tormek SVD-185 User manual

75

Gouge Jig SVD-185

Grinding direction:

Away from the edge.

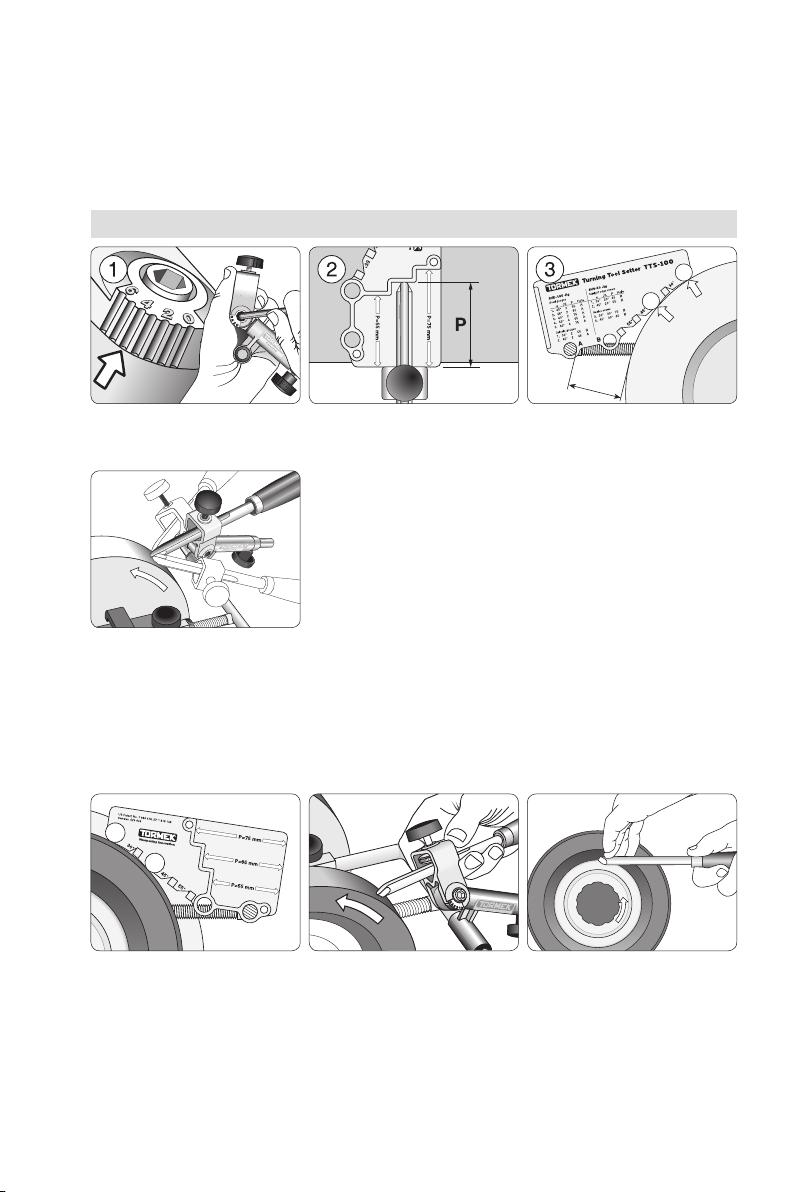

Design

The jig comprises a tool holder (1) which runs in a sleeve (2). The tool is aligned with a disc

(4) and tightened with a knob screw (5). There is a washer (6) for wide gouges. The stop ring

(7) can be set for a convex bevel with a screw (8).

The tool holder can be set in any position from 0 to 6 with the 5 mm Allen key (9). The setting

can be noted on a special prole label (10), which is attached to the ferrule. A special pen,

which works on these labels is included (11). For turning cutters there is a shaft (12) with a

mounting screw (13) and a 2,5 mm Allen key (14).

Positioning of Machine

TURNING TOOLS

Bowl gouges

Spindle gouges

Turning cutters

CARVING TOOLS

Curved gouges

Spoon-shaped gouges

Back bent gouges

Down bent gouges

Curved V-tools

Max tool width 25 mm (1").

