MetaSystem Metafer User manual

Quick Guide

Metafer

)

=

e

MetaSystems Hard & Software GmbH

(MetaSystems)

Robert-Bosch-Str. 6

68804 Altlussheim

Germany

Tel: +49 (0)6205 39610

Fax: +49 (0)6205 32270

Document Number :

H-1200-004-SA –Rev. 1 (2021-09)

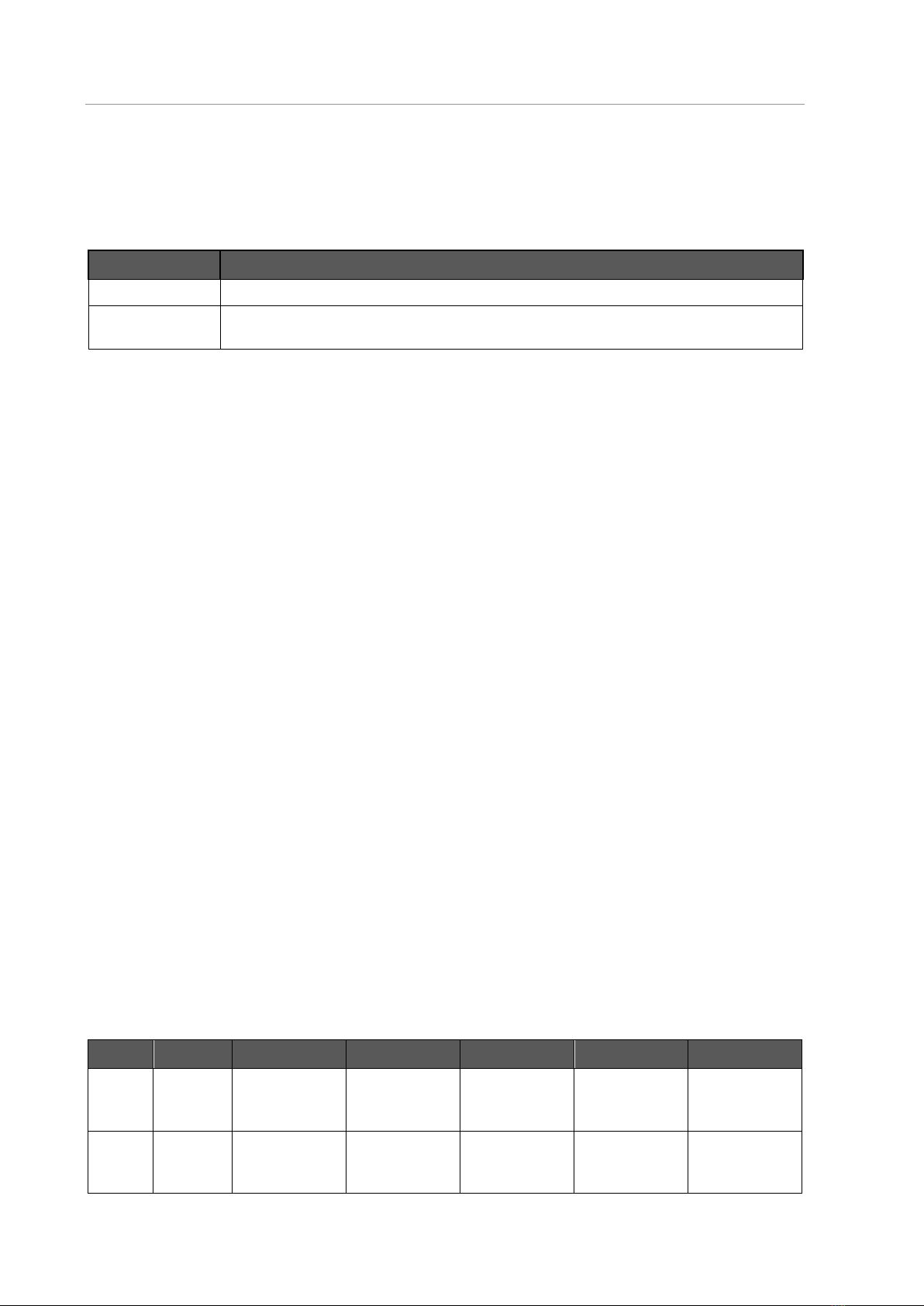

Revisions

Revision

Release Date

Changes

1

2021 - 09

Document release –first revision

Quick Guide

1

About this Quick Guide

This Quick Guide is intended for novice users and users, who have been using previous

versions of MetaSystems imaging systems, namely laboratory staff operating, maintaining,

and analyzing data generated by MetaSystems systems.

The Quick Guide contains important information for the reliable operation of your

MetaSystems system:

aSymbols Used

aSafety Instructions

aProduct Descriptions

aImportant Notices for Setup and Operation

aInstructions for Use

Please familiarize yourself with its content prior to using the system and pay special atten-

tion to the hints concerning safe operation of the instrument. The specifications are subject

to change; the Quick Guide is not covered by an update service.

Assumptions on Previous Knowledge

The Quick Guide assumes you have:

aBasic computer literacy, including a general understanding of data storage, file trans-

fers, and copying and pasting.

aSufficient knowledge of applicable laboratory techniques to interpret images gener-

ated by MetaSystems Metafer/Relosys, Ikaros, and Isis imaging systems.

