Temperature

Morethan25℃

10〜25℃

10〜0℃

Lessthan0℃

Useoil

SAE#30

SAE#30,#20

SAE#20

SAE#10

5.INSPECTION BEFORE OPERATION

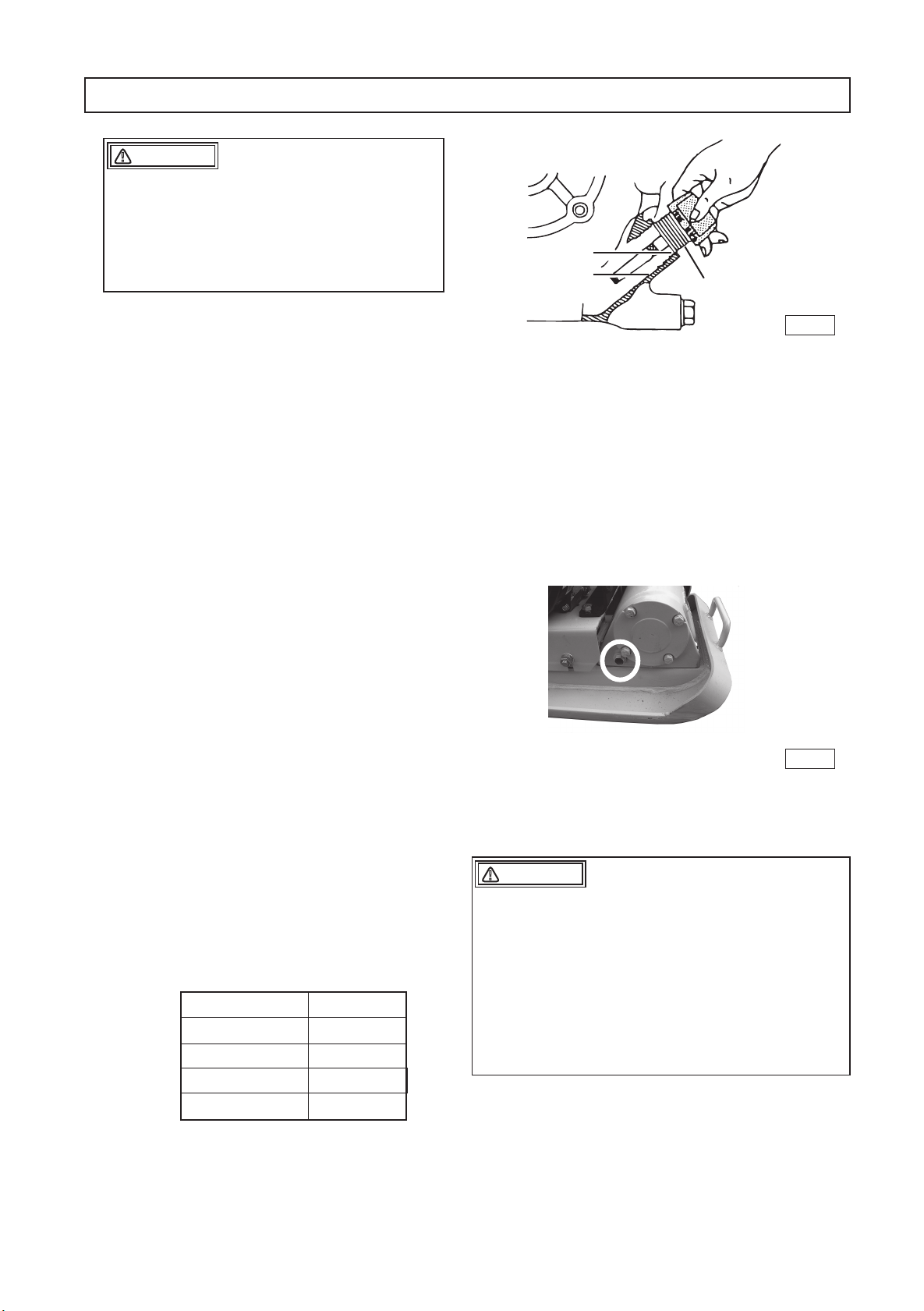

Set the machine on a level surface, then

remove the oil gauge of the vibrator. Check

the oil gauge to see if the oil is at the speci-

fied level. Use engine oil SAE10W-30 as

lubrication oil.