76

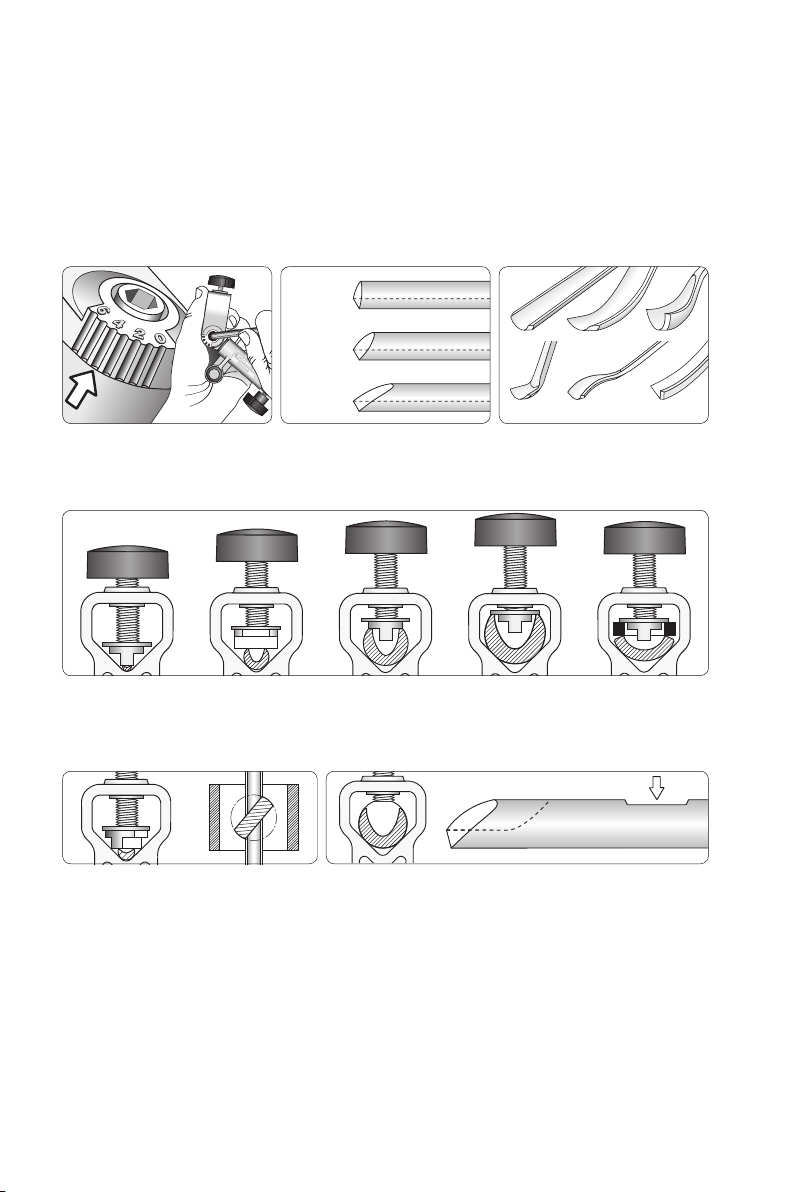

The special locking disc fits any size of tool, which is automatically aligned in the same position

every time it is mounted. The disc can be positioned either along (a) or across (b) the tool. For wide

spindle gouges there is a removable washer, which fits on the disc (c).

Turning Gouges and Carving Tools

You can grind turning gouges with the so called ngernail shape as well as carving gouges

with various shapes. You can also grind straight and curved V-tools.

The jig causes the tool to move towards the grindstone in a special way, according to the set-

ting selected from 0 to 6. This means, that for turning gouges you can decide the maximum

length of the side edges. For curved carving gouges, which are not ground with a ngernail

shape, the jig setting compensates for the shape of the shank.

The jig can be set from 0 to 6,

which permits the grinding of …

… turning gouges with various

lengths of side bevels and …

… carving gouges with various

shapes and V-tools.

The disc also works if placed diagonally.

Section seen from above.

For a large gouge with a short flute the locking disc is

removed. Flatten the top surface of the shank with a file for

repeatable alignment.