How to Obtain More Information

aWhile this Guide provides just a brief introduction, a comprehensive description about

the system functionality is available through manual and help files:

sInside Metafer, press the [F1] key to open a built-in help file.

sThe help file is also available as a printable PDF file (in ...\Neon\Manuals). You need

a PDF reader software to open, display and print the PDF file. PDF reader software

is available from various sources on the Internet.

aIn addition to the present Quick Guide and the software manuals, the following oper-

ating manuals for optional equipment should also be consulted depending on the

configuration:

sOperating manuals for the computer, monitor, and printer.

sOperating manual for the microscope, transmitted and reflected light fluorescence

illuminator.

Quick Guide

2

Errors and Suggestions

If you spot any mistakes in this online help or if you have any suggestions for improvement,

please contact MetaSystems in Germany.

Compliance Notice

Systems by MetaSystems have been designed, produced and tested to meet the require-

ments regarding:

aElectrical safety

Directive 2006/95/EC for electrical equipment

designed for use within certain voltage limits.

EN 61010-2-101:2002 Safety requirements for

electrical equipment for measurement, con-

trol, and laboratory use –Part 2-101: Particular

requirements for in vitro diagnostic (IVD) med-

ical equipment (IEC 61010-2-101:2002 (Modi-

fied)).

aElectromagnetic Compatibility

(EMC)

Directive 2014/30/EU for electromagnetic com-

patibility.

EN 61326-2-6:2006 Electrical equipment for

measurement, control and laboratory use –

Part 2-6: Particular requirements –In vitro di-

agnostic (IVD) medical equipment (IEC 61326-2-

6:2005).

And meet the requirements of the

EU directive 98/79/EC for IVD products (In Vitro

Diagnostics)

Instrumentation identification marking

)

mark

Symbols Used

)

This product complies with the requirements in the EU directive 98/79

EC on in vitro diagnostic medical devices.

=

For in vitro diagnostic use.

e

Manufacturer.

&

Caution.

§

Consult instructions for use.

Quick Guide

3

Safety Instructions

General Provisions

Imaging systems by MetaSystems:

aAre intended for laboratory use only and, thus, may only be operated by qualified and

trained persons. MetaSystems or its representatives provide the technical training as

part of the service. It is the responsibility of the laboratory to provide and maintain the

necessary knowledge of the operator and to utilize all functions in compliance with

standard laboratory practice and regulatory guidelines.

aAid lab technicians in the documentation of microscopic brightfield and fluorescence

images.

aRequire the presence of a hardware token for software protection, also known as

'dongle', to be started and executed. Failure to plug in the dongle will result in the soft-

ware not running. A MetaSystems' dongle does not only work as a security key, but

also as a physical license key, which enables particular features in the MetaSystems

software. Each dongle has an individual serial number. Thus, each dongle requires its

own individual license key. Only features enabled by the license key are available in

the respective software. All other software features are disabled, but can be enabled

after purchasing the respective license and reprogramming the dongle.

aAre only auxiliary components in the complex process of diagnosing the final result.

The quality of the final result depends decisively on the process of specimen prepara-

tion. Although imaging systems have some capabilities to enhance images captured

from difficult specimens but they cannot generally correct or compensate for short-

comings or imperfections such as inadequate brightfield staining or fluorescence in-

situ hybridizations. Some of the system’s image enhancement functions may have a

distinct influence on the images. The operator should be careful about using them

and be aware that - when applied excessively or inappropriately - they may reduce the

quality and result in loss of image details.

It is part of the operator’s responsibility to:

sCheck the plausibility of each result by reviewing the images on screen and the

slide directly under the microscope.

sFollow all procedures and recommendations for keeping the Metafer system

within the specifications permanently (§).

Quick Guide

4

Specific Provisions

Your system was built and thoroughly tested according to our quality system. In order to

ensure continuous safe and reliable operation please observe the safety notices and cau-

tion signs below.

&

Caution: Laboratory Safety Guidelines!

Before using Metafer it is essential to consult applicable laboratory safety guide-

lines and regulations in their latest versions, particularly those on the use of elec-

tric laboratory equipment, glass microscopic slides and potentially hazardous

samples.

&

Caution: Operation by qualified Laboratory Personnel only!

The system must be operated only by qualified and trained laboratory personnel,

who have been advised on the risks of operating a microscope and performing

the respective assay.

&

Caution: Power Point! Risk of electric Shock!

Plug the individual system components into properly grounded electrical outlets.

The cables are equipped with 3-prong plugs to ensure proper grounding (protec-

tive earth conductor). If you must use an extension cable, although it is not rec-

ommended, use a 3-wire cable with properly grounded plugs. Do not remove the

grounding prong from a cable. Consult also the safety instruction in the product

information supplied with the individual components.

In case of error there is a risk of contact with life-threatening voltage.

&

Caution: Motorized Focus Drive! Risk of Personal Injury and Sys-

tem Damage!

On microscopes with a motorized focus drive, do not place your hand or any ob-

ject between microscope stage and objectives, while the stage is moving upwards.