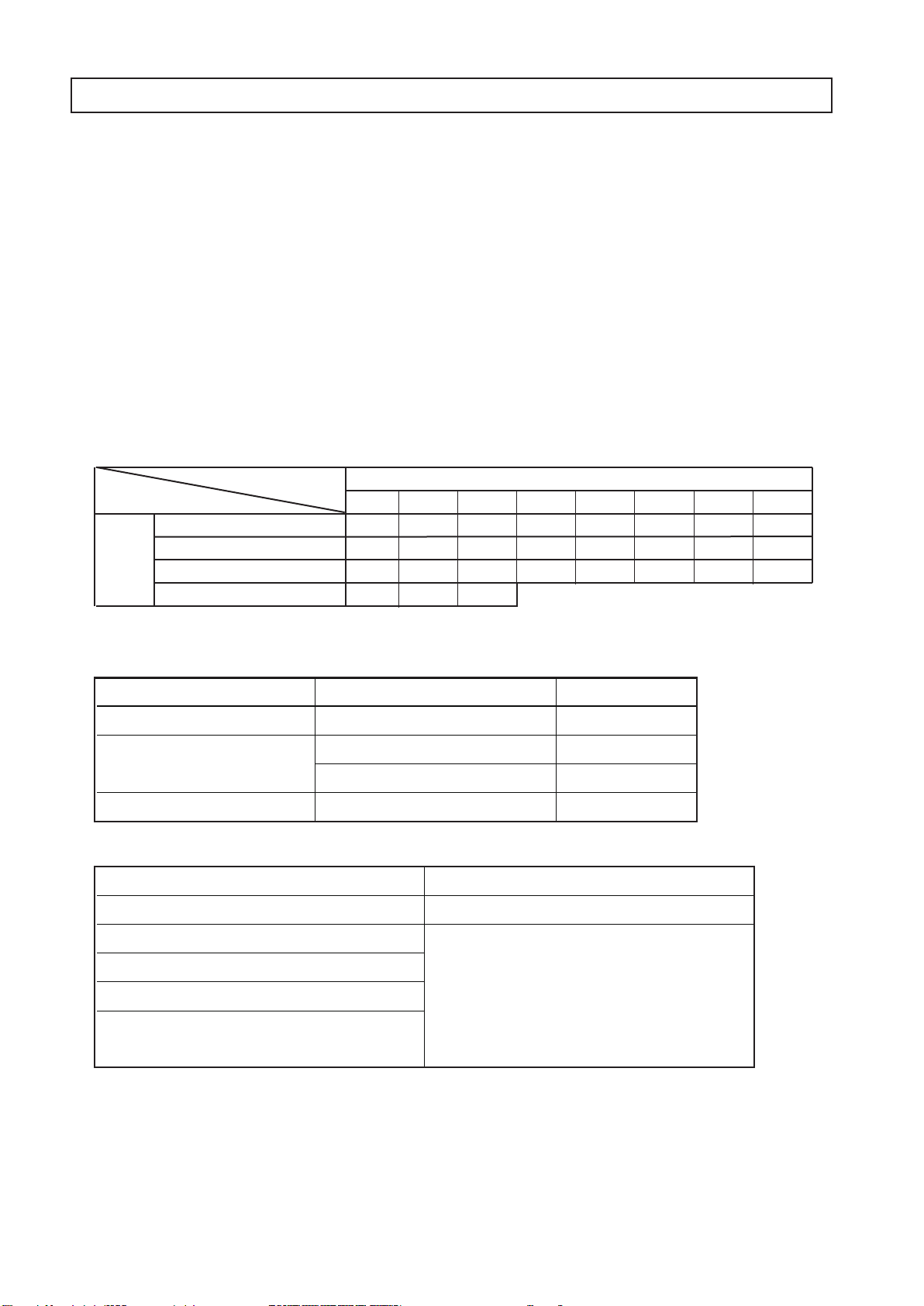

Remove the drain plug in Vibrator Assembly

and check the oil level. Make sure the oil

quantity is set at level of plug hole for check-

ing. Every month or every 200 hours of op-

eration, replace the oil.

A regular grade gasoline should be used in

the engine. When filling the fuel tank, make

sure the fuel filter is used.

Never refuel this machine while leaving the

engine running. There is danger of fire.

Never smoke, or put other flames close to

this machine while refueling. Serious haz-

ards such as burns and fire may result.

Choose a place free from flammable sub-

stances for refueling. Be careful not to spill

fuel. In case fuel should be spilled, wipe off

the spilled fuel completely.

Clean each part of the machine well to main-

tain dirt and dust-free condition. Pay special

attention to the soil adhered to the bottom of

the vibrating plate, engine cooling air inlet,

and the carburetor and air cleaner area to

keep those parts clean.

Check each part for any looseness of bolts.

Vibration causes bolts & nuts to loosen,

which might result in unexpected accident or

malfunction.

Inspect the guard hook, belt cover and an-

ti-vibration rubber, as well as to check the

function of speed adjustment wire and

speed adjusting lever.

Check V-belt tension. The belt should have

about 10 – 15mm of flexibility when pushed

strongly with a finger at the mid-point be-

tween the axes. If V-belt is loosened, power

is not transmitted well, which reduces com-

pacting force and shortens the life of V-belt.

In addition, the generated compaction force

will lead to irregular vibrations when the

engine revolutions are increased, and may

result in a machine failure.

Set the engine on a level surface to check

the oil level. If the oil level is low, add oil.

Use the following engine oil.

1.

2.

3.

4.

5.

6.

7.

●

●

●

Conduct inspection while the engine is

stopped.If you get caught in the rotating

parts, you may suffer serious damage.

Conduct inspection after making this ma-

chine level and checking that the body

does not move.

DANGER

!

Quality

:

Gasoline engine oil, Grade SE or above

Viscosity: SAE No. 30 at 20°C and above (summer)

SAE10W-30

Fig. 1

Upper level

Lower level

(refil needed) Oil gauge

DANGER

!

5

Fig. 2

※ The illustration is shown for model, "MVC-F60"