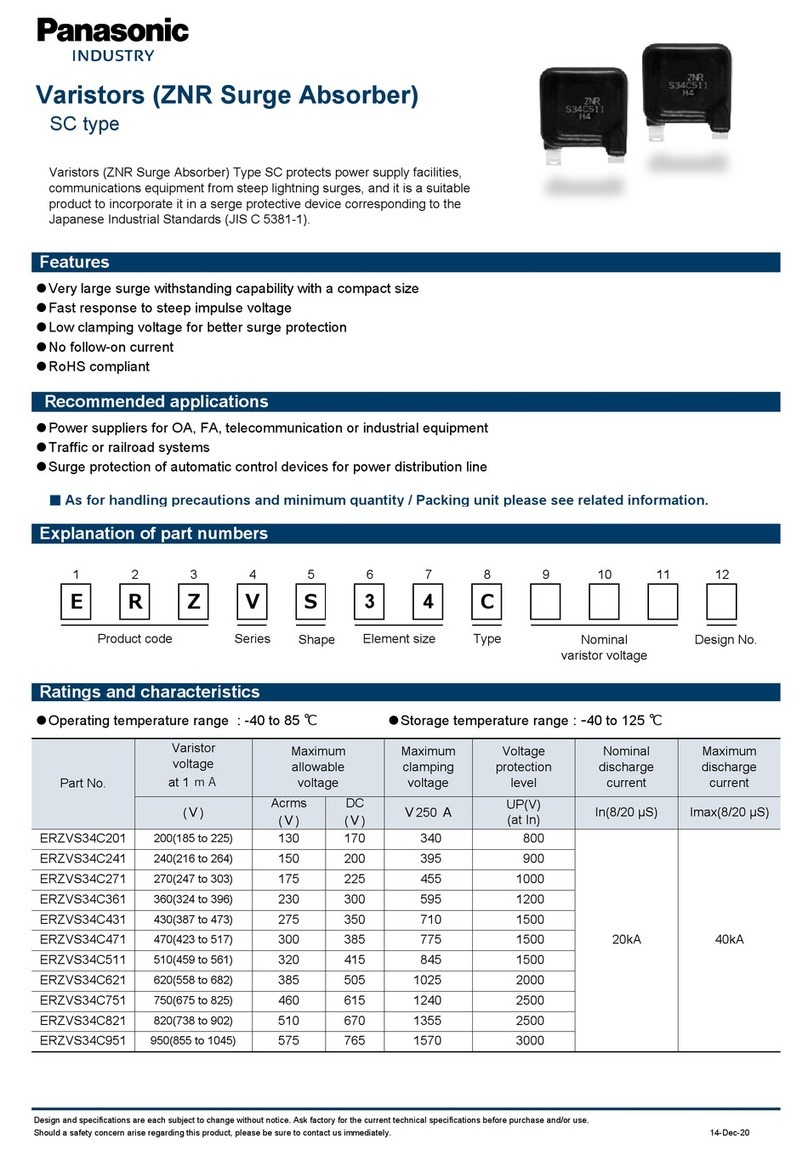

11

OPERATION MANUAL PB-CL SERIES

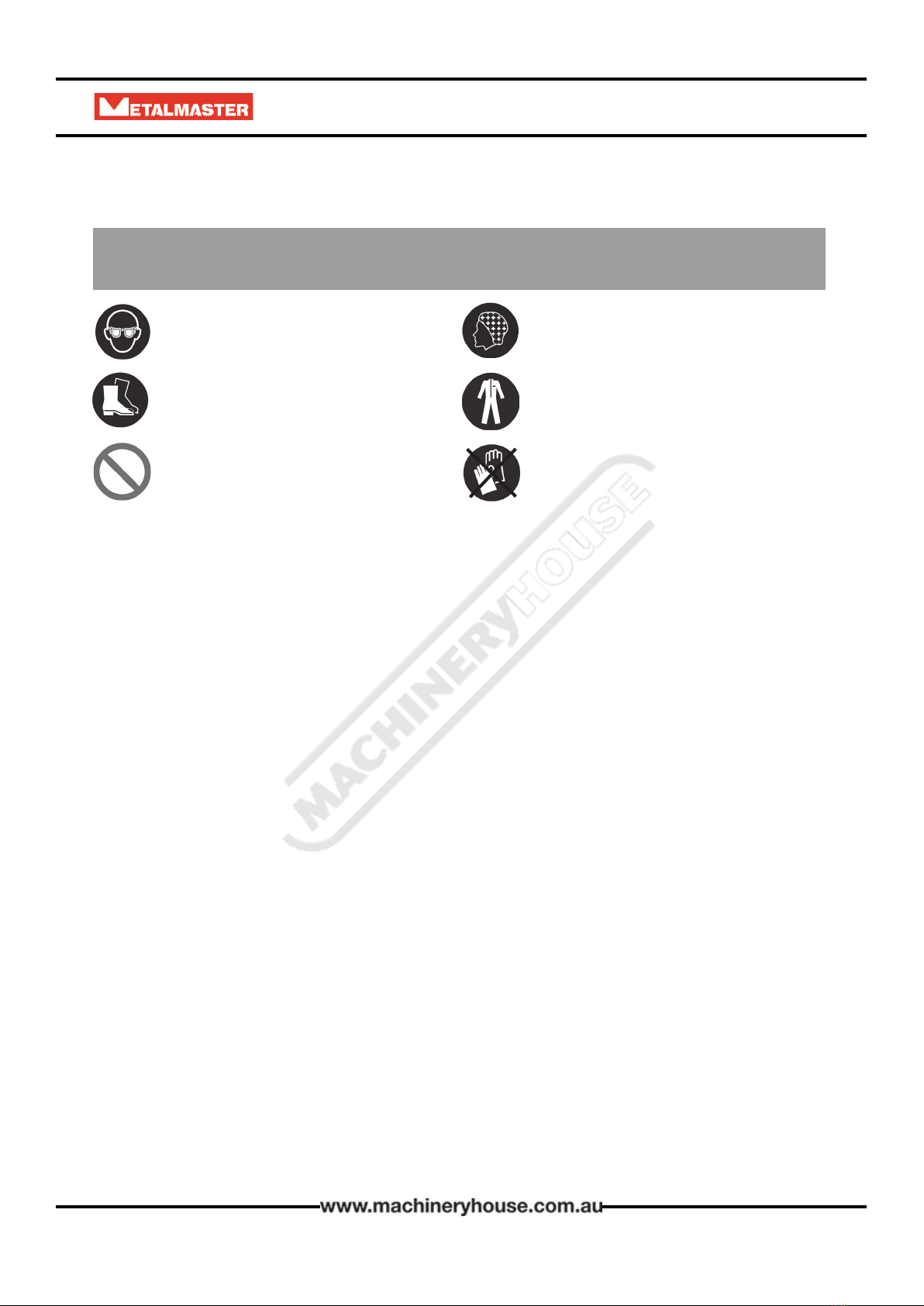

2.2 HYDRAULIC PRESS BRAKE SAFETY PROCEDURE

DO NOT use this machine unless you have been instructed in its safe use and

operation and have read and understood this manual

Long and loose hair must be

contained or restrained

Safety glasses must be worn at all

times in work areas.

Appropriate protective footwear with

substantial uppers must be worn

Coveralls, protective clothing, or a

workshop apron, is recommended

Rings and jewelery must not be worn. DO NOT wear large leather gloves

when operating this machinery

PRE-OPERATIONAL SAFETY CHECKS

1. Ensure that all guards and safety devices are in position and secured.

2. Adjust all guards to minimum practicable clearances for the material to be pressed.

3. Note: any guards and safety devices should NEVER be removed, except for maintenance

purposes, and only by an authorised sta member.

4. Working parts should be well lubricated and all jaws, ngers, ‘V’ blocks and blades be free of

rust and other foreign matter.

5. Adjust the head rams to suit the material thickness.

6. Adjust and check that the‘v’ forming blocks and/or knife blades are aligned correctly.

7. Be aware of any other personnel in the immediate vicinity and ensure the area is clear

before using this equipment.

8. Familiarize yourself with all electrical, hydraulic and mechanical operations and controls,

including the roving foot pedal control.

OPERATIONAL SAFETY CHECKS

1. Strictly only one operator is to use this heavy duty press brake, and, when necessary, with a

safety observer present.

2. Never use any press or pan brake to bend or fold beyond the capacity of the machine.

3. Ensure that both hands are positioned away from any possible pinch point

4. Particular preparation and caution is to be observed when bending rod, strap or spring

steel.