The same care should be taken when the stage is moving downward. You may be

injured and/or damage the microscope in both instances. Please consult the safety

and operating instructions of the microscope manufacturer (§).

&

Caution: Gas Discharge Lamps! Risk of Personal Injury and Sys-

tem Damage!

Microscopes with fluorescence equipment, used in conjunction with

MetaSystems systems, may include gas discharge lamps. They can explode if safe

handling and operation is not observed. Gas discharge lamps emit ultraviolet ra-

diation that may burn the eyes and skin.

Please follow the safety and operating instructions given by the microscope man-

ufacturer (§).

Quick Guide

5

&

Caution: Risk of Ineffective Safety Measures!

If it is determined that protective measures are no longer effective, the device

must be taken out of service and secured against inadvertent operation, to avoid

the risk of injury. Contact MetaSystems or its representative to have the device

repaired.

&

Caution: Build-up of Heat! Risk of Fire

Obstruction of vents may cause a build-up of heat in one of the system compo-

nents. This may cause damage or fire in extreme circumstances. Ensure that the

vents are always kept clear of obstructions (min. distance 15 cm).

Notes on Warranty

All MetaSystems systems are covered by a one-year warranty. The manufacturer and its

representative guarantee that the instrument is free of material or manufacturing defects

upon installation. Any defects must be reported immediately and steps taken to minimize

damage. If such a defect is reported, the manufacturer shall be obliged to correct the fault,

either by repairing the device or by replacing it with a new one, at the manufacturer’s dis-

cretions. No warranty is given for defects caused by normal wear and tear (particularly of

moving parts) and improper use of the device.

The manufacturer shall not be liable for damage caused by misuse, negligence or any other

tampering with the device, particularly the removal or replacement of device components,

or the use of unapproved accessories from other manufacturers. Service and maintenance

may only be carried out by trained personnel of MetaSystems. Improper use or modifica-

tion of the hardware in any manner may void the warranty.

Maintenance and service work is to be carried out only by MetaSystems or individuals au-

thorized by MetaSystems. In the event of a problem with the device, please contact Meta-

Systems or its representative.

Various warranty extensions and/or service contracts for software and hardware are avail-

able on request.

Setup and Operation

Ambient conditions —The ambient conditions as outlined under Technical Data should be

adhered to. Select an installation site which is as temperature-stable as possible.

Fluorescence preparations —When documenting fluorescence preparations, do not expose

the microscope to direct sunlight. This helps minimize the influence of stray light.

Staining / FISH—Although imaging software has some capabilities to enhance difficult spec-

imens, it cannot generally correct or compensate for shortcomings or imperfections caused

Quick Guide

6

by inadequate staining and/or FISH (fluorescent in situ hybridization). Follow your evaluated

laboratory protocols and applicable SOPs.

Avoid Vibrations —For prolonged experimental procedures using the microscope choose

an installation location with minimum vibration. Vibration stemming e. g. from forced ven-

tilation, floor impact or other shocks can lead to reduced image quality and experimental

errors. To reduce vibrations at the installation location, engage suitable damping measures.

Minimal space requirements —The minimal area required for setting up your system is 100

cm x 60 cm [Metafer 150 cm x 60 cm] (width x depth). Observe the applicable national

regulations for VDU work stations and EN ISO 9241.

Power supply —If the electricity is subject to local voltage fluctuations, we recommend the

usage of a UPS (uninterrupted power supply). Laser printers must NOT be connected to a

UPS due to their high initial current peak during warm up.

Computer network —Several systems can be networked together using “Cat. 5” cables with

standard RJ-45 connections. The required data transfer rates are at least 100 Mbps. The

network installation is not included in the system price.

Changing system settings —The system settings are preconfigured by MetaSystems or it’s

representatives. These settings should only be changed by MetaSystems personnel or by

experienced users. Pleased make a note of any changes made as some modifications may

cause severe software malfunctions Please consult the accompanying manuals and contact

MetaSystems (§).

Dust - Protect the microscope and camera from dirt and dust, which may impair with the

functionality of the camera and other system components. If you remove the camera from

the microscope, please ensure that the sensor is pointing downwards. The sensor is not

protected by a glass filter. Do not touch the sensor and do not try to clean the camera

yourself. Cameras should only be cleaned by the camera manufacturer or by MetaSystems

Cleaning —Shut down all pieces of equipment belonging to the device and remove the

power cord of all system components prior to cleaning. Only use a soft damp cloth for

cleaning. Never employ liquid or spray cleaner containing inflammable substances.

Sensitive Fluorescence Filters —If your microscope is equipped with fluorescence filters, you

should be aware that they are particularly sensitive to heat radiation. Prolonged exposure

to fluorescence light may cause irreversible damage leading to a complete loss of function-

ality. Ensure that proper heat protection filters are positioned in the light path between

lamp and fluorescent filters. Please follow the guidelines of the filter manufacturer with

regard to filter maintenance and cleaning (§).

Software updates —Software updates are available free of charge for 1 year during the

initial free upgrade period after installation. You can update the software yourself following

the detailed installation instruction included. You may receive new software versions elec-

tronically or on CD-ROM.

Warming up of the Camera —Cameras can get warm during operation. This may lead to a

poorer signal-to-noise ratio causing a reduction in image quality. Ensure a tight connection

between camera and microscope (camera adapter) to dissipate this heat energy through

the microscope.

