (post, freight, sea, air, ex-

press)

- Shipping address

Spare parts orders without the aforementioned data can-

not be taken into account. The supplier shall deter-mine

the shipping type if no relevant data was provided.

Information about the device type, item number and year

of manufacture can be found on the type plate. The type

plate is mounted on the device.

Example

The wheel for theCompressing and stretching machine

SSG 16 must be ordered. The wheel has the number 47

in the spare parts drawing 1.

By ordering spare parts, send a copy of the spare parts

drawing (1) with the marked part (wheel) and marked po-

siton number (47) to the dealer or spare parts depart-

ment and provide the following information:

- Type of device: Compressing and stretching ma-

chine SSG 16

- Item number: 3776103

- Drawing number: 1

- Position number: 47

Item number of your device:

Compressing and stretching machine SSG 16: 3776103

DANGER!

Risk of injury caused by the use of

incorrect spare parts!

The use of incorrect or faulty spare parts may cause

risks for operating staff and damage as well as mal-func-

tions.

- Exclusively genuine spare parts made by the man-

ufacturer or spare parts authorized by the manufac-turer

shall be used.

- Always contact the manufacturer if you are unsure.

Tips and recommendations

The manufacturer warranty shall be rendered void in

the event of a use of unauthorised spare parts.

12 SSG 16 | Version 2.01

Spare parts drawing

12 Spare parts drawing

The following drawing are intended to identify the required spare parts in the event of service. If applicable, submit a copy

of the parts drawing including the highlighted components to your authorized retailer.

Fig. 22: Spare parts drawing SSG 16

Notes

SSG 16 | Version 2.01 13

13 Notes

www.metallkraft.de

This manual suits for next models

1

Table of contents

Other Metallkraft Tools manuals