5. This heavy duty press brake is likely to be tted with infra-red safety beams or electronic

sensors to detect hazardous circumstances. If so, this machine should NOT operate if these

safety devices are breached in any way, either by materials or by the operator.

6. Never leave the machine in operational mode while unattended.

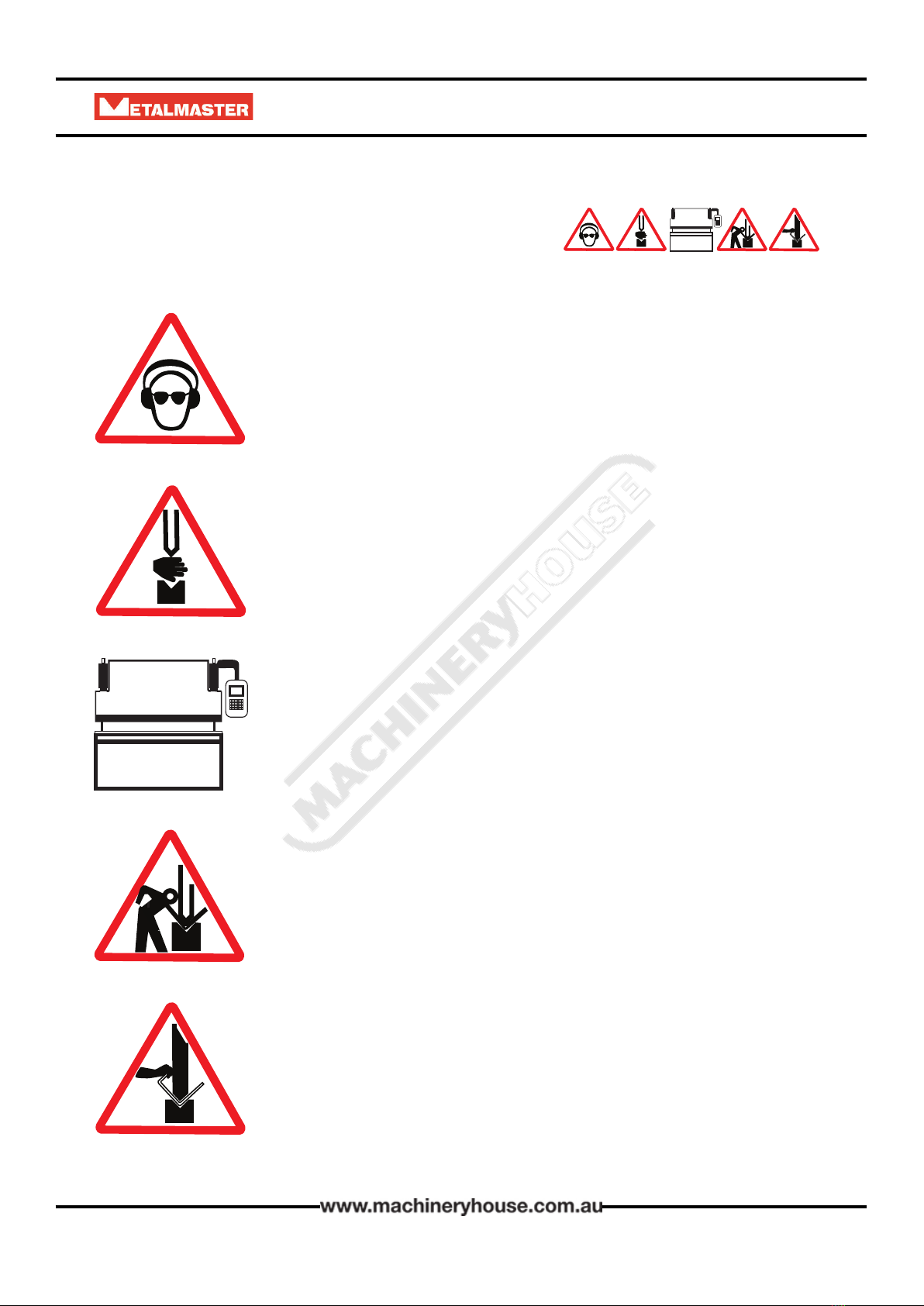

POTENTIAL HAZARDS

Entanglement and entrapment Striking and shearing

Pinch, crush and squash Manual handling

Electrical and hydraulic components Eye injury