Quick Guide

7

Product Descriptions

MetaSystems products consist of software modules, hardware components and accesso-

ries in different configurations.

The entire system subject to this declaration consisting of specified, verified and validated

hardware components, software modules and their accessories after by Metasystems

specialists or authorized third parties.

Only components, modules and accessories specified, verified and validated by MetaSys-

tems can be replaced by MetaSystems specialists or authorized third parties as part of

maintenance or servicing.

Metafer V4.x and Ikaros / Isis V6.x strictly depend on Neon V1.x for case and data manage-

ment as well as for reporting (‘x’ represents the actual release version). Metafer and Ika-

ros/Isis appear in Neon as Modules and can only be started from within Neon.

All Ikaros, Isis, and Metafer version prior to those named above are not compatible with

Neon and can be executed independent from each other.

Neon

Intended Use

Neon is MetaSystems' platform for case and image data organization, for all MetaSystems

devices. MetaSystems solutions are designed to address particular imaging and image anal-

ysis tasks. Neon collects the data from any imaging job, and from external sources, and

presents them in comprehensive and versatile case management dashboard. Hence, Neon

always has the most relevant information for the user at hand; fast and secure, regardless

of where the information originates. Strong data management algorithms, several conven-

ient display modes, and many options for selecting and filtering content make Neon the

perfect basis to organize large quantities of heterogeneous information. Neon does not

provide any in vitro diagnostic function by itself but is an accessory for the imaging plat-

forms Ikaros, Isis and Metafer.

Legal Classification

MetaSystems products are used in many countries worldwide. Depending on the regula-

tions of the respective country or region, some products may not be used for clinical diag-

nostic use. In Europe, MetaSystems products are CE-labeled as in vitro diagnostic (IVD) de-

vices:

EU

Australia

Brazil

Canada

Japan

U.S.A

Neon

)*

Class 1 / TGA

ARTG inclusion

Anvisa

DOU entry

—

MAH License no.

13B3X10527

Class 1 / Listing

* 98/79/EC IVD directive

Quick Guide

8

Product Variants

Besides the (full) Neon client licenses which come with every Ikaros, Isis or Metafer license,

additional Neon client licenses can be purchased. There are two Neon product variants:

and. It is possible to combine both license options to enable the full feature range:

Reference No.

Description

P-2500-002-MS

Neon Case Data Management (for Case Data entry)

P-2500-003-MS

Neon Gallery Reviews Upgrade (Enables Metafer and Ikaros/Isis Gallery, Counters and

Statistics views in the Case Window and reporting)

aIf you have purchased any other Metafer and/or Ikaros / Isis license, both Neon vari-

ants are automatically included. Neon will start with Metafer and Ikaros galleries if at

least an Ikaros analysis or Metafer Review license is also available.

aThe Combined Karyogram view is only accessible, if an Ikaros / Isis full or analysis li-

cense is available, too.

aIf Neon is started with a network license, by default Neon tries to obtain the licenses

for the full functional range. You can start a Neon network license with the Case Data

Management license only, if you include command line argument /NoGalleryReview in

the desktop link.

Metafer

Intended Use

Metafer is intended to be used for the acquisition of microscopic images. Based on a mo-

torized microscope the slide scanning platform Metafer provides the tools for automating

the image acquisition process in brightfield as well as in fluorescence imaging. Multiple

slide positions can be sequentially relocated without user interaction in order to capture

the respective fields of view in a fully automated way. Metafer does not provide any re-

sults. It is the responsibility of the operator to interpret the images.

Legal Classification

MetaSystems products are used in many countries worldwide. Depending on the regula-

tions of the respective country or region, some products may not be used for clinical diag-

nostic use. In Europe, MetaSystems products are CE-labeled as in vitro diagnostic devices

