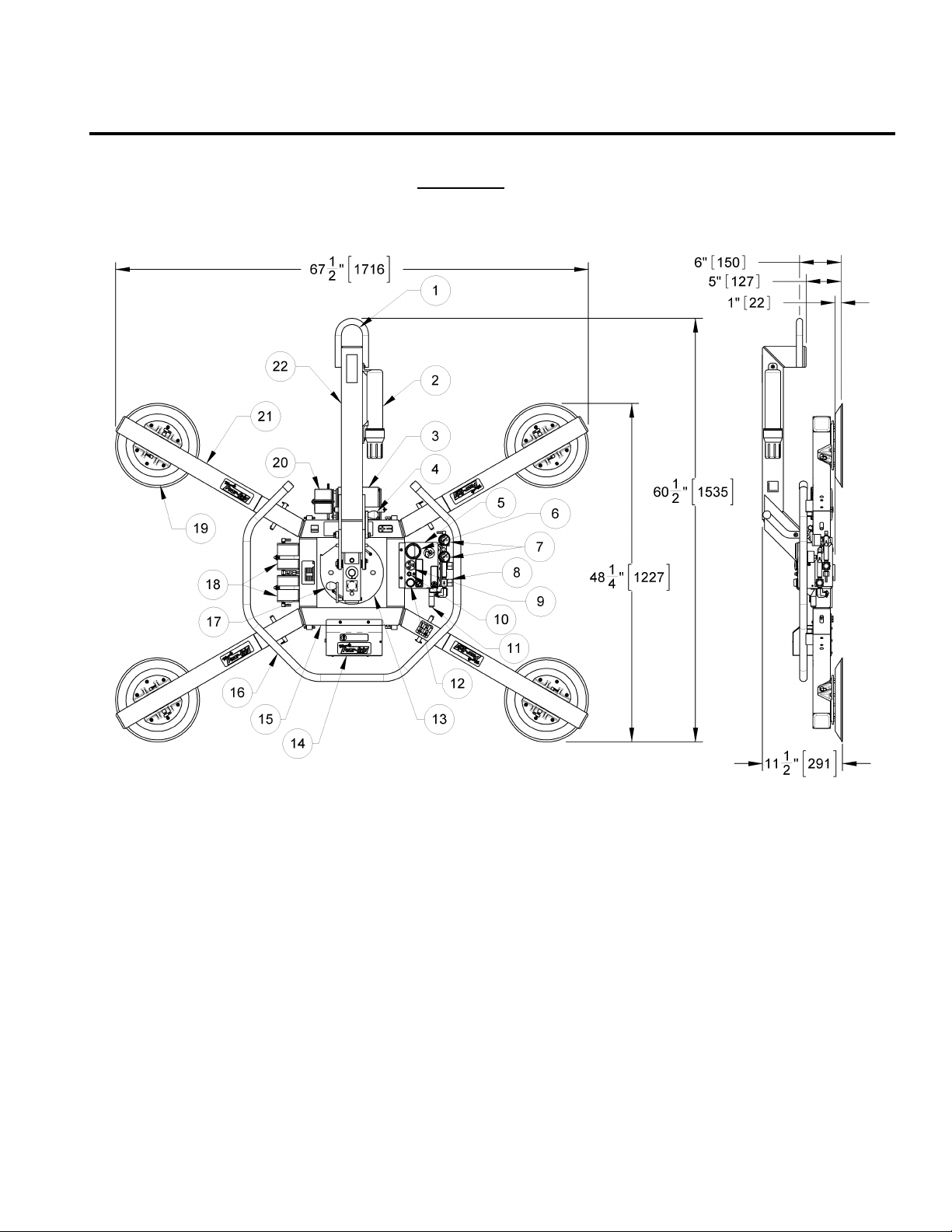

Rev 12.0/5-13 1 MRT4-DCO-DVS: #35071

TABLE OF CONTENTS

SPECIFICATIONS............................................................................................................ 3

WARNINGS ..................................................................................................................... 4

OPERATING FEATURES................................................................................................... 5

ASSEMBLY....................................................................................................................... 6

TO SET UP THE LIFTER ................................................................................................................ 6

TO CHANGE THE PAD FRAME CONFIGURATION ................................................................................6

Basic Configuration ......................................................................................................................................7

Linear Configuration.....................................................................................................................................7

Extended Configuration ................................................................................................................................7

Secondary Rotation Stops.............................................................................................................................7

INTENDED USE ............................................................................................................... 8

LOAD CHARACTERISTICS ............................................................................................................. 8

OPERATING ENVIRONMENT .........................................................................................................9

DISPOSAL OF THE LIFTER ............................................................................................................ 9

OPERATION .................................................................................................................. 10

BEFORE USING THE LIFTER........................................................................................................10

Taking Safety Precautions ..........................................................................................................................10

Performing Inspections and Tests ...............................................................................................................10

TO APPLY THE PADS TO A LOAD..................................................................................................11

Positioning the Lifter on the Load ...............................................................................................................11

Sealing the Pads against the Load...............................................................................................................11

Reading the Vacuum Gauges ......................................................................................................................12

Vacuum Level on Optimal Surfaces .............................................................................................................12

Vacuum Level on Other Surfaces ................................................................................................................12

TO LIFT AND MOVE THE LOAD ....................................................................................................13

Positioning the Lift Bar ...............................................................................................................................13

Load Capacity and the Warning Light ..........................................................................................................13

Monitoring Vacuum Indicators ....................................................................................................................13

Low Vacuum Warning Buzzer .....................................................................................................................14

Controlling the Lifter and Load....................................................................................................................14

In Case of Power Failure ............................................................................................................................14

TO ROTATE THE LOAD EDGEWISE................................................................................................ 15

TO TILT THE LOAD ...................................................................................................................16

TO RELEASE THE PADS FROM THE LOAD .......................................................................................16

AFTER USING THE LIFTER..........................................................................................................17

Storing the Lifter........................................................................................................................................17