abaac

77

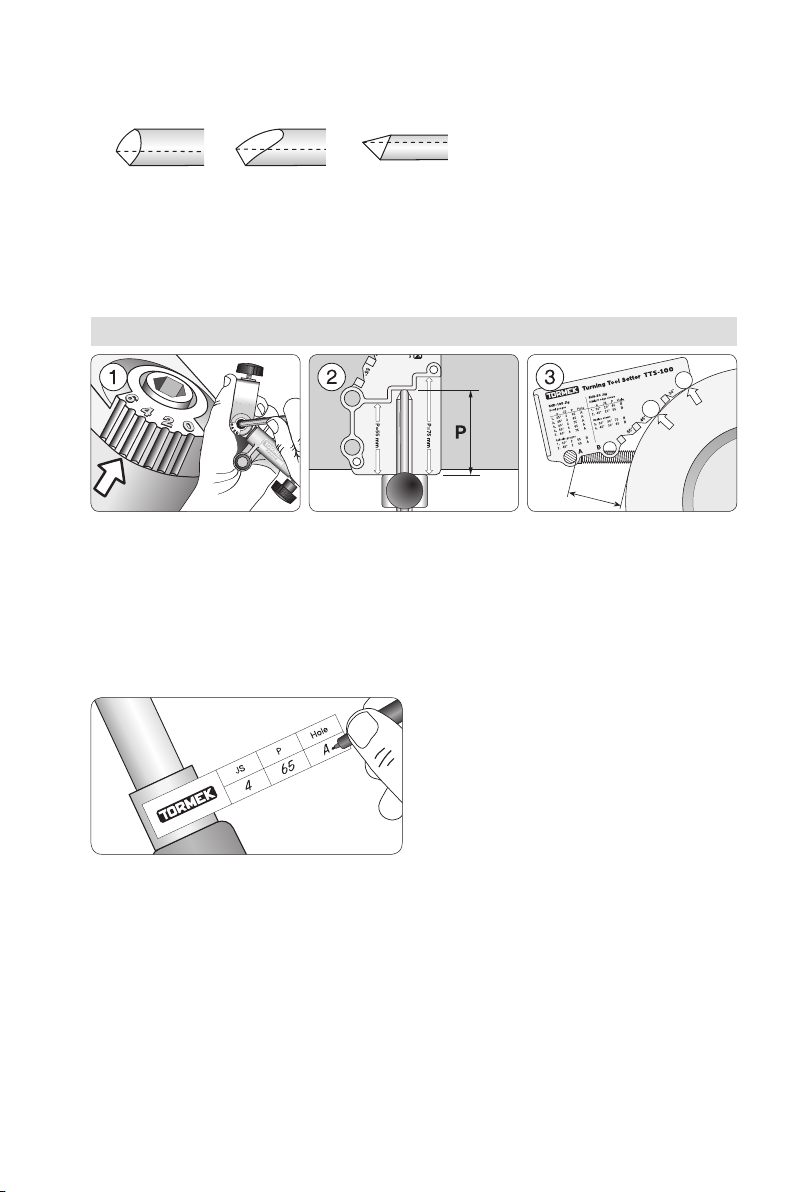

Turning Gouges

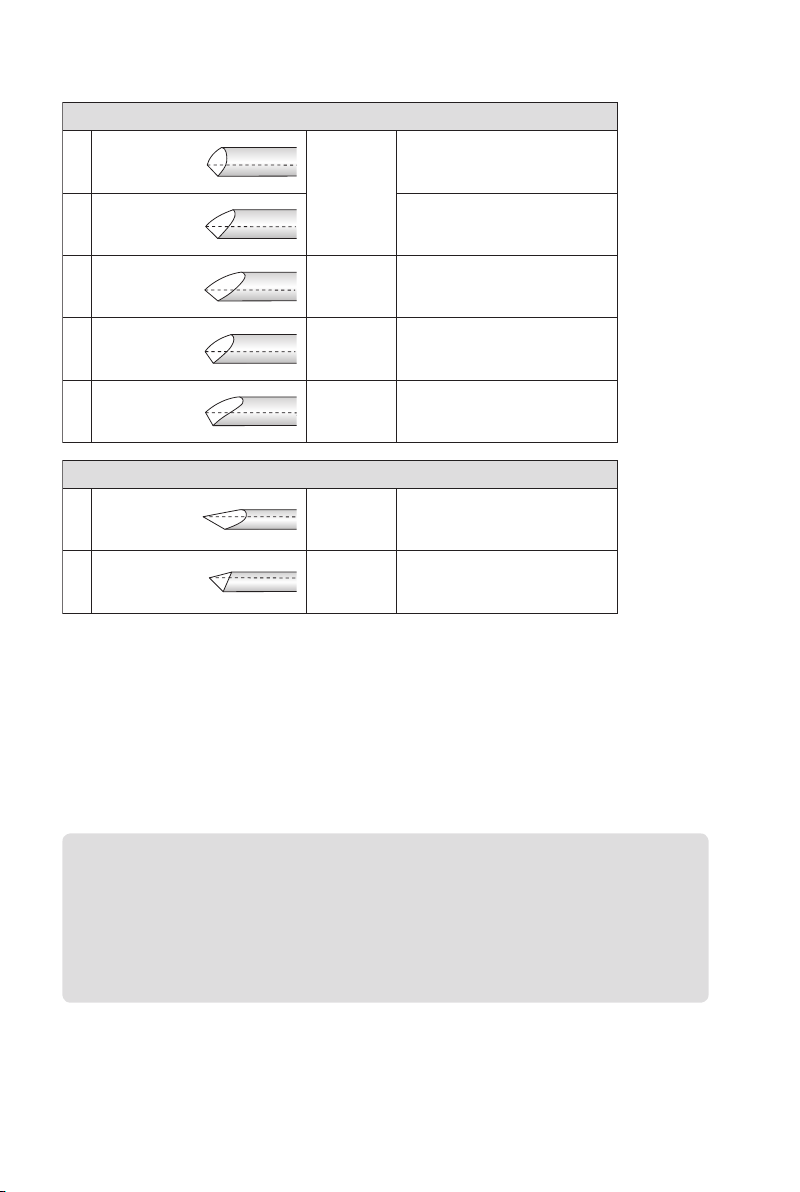

Note the settings on the Profile

Label and put it in on the ferrule.

Aset of labels comes with the jig.

The protrusion of the

toolinthejig, P.

The setting of the jig, JS. Universal Support position.

Use hole A or hole B.

Shaping

The jig positions the gouge on the grindstone so that you can get a specic and repeatable

grinding at any point along the bevel. This enables you to get an even, single bevel around

the entire prole from the left to the right wing.

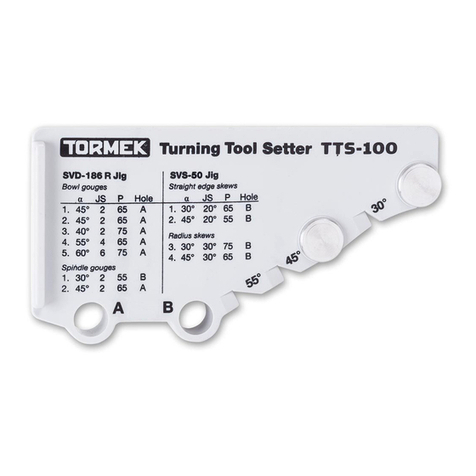

With the Turning Tool Setter TTS-100 you control these factors. Select the prole you want

from the chart on the next page and use the three settings, which give that shape. Note the

settings on the Prole Label and put it on the ferrule. After the initial shaping you can exactly

replicate your favourite shape at every sharpening in less than a minute.

These three factors determine the geometry of a gouge

78

These geometries, i.e. the shape and edge, angle are recommended by experienced wood-

turners and recognized woodturning workshops around the world, e.g. Craft Supplies in USA

and Drechselstube Neckarsteinach in Germany.

