User Manual - UNI-CAT 3 of 8 labelmateusa.com

STEP 1: INSTALL THE BRACKET GUIDE

• The Bracket Guide (BG) is mounted on the Right side for labels moving from Right-to-Le. (FIG.1 and FIG.11)

• The Bracket Guide (BG) is mounted on the Le side for labels moving from Le-to-Right. (FIG.2 and FIG.10)

• Loosen (but do not remove) the 3 upper screws on the chassis and slide the BG in between the screws and chassis

as shown in FIG.1, FIG.2 , and FIG.3. Tighten the screws to rmly ax the BG in place.

• Install the black sha onto the BG and slide the media guide collar onto the sha. (FIG.4)

STEP 2: INSTALL THE TENSION ARM

• The Tension Arm can be mounted right or le, depending on the printer posion (FIG.5, RIGHT mount shown),

but it is always mounted on the same side as the Bracket Guide (BG).

• Remove (but do not discard) the large Screw from the face of the Tension Arm Sha (Sha below the main

Motor Sha).

• Loosen the Set Screw at the end of the Tension Arm and posion the Arm with the Set Screw facing the at on the

Tension Arm Sha. (FIG. 6)

• Tighten the Set Screw facing the at on the Sha. (FIG.6)

• Re-insert and ghten the Tension Arm Sha Screw into the Tension Arm Sha to mount the Tension Arm rmly.

STEP 3: INSTALL THE TAKE-UP SHAFT

• CHUCK (FIG.8): Mount the inner Flange onto the Quick-Chuck with two screws provided.

• STANDARD, 1-INCH and W10 (FIG.7): Slide the Flange Plate onto the hollow end of the Rewind Sha. For maximum

width, the Flange face should be ush with the end of the Sha. Tighten the screw in the Hub if necessary.

• Slide the Sha and Flange Assembly onto the UNI-CAT Motor Sha allowing for clearance between the Chassis and

Motor Screws. Tighten the Allen Screw onto the at part of the Motor Sha unl it is ght.

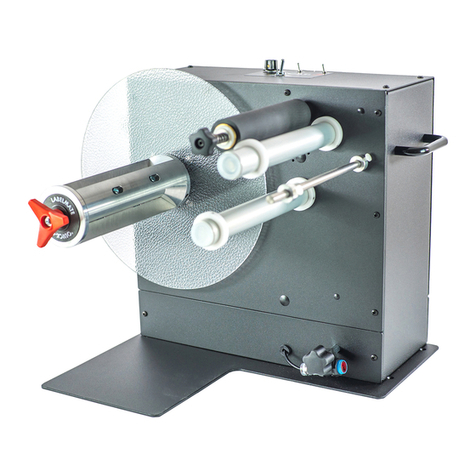

• ACH (FIG.9): Slide the Hub of the ACH over the motor Sha of the UNI-CAT. Posion the Hub so there is a gap

between the ACH Hub and the Rewinder Drive Unit Chassis. Tighten the Allen Screw onto the at part of the Motor

Sha unl it is ght.

• Set the UNI-CAT in place near the label exit slot of the printer.

• Plug the Power Supply into a suitable power outlet and connect it to the UNI-CAT.

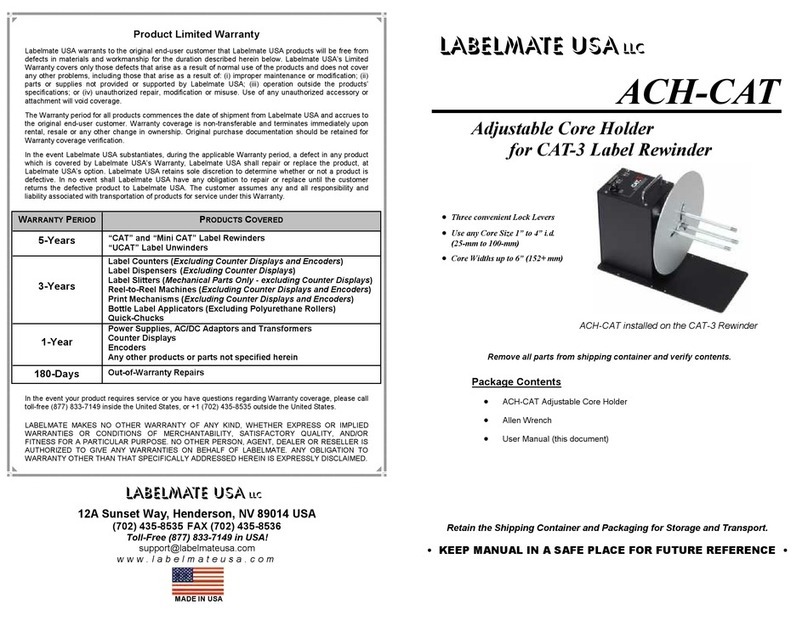

USING THE ACH (ADJUSTABLE CORE HOLDER)

• Loosen the three Lock Levers on the back of the ACH Flange Plate.

• Grasp the silver colored front Flange Plate with one hand and the black rear Flange Plate with the other.

• Rotate the Plates in opposite direcons unl the three Core Fingers contract to the center of the ACH.

• Slide an empty cardboard core only partway over the Fingers, leaving approximately 2” (50mm) between the

ange and the core.

• Rotate the Flange Plates in opposite direcons to expand the Fingers against the inside of the cardboard core.

Holding the Flanges rmly so that the Fingers remain pressed against the inside of the core, rotate one of the

Locking Levers clockwise unl it is xed. DO NOT OVER TIGHTEN.

• Rotate the Flange Plates and move the other two (2) Locking Levers into the LOCK posion as well.

• Slide the core all the way on up against the inside Flange. If the core is too ght, loosen the Lock Levers and repeat

the process, but sliding the core a lile bit further down onto the Fingers prior to ghtening.