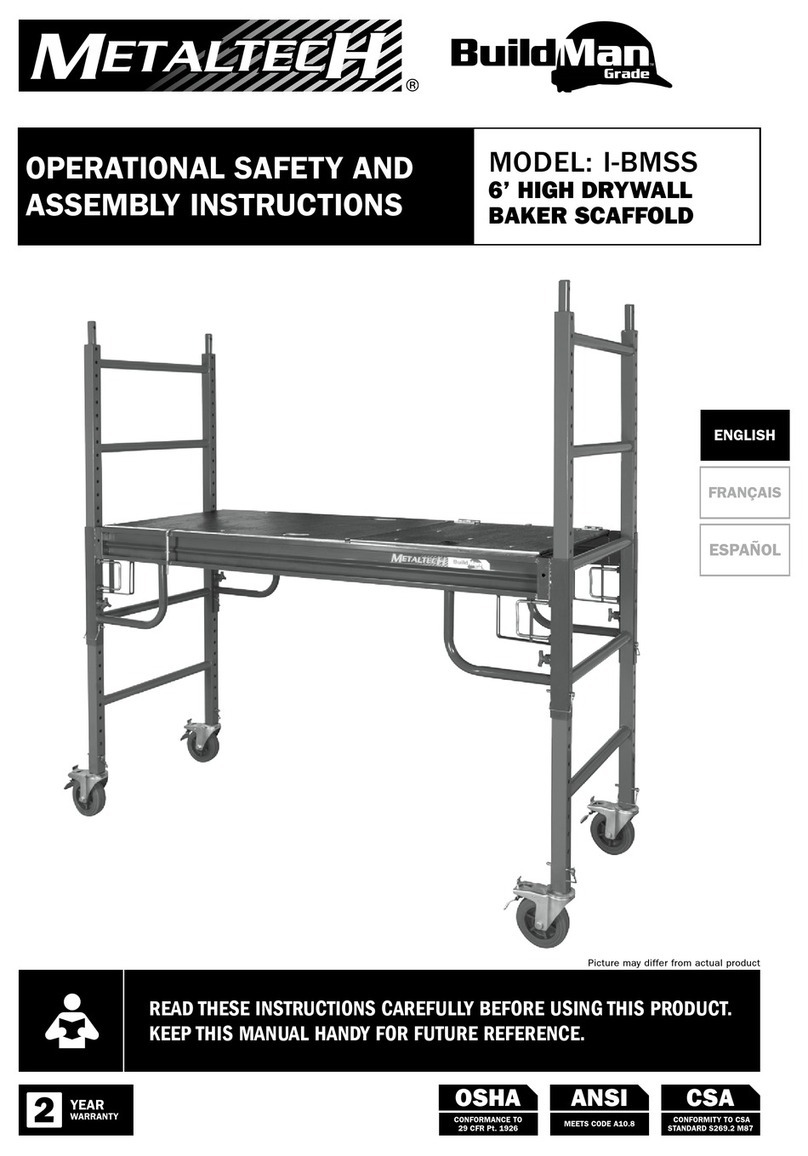

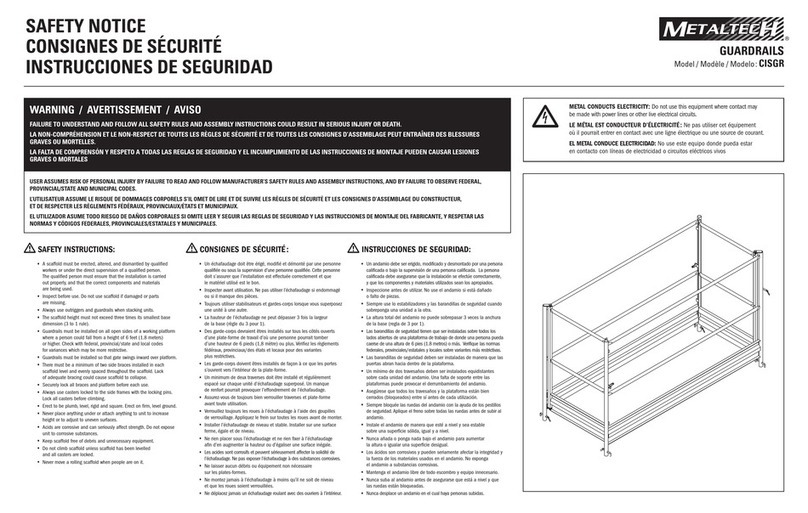

OPERATIONAL SAFETY

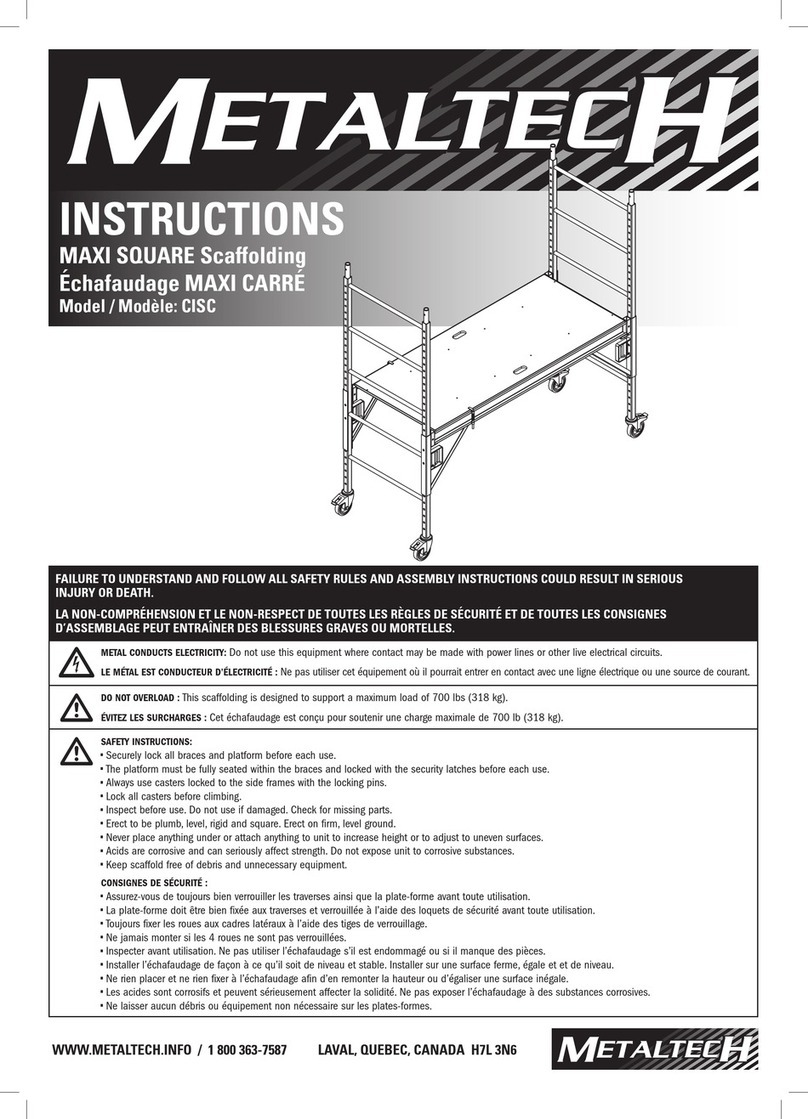

METAL CONDUCTS ELECTRICITY:

Do not use this equipment where contact may be made with power lines or other live electrical circuits.

DO NOT OVERLOAD:

This scaffolding is designed to support a maximum load of 700 lb (318 kg)

Per platform: 230 lb (104 kg)