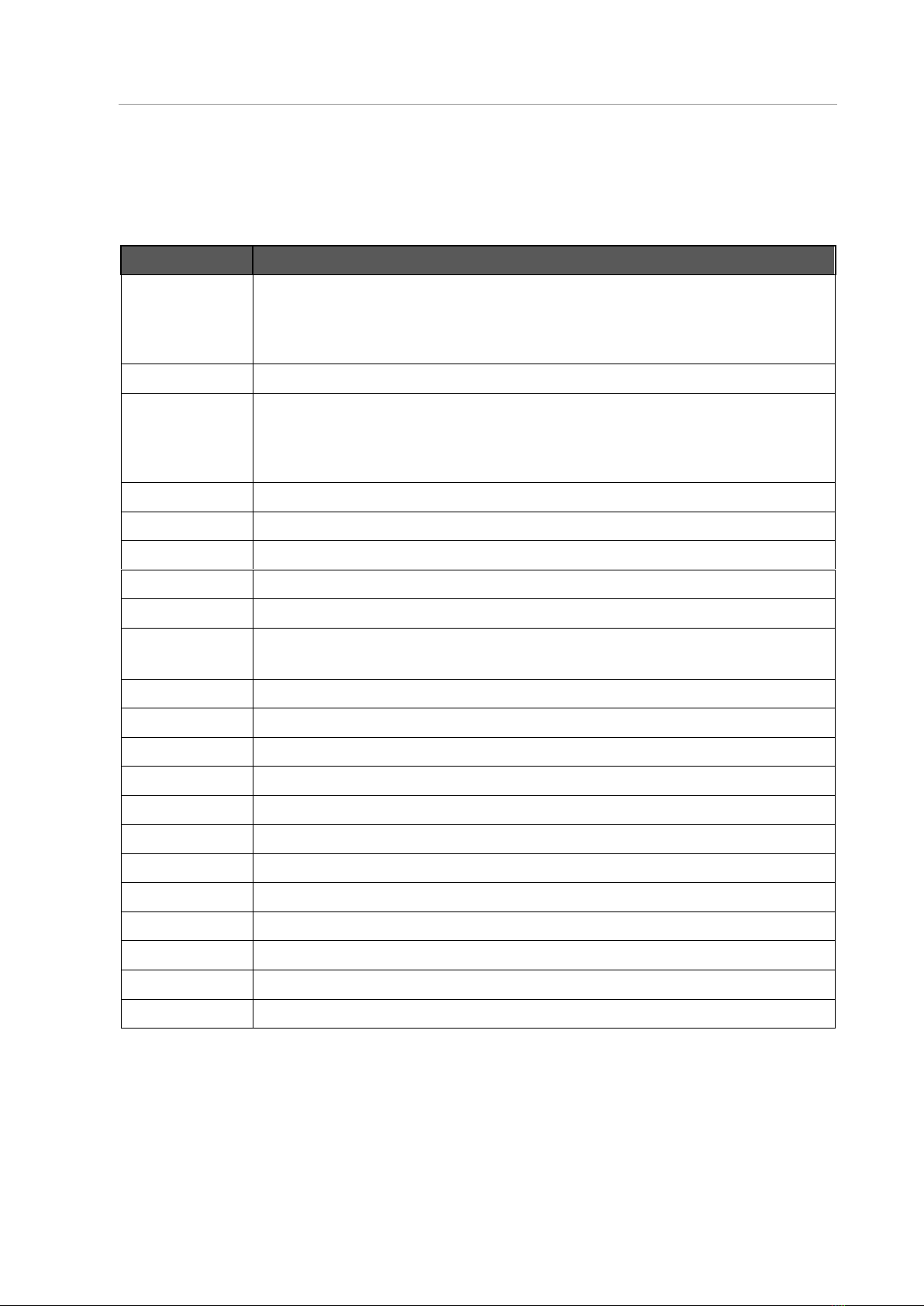

(IVD):

EU

Australia

Brazil

Canada

Japan

U.S.A

Metafer

Micro /

Relosys

)*

Class 2 / TGA

ARTG inclusion

Class 1 / Anvisa

DOU entry

Class 2 / License

(SOR-98-282)

MAH License no.

13B3X10527

Class 1 / Listing

Metafer

Modules

)*

Class 2 / TGA

ARTG inclusion

Class 1 / Anvisa

DOU entry

Research Use

Only

MAH License no.

13B3X10527

Research Use

Only

* 98/79/EC IVD directive

Quick Guide

9

Product Variants

Metafer is available in different configurations, several software modules for different au-

tomated scanning and analysis modes are available for the Metafer slide scanning plat-

form.

Reference No.

Description

P-2000-001-MS

Automated Metaphase Finder System Metafer –MSearch —Automatic metaphase finder

for searching and relocation of metaphases spreads on standard microscope slides; incl. Au-

toCapt - Automatic relocation, focussing and image capture of previously detected objects at

high objective magnification.

P-2000-002-MS

MSearch upgrade for Metafer (additional application)

P-2010-001-MS

Automated Scanning System Metafer –MetaCyte —Automatic system for the analysis of

cells and evaluation of cellular parameters on microscope slides; incl. AutoCapt - Automatic

relocation, focussing and image capture of previously detected objects at high objective mag-

nification.

P-2010-002-MS

MetaCyte upgrade for Metafer (additional application)

P-2010-003-MS

MetaCyte Lite

P-2010-004-MS

MetaCyte Lite system upgrade to full MetaCyte scanning system

P-2015-001-MS

CometScan upgrade for Metafer - MSearch (additional application)

P-2015-002-MS

Automated Scanning System Metafer - CometScan

P-2020-001-MS

Automated Scanning System Metafer –RCDetect —Automatic system for the detection and

relocation of rare cells.

P-2020-002-MS

RCDetect upgrade for Metafer (additional application)

P-2025-001-MS

Virtual Slide Scanner Metafer - VSlide

P-2050-007-MS

Metafer Analysis Station (w/o monitor)

P-2050-008-MS

Metafer Review Station (w/o monitor)

P-2070-002-MS

DCScore upgrade for Metafer MSearch

P-2070-003-MS

MNScore upgrade for Metafer - MSearch

P-2070-004-MS

AutoCapt upgrade for Metafer - MSearch or RCDetect

P-2070-005-MS

CometScan upgrade for Metafer - MetaCyte

P-2070-008-MS

MetaCyte PV upgrade

P-2070-010-MS

Metafer analysis upgrade for Isis

P-2070-011-MS

TissueFISH Module for MetaCyte-Analysis or MetaCyte Lite

P-7500-005-MS

MycobacteriaDetect Module for Metafer

Quick Guide

10

Accessories

Reference No.