Since a tool can have an unlimited number of combinations of shapes and edge angles, a

new tool has a more or less a different shape compared to any of the shapes on the chart.

Therefore, you rst need to shape your tool to one of the shapes on this chart. Then the fol-

lowing sharpenings will be an easy task and done in less than a minute.

Tip Stick to the shape you have selected and do not switch from one shape

to another. Then you will get the full benefit of the Tormek TTS-100 Setter,

since you can instantly replicate exactly the same shape every time. Should

you need a different shape, then buy another tool and grind it to your alterna-

tive shape. This way of working will give you more time for turning and fewer

interruptions for shaping and sharpening.

Bowl gouges

1α=45° JS 2

P 65

Hole A

Standard profile.

Only lightly swept back wings.

For turners of all skill levels.

2α=45°

Irish profile. Swept back wings.

Swing the tool 180° from side

to side.

3α=40°

JS 2

P 75

Hole A

With long swept back wings.

Somewhat aggressive.

For professional level turners.

4α=55°

JS 4

P 65

Hole A

The larger edge angle is beneficial

when turning deep bowls.

5α=60°

JS 6

P 75

Hole A

“Ellsworth” shape.

Wings are pronounced convex.

Spindle gouges

1α=30°

JS 2

P 55

Hole B

For tight spots, detail work and

fi nest fi nish.

For professional level turners.

2α=45°

JS 2

P 65

Hole A

Standard profile.

For turners of all skill levels.

Skews

1

Straight edges JS 20°

P 65

Hole B

For tight spots, detail work and

fi nest fi nish.

For professional level turners.

α=30°

2

Straight edges JS 20°

P 55

Hole B

For broad application.

Easier to control than

a 30° edge angle.

α=45°

3

Radius edges JS 30°

P 75

Hole B

For tight spots, detail work and

fi nest fi nish.

For professional level turners.

α=30°

4

Radius edges JS 30°

P 65

Hole B

For broad application.

Easier to control than

a 30° edge angle.

α=45°

Flat

Flat

Flat

Flat

Oval

Oval

Oval

Oval

Selection Chart

79

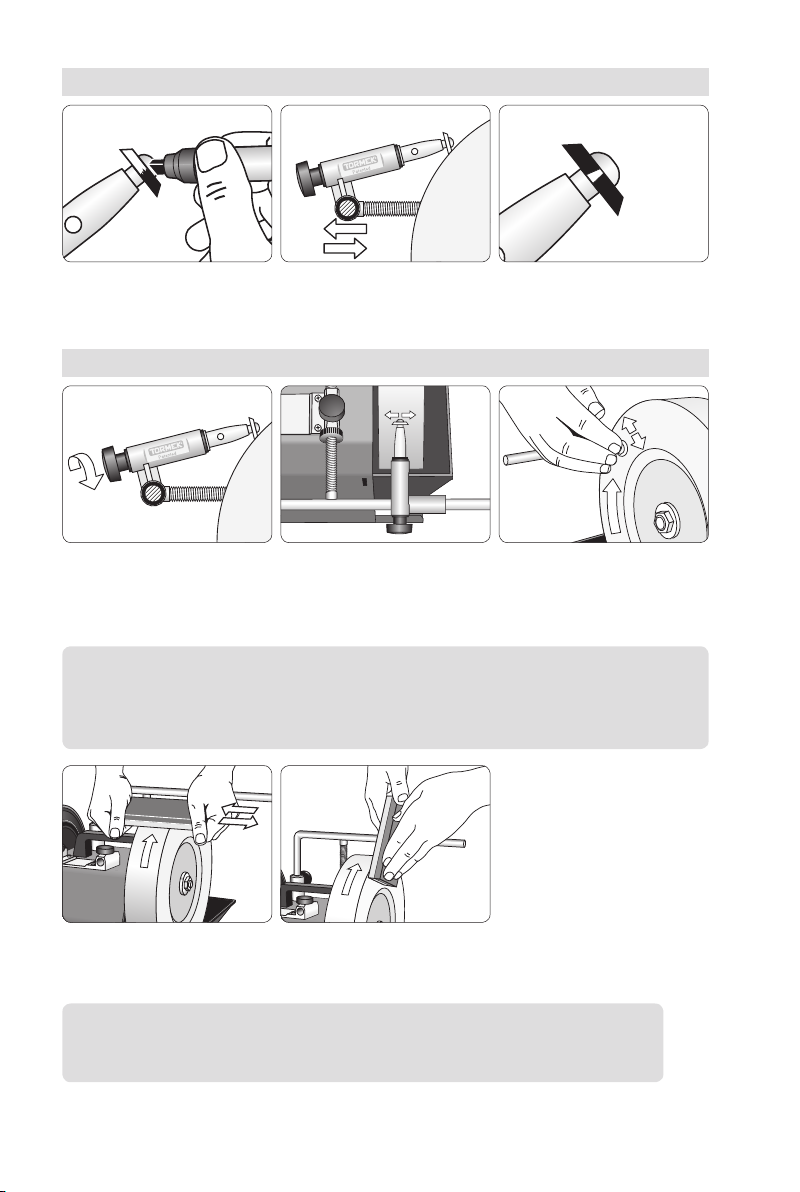

Shaping

You can do the initial shaping either directly on your Tormek or, if a lot of steel needs to

be removed, on a bench grinder using the Tormek Bench Grinder Mounting Set BGM-100

(page 29).