FAILURE TO UNDERSTAND AND FOLLOW ALL SAFETY RULES AND ASSEMBLY INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

OPERATION AND SAFETY

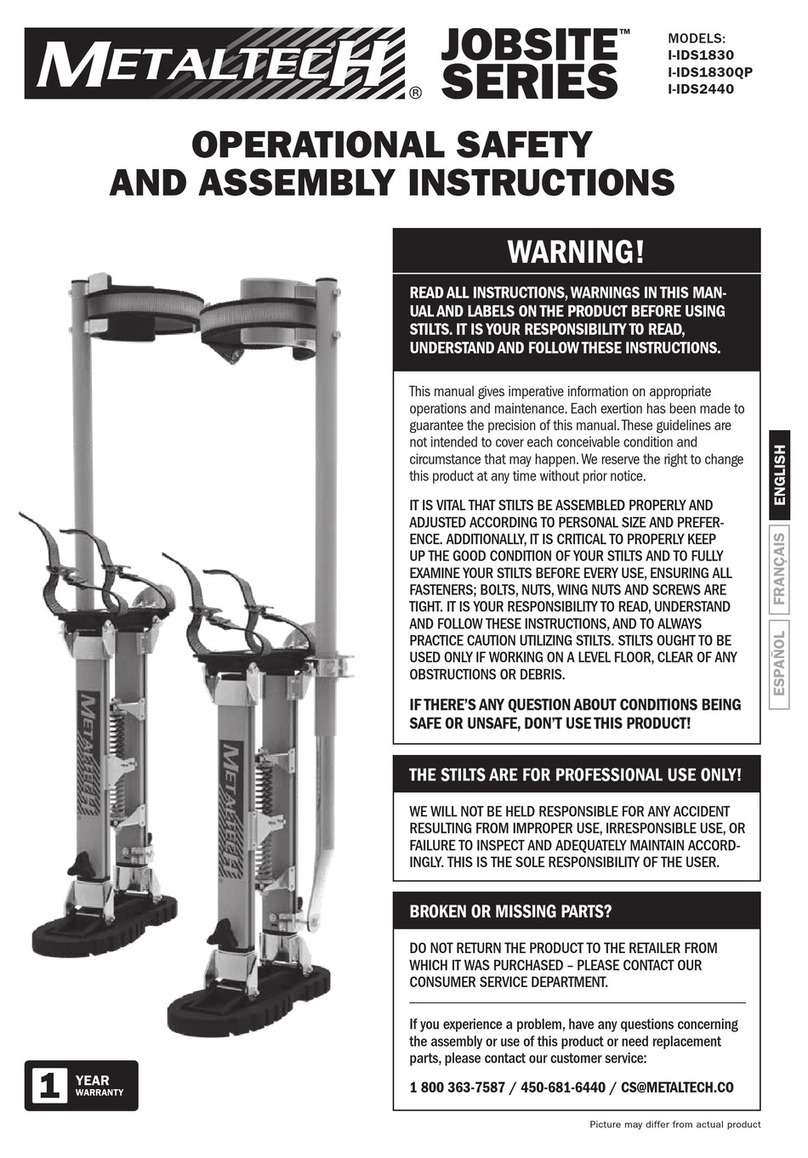

Do not use this equipment if you are in poor health, taking

medications, drugs, or have been consuming alcohol, all of which may

impair your ability to work safely on this product.

Always use this scaffold in conformity with local or national legislation

which applies.

Inspect before use. Do not use scaffold if damaged

or parts are missing.

Examine thoroughly to make sure unit is properly set up.

A safe working deck must have a minimum

width of 18 inches (45.7 cm).

Do not climb unless all casters are in locked position.

Erect to be plumb on firm and level surface.

Always install all platforms. Make sure platforms are well engaged on

the structure rungs.

This scaffold must be used on a firm surface that is free

of pits, debris, holes or obstructions.

Do not use the structure to climb up or down the scaffolding, always

use the platforms.

Never place anything under or attach anything to this scaffold to

increase height or to adjust to uneven surfaces.

Acids are corrosive and can seriously affect strength.

Do not expose this scaffold to corrosive substances.

Keep scaffold free of debris and unnecessary equipment.

Always keep body centered inside structure of scaffold.

Remove or fasten all tools, material or equipment before moving. Use

extra caution when moving to avoid tipping.

Never try moving this scaffold while standing on it.

Never move a scaffold with a worker within.

Do not use powered devices to propel this scaffold. Use extra caution

near operating machinery.

Do not use if the surface is not firm and level.

Do not use in inclement weather or high winds.

Maintain a firm grip while climbing.

Do not modify the scaffold or any of its components.

Do not use the scaffold as a footbridge.

Do not use this product with a distorted piece of aluminum. Do not try to

fix or untwist a piece of aluminum. Distorted piece of aluminum must be

removed and replaced before using this product.

READ BEFORE BEGINNING ASSEMBLY.

ALWAYS KEEP BODY

CENTERED INSIDE

STRUCTURE OF UNIT

UNIT SHALL ONLY BE

USED ON FIRM AND

LEVEL SURFACES

ALWAYS LOCK

THE ALL CASTERS

BEFORE CLIMBING

NEVER PLACE

ANYTHING UNDER OR

ATTACH ANYTHING TO

UNIT

DO NOT USE

THE UNIT AS

A FOOTBRIDGE

NEVER TRY MOVING

THE UNIT WHILE

STANDING ON IT

DO NOT USE IN

INCLEMENT WEATHER

OR HIGH WINDS

METAL CONDUCTS

ELECTRICTY

ACIDS ARE

CORROSIVE.

DO NOT EXPOSE

UNIT TO CORROSIVE

SUBSTANCES

ERECT ON FIRM

AND LEVEL GROUND

REMOVE OR FASTEN

TOOLS, MATERIAL OR

EQUIPMENT BEFORE

MOVING. NEVER MOVE

A SCAFFOLD WITH

WORKER WITHIN.

ALWAYS INSPECT

BEFORE USE LB

/

KG

MAX. 700lb

(318 kg)

SCAFFOLD

MAXIMUM LOAD

CAPACITY:

700 lb (318 kg)

350 lb PER

PLATFORM (159 kg)

DO NOT STAND OR

ATTEMPT TO CLIMB

THE PLATFORMS WHEN

THEY ARE INSTALLED

ON THE UPPER RUNG

OF THE STRUCTURE

DO NOT USE

THE STRUCTURE

TO CLIMB UP

OR DOWN THE

SCAFFOLDING.