Description

P-2500-002-MS

Neon Case Data Management

P-2070-006-MS

Barcode Software upgrade for Metafer

P-6000-003-MS

Automated SlideFeeder x80 for Metafer

P-6010-004-MS

AutoOiler Module for AxioImager

P-6010-012-MS

BarCodeReader Module for SlideFeeder x80

Hardware Components

All hardware components are carefully selected and tested to ensure compatibility. Wher-

ever possible, standard components from well-known manufacturers are used in order to

ensure consistently high quality, availability of spare parts and low maintenance costs.

Systems from MetaSystems comprise the following components:

Component

Comment

PC / operating system

Standard office PC, model selected and tested by MetaSystems

Computer mouse

Computer wheel mouse and trackball

Camera

Optional for systems with capture functionality (see below)

Monitor

24“ or 30” TFT monitor (Full HD) (see below)

Scanning stage

Motorized microscope stage with 8 (Metafer) or 1 (Relosys) slide bay(s)

Camera and monitor packages:

Reference No.

Description

P-2070-020-MS

Metafer CoolCube1m Camera Package

P-2070-021-MS

Metafer CoolCube1c Camera Package

P-2070-024-MS

Metafer CoolCube4m Camera Package

P-2070-025-MS

Metafer CoolCube4c Camera Package

P-2070-026-MS

Metafer CoolCube4m TEC Camera Package

P-2070-027-MS

Metafer CoolCube4c TEC Camera Package

C-0005-012-DE

24" Monitor [1920x1200]

C-0005-015-DE

30" Monitor [2560x1600]

Quick Guide

11

Instructions for Use -

How to complete the first scan

All main functions for image acquisition and processing are accessible directly through

command buttons on the right-hand side of the screen. Most functions can be activated

and completed with a three-button mouse. A function is started with a left mouse click and

confirm it with a right click. Shortcut keys are also available for many functions. A complete

summary of all command buttons, menu commands, mouse clicks and key shortcuts can

be found in the accompanying manuals (§).

aThe microscope should be switched on, ready for use (with AxioImager microscopes

wait until boot sequence is finished) and connected to the PC when the Metafer soft-

ware is started. If the communication with the microscope fails (e.g. objective, reflector,

filter wheel or shutter change takes more than 10 seconds), an error message is dis-

played and the microscope can be switched on or all microscope related functions are

disabled. To enable them again, please exit Metafer, solve the problem (e.g. switch on

the microscope and wait a few seconds until it is ready) and start again.

aWait until the boot sequence of the microscope is complete, before you click the corre-

sponding program icon on the computer desktop. The Metafer software checks the

communication with the all relevant hardware components (microscope, camera, mo-

torized stage and slide feeder, if present). Only if all checks are successful, all Metafer

can be used. Otherwise, functions requiring hardware access is disabled. See Trouble-

shooting.

aWithout Neon:

sOn the Windows desktop, click on the Ikaros program icon.

aWith Neon:

sOn the Windows desktop, click on the ‘Neon’ program icon

sLoad a case in the ‘Cases’ view or setup a new on by clicking the ‘Create Case’ com-

mand button in the ‘Create Case’ view.

sGo to the ‘Scans’ view and click on the ‘Metafer’ icon in the sidebar on the right

side.

aWith the ‘Mode’ command you can select the desired operational mode.

aYou must activate the required slide positions with a left mouse click on the fields 1 … 8

at the bottom of the program screen.

aClick on ‘Setup’ to define the search parameter: the ‘Name’ of the slide, the ‘Classifier’,

the ‘Search Window’ and its ‘Size’ as well as the maximum object count (‘Max. Cnt.’) must

be completed. Confirm the information by clicking ‘OK’. The software will then return to

the main program window.

aClick on ‘Search’ and follow the instructions on screen.

aThe search is carried out by the system without any user interaction. After the search is

completed, images of all detected objects are displayed in gallery and saved including

Quick Guide

12

the object coordinates. Values of search parameters are displayed in the gallery images

according to mode and classifier used.

aTo relocate an object just click left on the corresponding gallery image. Switch to an

objective with higher magnification, if necessary.

aTo load a previous search run, right click on the slide position (in Relosys: the first) and

then select the desired slide in the ‘Open’ dialog box.

aIf Ikaros or Isis is installed on your Metafer / Relosys system, you can start the program

by a left click on the corresponding command button (see above).

aYou can quit the Metafer / Relosys with a left mouse click on the “Exit” button.

aWithout Neon:

sPrint a report by clicking the ‘Print Reports’ command in the ‘Slide’ menu.

sSave scans ‘File – Save Slide’.

sYou can exit the program by selecting ‘File – Exit’.

aWith Neon:

sPress the key combination [Alt] + [Tab] to bring Neon to the front.

sAdd ‘Cell Data’ by clicking on the respective icon in the sidebar or add case data by

clicking the ‘Data’ view tab.

sPrint a report by clicking on the ‘Report’ icon in the Neon header and select the

wanted report template.

sExit Neon and Metafer by clicking on the ‘Main’ icon in the Neon header, followed

by click on the ‘X’ (Exit) icon in the headline of the Neon program window.