When shaping on the Tormek, contrary to a high speed bench grinder, you need to apply a

high grinding pressure. Therefore, press with your hand or thumb on the tool to increase the

grinding pressure. Grind one side at the time. This is easier since you do not need to swing

the tool from side to side. Finish the grinding with a full swing over the entire bevel. Do not

spend too long on the same spot on the grindstone, as it will leave grooves on the stone.

Instead, grind on new spots so that you use the whole width of the stone.

By this technique the remaining grooves will not be too pronounced. They will reduce with

future grindings of straight edges. If you immediately require a at surface of the stone, you

can true it with the Truing Tool TT-50.

Check your grinding frequently to ensure that the gouge acquires an even shape. Grind more

on the spots where it is needed. Your hands and eyes decide the nal evenness and shape

of the bevel. Remember that once you have created your desired ngernail shape, this can

be kept forever and you will always benet from the time spent on the initial shaping. This

initial shaping needs only to be made once. It takes 10–20 minutes depending on the original

shape of the tool and on how much steel you need to remove.

Make the first rough shaping on one side at the time. Move the tool sideways so you use the whole

width of the stone and avoid creating grooves.

Grind the other side. Again use the whole width of the stone to wear the stone evenly. Check

frequently to ensure that you are grinding evenly. Grind more where it is needed. Decrease the

grinding pressure as you complete the shape and finish the grinding with a full swing over the

entire bevel.

Grind more here

Both wings now

symmetrical

80

When the desired shape is achieved, check that the protrusion

has not decreased during the shaping. If so, re-position the

tool to the correct protrusion and then make the final shaping.

By doing so, you will ensure that you exactly replicate the edge

geometry at future sharpenings.

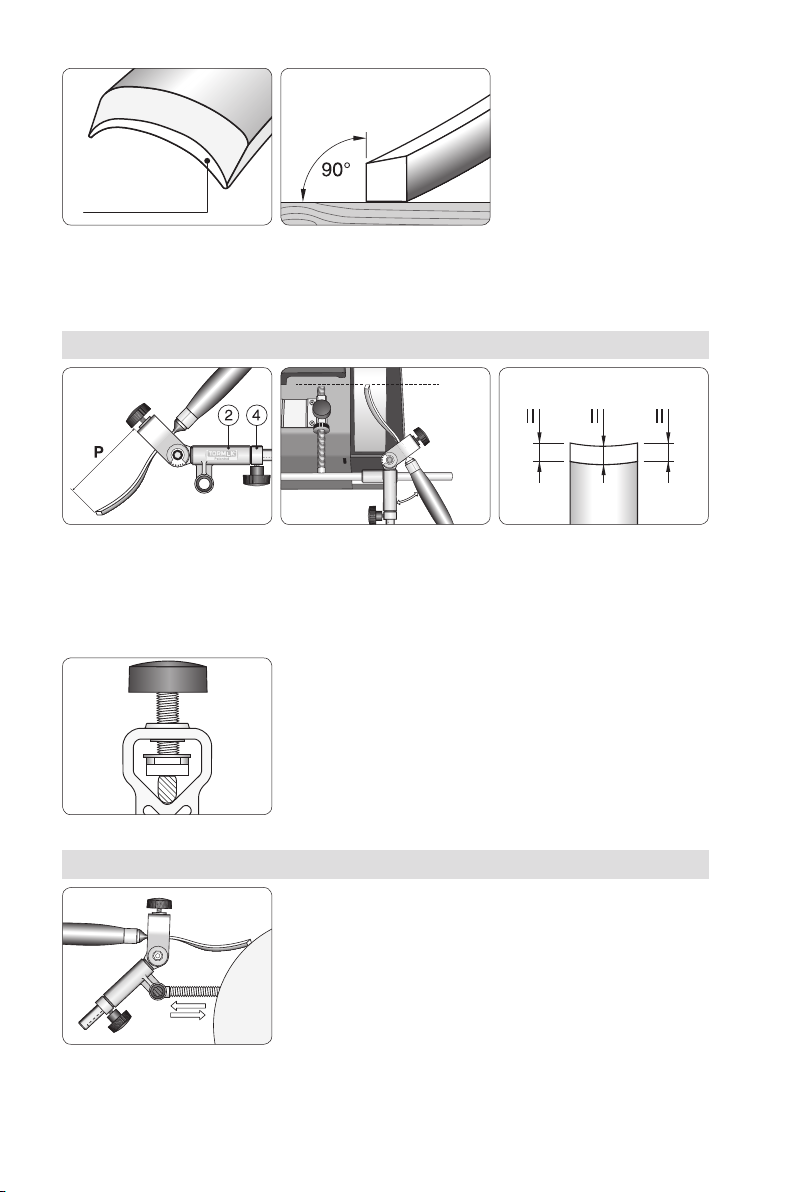

Rounding Off the Heel

Some turners round off the heel of the bevel on bowl gouges and spindle gouges. The jig

is designed so that you can move the tool towards the stone and grind the heel. The heel

can be ground either as a at secondary bevel or rounded off by sliding the jig back and

forth during grinding. If you want a more pronounced rounding off, you move the Universal

Support a little towards the grindstone.

You can round off the heel by

moving the stop ring (4) and

thesleeve (2) backwards.

Press the jig towards the grind-

stone so that the stop ring (4) is

in touch with the sleeve (2).

Moving the Universal Support

closer towards the grindstone

gives you a more pronounced

rounding off.