Quick Guide

13

Microscopes

Microscopes are not part of MetaSystems systems. The camera and microscope must be

connected by a C-mount adapter for 2/3“ CCD cameras (not included). Please contact your

microscope representative for details. MetaSystems software supports a number of mo-

torized microscopes. Suitable control cables are available from the microscope manufac-

turers (not included).

A detailed description of supported microscopes and system configuration can be found in

the accompanying manuals (§).

Köhler Illumination

It is common knowledge among microscopists that correctly adjusted microscope is es-

sential for good image quality and, hence, the basis for a successful analysis of micro-

scope slide. The Köhler illumination provides a homogeneously illuminated field of view,

reduced optical glare from the light source and an increase in optical resolution. The pre-

requisite for Köhler illumination is a vertically adjustable, centerable condenser with iris

diaphragm. It is recommended to check the illumination on a regular basis (according to

laboratory SOPs):

1. Move up condenser with the top lens swung in (if available).

2. Focus on specimen with a low power objective (e.g. 10x or 16x).

3. Close down the lamp field stop (diaphragm in the microscope stand) while viewing.

4. Lower condenser slightly until the diaphragm (lamp field stop) image is in focus.

5. Center diaphragm image using the condenser centering screws.

6. Open diaphragm to the edge of field of view, then fine focus and open it further to just

clear the field.

7. Adjust contrast using the condenser aperture diaphragm.

8. Remove eyepiece and check to see that 75% of visible aperture is filled with light.

Quick Guide

14

Troubleshooting

The following table list some of the most common problems:

Problem

Potential Cause

Action

System does not

work.

aInterrupted power.

aSystem is not turned on.

aPlease check that all power

cords are connected correctly

and that all system compo-

nents are switched on.

Monitor does not

display an image.

aMonitor is turned off.

aThe cable connecting the

monitor to the PC is not

plugged in correctly.

aPlease check that the power

chord and the monitor cable

are plugged in correctly and

that the monitor is switched

on.

Error message on

non-responding

hardware compo-

nents during soft-

ware initialization

aSystems with motorized mi-

croscope: communication

cable unplugged, micro-

scope is switched off or

boot sequence not yet com-

pleted, wrong firmware ver-

sions installed in micro-

scope stand.

aCheck cable connection be-

tween system and microscope.

Shut down software, switch on

microscope and wait until boot

sequence completed. If prob-

lem persists, contact MetaSys-

tems or representative.

aSystems with camera: cam-

era cable(s) unplugged on

system, corrupt camera

driver, wrong camera type

selected.

aShut down system, wait 30 sec-

onds and restart. If problem

persists, contact MetaSystems

or representative.

Error message: X / Y

axis exceeding stage

range

aThe axis indicated in the er-

ror message has been

moved to a position ex-

ceeded the defined move-

ment range of the stage. For

safety reasons the stepping

motors acting on the stage

axes were switched off.

aRemove the covers from the

stage axes. Use the yellow

knobs on the x- and y axis to

move the stage to a position

within the movement range of

the stage. Restart Metafer.

No live image is dis-

played when the

‘Capture’ (Ikaros/Isis)

or the ‘Scan’ (Meta-

fer) command is se-

lected.

aMicroscope illumination

turned off.

aLight path to the camera is

closed.

aPlease check that the required

microscope lamp is on and

that the light path to the cam-

era is open. For fluorescence

applications please verify that

the correct filter is positioned

in the light path.

Quick Guide

15

Live image too dark.

Transmitted light:

aLight source not properly

centered.

aLuminous-field or conden-

ser aperture diaphragms

closed too far.

aCenter light source and adjust

Köhler illumination (see above).

aLight level on the micro-

scope too low.

aIncrease light intensity on mi-

croscope.

aLive image exposure time

too short.

aIncrease live image exposure

time (§see Ikaros or Metafer

manuals).

Fluorescence:

aLight source operating be-

yond recommended live-

span.

aReplace light source (burner,

light guide, if applicable, see

light source manual).

aLive image integration time

too short.

aIncrease live image integration

time (§see Ikaros/Isis or Meta-

fer manuals).

Image not in focus /

Manual Focusing is

impossible

aObjective damaged.

aCheck objective’s front lens for

signs of damage. For immer-

sion objectives: Check,

whether ‘cushion’ mechanism

is working properly (front less

is moving inwards when a gen-

tle force is applied). Objectives

can only be repaired by micro-

scope manufacturer.

aNo coverslip.

aUse coverslips for coverslip-

corrected objectives.

aSpecimen too thick or une-

ven.

aPrepare fresh samples with re-

duced and homogeneous

thickness.

aNot sufficient immersion oil

for high magnification oil

objectives.

aUse more immersion oil.

aWrong immersion oil (im-

mersion objectives).

aUse immersion oil specified by

microscope manufacturer for

the particular objective. For

fluorescence (FL) applications:

use only FL-compatible immer-

sion oil, e. g. ZEISS 518F.

aMotorized microscope:

stage was lowered to ‘Load’

position before microscope

was switched off. Metafer

use the current focus (Z) po-

sition as default focus plan

aConsult microscope manual

how to return to correct focus

plane.

aMetafer systems: Apply ‘Move

to Focus Plane’ command from

the ‘Tools’ menu (§See

Quick Guide

16

and limits the focus move-

ment range for safety rea-

sons.

Metafer manual).

Metafer: Auto-focus

does not work

properly

aSlide frame (slide frame

adapter on systems with

slide-feeder) not firmly

seated in scanning stage.

aSlide not firmly seated in

the slide frame.

aIncorrect microscope setup.

aSearch area too large com-

pared to cell drop or tissue

section areas.

aArtifacts like trapped air

bubbles, oil droplets on the

cover slip, etc. .

aDefect focus drive: focus

drive is skipping focusing

steps.

aAuto-focus range is limited

by software settings.

aRemove slide frame/slide

adapter and reinsert it cor-

rectly.

aInsert slide correctly.

aCheck the microscope set-

ting and consult the micro-

scope manual.

aReduce the search area so

that there are objects al-

lowing focusing for most of

the image fields.

aAvoid artifacts during sam-

ple preparation and re-

move these artifacts from

existing slides.

aRun a simple test: focus a

sample manually, move

the focus drive a few steps

down and then the same

number of steps up again

(check the Z-position on

the microscope’s display):

the sample should be in fo-

cus again. If the sample is

not in focus, quit Metafer,

switch the microscope off,

wait 10 seconds, switch it

on again, wait another 10

seconds and then restart

Metafer. If the problem

persists, please contact

MetaSystems.

aIncreased focus range in

Metafer settings (§see

Metafer manual).

Quick Guide

17

Images have poor

contrast.

aWeak staining

aRepeat staining, if possible.

aPrepare fresh specimen with

prolonged staining.

aWeak FISH signals

aCheck system capabilities with

(commercial) control slides: if

results are better with control

slides, check FISH protocol, all

reagents and temperature of

water baths and heating

plates.

aIf results are similar, check re-

flected light path on the micro-

scope (filters, light source),

check software configuration

parameter.

No printout is ob-

tained.

aPrinter is switched off.

aThe cable connecting

printer and PC is not

plugged in correctly.

aNetwork printer: printer is

not ‘shared’.

aPrinter is not selected in the

MetaSystems program.

aPlease check that the power

and printer cables are plugged

in correctly and that the

printer is switched on. Verify

that the network share for a

network printer is configured

properly. Check the program

settings to ensure the desired

printer is selected (§see also

accompanying manuals).

Warning messages:

insufficient disk

space.

aThe amount of data on the

storage drive has reached a

critical level (usually 90 %

full)

aSoftware version prior to

Neon: archive cases with

MetaArchive software and free

disk space with built-in soft-

ware functions (§see

MetaArchive manual).

aSoftware version based on

Neon: define clean-up rules in

‘Data Folder’-Settings.

If this does not solve the problem, or your problem is not listed, please contact

MetaSystems.

Quick Guide

18

Technical Data

Dimensions (width x depth):

Ikaros, Isis and Metafer (without SFx80):......................................................... 120 cm x 60 cm

Metafer w/ SFx80 on Base Plate S: ................................................................... 127 cm x 60 cm

Metafer w/ SFx80 on Base Plate M:.................................................................. 127 cm x 80 cm

Height (dependent on configuration): ............................................................. 63 cm —75 cm

Weight (dependent on configuration, incl. microscope): ...................approx. 30 kg —85 kg

Ambient conditions

Transport (in packaging)

Permissible ambient temperature: ..................................................................- 20 °C —+60°C

Storage:

Permissible ambient temperature: .................................................................+ 10 °C —+35°C

Permissible relative humidity (no condensation): ......................................max. 75 % at 35°C

Operation:

Permissible ambient temperature: .................................................................+ 10 °C —+35°C

Permissible relative humidity: ......................................................................max. 75 % at 35°C

Atmospheric pressure.............................................................................. 800 hPa —1060 hPa

Altitude ....................................................................................................................max. 2000 m

Pollution degree......................................................................................................................... 2

Operating environment ........................................................................................ Closed Room

Protection Class ...........................................................................................................................I

Protection Type.................................................................................................................... IP 20

Electrical safety ......................................... in compliance with DIN EN 61010-1 (IEC 61010-1)

Overvoltage category .................................................................................................................II

Radio interference suppression ................................... in accordance with EN 55011 Class B

Noise immunity.................................................................in accordance with DIN EN 61326-1

Line voltage ............................................................. 100 V to 127 V and 200 V to 240 V ± 10 %

Line frequency .......................................................................................................50 Hz –60 Hz

Power consumption (dependent on configuration) ...........typical: 150 - 300 W, max. 800 W

Copyright © MetaSystems Hard & Software GmbH, 2021

Table of contents

Popular Laboratory Equipment manuals by other brands

TAN Bead

TAN Bead Smart LabAssist Series user manual

MELAG

MELAG Cliniclave 45 MD Technical manual

Vircell

Vircell VirClia Lotus user manual

Agilent Technologies

Agilent Technologies 1290 Infinity LC System System Manual and Quick Reference

Thermo Scientific

Thermo Scientific MaxQ SHKA4000 operating manual

VWR

VWR peqlab PCR Workstation Pro instruction manual