Full swing.Limited swing.

Length of the Wings

The length of the wings depends on how

wide you swing the tool from side to side.

Shape of the Wings

Watch that you grind on the right spots

on the bevel so the wings become sym-

metrical and slightly convex or straight.

They must never be concave. Convex. Concave. Not suitable!

Note You decide how much grinding takes place on any

one spot and hence the final shape. If the wings tend to

be concave, then grind more on the centre of the edge.

81

Sharpening

Once you have created the shape of the edge, it is an easy task to quickly re-sharpen the

tool. The sharpening should be done on your Tormek machine for the best nish and to

ensure that the edge is not overheated. Make the three settings noted on the Prole Label

carefully and you will obtain exactly the same shape every time even when the stone wears

and decreases in diameter.

Set the jig, JS. Mount the tool with

afixed protrusion, P.

Set the Universal Support.

Use hole A or hole B.

Sharpen with a light pressure

and swing the tool from side to

side. Since the shape is exactly

replicated and the edge is just

touched up, the sharpening

takes just 20–30 seconds.

Move the Universal Support to

the honing wheel and make the

same setting with the Setter.

Hone by swinging the tool

from side to side. You now

have an extra fine finish.

Polish the flute and remove

theburr on the Profiled Leather

Honing Wheel LA-120.

Honing

Honing and polishing the bevel and the ute to a ner nish will make the sharpness more

durable. Also, use the Setter and jig for this operation and you are sure that you are honing

to exactly the same shape as the sharpening plus you do not risk rounding off the very tip

of the edge.

These three factors determine the geometry of a gouge

82

Other Shapes

You can of course shape your gouge to a different geometry from those provided with the

TTS-100 Setter. This graph shows examples of shapes which you can achieve on a bowl

gouge at various jig settings and edge angles. In each example, the protrusion of the tool in

the jig (P) is 65 mm (2½"). The gouge is swung fully 180º from side to side.

* Geometries achieved with the TTS-100 Setter.

Jig Setting Edge angle

35°

Edge angle

45°

Edge angle

55°

Edge angle

75°

JS 0

JS 1

JS 2

JS 3

JS 4

JS 5

JS 6

*

*

83

Loosen and remove the screw

(8) and the tool holder (1).

Insert the shaft (12) into the

sleeve (2). Note: Position the

sleeve according to the picture!

Mount the screw (8). Lock the

shaft with the Allen key (9)

when tightening.

Turning Cutters

Mounting the jig

Cutters with 5 and 6 mm

(

⁄

"–¼") holes are centered on

the first shoulder on the shaft.

Cutters with 4 mm (

⁄

") holes

are centered bythe M4 screw.

Cutters with 8 mm (

⁄

") holes

are centered on the second

shoulder on the shaft.

Use the Allen key (14), which

comes with the jig.

Mounting the cutter

There are various types and sizes of exchangeable

cutters for hollowing and scraping. The holes vary

from 4–8 mm (⁄–⁄"), but due to a shoulder on the

shaft they can all be mounted with the same screw.

The cutters can be sharpened to their existing shape

or to a new shape.

84

Colour the bevel with a marker. Set the universal support so

thatthe grindstone touches the entire length of the bevel when

rotating it by hand.

At the right setting the stone

removes the colouring along

the whole length of the bevel.

Setting the edge angle

Rotate the jig all the time during the sharpening so you achieve an

even grinding around the whole circumference. Use only a light

pressure for the best result. Slide the jig sideways on the Univer-

sal Support so the grindstone wears evenly.

Smooth the back on the

machined, flat outside of the

grindstone. Move the cutter in

order to use the whole surface

of the stone.

Sharpening

Tip When smoothing the back of the cutter, hold it towards the grindstone

before you start the machine. This is easier and you do not risk dropping it

into the water trough.

If you want an extra fine surface on the bevel, grade the grind-

stone with the Stone Grader SP-650 so it grinds more finely

corresponding to a 1000 grit grindstone.

Important Do not hone these small tools on the leather honing wheel!

They can easily get caught on the leather surface and spoil the leather.

85

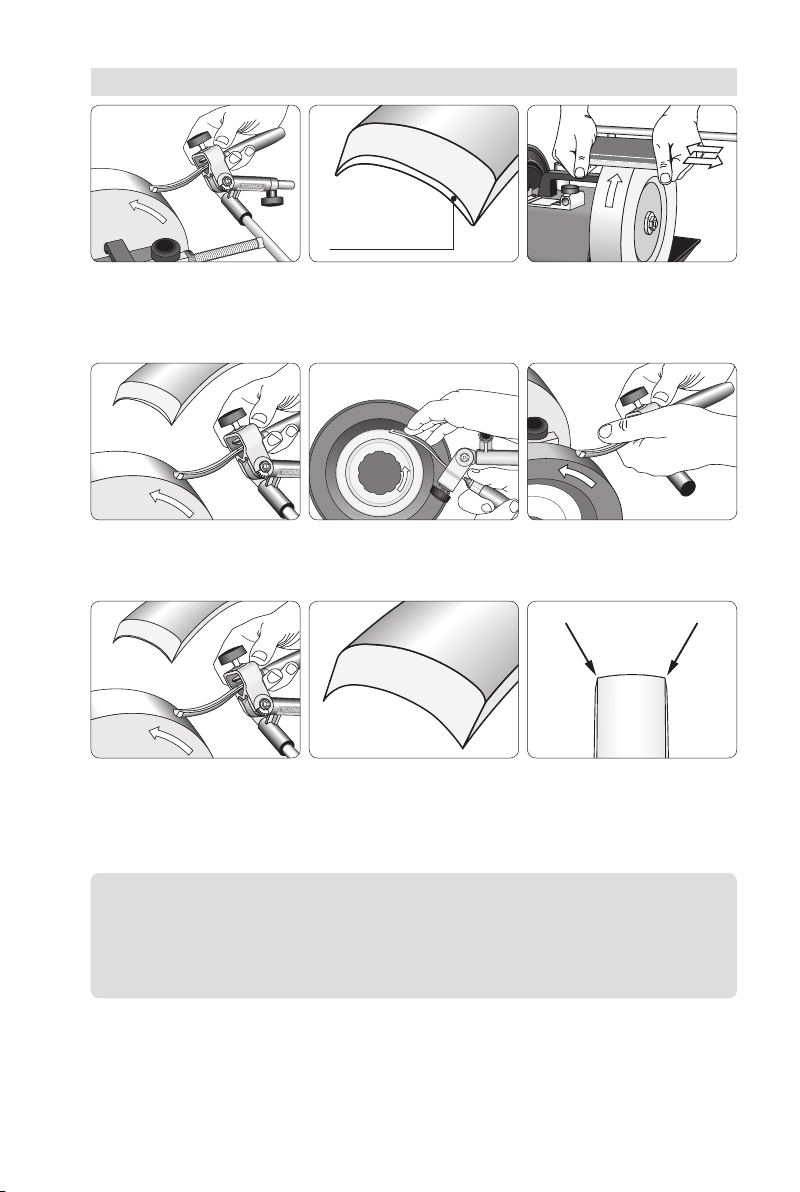

Carving Gouges

Carving gouges can be straight, curved or spoon

shaped. They can also be back bent, down bent

or tapered. The jig can be set to compensate for

any radius on the curve so that the grinding takes

place evenly across the edge, so creating a con-

stant edge angle from the centre to the sides of

the gouge.

Unlike turning gouges, carving gouges should not be ground with side bevels. The edge

should form a straight line viewed from above and the corners must be sharp.

The Principle

Use the technique as described in Sharpening Techniques for Carving Gouges and V-tools

on page 20.

Edge Angle

As described in the above chapter on page 24, the choice of edge angle is very important

for a carving gouge. The method of setting the jig for a certain angle depends on whether you

want to replicate an existing edge angle or if you want to put a new edge angle on your tool.

When replicating an existing edge angle, you should use the Marker Method, which is de-

scribed on page 41. If you want to put a new edge angle to your tool, you can either set

the angle by eye or you can use the AngleMaster (page 142).

Shape the edge by resting the

tool on the Universal Support

placed horizontally and close to

the stone.

The edge plane angle (γ) should

be approx. 20° (page 21).

Flatten and smooth the blunted

edge with the fine side of the

Tormek Stone Grader, SP-650.

Shaping the edge

86

Now you have a line of light,

which is your guide as to where

to grind.

When cutting steep bowls using

a curved or a down bent gouge,

the edge plane angle can be

decreased. Here it is 0°.

Line of light

Mount the gouge in the jig

protruding approx. 100 mm (4").

The stop ring (4) must be locked

close to the sleeve (2).

Put the jig on the Universal

Support and swing it to one

side. Set the jig so that the

plane of the edge is approx.

parallel to the axis of the stone.

The edge angle will now be

equal across the edge. If the

thickness of the steel is even,

the bevel length will also be

equal along the edge.

Setting the jig

If the shank has a convex upper

side, you should grind it flat to

make sure that the tool does

not turn in the jig.

Set the edge angle by adjust-

ing the Universal Support. When

replicating an existing angle, use

the Marker Method. When setting

a new angle you can use the

AngleMaster.

Setting the edge angle

87

Always grind where the line of

light is the thickest while swing-

ing the tool.

Check frequently where the

grinding takes place. Grind until

you get an even and thin line

of light.

Grade the grindstone for fine

sharpening with the fine side

ofthe Stone Grader SP-650.

Grinding

Line of light

Continue sharpening.

Check the result frequently.

Remove the burr on the leather honing wheels to observe the

lineof light more clearly. The tool is left mounted in the jig.

Sharpen again. Now with a

very light pressure. Check

frequently so that you do not

over-sharpen.

Stop sharpening immedi-

ately when the line of light

disappears, which is a sure

sign that the edge is sharp.

Be careful so you do not

roundoff the corners.

Woodcarving tools should

havesharpcorners!

Important It is very easy to be misled by the burr and mistake the burr for

the line of light! Therefore you must remove the burr frequently during the

finishing of the grinding operation, so you clearly can watch the progress ofa

gradually thinner the line of light.

88

It is very easy to over-sharpen the

edge at the end of the sharpen-

ing. If this happens, you need to

reshape the edge and start again

from the beginning.

Keep the tool in the jig and

honeand polish the inside on

the Profiled Leather Honing

Wheel LA-120.

Hone and polish the bevel. Set the Universal Support so that the

honing angle is the same as the grinding angle. Use the Marker

Method. Hone away the burr and polish the bevel to a mirror

finish.

Honing

Leave the tool in the jig and

test the sharpness by pushing

the edge across the fibres in a

piece of wood. The edge should

cut easily and leave a smooth

surface without tearingthe

fibres.

If the edge needs further honing or sharpening on some spots,

you can continue with the same setting. When you are satis-

fied with the result, you remove the tool from the jig after having

measured and noted the protrusion (P) and the jig setting.

Please see the next page.

Testing the sharpness

89

Documentation of the Shape

The shape of the gouge is determined by the jig setting (JS) and the protrusion (P). Note

these settings on the prole label, which comes with the jig. Now you can exactly replicate

this shape at future re-sharpenings. Set the edge angle with the Marker Method or the Spacer

Block Method.

Note the jig setting (JS) and the protrusion (P) on the label.

Usethe water proof pen which comes with the jig.

Attach the label to the ferrule

and you are assured that you

have the same settings at future

sharpenings.

A back bent gouge is ground

with the jig setting 0.

You can also grind a down bent

gouge. The jig is set as shown

on page 86.

Back Bent and Down Bent Gouges

90

V-tools

These tools are considered the most difcult to

grind. The reason is that it has two edges joined

with a radius.

However, with the method described here, you

will also manage to achieve a sharp and correctly

shaped edge on these tools.

The principle is the same as for carving gouges,

i.e. you rst give the tool its right shape and then

let the line of light guide you as to where to grind.

The Principle

Use the technique as described in Sharpening Techniques for Carving Gouges and V-tools

(page 20).

Edge Angle

As described in the chapter above on page 24, the choice of edge angle is very important

for a carving gouge. The method of setting the jig for a certain angle depends on whether you

want to replicate an existing edge angle or if you want to put a new edge angle on your tool.

Shape the edge. Rest the tool

on the Universal Support posi-

tioned horizontally.

The edge plane angle (γ) should

be approx. 20° (page 21).

Flatten and smooth the blunt

edge with the fine side of the

Tormek Stone Grader, SP-650.

Shaping the edge

The blunt edge appears as

a line of light, which is your

guide as to where to grind.

Line of light

91

Mount the tool in the jig pro-

truding approx. 100 mm (4").

The stop ring (4) must be locked

close to the sleeve (2).

Turn the jig so one wing lies flat

on the grindstone. Set the jig so

that the edge is approximately

parallel to the axis of the stone.

Now the jig is set to suit the

shape of the tool, the edge

angle will be uniform.

Setting the jig

Setting the edge angle

Control the grinding pressure with your thumb and control where the grinding takes place by gently

turning the tool with your hand. Check frequently where the grinding is taking place. Only grind

where the line of light is the thickest. Do not slide the tool sideways. Keep it on the same spot on

the grindstone for the best control. Rest your hands on the Universal Support all the time and you

get a good control.

Grinding

Set the edge angle by adjusting

the Universal Support. When

replicating an existing angle,

use the Marker Method. When

setting a new angle you can

use the AngleMaster.

92

Grind until you get an even and

thin line of light.

Now grind the other wing in the

same way.

Then grind the keel. Turn

the tool from side to side to

equalise the grinding towards

the wings.

Grade the grindstone for fine

sharpening with the fine side

ofthe Stone Grader SP-650.

Continue sharpening one wing

at a time and then the keel.

Check the results frequently.

Remove the burr on the leather

honing wheels so that you can

better observe the line of light.

Now sharpen again with a

very light pressure. Check

frequently so that you do not

over-sharpen.

Stop sharpening immediately

when the line of light disap-

pears, which is a sign that the

edge is sharp.

Important It is very easy to be misled by the burr and mistake the burr for

the line of light! Therefore you must remove the burr frequently during the

finishing of the grinding operation, so you clearly can watch the progress of a

gradually thinning line of light.

93

Keep the tool in the jig and

hone and polish the inside on

the Profiled Leather Honing

wheel LA-120.

Hone and polish the bevels. Set the Universal Support so that the

honing angle is the same as the grinding angle. Use the Marker

Method. Hone away the burr and polish the bevels to a mirror

finish.

Honing

It is easy to over-grind the edge

at the end of the grinding. If this

happens, you need to reshape

the edge and start again from

the beginning.

This is now how the tool should

appear. The keel is slightly

longer than the bevel of the

wings since the steel is thicker

in the centre.

The tool cuts more easily if you

round the keel. Move the Uni-

versal Support slightly towards

the grindstone and grind gently

while swinging the tool from

side to side.

Keep the tool in the jig and test the sharpness by pushing the

edge across the fibres in a piece of wood. The edge should cut

easily and leave a smooth surface without tearing the fibres. If

the edge needs further honing, you can continue with the same

setting. When you are satisfied with the result, you remove the

tool from the jig.

Testing the sharpness

94

If the steel thickness varies, the length of the bevel will also vary

despite the fact that the edge angle is the same. This has no

influence on the function of the tool, as it depends on the edge

angle. A V-tool with an even steel thickness has the same bevel

length on the whole wing.

Uneven thickness of the steel

Uneven thickness Even thickness

Other tormek Power Tools manuals

Popular Power Tools manuals by other brands

Campbell Hausfeld

Campbell Hausfeld DG460500CK Operating instructions and parts manual

Central Machinery

Central Machinery 59766 Owner's manual & safety instructions

molex

molex TM42 Operation manual

Planmeca

Planmeca PlanMill 40 S quick start guide

Milwaukee

Milwaukee M12 DE Original instructions

Hainbuch

Hainbuch vario flex operating instructions